1. Introduction

CNC (Computer Numerical Control) milling is one of the most widely used subtractive manufacturing processes,

enabling the precise removal of material to produce complex components with tight tolerances.

As industries evolve and demand higher efficiency, precision, and scalability, CNC milling has become indispensable in automotive, aerospace, medical, and consumer electronics manufacturing.

The Evolution of CNC Milling

The journey of milling technology dates back to the early 19th century when Eli Whitney developed the first milling machine in 1818.

Since then, manual milling has transitioned into fully automated, computer-controlled systems capable of multi-axis movement, extreme precision, and enhanced speed.

According to a report by Markets and Markets, the CNC machine tool market is projected to grow from $83.4 billion in 2022 to $128.6 billion by 2030,

driven by automation, AI integration, and the rise of smart factories.

The Impact of CNC Milling on Industrial Efficiency

- Precision & Repeatability: Modern CNC milling machines achieve tolerances as tight as ±0.002 mm, enabling mass production without quality degradation.

- Shorter Lead Times: Compared to traditional machining, CNC milling reduces production cycles by 30-70%.

- Enhanced Material Utilization: Subtractive manufacturing typically leads to material waste,

but with optimized tool paths and chip recycling, manufacturers can recover up to 98% of aluminum chips. - Global Supply Chain Resilience: CNC machining enables local production hubs, reducing dependence on overseas manufacturing and enhancing supply chain stability.

2. The Science and Engineering Behind CNC Milling

CNC milling is a highly precise and efficient manufacturing process that leverages advanced engineering principles to shape materials into complex geometries.

Understanding the mechanics, machine types, and core components behind CNC milling is crucial for optimizing performance, increasing tool life, and ensuring high-quality output.

2.1 The Mechanics of CNC Milling

At its core, CNC milling is a subtractive machining process that removes material from a solid workpiece using rotating cutting tools.

The process follows predefined computer-aided design (CAD) models and computer-aided manufacturing (CAM) instructions, ensuring consistency, repeatability, and precision.

Key Principles of CNC Milling

- Tool Paths and Motion Control

-

- CNC mills operate along multiple axes (X, Y, and Z) with controlled linear and rotational movements.

- Advanced 5-axis milling adds rotation in the A and B axes, enabling the machine to cut from multiple angles.

- Tool paths are optimized to minimize machining time while maximizing accuracy.

- Cutting Forces and Material Removal

-

- Feed rate (how fast the tool moves through the material) and spindle speed (how fast the tool rotates) directly impact cutting forces.

- The chip load, or the amount of material removed per tooth per revolution, affects tool wear and heat generation.

- Cutting forces are managed using high-speed machining (HSM) strategies, which reduce tool stress and improve surface quality.

- Heat Generation and Tool Wear

-

- During milling, friction between the tool and workpiece generates heat.

- Excess heat can cause tool deformation, workpiece expansion, and surface imperfections.

- Coolant systems and optimized tool coatings (TiN, TiAlN, and DLC) extend tool life by reducing thermal impact.

Chip Formation and Evacuation

Efficient chip removal is critical for preventing tool damage and ensuring smooth machining:

- Small, broken chips indicate proper cutting conditions.

- Long, stringy chips suggest improper speeds or feed rates.

- Compressed chips can cause excessive heat buildup and tool failure.

2.2. Types of CNC Milling Machines

CNC milling machines vary in complexity and functionality, offering different capabilities depending on the number of controlled axes, spindle orientation, and tool-changing mechanisms.

