1. Panimula

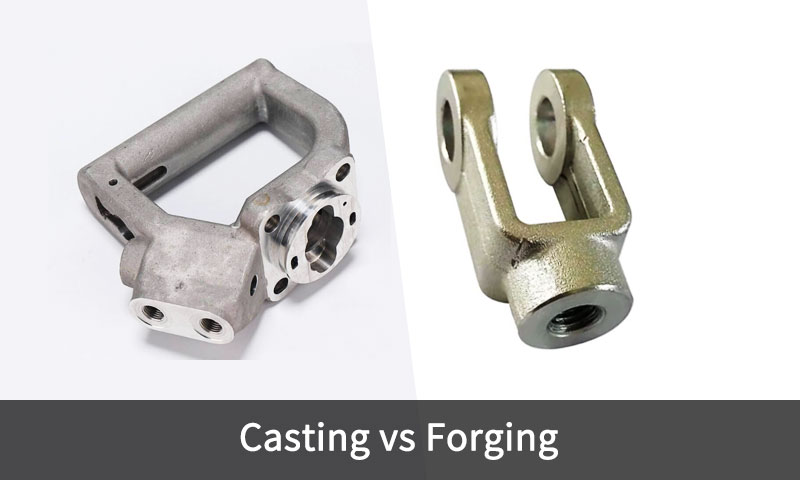

Paghahagis mga bes pagkukubli are two fundamental metal-shaping routes.

Casting excels at producing complex shapes, internal cavities and large parts with relatively low material waste and low per-part tooling cost for moderate geometries.

Pagbubuo ng mga produces parts with superior mechanical properties, improved fatigue resistance and better grain flow, but typically requires heavier tooling and more machining for complex geometry.

The right choice depends on the application’s mechanical requirements, geometry complexity, dami, cost targets and regulatory constraints.

2. Ano ang Paghahagis?

Paghahagis is a manufacturing process in which molten metal is poured into a mold cavity shaped like the desired component.

Kapag ang metal ay lumamig at tumibay, the mold is removed to reveal the cast part.

This process is one of the oldest methods of metal shaping, dating back thousands of years, and is still widely used because of its versatility in producing both simple and highly complex parts.

Buod ng Proseso

- Paglikha ng Pattern – A replica of the part (pattern) is made from wax, kahoy na kahoy, plastik na plastik, o metal.

- Paghahanda ng Amag – A mold is created using sand, keramika, o metal, depende sa casting method.

- Natutunaw na & Pagbubuhos ng – Metal alloys are melted (typically at 600–1,600 °C depending on alloy) and poured into the mold.

- Pagpapatibay & Paglamig – Controlled cooling allows the metal to take the shape of the mold cavity.

- Pag-iling & Paglilinis – The mold is broken or opened, and excess material (Mga Gate, Mga Riser) ay inalis.

- Pagtatapos & Inspeksyon – Heat treatment, machining, and surface finishing are applied as required.

Variants of Casting

- buhangin paghahagis – Cost-effective, suitable for large and heavy parts; dimensional tolerance typically ±0.5–2.0 mm.

- Pamumuhunan sa Paghahagis (Nawawalang Waks) – Produces highly detailed, near-net-shape parts with excellent surface finish (Ra ≈ 1.6–3.2 µm).

- mamatay paghahagis – High-pressure injection of molten non-ferrous alloys (Al, Zn, Mg) into permanent molds; excellent for high-volume production.

- Centrifugal Casting – Used for cylindrical parts like pipes, with high density and minimal defects.

- Patuloy na Paghahagis – Industrial process for producing billets, mga slab, and rods directly from molten metal.

Mga Pangunahing Bentahe

- Ability to produce kumplikadong mga geometries, including internal cavities and thin-walled sections.

- Wide range of alloy flexibility (mga bakal na bakal, Mga bakal, aluminyo, tanso, nikel, titan).

- Near-net shape capability reduces machining requirements.

- Cost-effective para sa malalaking bahagi at low-to-medium volumes.

- Scalability — from prototypes to high-volume production (especially with die casting).

Mga Limitasyon

- Casting defects such as porosity, pag urong ng mga cavities, mga inclusions, and hot tears.

- Mga katangian ng mekanikal (lakas ng paghatak, paglaban sa pagkapagod) are often inferior to forged equivalents due to dendritic microstructures and porosity.

