1. Panimula

Lost wax casting — commonly called pamumuhunan paghahagis — is a precision metal-casting method that transforms expendable patterns into high-quality metal components.

Combining centuries-old craft with modern materials science and process control, investment casting uniquely delivers complex geometry, excellent surface finish and predictable metallurgy across a very wide range of alloys.

It occupies the niche between prototype flexibility and production integrity: the process handles one-off and low-to-medium series production while producing parts that often require little or no secondary finishing.

2. Ano ang Lost Wax Casting?

Nawala ang wax casting, kilala rin bilang pamumuhunan paghahagis, is a metal casting process in which a disposable pattern, traditionally made of wax, is used to create a ceramic mold.

Once the pattern is removed, molten metal is poured into the cavity to form the final part.

The defining characteristic of lost wax casting is the expendable nature of the pattern and mold: each casting requires a new wax pattern, Ginagawa itong perpekto para sa kumplikadong, masalimuot na, or high-precision components that cannot easily be produced using permanent molds or die casting.

Unlike sand casting, which uses reusable or expendable molds but typically limits surface quality and geometric complexity, lost wax casting achieves near-net-shape parts with excellent dimensional accuracy, making it suitable for critical applications across aerospace, medikal na, enerhiya, and industrial sectors.

Key features

- Exceptional geometry freedom: mga undercuts, thin sections, internal cavities and intricate detail are possible.

- Broad alloy range: from aluminum to stainless steel, nickel superalloys and titanium.

- High surface quality and dimensional accuracy: often limits or eliminates downstream finishing.

- Scalable to both single pieces and small-to-medium series: tooling costs are moderate compared with high-pressure die casting.

3. Lost Wax Casting Process — Step-by-Step

Nawala ang wax casting, or investment casting, is a multi-stage process that transforms a wax pattern into a precise metal component.

Each step is critical to achieving dimensional accuracy, high surface quality, at integridad ng metalurhiko.

Hakbang 1 — Pattern production (wax or printed pattern)

Layunin: produce an accurate, repeatable pattern that defines the casting geometry.

Mga Pamamaraan: injection wax into metal dies; direct 3D-printed wax or polymer patterns for prototypes/low volumes.

Key controls / tips:

- Use polished metal dies for critical cosmetic surfaces.

- Maintain consistent wax temperature and injection pressure to avoid voids and short shots.

- For printed patterns, check surface finish and dimensional fidelity—post-process (wash/cure) as required.

Typical facts: wax melt points ~60–90 °C (depends on formulation); injection cycle seconds → minutes depending on shot size.

Hakbang 2 — Assembly, gating and treeing

Layunin: create a feeding network (tree) that ensures good metal flow and directional solidification.

Key controls / tips:

- Design gates to feed thick sections first and avoid flow across thin critical faces.

- Minimize turbulence by using streamlined gates and bottom/side entry where appropriate.

- Position feeders/riser nodes to promote directional solidification to the sprue.

Practical checklist: balance number of patterns per tree with shell handling limits and pour capacity.

Hakbang 3 — Shell building (ceramic coating and stucco)

Layunin: build a strong, thermally stable ceramic mold around the wax tree.

Proseso: alternate slurry dips (fine refractory) with stucco (graded sand) mga layer.

Typical parameters & guidance:

- Mga Coats: commonly 6–12 coats (can be more for heavy alloys).

- Kapal ng shell: ~4-12 mm kabuuang (thin for small aluminum parts, thicker for high-temp alloys).

- Layering: start with fine slurry/stucco for surface fidelity; progress to coarser stucco for strength.

- Pagpapatayo ng mga: allow adequate drying between coats; control humidity/temperature to avoid cracking.

Tip: record and standardize slurry viscosity, stucco grain sizes and drying times — shell consistency is the primary driver of casting repeatability.

