Pamumuhunan sa paghahagis shell making is not a single activity but a sequence of interdependent subprocesses.

Most common shell defects (surface blemishes, sand inclusion, local thinning or piling, blisters, shell flaking, “mouse tails”, veining, bulging, atbp.) trace back to specific process mistakes — often subtle — in cleaning, slurry preparation, dipping/stuccoing or drying.

Some casting defects are primarily due to melting/pouring, but a very large share is caused or enabled by shell-making details and environmental control.

Controlling these details reduces scrap, stabilizes yield and shortens troubleshooting cycles.

When reviewing defects, group them by how they present and then by likely origin:

- Surface irregularities: mga nodulo, “metal beans” (metal bead imprint), “cucumber-like” spikes, veining (flow lines).

Typical causes: uneven face coat, poor slurry dispersion, inadequate stucco size control, contamination or surface residues. - Leakage / washout / shell reaction: steel droplet leakage, washout zones.

Typical causes: incompatible face coat (chemistry/contamination), excessive slurry superheat / mismatch of temperatures, improper slurry mix. - Mechanical defects: flashing (excess spurs), burrs, edge chipping.

Typical causes: poor stucco bonding, inconsistent drying leading to weak shell layers, improper flip/handling. - Dimensional/structural failures: bulging, shell delamination, shell collapse, “mouse tail” features (thin trailing edges).

Typical causes: non-uniform drying, trapped air, underfilled layers, poor transition layers. - Mga Pagsasama & sand entrapment: localized sand pockets, “clumped” sand particles.

Typical causes: contaminated sand bucket, insufficient sieving, agglomeration in slurry. - Porosity, shrinkage-related visible defects: often later linked to melting, but enabled by shell defects such as blocked vents or non-permeable layers.

Some defects are almost always a combined result of shell-making + Pagtunaw; others are dominantly materials issues (refractory quality) rather than procedural. The goal is to remove the procedural contributors first.

2. Wax Assembly Cleaning Stage

The wax assembly cleaning stage lays the foundation for uniform coating adhesion and defect-free shell formation, with surface contamination and temperature inconsistency being the primary failure points.

- Thorough Cleaning Requirement: Wax assemblies must be cleaned completely to eliminate residual mold release agents on the surface, which are the leading cause of poor coating wetting and adhesion.

Incomplete cleaning results in localized coating discontinuities, leading to defects such as metal nodules and sand inclusions in subsequent casting. - Cleaning Solution Maintenance: Cleaning solutions must be regularly filtered and replaced.

Prolonged use degrades the cleaning efficacy, as accumulated contaminants and dissolved wax residues reduce the solution’s ability to remove surface impurities. - Temperature Equilibration: The temperature of the wax assembly must be consistent with the shell making shop temperature.

If there is a discrepancy (hal., wax stored in a different environment), the assembly should be acclimated in the shell making area for several hours prior to processing to prevent thermal stress and coating unevenness. - Post-Cleaning Rinsing and Drying: Cleaned wax assemblies should be thoroughly rinsed with pure water to remove residual cleaning agents, then air-dried or blow-dried completely before proceeding to the coating stage.

Residual moisture or cleaning chemicals on the wax surface cause coating defects such as bubbling and poor adhesion.

3. Face Coat Slurry Preparation Stage

The face coat (surface layer) is the most critical layer of the investment casting shell, directly determining the surface finish of the final casting.

Strict formulation and mixing procedures are essential to ensure coating uniformity and surface quality.

- Precise Weighing and Powder-to-Liquid Ratio: All raw materials must be weighed accurately to establish a clear powder-to-liquid ratio for the slurry.

This ratio is the fundamental parameter governing slurry viscosity, densidad, and coating performance; arbitrary preparation without measurement leads to inconsistent coating quality. - Colloidal Silica Temperature Consistency: The temperature of colloidal silica used for slurry preparation must match the ambient temperature of the shell making shop to avoid thermal-induced viscosity fluctuations and coating defects.

- Sequential and Controlled Material Addition: The preparation process follows a fixed sequence: first add colloidal silica, then add diluted wetting agent and mix uniformly,

followed by gradual addition of zircon flour (with powder agglomerates manually broken to prevent undispersed lumps), and finally add defoamer.

