1. Introduction

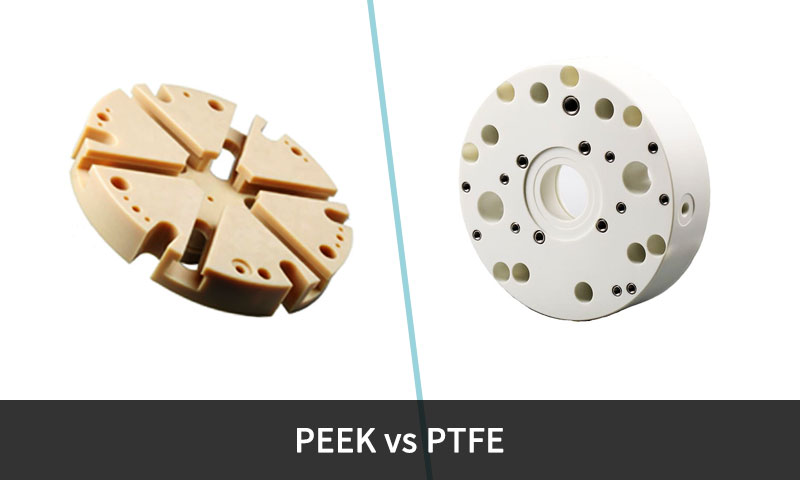

PEEK (polyetheretherketone) and PTFE (polytetrafluoroethylene) are high-performance engineering polymers but with very different strengths and weaknesses.

PEEK is a semi-crystalline, high-strength, high-stiffness thermoplastic with excellent creep resistance, dimensional stability and high-temperature mechanical performance; it is used where structure, long-term mechanical reliability and sterilizability are required.

PTFE is an ultra-inert fluoropolymer famous for exceptionally low friction, virtually universal chemical inertness and outstanding dielectric performance but it has low mechanical strength, high creep (cold flow) and abrasion susceptibility.

In short: choose PEEK when structural strength, stiffness and low creep matter; choose PTFE when unrivalled chemical inertness and friction reduction are the primary demands.

2. Material fundamentals

What is PEEK (PolyEtherEtherKetone)

- A semicrystalline thermoplastic (aromatic polyaryletherketone family).

- Melting point ≈ 343 °C; glass transition ≈ 143 °C.

- Processable by standard thermoplastic routes (injection molding, extrusion, compression molding), machinable and weldable (hot-plate, ultrasonic, vibration or laser in controlled setups).

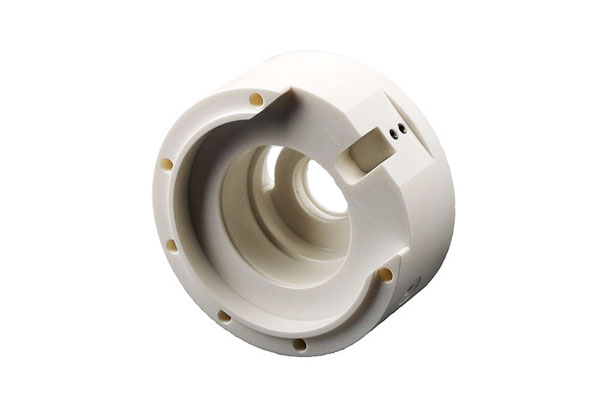

- Typical uses: bearings and wear parts (filled grades), structural components, medical implants, hot-oil system parts, connectors.

What is PTFE (Polytetrafluoroethylene)

- A fluoropolymer with fully fluorinated carbon backbone; highly symmetric and highly chemically inert.

- Melting point ≈ 327 °C, but it is not melt-processable in conventional thermoplastic equipment — it is processed by paste extrusion, ram extrusion, compression molding and sintering.

- Outstanding chemical inertness, very low coefficient of friction and excellent dielectric properties.

- Typical uses: seals, gaskets, chemical liners, low-friction coatings, electrical insulation.

3. Key properties — data table (typical ranges) and practical notes

All numeric ranges are typical engineering guidance for common commercial grades (neat polymer). Composite/filler grades (carbon, glass, bronze, MoS₂) change values substantially.

| Property | PEEK (unfilled, typical) | PTFE (virgin) | Practical implication |

| Density (g·cm⁻³) | ≈ 1.30 | ≈ 2.12 | PTFE is substantially heavier per volume. |

| Tensile strength (MPa) | ~90–110 | ~20–35 | PEEK is structurally strong; PTFE is weak in tension. |

| Young’s modulus (GPa) | ~3.6–4.1 | ~0.5 | PEEK stiff; PTFE very flexible/low stiffness. |

| Elongation at break (%) | ~20–50 | ~200–400 | PTFE deforms a lot before breaking. |

| Hardness (Shore/others) | Moderate (~80–90 Rockwell/var) | Very low | PEEK resists indentation better. |

| Glass transition (°C) | ~143 | amorphous/very low | PEEK has defined Tg—affects dimensional stability. |