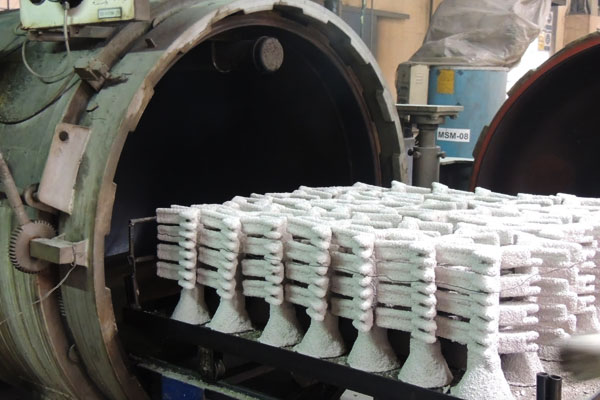

Hakbang 4 — Dewaxing (wax removal)

Layunin: evacuate wax to leave a hollow shell matching the part geometry.

Mga Pamamaraan: steam autoclave, oven meltout, or solvent extraction for specialized waxes.

Typical parameters & tips:

- Steam autoclave is most common—steam/condensate melts wax quickly and extracts it from the shell.

- Avoid rapid heat spikes that cause shell spalling; kinokontrol, staged dewax reduces shell damage.

- Collect and recycle wax where possible.

Kinalabasan: clean cavity and reduced residual organics prior to firing.

Hakbang 5 — Firing / shell strengthening

Layunin: burn out residual binders/wax residues and sinter the ceramic to final strength and permeability.

Typical ranges & controls:

- Firing temperatures: commonly 600–1000 °C, higher for superalloy work (shell chemistry dependent).

- Soak times: hours depending on shell mass and alloy sensitivity.

- Epekto: improves shell strength, sets permeability for metal flow and gas escape.

Tip: correlate firing profile with alloy and pour method — shells for high-temp alloys require more robust firing cycles.

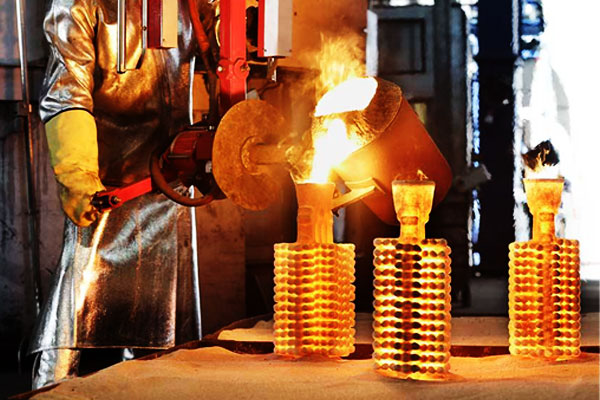

Hakbang 6 — Metal melting and pouring (filling)

Layunin: melt alloy to specification and introduce it into the shell with controlled flow.

Melting methods: induction (vacuum or air), gas-fired, vacuum induction for reactive/high-value alloys.

Pour techniques: gravity pour, vacuum-assist, or pressure-assist (low pressure / counter-pressure) depending on alloy and casting integrity needs.

Typical melt & pour data (indicative):

- Aluminyo: melt ~650–750 °C

- Hindi kinakalawang na asero: melt ~1450–1600 °C

- Nickel superalloys: melt ~1350–1500 °C

- Pour controls: superheat minimized to reduce oxidation/dross; filtration and degassing are essential for low-porosity parts.

Best practice: preheat shells to reduce thermal shock and misruns; use ceramic filters and degassing (argon/argon-bubbling, rotary degassing) as required.

Hakbang 7 — Cooling and solidification

Layunin: control solidification path to minimize shrinkage defects and set microstructure.

Mga kontrol & tips:

- Use feeders/riser design on the wax tree to ensure directional solidification.

- Allow adequate soak time in molds prior to shell knockout for small parts; larger sections require longer chill times.

- Cooling rate affects grain size — faster extraction at the shell wall gives fine grains; center may remain coarser.

Typical solidification times: from seconds to many minutes depending on mass; plan for thermal mass and shell thickness.

Hakbang 8 — Shell removal (Knockout)

Layunin: separate ceramic shell and reveal castings.

Mga Pamamaraan: mekanikal (panginginig ng boses, pagbagsak, blast), chemical dissolution, or thermal fracturing.

Practical notes: reclaim and recycle ceramic stucco where possible; manage dust and particulate emissions.

Hakbang 9 — Cut-off, pagtatapos ng, paggamot ng init

Layunin: convert raw castings into dimensionally accurate, fit-for-service components.