Comparison of CNC Milling Machine Types

| Machine Type | Axes | Best Used For |

|---|---|---|

| 3-Axis CNC Milling | X, Y, Z | Standard machining, flat and simple parts |

| 4-Axis CNC Milling | X, Y, Z + A (rotational) | Helical cutting, complex profiles |

| 5-Axis CNC Milling | X, Y, Z + A, B (rotational) | Aerospace, medical implants, intricate parts |

| Horizontal CNC Milling | X, Y, Z + horizontal spindle | Heavy-duty machining, deep cavities |

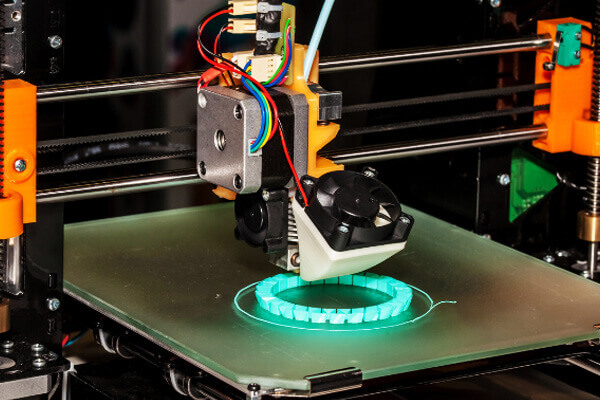

| Hybrid CNC Milling | X, Y, Z + additive manufacturing | Combining CNC milling with 3D printing or laser cutting |

Vertical vs. Horizontal Milling Machines

- Vertical CNC Milling Machines

-

- The spindle is oriented vertically, making them ideal for face milling, drilling, and slot cutting.

- It is best suited for smaller workpieces and complex contours.

- Horizontal CNC Milling Machines

-

- The spindle is oriented horizontally, allowing deeper and more aggressive cuts.

- Used in automotive, heavy machinery, and aerospace applications.

2.3. Core Components of CNC Milling Machines

To ensure high precision and efficiency, CNC milling machines are built with advanced mechanical, electrical, and software-driven components.

Spindle and Motor: Power and Speed Considerations

The spindle is the heart of a CNC milling machine, responsible for rotating the cutting tool at high speeds.

- Spindle speeds range from 3,000 RPM (for heavy materials like titanium) to 60,000 RPM (for high-speed micro-machining).

- High-power direct-drive spindles minimize vibration, improving tool stability.

- Variable-frequency drives (VFDs) adjust spindle speed dynamically for optimal cutting conditions.

Linear Guides and Ball Screws: Ensuring Precision and Durability

- Linear guides support the movement of the milling table, ensuring smooth motion with minimal backlash.

- Ball screws convert rotational motion into linear movement with exceptional accuracy, often achieving positioning tolerances of ±0.002 mm.

- Glass scale encoders further enhance precision by providing real-time feedback on tool position.

Coolant and Lubrication Systems: Role in Heat Dissipation and Tool Longevity

To manage heat and friction, CNC milling machines use liquid coolants, air blast systems, and mist lubrication.

- Flood Coolant: Provides continuous cooling for deep cuts and heavy material removal.

- High-Pressure Coolant (HPC): Removes chips efficiently and extends tool life.

- Minimum Quantity Lubrication (MQL): Reduces waste by delivering a fine mist of lubricant.

Automatic Tool Changer (ATC): Enhancing Productivity

Modern CNC milling machines use Automatic Tool Changers (ATCs) to swap tools in seconds, reducing downtime and increasing machining efficiency.

- Carousel ATCs hold 20-100 tools, allowing rapid switching.

- Robotic ATCs enable seamless, unmanned production.

3. Material Science: The Impact of CNC Milling on Different Materials

Understanding how CNC milling interacts with metals, non-metals, and composites helps manufacturers

optimize tool selection, feed rates, and cutting conditions to achieve high precision and cost-efficiency.

3.1. Milling of Metals

Metals are the most commonly machined materials due to their mechanical strength, durability, and conductivity.

However, each metal requires specific milling strategies to balance tool wear, heat generation, and surface finish quality.

Aluminum: High-Speed Machining for Lightweight Components

- Machinability: Excellent – aluminum is soft, allowing high-speed milling with minimal tool wear.

- Common Applications: Aerospace, automotive, consumer electronics (smartphone casings, heat sinks).