Melting point (°C) |

~343 | ~327 | Both high melting but processing differs. |

| Continuous service temp (°C) | ~250 (typical) | −200 to +260 (short term) | PEEK retains mechanical strength at high T; PTFE retains chemistry and tribology but creeps. |

| Thermal conductivity (W·m⁻¹K⁻¹) | ~0.25 | ~0.25 | Similar low thermal conductivity. |

| Coefficient of friction (dry) | ~0.15–0.4 (neat) | ~0.04–0.15 | PTFE offers much lower friction (excellent sliding). |

| Wear resistance | Good (excellent if filled) | Poor (improves when filled with bronze/glass) | PTFE often needs fillers for wear applications. |

| Creep & cold flow | Low–moderate (good resistance) | High (time-dependent deformation) | PTFE deforms (creeps) under load — poor for static seals under pressure. |

Chemical resistance |

Excellent to many solvents; attacked by strong oxidizers / concentrated halogens | Almost universal (resists nearly all chemicals) | PTFE is the gold standard for chemical inertness. |

| Electrical properties (εr) | ~3.0–3.5, good | ~2.0 (very low), excellent | PTFE preferred for high-frequency dielectric use. |

| Processability | Injection mouldable, machinable, weldable | Cannot be injection moulded; sintered/paste extruded; machinable from billets | PEEK easier for conventional thermoplastic manufacturing. |

| Biocompatibility | Many grades used in medical implants (good) | Used in medical devices but not common as permanent implant | PEEK is implantable; PTFE used in grafts/porous forms in some cases. |

| Cost (relative) | High | High but often lower than medical-grade PEEK | Both are premium polymers; PEEK often more expensive. |

Notes: filled grades (CF-PEEK, glass/bronze-filled PTFE) modify many entries: carbon-filled PEEK increases stiffness and reduces wear; bronze-filled PTFE increases load capacity and abrasion resistance but raises friction and density.

4. Thermal behavior & high-temperature performance

- PEEK: retains mechanical strength at elevated temperatures; typical continuous service up to ~200–250 °C, short excursions higher. Low thermal expansion relative to many polymers; good dimensional stability and low creep at elevated T compared with PTFE.

Decomposes above ~400 °C — thermal oxidation needs control. PEEK can be steam sterilized repeatedly (autoclave) — important for medical use. - PTFE: chemically stable at high temperatures and maintains low friction up to ~250–260 °C; above ~260–300 °C decomposition occurs and toxic fluorinated species (e.g., HF, though exact decomposition products vary) are emitted — thermal safety is a consideration.

Because PTFE creeps, its usable mechanical service temperature under load is often lower than its thermal stability suggests.

Practical implication: For structural components operating under load at high temperature choose PEEK; for chemical or sliding surfaces exposed to high temperatures but low mechanical load, PTFE is acceptable.

5. Chemical resistance & electrical properties

- Chemical resistance:PTFE approximates “resistant to everything” — it resists strong acids, bases, solvents, oxidizers and is often chosen where no other polymer will survive.

PEEK offers excellent resistance to hydrocarbons, oils, steam and many solvents; however, concentrated strong oxidizers and elemental fluorine attack PEEK.

For many chemical processing applications PEEK is adequate; for the most aggressive chemistries PTFE is safer. - Dielectric & RF use:PTFE has a low dielectric constant (~2.0), extremely low loss tangent — ideal for RF/microwave applications.

PEEK is a good electrical insulator but with higher dielectric constant and loss; chosen where mechanical and thermal demands outweigh the need for ultra-low dielectric loss.

6. Tribology, wear, sealing and dynamic behaviour

- Friction: PTFE has an extremely low coefficient of friction and provides excellent lubricity.

PEEK (neat) has higher friction but filled PEEK (carbon, PTFE blends) can significantly reduce friction. - Wear: PEEK generally has superior wear resistance relative to neat PTFE; for sliding applications under load PEEK (or filled PEEK) often outlasts PTFE.

PTFE’s advantage is lubricity and conformability — many bearings and low-friction bushings use PTFE-lined structures or filled PTFE (bronze/PTFE) for improved wear life. - Creep & static seals:PTFE creeps and cold-flows significantly under sustained loads — not ideal for static load-bearing components requiring dimensional stability.

