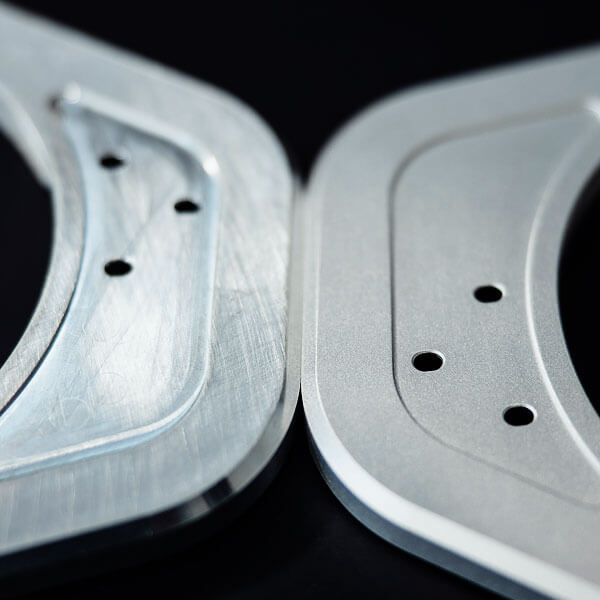

What is Bead Blasting?

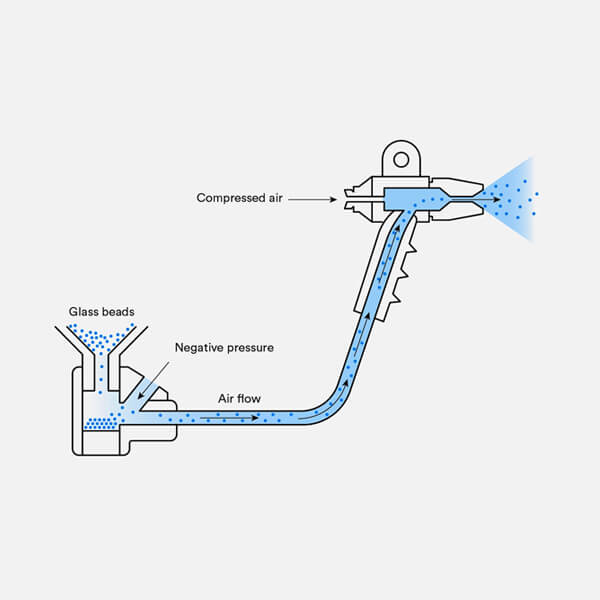

Bead blasting is a surface finishing process that uses fine spherical particles, known as blasting media, to clean, texture, or polish the surface of a material. The process involves propelling these beads at high velocity onto the material’s surface, effectively removing impurities, oxidation, or defects and creating a smooth, uniform finish.

Bead blasting is highly versatile and can be customized to achieve different textures, from matte to satin finishes. It is widely used for both aesthetic and functional purposes, including enhancing the appearance of parts, preparing surfaces for coating or anodizing, and restoring materials to their original condition. The process not only improves surface uniformity but also enhances corrosion resistance and removes sharp edges, making it an essential technique in manufacturing and restoration applications.