- Cutting Speeds:300 – 3,000 SFM (Surface Feet per Minute), much higher than steel.

- Challenges:

-

- Tends to form built-up edges (BUE) on cutting tools.

- Requires high-speed spindles and optimized coolant application.

- Best Practices:

-

- Use polished carbide tools with sharp edges to prevent sticking.

- Apply air blast or mist lubrication instead of flood coolant to prevent chip welding.

Titanium: Aerospace-Grade Strength with Machining Challenges

- Machinability: Poor – titanium is difficult to mill due to its low thermal conductivity and tendency to work hard.

- Common Applications: Aerospace, medical implants, military equipment.

- Cutting Speeds:100 – 250 SFM, significantly lower than aluminum.

- Challenges:

-

- Generates extreme heat, causing tool wear and thermal expansion.

- Tends to create long, unbroken chips that interfere with machining.

- Best Practices:

-

- Use low cutting speeds and high feed rates to reduce heat buildup.

- Apply high-pressure coolant (HPC) to improve chip evacuation and reduce tool wear.

- Utilize coated carbide or ceramic tools (TiAlN, AlCrN coatings) for enhanced durability.

Stainless Steel: Corrosion Resistance vs. Machining Complexity

- Machinability: Moderate to Poor – stainless steel is tough and work-hardens quickly.

- Common Applications: Food processing equipment, medical instruments, marine components.

- Cutting Speeds:100 – 500 SFM, varies by grade.

- Challenges:

-

- High work hardening rate reduces tool life.

- Generates significant heat, leading to thermal expansion and dimensional inaccuracies.

- Best Practices:

-

- Use low-speed, high-torque milling to prevent work hardening.

- Apply copious coolant flow to dissipate heat.

- Utilize high-rigidity machine setups to avoid vibration and deflection.

Copper and Brass: Soft Metals with High Conductivity

- Machinability: Excellent – both metals offer easy chip removal and smooth surface finishes.

- Common Applications: Electrical components, plumbing fittings, decorative elements.

- Cutting Speeds:400 – 2,000 SFM.

- Challenges:

-

- Copper is gummy, causing tool adhesion.

- Brass is easier to machine but prone to burr formation.

- Best Practices:

-

- Use sharp carbide tools with high rake angles.

- Apply air blasts instead of coolant for better chip evacuation.

3.2. Milling of Non-Metallic Materials

Beyond metals, CNC milling is widely used for plastics, composites, and ceramics, each presenting unique machining challenges.

High-Performance Plastics: PEEK, Delrin, and Nylon

Plastics are valued for their lightweight, chemical resistance, and insulating properties,

but they require specialized machining techniques due to their low melting points and tendency to deform under heat.

| Plastic Type | Properties | Challenges | Best Machining Practices |

|---|---|---|---|

| PEEK | High-strength, heat-resistant | Prone to thermal expansion | Use low cutting speeds, sharp tools |

| Delrin (Acetal) | Low friction, high machinability | Prone to chipping | Use high-speed carbide tools, avoid excessive coolant |

| Nylon | Flexible, wear-resistant | Absorbs moisture, expands | Dry machining preferred, sharp cutters |

Composite Materials: Carbon Fiber and Fiberglass

Composite materials are essential in aerospace, automotive, and sports industries due to their high strength-to-weight ratio.

However, they are challenging to machine due to their abrasive nature and layered structure.

- Machinability: Difficult – fibers cause rapid tool wear and delamination.

- Common Applications: Aircraft panels, automotive body parts, sports equipment.

- Challenges:

-

- Carbon fiber is extremely abrasive, dulling tools quickly.

- Fiberglass releases hazardous airborne particles, requiring dust extraction.

- Best Practices:

-

- Use diamond-coated tools for longer tool life.

- Employ low feed rates and climb milling to reduce delamination.

- Use vacuum extraction to remove fine dust particles safely.

Ceramics and Glass: High Hardness with Specialized Milling

- Machinability: Extremely difficult – requires diamond tooling and ultra-precise CNC control.