PEEK shows much better creep resistance and is preferred where seals or spacers must maintain preload over time. - Sealing: For low-pressure, conformable seals PTFE is excellent; for dynamically loaded seals requiring shape retention and high temperature strength, PEEK (often combined with elastomers or used as backup rings) or filled PEEK composites are preferred.

7. Processing, fabrication, joining, surface preparation

PEEK

- Processing: injection molding, extrusion, compression moulding, machining (CNC). High melt temperature requires controlled processing (drying, high mold temps).

- Joining: PEEK can be welded (hot-plate, ultrasonic) and adhesives bond after surface prep.

- Finishing: fairly easy to machine to tight tolerances; surface treatments can improve wear or friction.

PTFE

- Processing: PTFE is not melt-flowable in the sense of thermoplastics; it is processed by paste extrusion, ram extrusion, compression molding and subsequent sintering. Fine control required for porosity and densification.

- Joining & bonding: PTFE bonds poorly to adhesives unless chemically etched (e.g., Na/naphthalide etch) or plasma treated and primed. Mechanical fastening or overmolding are common.

- Fabrication: large components are often machined from extruded/sintered blocks or skived film. Coatings of PTFE are applied by spraying dispersions and baking.

Practical impact: If conventional high-volume thermoforming (injection molding) is required, PEEK is more straightforward. PTFE demands specialized processing equipment and sintering.

8. Cost, supply chain, regulatory & sustainability considerations

- Cost: both are premium polymers. PEEK grades (especially medical or filled grades) are typically more expensive per kg than standard PTFE, but cost depends on grade and volume.

Total part cost must factor processing complexity — PTFE processing and sintering can be costly. - Supply & lead times: PEEK supply can be constrained (few manufacturers), while PTFE is widely produced by multiple suppliers globally.

- Regulatory & safety: PEEK is used in medical implants (biocompatible grades, ISO/USP considerations).

PTFE is widely used in food contact and medical device components but PFAS environmental concerns (related to processing aids and life-cycle) have driven regulatory scrutiny;

thermal decomposition of PTFE can generate toxic fumes — manufacturing and use must manage fume risk. - Environmental: PTFE and related fluoropolymers are persistent in the environment (PFAS family concerns).

Recycling of both polymers is possible in certain streams, but both are more challenging to recycle than commodity plastics. PEEK is more readily reprocessed thermoplastically.

9. Application Comparison: PEEK vs PTFE

Bearings, bushings and sliding components

- Demands: low friction, wear resistance, dimensional stability, long life under load.

- PEEK: preferred for load-bearing bearings (e.g., thrust washers, bearings in pumps/motors) when stiffness and low creep are required; carbon- or glass-filled PEEK offers improved modulus and lower wear. PEEK tolerates machining to tight tolerances.

- PTFE: chosen for low-load sliding and conformable-lined bushings; bronze/PTFE composites provide improved load capacity vs virgin PTFE.

- Design tip: use PEEK where shaft support and minimal preload loss are critical; use PTFE (or PTFE-lined designs) where sliding friction must be minimized and the load is low.

Seals and gaskets

- Demands: sealing under compression, chemical exposure, temperature cycling.

- PTFE: excellent for static chemical seals, valve seats, gaskets in aggressive media.

Beware: PTFE cold-flows — design for compression set and consider backup rings or gasketing geometry minimizing sustained compressive strain. - PEEK: used for backup rings, mechanical support rings, and high-pressure seal carriers where creep resistance is required.

- Practical rule: pair PTFE sealing faces with PEEK backup components to combine chemical inertness and dimensional stability.

Chemical process industry (linings, valve components, diaphragms)

- Demands: nearly universal chemical resistance, thermal range, flange/valve geometry.

- PTFE is the default for liners, cage coatings, valve seats; virgin or specialty filled PTFE grades depending on abrasion and pressure.

- PEEK can be used for structural parts within chemical plants if chemicals are compatible and mechanical loads are high (e.g., mountings, housings).

- Qualification: use immersion and tensile retention tests per expected service media and temperature.

Electrical / RF / microwave components

- Demands: low dielectric constant, low loss tangent, dimensional stability.

- PTFE is preferred for dielectric substrates, coaxial spacers, RF insulators.

- PEEK is acceptable for insulating structural components where dielectric properties are secondary to mechanical needs.

Aerospace and high-temperature mechanical components

- Demands: weight, dimensional stability across temperature, creep resistance, flame/oxidation resistance.

- PEEK (including carbon-filled grades) is widely used for structural brackets, bearing cages, connector housings, and parts in engine accessory systems.