- Dimensional accuracy and surface finish vary significantly by process.

- Cooling rates can cause segregasyon and anisotropy in mechanical performance.

3. Ano Ang Pagpepeke?

Pagbubuo ng mga is a metalworking process in which metal is shaped into desired geometries through compressive force, typically using hammers, Pindutin ang mga pindutin, o namamatay.

Hindi tulad ng paghahagis, where the material is melted and solidified, forging works the metal in a solid state, improving its grain structure and enhancing mechanical properties.

Forging is one of the oldest metal-shaping methods, historically performed by blacksmiths with simple hand tools.

Ngayong araw, it is a high-precision industrial process widely used in aerospace, automotive, langis & gas, pagbuo ng kapangyarihan, and defense industries.

Buod ng Proseso

- Pag init ng katawan (Opsyonal na) – Metal is heated to a plastic state (for hot forging) or left at room temperature (for cold forging).

- Pagpapapangit – The metal is compressed or hammered into shape between flat or shaped dies.

- Pag-trim – Excess material (flash) ay inalis.

- Paggamot ng Heat (kung kinakailangan) – Normalizing, pagpapawi ng, and tempering are applied to optimize strength, tigas na tigas, at ductility.

- Pagtatapos – Machining, ibabaw ng pagtatapos, and inspection complete the process.

Types of Forging

- Pagpapalabas ng Open-Die – Large parts shaped between flat dies; used for shafts, discs, and large blocks.

- Closed-Die (Impression-Die) Pagbubuo ng mga – Metal pressed into shaped cavities for near-net shape parts; widely used in automotive and aerospace.

- Cold Forging – Performed at room temperature; excellent dimensional accuracy and surface finish.

- mainit na pagbubuo – Performed above recrystallization temperature; allows shaping of large, tough alloys with reduced work hardening.

- Isothermal & Precision Forging – Advanced methods for titanium, nikel, and aerospace alloys, reducing machining and material waste.

Mga Pangunahing Bentahe

- Superior mechanical properties due to refined grain structure and elimination of internal voids.

- Mataas na paglaban sa pagkapagod and impact strength compared to castings.

- Consistent katumpakan ng sukat in precision forging.

- Angkop para sa Mga Kritikal na Aplikasyon such as aircraft engine parts, automotive crankshafts, presyon vessels, and nuclear power components.

- Minimal porosity and excellent metallurgical integrity.

Mga Limitasyon

- Mas mataas na gastos kaysa sa casting, especially for complex shapes.

- Limited to parts that can be formed by deformation — less suitable for hollow, manipis na pader, or highly intricate geometries.

- Nangangailangan ng specialized tooling and high-tonnage presses for large parts.

- Longer lead times for custom dies.

4. Microstructure & Grain Flow of Casting vs. Pagbubuo ng mga

One of the most fundamental differences between casting and forging lies in the internal microstructure ng materyal na.

How the grains are formed, aligned, and distributed during processing directly influences the mechanical strength, tigas na tigas, and fatigue resistance of the final component.

Casting Microstructure

- Solidification Process – In casting, molten metal cools and solidifies inside the mold.

Grains nucleate randomly and grow outward, pagbuo ng Equiaxed o columnar grains depending on cooling conditions. - Grain Orientation – No preferred orientation (isotropic structure), but often heterogeneous. Grain boundaries may be weak points under stress.

- Mga depekto – Possible porosity, pag urong ng mga cavities, mga inclusions, and segregation of alloying elements due to uneven cooling. These reduce fatigue resistance and fracture toughness.

- Mga Katangian – Adequate for static loads and complex shapes but generally lower tensile strength and fatigue resistance compared to forged parts.

Forging Microstructure

- Plastic Deformation Process – Forging plastically deforms metal in its solid state, breaking up cast dendritic structures and eliminating porosity.

- Grain Flow Alignment – Forging aligns grains in the direction of applied forces, Paggawa ng isang continuous grain flow that follows the shape of the part.

This improves impact strength and fatigue resistance, especially in components like crankshafts and turbine blades. - Defect Reduction – Forging compacts voids and inclusions, reducing defect size and improving metallurgical integrity.

- Mga Katangian – Forged parts show superior mechanical properties, especially in dynamic or cyclic load conditions.