- Common Applications: Semiconductor industry, biomedical implants, cutting tools.

- Challenges:

-

- Brittle nature leads to cracking under mechanical stress.

- Requires coolant to prevent thermal shock.

- Best Practices:

-

- Use slow feed rates and minimal force to prevent chipping.

- Apply ultrasonic-assisted machining for improved results.

3.3. Surface Finish and Post-Processing Considerations

The surface finish achieved in CNC milling depends on material properties, tool sharpness, and machining parameters.

Understanding Surface Roughness Parameters

| Parameter | Description | Typical Range (µm Ra) |

|---|---|---|

| Ra (Roughness Average) | Average deviation from mean surface | 0.2 – 6.3 |

| Rz (Average Maximum Height of the Profile) | Peak-to-valley roughness | 1.0 – 25.0 |

| Rt (Total Roughness Height) | Maximum peak-to-valley height | 5.0 – 50.0 |

Common Post-Processing Techniques

| Method | Purpose | Materials Applied To |

|---|---|---|

| Anodizing | Increases corrosion resistance | Aluminum |

| Plating (Nickel, Chrome, Zinc) | Improves wear resistance | Steel, brass, copper |

| Heat Treatment (Annealing, Hardening) | Enhances strength and toughness | Steel, titanium |

| Polishing & Lapping | Achieves mirror-like surface | Stainless steel, plastics, ceramics |

4. CNC Milling vs. Alternative Manufacturing Techniques

CNC milling is a versatile, high-precision, and efficient subtractive manufacturing method, but it is not the only option available.

Depending on factors such as cost, material properties, production volume, and design complexity,

other manufacturing techniques like 3D printing, injection molding, and EDM (Electrical Discharge Machining) may be more suitable for specific applications.

This section provides a detailed comparative analysis of CNC milling versus these alternative manufacturing methods, helping engineers and manufacturers make informed decisions.

CNC Milling vs. 3D Printing

Fundamental Differences

CNC milling is a subtractive process, which means it starts with a solid block of material and removes excess material to achieve the final shape.

In contrast, 3D printing (Additive Manufacturing) builds parts layer by layer from materials like plastic, metal, and resin.

| Factor | CNC Milling | 3D Printing |

|---|---|---|

| Process Type | Subtractive | Additive |

| Material Waste | High (chips removed) | Low (only needed material used) |

| Precision | ±0.005 mm | ±0.1 mm |

| Surface Finish | Excellent | Often requires post-processing |

| Material Options | Broad (metals, plastics, composites) | Limited, mostly polymers and some metals |

| Production Speed | Faster for simple and medium-complexity parts | Faster for complex, lightweight designs |

| Tooling Costs | Requires cutting tools | No tooling required |

CNC Milling vs. Injection Molding

Key Differences

Injection molding is a high-volume manufacturing process where molten plastic or metal is injected into a mold cavity, then cooled and ejected as a final part.

CNC milling, on the other hand, cuts directly from solid material, making it more suitable for low to medium-volume production and prototyping.

| Factor | CNC Milling | Injection Molding |

|---|---|---|

| Production Volume | Low to medium (1-10,000 parts) | High (10,000+ parts) |

| Lead Time | Short (days) | Long (weeks to months for tooling) |

| Upfront Costs | Low (no mold required) | High (expensive tooling) |

| Material Flexibility | Wide range (metals, plastics, composites) | Limited to moldable materials |

| Complex Geometries | Possible but with limitations | Very complex shapes possible |

| Surface Finish | Excellent (±0.005 mm tolerance) | Excellent, but may require post-processing |

CNC Milling vs. EDM (Electrical Discharge Machining)

How They Work

- CNC Milling: Uses rotating cutting tools to remove material through physical contact.