Wetting agents and defoamers must be weighed precisely—excessive addition causes surface defects such as pinholes and poor adhesion, while insufficient addition fails to achieve the desired wetting and defoaming effects. - Adequate Mixing Duration: Sufficient mixing time (typically 60–120 minutes for face coat slurries) is mandatory to ensure uniform dispersion of refractory particles, consistent coating thickness, and complete wetting of the wax surface.

Inadequate mixing results in uneven particle distribution, localized coating thinning, and poor coating adhesion. - Wetting Agent Addition for Transition/Backup Layers: Transition and backup layer slurries can be appropriately supplemented with wetting agents to enhance inter-layer bonding and improve the overall structural integrity of the shell.

- Raw Material Quality Verification: The quality of zircon flour, wetting agents, and defoamers must be strictly inspected.

Substandard raw materials (hal., impure zircon flour, degraded additives) are the root cause of numerous surface defects and cannot be remedied by operational adjustments alone.

4. Slurry Quality Control Stage

Slurry quality is a dynamic parameter that requires continuous monitoring and maintenance to ensure stable performance throughout the production cycle.

- Comprehensive Parameter Monitoring and Data Archiving: In addition to viscosity measurement, pH value, slurry density, and actual coating thickness must be measured regularly.

Establishing a digital data archive enables real-time tracking of slurry quality changes and facilitates proactive defect prevention. - Daily Water Replenishment and Sterilization: Pure water must be added daily to compensate for moisture loss,

and a suitable bactericide must be incorporated to prevent bacterial growth, which degrades colloidal silica and causes slurry deterioration. - Regular Filtration and Cleaning: Prior to daily use, the slurry surface must be filtered to remove floating debris.

Slurry barrels should be thoroughly cleaned monthly to eliminate accumulated sediment and cured slurry residues.

Backup layer slurries require additional attention to remove trapped refractory sand particles that compromise coating uniformity.

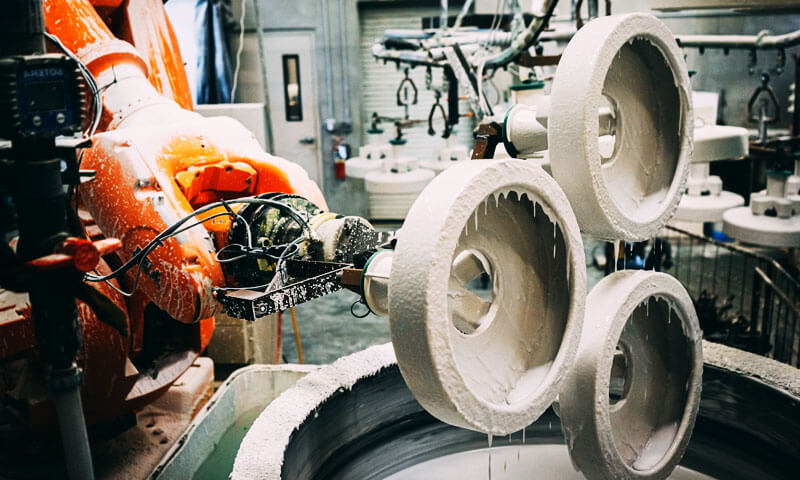

5. Slurry Coating and Sand Sprinkling Stage

This stage involves the physical application of the slurry and refractory aggregate, with operational techniques directly influencing coating uniformity, sand adhesion, and the formation of structural defects.

- Controlled Slurry Dipping and Drainage: Wax assemblies must be dipped into the slurry at a controlled angle and slow speed to ensure complete wetting.

During slurry drainage, prolonged unidirectional dripping must be avoided; sa halip, uniform slurry return is required to prevent localized coating thinning or excessive stacking. - Detailed Processing for Critical Features: Text, mga grooves, and other precision features must be manually treated with an air gun or brush to ensure complete coating coverage.

A secondary face coat dipping is recommended for critical components to enhance surface finish and defect resistance. - Sand Hopper Pre-Operation Cleaning: Sand hoppers must be thoroughly cleaned before use to remove metal nodules, agglomerated sand particles, and cured slurry residues, which cause sand inclusions and coating discontinuities.