5. Typical Mechanical Property of Casting vs. Pagbubuo ng mga

| Pag-aari (sa RT) | Paghahagis (316 SS) | Pagbubuo ng mga (316 SS) |

| Lakas ng Paghatak (MPa) | 485–515 | 560–620 |

| Yield Lakas (0.2% MPa) | 170–240 | 240–310 |

| Pagpapahaba (%) | 20–30 | 35–40 |

| Ang katigasan ng ulo (HB) | 135–150 | 150–160 |

| Epekto ng Charpy (J) | 60–80 | 100–120 |

| Lakas ng Pagkapagod (MPa, 10⁷ Mga siklo) | ~170 | ~ 240 |

6. Kalayaan sa Disenyo, Mga pagpapaubaya, and Surface Finish

When comparing casting vs forging, one of the most decisive factors is the balance between design flexibility, dimensional control, at kalidad ng ibabaw.

Each process has unique strengths and limitations, which determine suitability for different applications.

Kalayaan sa Disenyo

- Paghahagis offers unmatched design flexibility. Complex geometries such as internal cavities, manipis na pader, Mga istraktura ng sala-sala, and undercuts can be produced directly in a single pour.

Investment casting in particular enables near-net-shape parts, reducing machining by up to 70%.

Components like pump impellers, mga blades ng turbine, or intricate brackets are almost exclusively made by casting because forging such shapes would be impossible or economically prohibitive. - Pagbubuo ng mga, sa kabaligtaran, is constrained to relatively simpler geometries.

Although closed-die forging allows near-net-shape parts, intricate internal passages, fine lattice structures, or sharp undercuts are not achievable.

Forging excels when the part requires solid, continuous geometry without hollow sections, such as shafts, mga gears, and connecting rods.

Dimensional Tolerances (ISO 8062 Sanggunian)

| Proseso | Typical Tolerance Class | Halimbawa (100 mm Dimension) | Critical Feature Tolerance (hal., Bore Diameter) |

| buhangin paghahagis | CT8–CT10 | ±0.4 – 0.8 mm | ±0.2 – 0.4 mm |

| Pamumuhunan sa Paghahagis | CT4–CT6 | ±0.05 – 0.2 mm | ±0.03 – 0.08 mm |

| mamatay paghahagis (Al/Zn/Mg) | CT5–CT7 | ±0.1 - 0.3 mm | ±0.05 – 0.15 mm |

| Pagpapalabas ng Open-Die | CT10–CT12 | ±0.8 – 1.5 mm | ±0.4 – 0.8 mm |

| Sarado-Mamatay na Pag-forging | CT7–CT9 | ±0.2 – 0.6 mm | ±0.1 - 0.25 mm |

Tapos na sa ibabaw (Roughness Ra, μm)

| Proseso | Bilang Cast / As-Forged Ra (μm) | Post-Finishing Ra (μm) |

| buhangin paghahagis | 10 – 20 | 5 – 10 |

| Pamumuhunan sa Paghahagis | 1.2 – 5 | 0.8 – 2 |

| mamatay paghahagis (Al/Zn/Mg) | 2 – 10 | 1.2 – 5 |

| Pagpapalabas ng Open-Die | 10 – 40 | 5 – 10 |

| Sarado-Mamatay na Pag-forging | 5 – 12 | 2.5 – 5 |

7. Secondary Operations and Heat Treatment Impact

Secondary operations and heat treatment play a critical role in optimizing the performance of components produced by casting or forging.

These post-process steps directly influence mechanical properties, katumpakan ng sukat, tapos sa ibabaw, and long-term durability.

Pangalawang Operasyon

Machining:

- Paghahagis: Cast components often require significant machining to achieve tight tolerances and critical surfaces, especially for holes, mga thread, and mating faces.

Investment casting reduces machining requirements due to near-net shape capabilities, whereas sand casting usually requires more extensive post-machining. - Pagbubuo ng mga: Forged parts generally require minimal machining, mostly for finishing surfaces and precision holes, due to the uniformity and near-final dimensions of closed-die forging.

Pagtatapos ng Ibabaw:

- Polishing at paggiling: Enhance surface quality, reduce roughness, and remove minor surface defects. Investment castings can reach Ra < 1.5 μm after mechanical or electropolishing.

- Pagsabog ng Shot / Bead pagsabog: Used to remove scale, flash, and improve surface uniformity.

- Mga patong at pag-plating: Secondary coatings (hal., passivation for stainless steel, zinc or nickel plating for corrosion protection) are often applied post-machining.