- EDM: Uses electrical discharges (sparks) to erode material, ideal for hard metals and intricate details.

| Factor | CNC Milling | EDM (Electrical Discharge Machining) |

|---|---|---|

| Material Removal Process | Mechanical (cutting tools) | Electrothermal (sparks erode material) |

| Best Suited For | Soft to hard materials, general machining | Ultra-hard materials, intricate cavities |

| Precision | ±0.005 mm | ±0.002 mm (higher accuracy) |

| Surface Finish | Smooth but requires polishing for extreme finishes | Extremely smooth (mirror-like) |

| Speed | Faster for general machining | Slower due to spark erosion process |

| Material Restrictions | Works on most metals and plastics | Only conductive materials (metals) |

5. Pros and Cons of CNC Milling

CNC milling offers numerous advantages that have made it a cornerstone of modern manufacturing, yet it also presents certain limitations that must be considered.

Advantages

- High Precision and Repeatability:

CNC milling can achieve tolerances as tight as ±0.002 mm, ensuring each part is produced to exact specifications.

This level of precision is essential in industries such as aerospace and medical device manufacturing. - Versatility in Material Processing:

CNC milling works with a wide range of materials—including metals like aluminum, titanium, and stainless steel, as well as plastics and composites.

This flexibility allows manufacturers to tailor their processes to various applications. - Automation and Efficiency:

By automating tool paths based on CAD/CAM data, CNC milling minimizes human error and enhances production efficiency.

In fact, automated systems can reduce production cycles by 30-70% compared to manual machining. - Reduced Lead Times for Prototyping:

CNC milling is ideal for both rapid prototyping and low-volume production, providing quick turnaround times that accelerate product development cycles. - Consistency and Quality Control:

The use of advanced metrology tools, such as CMM (Coordinate Measuring Machines),

ensures each part meets stringent quality standards, thereby reducing scrap rates and ensuring reliability.

Drawbacks

- High Initial Investment:

CNC machines, especially advanced 5-axis systems, can be expensive, with initial investments ranging from $50,000 to $500,000.

This high capital cost may be a barrier for smaller operations. - Material Waste:

As a subtractive process, CNC milling generates significant amounts of material waste.

Although strategies like chip recycling (up to 98% recovery for aluminum) mitigate this, waste management remains a concern. - Complex Programming and Skill Requirements:

CNC milling requires highly skilled operators and programmers.

The complexity of programming multi-axis machines can result in a steep learning curve and potential for errors during setup. - Tool Wear and Maintenance:

Cutting tools are subject to wear and need regular replacement. For example, improper chip control can lead to increased tool wear, thereby raising operational costs and downtime. - Limitations with Certain Geometries:

While CNC milling excels at producing intricate shapes, it may struggle with complex internal geometries or deep cavities that require a combination of machining methods.

6. Industrial Applications

CNC milling has become a cornerstone technology across various industrial sectors due to its remarkable precision, efficiency, and versatility.

By enabling the production of complex geometries with tight tolerances, CNC milling drives innovation and quality in high-performance components.

Below, we explore how CNC milling shapes the world across multiple industries.

Aerospace & Defense

CNC milling plays a pivotal role in aerospace and defense by producing components that demand exceptional accuracy and strength.

For instance, turbine blades and structural components often require tolerances within ±0.002 mm and must withstand extreme thermal and mechanical stresses.

The aerospace industry, valued at over $838 billion globally, relies on CNC-milled lightweight alloys to improve fuel efficiency and ensure safety.

Moreover, defense applications use CNC milling to create high-precision parts for missile guidance systems and armored vehicles, where even the smallest error can compromise performance.

Automotive Manufacturing

In the automotive sector, CNC milling facilitates the production of custom engine parts, precision gears, and chassis components.

Modern vehicles require parts that not only meet strict quality standards but also contribute to overall efficiency and performance.

For example, CNC-machined components in electric vehicles (EVs) improve thermal management and reduce weight, ultimately enhancing battery performance.

As the automotive industry shifts towards sustainability, the demand for CNC milling in prototyping and low-volume production remains strong,

with parts manufactured to tolerances as tight as ±0.005 mm.