Typical operations: remove gates/sprues; grind/finish surfaces; heat treat (Solusyon + pagtanda, anneal, pag-uugali) as alloy requires; machine critical features (bore, faces).

Guidance: sequence machining after final heat treatment/stress relief to avoid distortion; maintain traceability (melt lot, heat treat record).

Hakbang 10 — Inspection, testing and packing

Layunin: verify conformity to specification.

Typical inspections: visual, dimensional (CMM), NDT (radiography/X-ray, ultrasonic), metallography, hardness and mechanical testing, leak/pressure testing for sealed parts.

Deliverable: inspection reports, traceability records, certificates of compliance.

4. Post-casting Treatment

Post-casting converts an investment casting into a functional component. Typical operations:

- Lunas sa init: solutionizing, pagtanda, annealing, or tempering — depending on alloy and required properties.

- Email Address *: shot blast, bead blast, paggiling ng mga, buli na, chemical etch, Email Address *, anodizing or painting.

- Katumpakan machining: bores, mga thread, bearing surfaces stabilized after heat treatment and stress relief.

- NDT and validation: radiography, ultrasonic, Tinain na penetrant, and pressure testing for sealed parts.

- Secondary assembly and balancing: dynamic balancing for rotating parts, fixture verification, assembly tests.

5. Variants and Process Families

Lost wax casting is a versatile process, and over time, specialized variants have emerged to meet different materials, pagiging kumplikado, and production requirements.

| Variant | Core Feature | Key Materials | Mga Karaniwang Aplikasyon |

| Ceramic Shell Casting | Industrial standard; uses alumina/silica ceramic shell capable of withstanding high temperatures | Mga Superalloys, titan, hindi kinakalawang na asero | Aerospace turbine blades, high-performance engine components, medikal na implants |

| plaster magkaroon ng amag paghahagis | Uses plaster-based investment; suited for low-temperature alloys and small parts | Aluminyo, mga haluang metal ng tanso, precious metals (ginto na, pilak na pilak, platinum) | Mga Alahas, pandekorasyon sining, Mga prototype |

| Vacuum Pamumuhunan sa Paghahagis | Dewaxing and/or metal pouring under vacuum to minimize porosity and gas entrapment | Titanium, mga superalloys na nakabase sa nickel (Inconel), high-purity alloys | Aircraft structural components, dental implants, high-integrity aerospace parts |

| Direct Lost Wax Casting / Printed Patterns | Wax or polymer pattern directly produced via 3D printing; no injection molds required | Hindi kinakalawang na asero, titan, aluminyo | Mabilis na prototyping, low-volume custom medical devices, complex experimental designs |

6. Materials and Alloy Compatibility of Lost Wax Casting

Selection of the proper alloy depends on Mga kinakailangan sa mekanikal, paglaban sa kaagnasan, pagganap ng thermal, and application-specific factors.

| Alloy Group | Mga Karaniwang Grade | Densidad ng katawan (g/cm³) | Typical Ultimate Tensile Strength (MPa) | Typical Pouring Temperature (°C) | Mga Tala |

| Mga Alloys ng Aluminyo | A356, A413, 319 | 2.6–2.8 | 140–320 | 650–750 | Napakahusay na katatagan, paglaban sa kaagnasan, heat-treatable for mechanical performance. Ideal for lightweight automotive, aerospace, at mga bahagi ng industriya. |

| Tanso Mga haluang metal / tanso | C954, C932, Brass variants | 8.2–8.9 | 200–500 | 1000–1100 | Mahusay na paglaban sa pagsusuot, high conductivity. Used in industrial, marine, at pandekorasyon na mga aplikasyon. |

| Hindi kinakalawang na asero | 304, 316, 17-4PH | 7.7–8.0 | 400–900 | 1450–1600 | Paglaban sa kaagnasan, integridad ng istruktura, and high-temperature capability. Suitable for aerospace, medikal na, and food-grade components. |