Assembly & Fitting:

- Critical for components with multiple parts, such as bushings, Mga Pin, or hinge assemblies. Proper secondary operations ensure proper clearance, interference, and functional alignment.

Paggamot ng Heat

Layunin:

Lunas sa init is employed to enhance mechanical properties such as strength, tigas na tigas, ductility, at magsuot ng resistensya. Its effects vary between cast and forged components.

- Paghahagis:

-

- Cast stainless steel and low-alloy steels often undergo solusyon annealing, stress relieving, o age hardening to reduce residual stresses, homogenize microstructure, and improve machinability.

- Care must be taken to avoid partial melting or grain coarsening in thin sections, particularly in investment castings.

- Pagbubuo ng mga:

-

- Forged components benefit from Normalisasyon o quenching and tempering to refine grain structure and maximize mechanical performance.

- Forging inherently produces a denser, Mas pare-pareho ang microstructure, so heat treatment mainly optimizes hardness and stress relief rather than compensating for defects.

Advanced post-processing

- HIP can close internal porosity in castings, bringing properties closer to wrought/forged material at high cost.

- Surface treatments (pagbaril ng peening, nitriding, carburizing) improve fatigue life and wear resistance.

8. Industry Applications: Matching Method to Need

Casting and forging dominate distinct industrial sectors based on their inherent strengths—geometry complexity, mekanikal na pagganap, Mga kinakailangan sa dami, and cost constraints.

Casting Applications

Automotive:

- Mga bloke ng engine: Sand casting is widely used for iron engine blocks, accommodating complex water jackets and internal cavities.

- Mga Ulo ng Silindro: Investment casting enables precision cooling channels and intricate geometries in high-performance engines.

- Aluminum Wheels: Die casting allows high-volume production with excellent surface finish and dimensional consistency.

Aerospace:

- Turbine Blades: Investment casting of superalloys like Inconel 718 achieves complex airfoil geometries essential for efficiency and high-temperature resistance.

- Engine Housings: Sand casting of aluminum alloys supports lightweight structures with moderate complexity.

Langis & Gas:

- Mga Pabahay ng Bomba: Sand casting of cast iron or steel provides robust, cost-effective solutions for fluid handling.

- Mga Katawan ng Balbula: Investment casting in 316L stainless steel achieves tight tolerances and corrosion resistance for critical valves.

Konstruksyon & Imprastraktura:

- Manhole Covers: Sand casting in ductile iron offers high strength and durability.

- Pipe Fittings & Mga Bahagi: Die casting aluminum or brass provides lightweight, corrosion-resistant solutions for water and gas networks.

Pagpe-forging ng mga Application

Automotive:

- Mga Crankshaft: Closed-die forging in AISI 4140 steel ensures high fatigue resistance and superior grain flow for performance engines.

- Connecting Rods: Forged from 4340 steel for strength and toughness under repeated dynamic loading.

Aerospace:

- Landing Gear Components: Closed-die forging in titanium alloys combines high strength-to-weight ratio with excellent fatigue life.

- Engine Shafts: Open-die forging of Inconel 625 produces components resistant to high temperatures and stresses.

Langis & Gas:

- Drill Collars: Open-die forging in AISI 4145H steel ensures high-pressure endurance in harsh downhole environments.

- Valve Stems: Closed-die forging of 316L stainless steel guarantees dimensional accuracy and corrosion resistance.

Malakas na makinarya & Mga Kagamitan sa Industriya:

- Gear Blanks: Closed-die forging in AISI 8620 steel achieves high hardness and wear resistance for power transmission.

- Hydraulic Cylinders & Mga shaft: Open-die forging in A36 steel ensures toughness and impact resistance for heavy-duty operations.

9. Comprehensive Comparison of Casting vs. Pagbubuo ng mga

Casting vs forging are foundational manufacturing methods, each with distinct advantages, Mga limitasyon, at mga perpektong kaso ng paggamit.

