1045 Carbon Steel – A Comprehensive Analysis

1. Introduction 1045 carbon steel stands as a prime example within the medium-carbon steel family. With approximately 0.45% carbon content, it strikes a balance between strength and ductility, making it

Welcome to our blog for insights into different manufacturing processes.

1. Introduction 1045 carbon steel stands as a prime example within the medium-carbon steel family. With approximately 0.45% carbon content, it strikes a balance between strength and ductility, making it

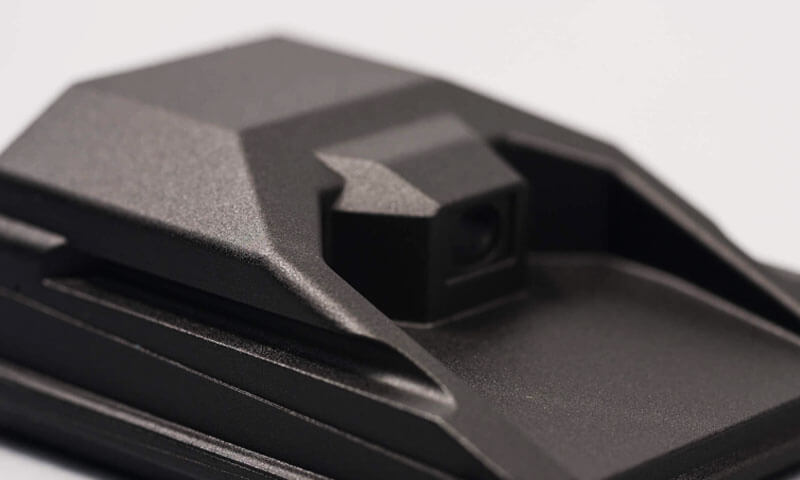

1. Introduction PVD coatings involve depositing thin films onto substrates through a physical process that occurs in a vacuum environment. This unique method significantly improves surface properties such as hardness,

1. Introduction 1.4573 stainless steel, designated GX3CrNiMoCuN24-6-5, stands as a high-performance austenitic stainless steel engineered to meet the most demanding industrial challenges. This advanced alloy leverages a unique alloying system

1. Introduction 1.4541 stainless steel, also known by its designation X6CrNiTi18-10, is a high-performance, titanium-stabilized austenitic stainless steel engineered to excel in extreme environments. With a unique balance of corrosion

1. Introduction 1.4469 stainless steel (EN designation: X2CrNiMoN22-5-3 ), commonly referred to by its UNS designation S32760 or trade names such as Zeron® 100, belongs to the family of super

1. Introduction 1.4435 stainless steel (EN designation: X2CrNiMo18-14-3) is a premium-grade austenitic stainless steel known for its superior corrosion resistance, excellent formability, and reliable performance in aggressive chemical environments. As

1. Introduction 1.4404 stainless steel (EN/ISO designation X2CrNiMo17-12-2) stands as a benchmark among high-performance austenitic stainless steels. Renowned for its exceptional corrosion resistance, mechanical strength, and thermal stability, this alloy

1. Introduction Nickel alloys, composed primarily of nickel and various other alloying elements, are celebrated for their unparalleled corrosion resistance, high-temperature performance, and mechanical durability. These advanced materials have become

1. Introduction Cast iron has earned its reputation as a fundamental material in both historical and modern engineering. This iron-carbon alloy, typically containing between 2–4% carbon and varying amounts of

A383 aluminum alloy stands out as a specialized material in high-pressure die casting, engineered to deliver improved strength, enhanced corrosion resistance, and superior castability. This alloy has been developed as

1. Introduction A380 aluminum alloy is one of the most widely used materials in the die casting industry. Recognized for its superior fluidity, strength, and cost-efficiency, A380 plays a crucial

1. Introduction Metal bending involves deforming a metal workpiece by applying force to achieve a desired shape, offering a reliable means to shape metal sheets, plates, and tubes without removing

1. Introduction Metal finishing technologies play a crucial role in enhancing the durability, corrosion resistance, and aesthetic appeal of various components. Among the most widely used techniques, E-coating (Electrophoretic Deposition)

Electrophoretic Deposition (EPD), commonly known as E-coating, has revolutionized the field of surface treatment by providing an efficient, uniform, and environmentally friendly method for applying protective and decorative coatings. In

1. Introduction Metal stamping is a manufacturing process that forms, cuts, and shapes metal sheets into precise components. This method plays a critical role in modern production, driving innovation in

Copyright © 2024 LangHe Industry Co., Ltd.2025

Powered by LangHe Industry Co., Ltd.2025

Please fill in your information and we will contact you promptly.