Nickel Superalloys |

Inconel 718, 625 | 8.2–8.9 | 600–1200 | 1350–1500 | Exceptional high-temperature strength and oxidation resistance. Widely used in turbine engines and high-performance industrial applications. |

| Mga Alloy ng Cobalt | Stellite series | 8.3–8.6 | 500–1000 | 1350–1450 | Excellent wear and temperature resistance; ideal for cutting tools, Mga balbula, at biomedical implants. |

| Mga haluang metal ng Titanium | Ti-6Al-4V (limitado) | 4.4–4.5 | 800–1100 | >1650 (vacuum) | Magaan ang timbang, malakas na, hindi lumalaban sa kaagnasan; reactive nature requires vacuum or inert gas pouring. Used in aerospace, medikal na implants, and high-performance engineering parts. |

| Precious Metals | Ginto, Pilak, Platinum | 19–21 (Au) | varies | 1000–1100 (Au) | High-value jewelry, fine art, and specialized electrical contacts; process emphasizes surface finish and detail reproduction. |

7. Typical Tolerances and Surface Finish

Nawala ang wax casting (pamumuhunan paghahagis) ay pinahahalagahan para sa kanyang high dimensional accuracy and fine surface finish, making it ideal for components where precision and minimal post-processing are critical.

Dimensional Mga pagpapaubaya

| Uri ng Tampok | Tipikal na pagpapaubaya | Mga Tala |

| Mga dimensyon ng linear | ±0.05–0.5 mm per 100 mm | Depends on part size, geometry, and alloy; tighter tolerances achievable with premium tooling and careful process control. |

| Angular/draft | ±0.5–1° | Draft angles of 1–3° recommended to aid wax removal and shell building. |

| Hole diameter / pag-ikot | ±0.05–0.2 mm | Critical holes may require light machining post-casting. |

| Kapal ng pader | ±0.1–0.3 mm | Manipis na pader (<1.5 mm) may experience minor variation due to metal flow and shell thermal mass. |

Tapos na sa ibabaw

| Pagsukat | Karaniwang Saklaw | Mga Tala |

| Ra (roughness) | 0.8–6.3 μm (32–250 μin) | As-cast surface; depends on wax pattern quality, ceramic slurry finish, and stucco size. |

| Premium finish (polished shell) | 0.4–0.8 μm (16–32 μin) | Achievable with fine wax tooling polish and careful shell preparation. |

| Post-processing (opsyonal) | <0.4 μm (16 μin) | Pagsabog ng baril, buli na, chemical etching, or plating can further reduce roughness. |

8. Mga Karaniwang Depekto, Root Causes, and Practical Countermeasures

| Depekto | Root causes | Practical countermeasures |

| Porosity (gas) | Entrapped gas, hydrogen pickup, kaguluhan | Melt degassing, filtration, vacuum pour, streamline gating |

| Pag-urong ng porosity | Inadequate feed, poor riser placement | Improved feeder design, direksyon solidification, Mga panginginig |

| Mga Pagkakamali / malamig na mga shut | Low pouring temp, poor fluidity | Increase superheat within spec, preheat shell, adjust gating |

| Mga Pagsasama / non-metallics | Contaminated melt, degraded fluxing | Better melt cleaning, ceramic filtration, strict melt handling |

| Pag-crack ng shell | Thermal shock, weak shell, poor dewax | Controlled dewax and firing profile, shell thickness optimization |

| Wax pattern defects | Incomplete injection, flash, pagbaluktot | Improve wax die design, control injection parameters, proper cooling |

| Mainit na luha | Constrained solidification, geometry stress concentrators | Add fillets, adapt geometry, control cooling gradients |

9. Advantages and Disadvantages

Advantages of Lost Wax Casting

- Complex Geometry

-

- Produces intricate shapes, manipis na pader, mga undercuts, panloob na lukab, and fine surface details difficult for other casting methods.

- Mataas na Dimensional na Katumpakan

-

- Linear tolerances typically ±0.05–0.5 mm per 100 mm, enabling near-net-shape parts with minimal machining.

- Napakahusay na Tapos sa ibabaw

-

- As-cast roughness Ra ~0.8–6.3 μm; premium tooling can achieve Ra ≤0.8 μm, reducing post-processing.

- Kakayahang umangkop ng haluang metal

-

- Supports aluminum, tanso, hindi kinakalawang na asero, nickel/cobalt superalloys, titan, and precious metals.