The table below summarizes the key differences across multiple dimensions, providing an at-a-glance guide for engineers, mga designer, and production managers:

| Aspeto | Paghahagis | Pagbubuo ng mga |

| Process Principle | Molten metal poured into a mold and solidified | Metal deformed under compressive force, usually at high temperature |

| Paggamit ng Materyal | Moderate to high scrap reduction in investment/die casting; some gating/riser waste | Very high material efficiency; minimal scrap when properly planned |

| Kalayaan sa Disenyo | Excellent for complex geometries, manipis na pader, panloob na mga talata, mga undercuts | Limited to shapes that can be forged; internal cavities require machining or secondary operations |

| Katumpakan ng Dimensyon | Pamumuhunan sa paghahagis: ±0.05–0.3 mm; Buhangin paghahagis: ±0.5-1.0 mm | Closed-die forging: ±0.1–0.8 mm; Open-die forging: ±0.5–2.0 mm |

| Tapos na sa ibabaw | Investment casting Ra 1.6–6.3 μm; sand casting Ra 6.3–25 μm | Closed-die forging Ra 3.2–12.5 μm; open-die forging Ra 6.3–50 μm |

| Mga Katangian ng Mekanikal | Katamtamang lakas; isotropic properties in simple castings; lower fatigue resistance due to porosity | Superior strength and toughness; aligned grain flow improves fatigue and impact resistance |

Heat Treatment Compatibility |

Fully compatible; may relieve internal stresses and improve microstructure | Compatible; forging produces work-hardened regions and directional grain flow that enhance mechanical properties |

| Dami ng Produksyon & Gastos | Mataas na dami ng produksyon (die/investment casting) reduces per-part cost; low-volume may be costly | Low-to-medium volume most economical; high-volume can be expensive due to tooling and press costs |

| Mga Karaniwang Aplikasyon | Complex pump housings, mga katawan ng balbula, mga bloke ng engine, mga blades ng turbine | Mga Crankshaft, pagkonekta ng mga rod, mga shaft, mga landing gear, high-stress mechanical components |

| Lead Time | Katamtaman; mold and pattern development can take weeks | Moderate to long; forging dies require precise design and machining |

| Pros | Mga kumplikadong hugis, Malapit sa net na hugis, less machining, internal passages possible | Mataas na lakas, Higit na mahusay na paglaban sa pagkapagod, directional grain flow, napakahusay na katigasan |

| Mga kahinaan | Lower mechanical performance, potential porosity, pag urong, limited high-stress performance | Limited geometric complexity, higher tooling costs, secondary machining often needed |

10. Pangwakas na Salita

Casting vs forging are not competitors but complementary tools—each optimized for specific manufacturing needs:

- Choose Casting If: You need complex geometries, low upfront cost for low volume, or parts made from brittle metals (cast iron).

Investment casting excels at precision, sand casting at cost, and die casting at high-volume non-ferrous parts. - Choose Forging If: You need high strength, paglaban sa pagkapagod, or tight tolerances for simple-to-moderate shapes. Closed-die forging is ideal for high-volume, Mga bahagi na may mataas na stress; open-die forging for large, low-volume components.

The most successful manufacturing strategies leverage both methods—e.g., a car engine uses cast blocks (pagiging kumplikado) and forged crankshafts (lakas ng loob).

By aligning process selection with part function, dami, at gastos, engineers can optimize performance, reduce TCO, and ensure long-term reliability.

Mga FAQ

Can forging produce parts with internal cavities?

No—forging shapes solid metal, so internal cavities require secondary machining (pagbabarena, nakakainip), which adds cost and reduces strength.

Paghahagis (especially sand or investment) is the only practical method for parts with internal features (hal., engine water jackets).

Which process is more sustainable for steel parts?

Forging is more sustainable for high-volume, Mga bahagi na may mataas na stress: it uses 30–40% less energy than sand casting, produces less waste (10–15% vs. 15–20%), and forged parts have longer service life (reducing replacement cycles).

Sand casting is more sustainable for low-volume, kumplikadong mga bahagi (lower tooling energy).

What is the maximum size for casting vs. pagkukubli mga bahagi?

- Paghahagis: Sand casting can produce parts up to 100 tonelada (hal., ship propellers); investment casting is limited to ~50 kg (mga bahagi ng katumpakan).

- Pagbubuo ng mga: Open-die forging can produce parts up to 200 tonelada (hal., power plant shafts); closed-die forging is limited to ~100 kg (Mga Bahagi ng Mataas na Dami).

Why are aerospace turbine blades cast instead of forged?

Turbine blades have intricate airfoil geometries and internal cooling channels—impossible to forge.

Pamumuhunan sa paghahagis (using single-crystal superalloys like Inconel 718) produces these features with the required precision, while heat treatment optimizes strength for high-temperature service.