- Prevention of Defects in Small Features: Small holes and narrow grooves must be free of slurry stacking, sand bridging, external blockage with internal hollowing, and other defects.

These issues are primary causes of casting defects such as insufficient filling and trapped gas. - Avoidance of Coating Thickness Misconception: Coating thickness is not a direct correlate of shell strength—excessive coating leads to prolonged drying times, pag crack na, and bulging, while optimal thickness balances structural integrity and drying uniformity.

- Pre-Wetting Colloidal Silica Management: Pre-wetting colloidal silica must meet the same quality and temperature requirements as slurry preparation silica.

Regular water replenishment and bottom sediment cleaning are essential to prevent deterioration and ensure consistent pre-wetting performance. - Local Defect Inspection During Operation: Continuous inspection for air entrapment (causing coating-free areas), incomplete sand adhesion,

and localized defects is mandatory during operation. Immediate remediation is required for any detected anomalies. - Refractory Aggregate Quality Control: The quality of refractory aggregates (hal., mullite, zircon sand) must be verified, including particle size distribution, dust content, and absence of foreign impurities.

Non-conforming aggregates cause sand inclusions, veining, and structural failure. - Equipment Condition Monitoring: The operational status of slurry mixers and sand hoppers must be checked regularly—uneven mixing, insufficient sand blasting pressure, or equipment blockage directly lead to coating and sanding defects.

- Slurry Temperature Monitoring: Slurry temperature must be monitored continuously; a significant deviation from room temperature indicates equipment failure or raw material issues that require immediate investigation.

6. Drying Stage

Drying is the most complex and critical stage of shell making, as it involves the synergistic effects of temperature, humidity, and air velocity, and is the primary source of structural defects such as cracking, bulging, and delamination.

- Stable Ambient Temperature Control: The overall temperature of the drying chamber must be consistent, with minimal fluctuations (typically ±1°C for face coats) to avoid thermal stress-induced cracking and uneven drying.

- Face Coat Drying Chamber Optimization: Face coat drying chambers should be appropriately sized (not excessively large) to facilitate precise humidity control,

which must be coordinated with the actual production cycle time to ensure complete and uniform drying. - Airflow Management in Backup Layer Drying Chambers: Airflow is the critical factor in backup layer drying.

If the production load exceeds the capacity of the drying equipment, both temperature and humidity control become ineffective, leading to incomplete drying and structural defects. - Synergistic Control of Drying Parameters: Drying is the combined result of temperature, humidity, and air velocity—especially for face and transition layers, where defects such as cracking and bulging predominantly occur.

Uniform drying across all components and features is mandatory to prevent structural failure. - Regular Equipment Maintenance: Drying chamber equipment, including air conditioners and constant temperature/humidity units, must be cleaned and maintained regularly to ensure optimal performance and stable environmental control.

7. Pangwakas na Salita

This article consolidates all critical operational details, quality control points, and defect prevention measures for investment casting shell making, covering the entire process from wax assembly cleaning to final drying.

The shell making process is a highly integrated system where every operational detail, environmental parameter, and raw material property directly impacts shell quality and final casting performance.

The defects analyzed in previous articles—from metal nodules and cucumber spikes to veining and bulging—are all traceable to non-compliance with these consolidated guidelines,

emphasizing that shell making success relies on rigorous process control rather than isolated operational adjustments.

This summary concludes our in-depth discussion of investment casting shell making.

Due to the limitations of the author’s current knowledge, certain advanced topics (hal., detailed performance characterization of shell making refractories, in-depth material science principles) remain unexplored,

and the production processes and performance parameters of refractory materials have not been elaborated in detail.

The author plans to conduct further systematic study of refractory material production, equipment performance, and material properties, and will share these advanced insights in future articles.

Readers are welcome to propose topics for discussion or contact the author via WeChat for in-depth thematic exchanges on investment casting processes.

As we transition to the next phase of our technical series—focused on the melting process—we will continue to explore the fundamental principles and practical guidelines that govern high-quality investment casting production.