Medical & Healthcare

CNC milling has transformed medical device manufacturing by enabling the production of biocompatible implants, surgical instruments, and prosthetics.

High-precision milling ensures that components such as titanium implants achieve the necessary surface finishes and dimensional accuracies required for patient safety and effective performance.

Additionally, the ability to produce customized components quickly allows healthcare providers to respond promptly to emerging needs.

With the global medical devices market projected to exceed $600 billion by 2025, CNC milling continues to be a critical technology in advancing patient care and medical innovation.

Consumer Electronics & Semiconductor Industries

The consumer electronics sector benefits from CNC milling through the production of

precision aluminum casings, heat sinks, and internal structural components for devices like smartphones, laptops, and tablets.

These components demand a flawless surface finish and precise dimensions to ensure device reliability and performance.

Furthermore, in the semiconductor industry, CNC milling is employed to manufacture housings and critical supports that protect sensitive electronics.

This capability has become increasingly vital as devices shrink in size while rising in complexity.

Additional Sectors

Beyond these primary industries, CNC milling supports manufacturing in sectors such as robotics, renewable energy, and industrial machinery.

In robotics, CNC-milled parts ensure that components operate smoothly and accurately, which is essential for automation.

Renewable energy applications, such as solar panel frames and wind turbine components, benefit from the high strength-to-weight ratios achievable through CNC milling.

Industrial machinery, which demands durability and precision, also relies on CNC milling for high-quality, reliable parts that extend the life of equipment.

7. The Economic and Business Impact of CNC Milling

CNC milling plays a significant role in modern manufacturing, influencing global supply chains, cost structures, and production efficiency.

As industries seek precision, automation, and scalability, CNC milling provides businesses with a competitive edge.

In this section, we explore the financial and strategic implications of CNC milling from multiple perspectives.

7.1 Cost Structure Analysis

Initial Investment vs. Long-Term Savings

Investing in CNC milling machines requires substantial capital, with high-end 5-axis CNC machines costing between $200,000 and $500,000.

However, these machines significantly reduce labor costs, material waste, and production times, leading to long-term savings.

Businesses that implement CNC milling often see a return on investment (ROI) within 2 to 5 years, depending on production volume and efficiency improvements.

Cost Breakdown in CNC Milling Production

To understand the total cost of CNC milling, it is essential to break down the major expense factors:

- Machine Costs – Includes the purchase, maintenance, and depreciation of CNC machines.

- Tooling & Consumables – Cutting tools, tool holders, and lubricants can account for 10–20% of the total production cost.

- Labor Costs – While CNC milling is highly automated, skilled machinists and engineers are required for programming, setup, and quality control.

- Material Waste – Subtractive manufacturing naturally produces waste, but advanced programming and nesting techniques can minimize material loss by up to 30%.

- Energy Consumption – CNC machines consume significant power, particularly in high-speed or 24/7 production environments.

Energy-efficient machines and optimized machining strategies can lower costs.

CNC Milling vs. Traditional Manufacturing Costs

Compared to manual machining, CNC milling provides greater consistency and repeatability, reducing defects and rework costs.

In contrast with 3D printing, CNC milling is more cost-effective for large-scale metal part production.

Moreover, while injection molding is cheaper for mass production, CNC milling is ideal for prototypes and low-volume production, avoiding expensive mold tooling.

7.2. Global Supply Chain Considerations

The Role of CNC Milling in Local and Decentralized Manufacturing

With increasing disruptions in global supply chains—such as material shortages and geopolitical tensions—many companies are shifting towards localized manufacturing.

CNC milling enables businesses to produce critical components in-house or through nearby suppliers, reducing reliance on overseas production.

This approach enhances supply chain resilience and shortens lead times.

CNC Milling in Reshoring vs. Outsourcing Decisions

Many companies, particularly in the U.S. and Europe, are reshoring manufacturing operations due to rising labor costs in traditional outsourcing hubs.