- Kahusayan sa Materyal

-

- Near-net-shape production minimizes machining scrap, especially for high-value alloys.

- Small-to-Medium Volume Friendly

-

- Economical for prototypes, pasadyang mga bahagi, or production runs up to tens of thousands annually.

- Critical Component Production

-

- Ideal for aerospace, medikal na, and energy parts where precision, kalidad ng ibabaw, and metallurgical integrity are essential.

Disadvantages of Lost Wax Casting

- Higher Cost for Large Volumes

-

- Slower cycle times and higher labor/material costs than die casting, making it less competitive for mass production.

- Mas mahabang oras ng lead

-

- Multiple steps (wax pattern, shell building, firing, pagbuhos, pagtatapos ng) extend production time.

- Pagiging kumplikado ng proseso

-

- Requires skilled labor and careful control of mold, shell, and metal parameters; multiple steps increase defect risk.

- Size and Design Limitations

-

- Practical limits for very large or very thin parts; complex undercuts may need special design considerations.

- Expendable Tooling

-

- Wax patterns are single-use; design changes require new tooling or printed patterns, affecting cost and lead time.

10. Mga Karaniwang Aplikasyon

- Aerospace & mga turbine ng gas: vanes, mga blade, combustion components, katumpakan na pabahay.

- Pagbuo ng kapangyarihan & enerhiya: turbine hardware, precision valves.

- Medikal na & dental: mga implants, kirurhiko instrumento, prosthetic components.

- Petrochemical & langis & gas: high-integrity valves and fittings.

- Automotive specialty: performance brake components, turbocharger parts, niche structural elements.

- Mga Alahas & decorative arts: high detail castings in precious metals.

- Industrial pumps & mga compressor: mga impeller, diffuser housings.

11. Paghahambing sa Iba pang Mga Pamamaraan ng Paghahagis

Nawala ang wax casting (pamumuhunan paghahagis) offers unique capabilities compared with common casting methods such as sand casting, permanenteng paghahagis ng amag, at mamatay sa casting.

Understanding these differences helps engineers and purchasing managers select the optimal process based on part complexity, materyal na bagay, dami, and surface requirements.

| Tampok / Paraan | Nawala ang Wax Casting (Pamumuhunan sa Paghahagis) | buhangin paghahagis | Permanenteng amag paghahagis | mamatay paghahagis |

| Geometry Complexity | Napakataas; manipis na pader, panloob na lukab, masalimuot na mga detalye | Katamtaman; undercuts possible but complex shapes require cores | Katamtaman; limited undercuts, thin sections feasible | Katamtaman; some undercuts allowed but limited |

| Katumpakan ng Dimensyon | Mataas na (±0.05–0.5 mm per 100 mm) | Mababa hanggang katamtaman (±0.5–1.5 mm) | Katamtaman hanggang mataas (±0.25–1 mm) | Mataas na (±0.1–0.5 mm) |

| Tapos na sa ibabaw (Ra) | Napakahusay (0.8–6.3 μm) | Magaspang (6-25 μm) | Mabuti na lang (2.5–7.5 μm) | Napakahusay (1–5 μm) |

| Kakayahang umangkop ng haluang metal | Very broad (Al, Cu, mga bakal na bakal, Ni/Cobalt superalloys, Ti, precious metals) | Very broad (Al, Cu, mga bakal na bakal, cast irons) | Limited to low-to-medium melting alloys (Al, Mg, Cu) | Mostly low-melting alloys (Al, Zn, Mg) |

| Dami ng Produksyon | Mababa hanggang sa katamtaman (prototypes to tens of thousands) | Mababa hanggang sa napakataas | Katamtaman (thousands to hundreds of thousands) | Mataas hanggang sa napakataas (hundreds of thousands to millions) |

| Gastos sa Tooling | Katamtaman (wax dies or 3D-printed patterns) | Mababa ang | Mataas na (metal molds) | Napakataas (Bakal na namamatay) |

| Lead Time | Moderate to long (shell build, firing, paghahagis ng mga) | Maikli hanggang katamtaman | Katamtaman | Short for high-volume production |

| Pagkatapos ng Pagproseso | Often minimal; precision surfaces and near-net-shape | Often extensive; machining required | Katamtaman; may require machining for critical features | Often minimal; Malapit sa hugis ng net |

| Mga Karaniwang Aplikasyon | Aerospace, medikal na implants, precision industrial parts, mga alahas | Mga malalaking pang-industriya na bahagi, mga bloke ng engine, Mga pabahay ng pump | Mga bahagi ng sasakyan, mga gulong, mga pabahay | Mga electronics ng consumer, automotive, Mga Bahagi ng Appliance |

