What is a Plug Valve?

1. Introduction Plug valve is a versatile quarter-turn valve widely used for isolation, diversion, and occasional throttling in industrial systems. Its simple design—a cylindrical or conical plug rotating within a

Welcome to our blog for insights into different manufacturing processes.

1. Introduction Plug valve is a versatile quarter-turn valve widely used for isolation, diversion, and occasional throttling in industrial systems. Its simple design—a cylindrical or conical plug rotating within a

1. Introduction The control valve is the primary final control element in most automated process systems: it receives a command from a controller and modulates a flow passage to regulate

1. Introduction A pressure reducing valve is a fundamental element in piping and process systems: it automatically reduces a higher inlet pressure to a stable, lower outlet pressure and maintains

1. Introduction A globe valve is a linear motion valve that uses a movable disk (plug) that seats against a stationary ring seat to regulate flow. Its configuration enables precise

1. Introduction Ball valves are quarter-turn shut-off devices that combine compactness, low pressure drop and strong sealing capability. Their straightforward operation and high reliability have made them a default choice

1. Introduction A check valve (non-return valves, one-way valves) is a fundamental component in fluid systems: simple in principle, they are often critical in practice. They protect equipment from reverse

1. Introduction A gate valve is a fundamental isolation device in industrial fluid systems. Their long-stroke, linear gate creates a near-unobstructed flow path when fully open and a positive mechanical

1. Introduction Industrial Machinery Castings are the foundation of modern heavy equipment manufacturing. They enable the production of large, kumplikado, and durable components that would be difficult or uneconomical to

1. Panimula 17-4 PH stainless steel (often specified as UNS S17400, AISI 630, or EN 1.4542) is one of the most widely used precipitation-hardening stainless steels in industry. Ito ay naghahatid ng

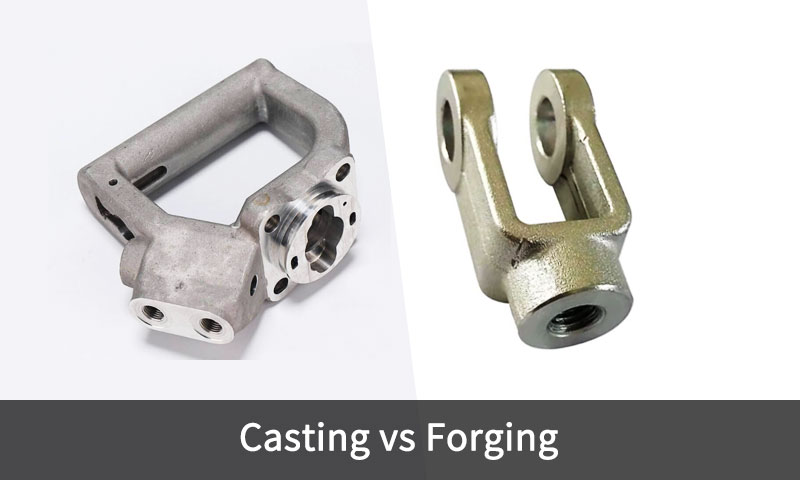

1. Introduction Casting vs forging are two fundamental metal-shaping routes. Casting excels at producing complex shapes, internal cavities and large parts with relatively low material waste and low per-part tooling

1. Introduction Investment casting (Nawawalang waks) is an excellent production route for stainless steel mount brackets that need complex geometry, attractive finishes and reliable mechanical performance. For medium to high mix

1. Introduction Stainless steel impeller is a critical component in pumps, mga compressor, and turbomachinery, where they transfer rotational energy to fluids. Their geometry—curved vanes, masikip na mga tolerance, and smooth hydraulic surfaces—directly

1. Introduction Stainless steel hinges are critical components for doors, cabinets, at makinarya, valued for their durability and corrosion resistance. To achieve complex shapes, makinis na ibabaw, and consistent performance, investment

1. Introduction The melting point of bronze is a key concept in metallurgy, pagmamanupaktura, and design. Unlike pure metals, bronze is an alloy — primarily of copper and tin, though

1. Introduction The melting point of brass is a fundamental property that governs its behavior in casting, hinang, brazing, at paggamot sa init. Unlike pure metals, brass exhibits a melting range

Karapatang-ari © 2024 LangHe Industry Co., Ltd.2025

Pinapatakbo ng LangHe Industry Co., Ltd.2025

Mangyaring punan ang iyong impormasyon at agad ka naming kokontakin.