CNC milling allows manufacturers to maintain high production quality without excessive labor costs.

In 2023 alone, over 350,000 manufacturing jobs were reshored to the U.S., largely due to automation and CNC technologies.

Lead Time and Production Efficiency

One of CNC milling’s biggest advantages is its ability to reduce lead times by 40–60% compared to traditional manufacturing methods.

CNC machines can run 24/7, improving production efficiency and allowing companies to meet urgent demands without significant delays.

7.3. Market Trends and Growth Projections

Industry Growth and Adoption

The CNC machining market was valued at $87.3 billion in 2023 and is expected to grow at a CAGR of 6.4% from 2024 to 2030. This growth is fueled by:

- Increased demand for precision components in aerospace, medical, and automotive sectors.

- Expansion of automation and smart manufacturing technologies.

- Rising adoption of multi-axis CNC machines for complex part production.

Emerging Industries Driving CNC Milling Demand

Several high-growth sectors are increasingly relying on CNC milling:

- Electric Vehicles (EVs): CNC milling is essential for battery components, lightweight chassis, and motor housings.

- Renewable Energy: Precision-milled parts are used in wind turbine gearboxes, solar panel frames, and hydroelectric systems.

- Space Exploration: Companies like SpaceX and Blue Origin depend on CNC milling for spacecraft components requiring extreme tolerances.

Automation and Industry 4.0 Integration

The rise of Industry 4.0 is transforming CNC milling with AI-driven process optimization, real-time monitoring, and predictive maintenance.

Smart factories utilizing CNC milling and automation have reported up to 25% cost savings and 30% higher production efficiency.

8. Challenges and Limitations of CNC Milling

While CNC milling has revolutionized the manufacturing industry with its precision, efficiency, and versatility, it also comes with its own set of challenges and limitations.

These challenges often require manufacturers to carefully weigh the benefits against the constraints when deciding whether CNC milling is the most suitable solution for their projects.

In this section, we explore the key obstacles that businesses encounter when using CNC milling and how they can mitigate these issues.

High Initial Investment and Operational Costs

Initial Investment

The purchase and setup of CNC milling machines are capital-intensive, especially for advanced multi-axis machines.

High-end 5-axis CNC mills can cost anywhere between $200,000 and $500,000, not including setup costs, installation, and training.

This hefty initial investment can be a significant barrier for small or medium-sized enterprises (SMEs) looking to adopt CNC milling.

Operational Costs

While CNC milling reduces labor costs through automation, it still incurs ongoing operational expenses. These include:

- Maintenance and repair costs: Regular maintenance is crucial to keep CNC machines running smoothly, and downtime can be costly.

Preventive maintenance schedules can help reduce unexpected repair costs. - Energy consumption: CNC mills can consume substantial amounts of energy, particularly when operating at high speeds or for extended periods.

Energy-efficient machines and optimized processes can mitigate this cost. - Tooling and consumables: CNC mills rely on cutting tools, which have finite lifespans and require frequent replacement or sharpening.

High-performance tooling can add significant costs, especially for industries like aerospace where precision is paramount.

Mitigation Strategies

- Leasing and financing: For businesses that cannot afford the upfront cost of CNC machines, leasing or financing options can spread the financial burden.

- Upfront cost-benefit analysis: A comprehensive cost-benefit analysis should be conducted to ensure that the long-term savings from CNC milling justify the initial investment.

Technical Skill Gap and Workforce Training

Need for Skilled Operators and Programmers

Although CNC machines are automated, they still require skilled professionals to operate, program, and maintain them.

Operators need to understand complex CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, as well as machine-specific programming languages like G-code.

The rapid pace of technological change in CNC machining means that operators must continually upgrade their skills.

Training Costs and Time

Training personnel to handle CNC machines can be expensive and time-consuming.

New employees must be trained in machine operation, troubleshooting, safety protocols, and quality control.

For businesses, this means investing in training programs or hiring experienced professionals.