12. Mga Makabagong-likha at Umuusbong na Mga Uso

Lost wax casting is evolving with technology to address limitations and meet sustainability demands:

Paggawa ng Additive (AM) Pagsasama sama

- 3D-Printed Wax Patterns: SLA resins (hal., 3D Systems’ Accura CastPro) reduce lead time by 70% and enable lattice structures for lightweight parts.

- Direct Metal AM vs. Nawala ang wax: DMLS competes for low volumes (<100 mga bahagi), but lost wax is 30–50% cheaper for 100–10,000 parts.

Advanced Ceramic Shells

- Nanocomposite Shells: Zirconia-alumina nanocomposites improve thermal shock resistance by 40%, enabling casting of 50 kg titanium parts (previously limited to 10 kg).

- Mga Eco Friendly Binders: Water-based binders reduce VOC emissions by 80% mga bes. alcohol-based alternatives.

Process Automation

- Robotic Dipping: Automated ceramic shell preparation reduces labor costs by 30–40% and improves coat thickness consistency (±0.1 mm vs. ±0.5 mm manual).

- AI-Powered NDT: Machine learning analyzes X-ray images to detect defects with 98% katumpakan (mga bes. 85% manual).

13. Pangwakas na Salita

Lost wax (investment) casting is a powerful, flexible manufacturing method that balances geometry freedom, material capability and high surface quality.

It is particularly well suited to components where complexity, metallurgy and finish are primary drivers of value.

Effective use requires careful design for casting, Mahigpit na kontrol sa proseso, and alignment of post-casting operations (paggamot ng init, machining, Inspeksyon) with end-use requirements.

For the right parts and volumes, investment casting provides unique value that few other processes match.

LangHe Lost Wax Casting and Post-Casting Services

LangHe provides end-to-end investment casting solutions tailored for engineering and industrial customers. Service highlights:

- Pattern & mga tooling: wax die design and production; 3D printing for rapid prototypes.

- Ceramic shell production: controlled multilayer shell build with engineered slurry systems.

- Katumpakan paghahagis: gravity, vacuum and pressure-assisted pours; experienced handling of stainless steels, Nickel Superalloys, cobalt alloys, titanium and copper alloys.

- Post-casting services: paggamot ng init, precision CNC machining, ibabaw ng pagtatapos (pagsabog ng baril, buli na, pag plating), and dynamic balancing.

- Kalidad & Pagsubok: dimensional inspection (CMM), radiography, pagsusuri sa ultrasonic, material analysis and full traceability per lot.

- Turnkey delivery: from prototyping to small/medium series production with process documentation and supplier qualification support.

LangHe positions itself as a partner for components that require metallurgical integrity, tight geometry control and dependable delivery.

Contact LangHe for capability discussions, sample programs or quoted proposals tailored to your part specification.

Mga FAQ

What production volumes suit lost wax casting?

Lost wax casting is economical from single prototypes up to small- and medium-series (typically up to the low tens of thousands per year); volume economics depend on part complexity and value.

Which alloys are best for lost wax casting?

The process handles a wide palette: aluminyo, tanso, hindi kinakalawang na asero, nickel and cobalt superalloys, titan (with special care), and precious metals.

How accurate are lost wax casting?

Typical tolerances are ±0.05–0.5 mm per 100 mm, with as-cast surface finish Ra ~0.8–6.3 µm; tighter features are achievable with good tooling and process control.

What are the main causes of porosity and how are they avoided?

Porosity arises from gas entrapment, dissolved gases and shrinkage.

Countermeasures: melt degassing, ceramic filtration, vacuum/pressure pour techniques and sound gating/feeder design.

How long does it take to go from design to production?

Prototype cycles with printed patterns can be days to weeks. Full production with wax dies, shell development and qualification commonly takes weeks to a few months.