Mitigation Strategies

- Investing in employee training: Offering in-house training programs or partnering with educational institutions can help bridge the skills gap.

Some companies provide virtual training programs to reduce costs and improve accessibility. - Automation and AI support: Integrating AI and machine learning technologies into CNC operations can assist operators in optimizing machine settings,

reducing the technical skill requirement, and enhancing overall efficiency.

Limitations in Complex Internal Geometries

Challenges with Intricate Internal Features

While CNC milling is highly capable of producing complex external geometries, it faces significant challenges when it comes to machining internal features.

For example, making deep holes, narrow internal cavities, or intricate undercuts can be difficult with traditional milling techniques.

In some cases, special tools or additional setup configurations may be required, which can increase production time and costs.

Limitations in Part Size and Material Constraints

Although CNC mills can handle a variety of materials, certain materials like titanium alloys or exotic metals can be particularly challenging to machine.

These materials require specific tooling, high cutting forces, and precise temperature control.

Additionally, machining large components can be restricted by the size of the CNC machine’s worktable or spindle.

Mitigation Strategies

- Hybrid manufacturing: One solution to overcoming limitations in internal geometries is the integration of CNC milling

with other manufacturing technologies like 3D printing or EDM (Electrical Discharge Machining).

This hybrid approach allows manufacturers to produce components with complex internal geometries that are difficult to achieve with milling alone. - Advanced tooling: Using specialized tools such as ball-end mills or small diameter tools can help access difficult-to-reach internal features, improving machining capability.

Material Waste and Environmental Impact

Subtractive Nature of CNC Milling

CNC milling is a subtractive process, meaning material is removed from a larger workpiece to achieve the desired shape.

While this ensures high precision, it can result in significant material waste,

especially when machining complex parts from expensive materials like titanium, stainless steel, or high-performance plastics.

Waste material can account for up to 20-40% of the raw material, depending on part complexity.

Environmental Concerns

The use of CNC milling machines also has an environmental impact due to high energy consumption and the disposal of waste materials.

Additionally, CNC machines typically require the use of coolants and lubricants, which can have harmful effects on the environment if not properly managed or recycled.

Mitigation Strategies

- Optimized part design and material usage: By employing design for manufacturability (DFM) principles,

engineers can reduce material waste by optimizing the geometry of parts and utilizing more efficient machining techniques. - Recycling and waste management: Implementing strategies like metal chip recycling and using eco-friendly coolants can reduce the environmental footprint of CNC milling operations.

Additionally, recycling scrap materials can recoup some of the costs associated with material waste.

Machine Limitations and Downtime

Limitations in Speed and Precision

Despite the advanced technology behind CNC milling, it still faces limitations in terms of speed and precision.

For extremely high-precision parts, 5-axis CNC milling machines can be slow compared to simpler 3-axis milling machines.

Additionally, tolerances in some cases may not meet the demands of highly specialized industries like aerospace or medical implants without meticulous quality control measures.

Downtime Due to Maintenance or Failure

Like any complex machinery, CNC mills require regular maintenance, and unexpected downtime can disrupt production schedules.

High-precision parts may also require multiple setups, leading to additional operational delays.

Mitigation Strategies

- Preventive maintenance programs: Establishing a routine preventive maintenance schedule can reduce machine downtime and improve overall reliability.

- IoT and predictive analytics: Advanced technologies like Internet of Things (IoT) and predictive maintenance

can help monitor CNC machine health in real time, allowing for preemptive repairs and minimizing unexpected downtime.

9. Conclusion

As industries demand higher precision, efficiency, and sustainability, CNC milling will remain indispensable.

By integrating AI, automation, and sustainable practices, manufacturers can push the boundaries of innovation while reducing costs.

Looking ahead, CNC milling will continue to shape aerospace, automotive, healthcare, and beyond, ensuring a future driven by precision engineering.

If you’re looking for high-quality CNC milling services, choosing LangHe is the perfect decision for your manufacturing needs.