PEEK’s combination of strength, low creep and thermal capability makes it appropriate for many aircraft interior and under-the-hood applications. - PTFE is used for low-friction liners and seals in aerospace fuel/feed lines where chemical inertness and friction are paramount but load is low.

Medical devices and implants

- Demands: biocompatibility, sterilization (autoclave / gamma), fatigue resistance.

- PEEK (medical grades) is established for implantable components (spinal cages, orthopedic devices) owing to biocompatibility and modulus closer to bone.

- PTFE (expanded PTFE, ePTFE) is used for vascular grafts, soft tissue patches and some implantable fabrics, but is less typical for load-bearing implants.

- Regulatory: select USP/ISO-compliant grades and maintain traceability.

Food, cookware and consumer goods

- Demands: food contact safety, temperature excursions, cleaning cycles.

- PTFE coatings are the dominant choice for non-stick surfaces; PTFE films or coatings are common. PEEK is used structurally where permitted and when higher stiffness/temperature resistance is required.

- Note on safety: PTFE coatings must be used within recommended thermal limits to avoid decomposition; PEEK offers good autoclave/oven stability.

Oil & gas / downhole applications

- Demands: pressure, temperature, corrosive fluids, abrasion.

- PEEK (filled) is often used for packer components, tool parts, centralizer elements where load and wear are relevant.

- PTFE is used for liners, wetted seals, chemical barriers where corrosion resistance overrides mechanical demands.

- Design caution: downhole demands may exceed standard grades; evaluate high-temperature PEEK variants and specialty PTFE composites.

Semiconductor, laboratory and ultra-clean systems

- Demands: chemical purity, low outgassing, ion mobility, particle cleanliness.

- PTFE is often selected for chemical transport liners, seals and valves due to chemical inertness and low extractables.

PEEK is used for structural holders, connectors and insulators where mechanical stability is needed. - Processing note: handle both polymers in clean environments; select low-ash, low-outgas grades.

10. Comparative Summary — PEEK vs PTFE

A compact, engineering-grade comparison that highlights the decision-critical differences between PEEK (polyetheretherketone) and PTFE (polytetrafluoroethylene).

Use this as a practical checklist when selecting materials for parts, seals, linings, bearings or electrical components.

| Attribute | PEEK | PTFE |

| Primary use case | Structural / high-temperature engineering polymer | Ultra-inert, lowest-friction fluoropolymer |

| Density (g·cm⁻³) | ≈ 1.30 | ≈ 2.12 |

| Tensile strength (MPa) | ~90–110 | ~20–35 |

| Young’s modulus (GPa) | ~3.6–4.1 | ~0.4–0.6 |

| Elongation at break (%) | ~20–50 | ~200–400 |

| Continuous service temp (°C) | ~200–250 (mechanical retention) | up to ~260 (chemical/thermal stability; mechanical service limited by creep) |

| Coefficient of friction (dry) | ~0.15–0.4 | ~0.04–0.15 (very low) |

| Creep / cold flow | Low (good long-term dimensional stability) | High (significant long-term deformation under load) |

| Chemical resistance | Excellent to many media; vulnerable to strong oxidizers/fluorinating agents | Outstanding — near-universal chemical inertness |

Dielectric properties |

Good (εr ~3–3.5) | Excellent (εr ~2.0; very low loss) |

| Processability | Injection-mouldable, extrudable, machinable, weldable | Not injection-mouldable; sintered/ram extruded/paste processed; machinable from billets |

| Typical fillers/variants | Carbon/glass/graphite for stiffness/wear; medical grades available | Bronze, glass, carbon filled for wear/load; expanded PTFE for membranes |

| Relative cost | High (premium) | High (but PTFE often cheaper/kg than medical/filled PEEK) |

| Environmental / regulatory notes | Well established medical credentials for specific grades | PFAS/fluoropolymer lifecycle & decomposition concerns — regulatory scrutiny |

11. Conclusion — PEEK vs PTFE

PEEK and PTFE are both premium engineering polymers, but they solve different problems.

The correct choice depends first and foremost on the primary functional requirement of the part or system.

- PEEK is a high-performance structural thermoplastic: high strength and stiffness, low creep, excellent dimensional stability at elevated temperature, machinability and weldability.

It is the preferred choice when mechanical integrity, long-term load retention and tight tolerances are required (e.g., structural parts, high-temperature bearings, medical implants). - PTFE is the ultra-inert fluoropolymer: exceptional chemical resistance, the lowest practical coefficient of friction and excellent dielectric properties, but with low mechanical strength and marked cold-flow (creep).

It is the material of choice for conformable seals, chemical liners, low-friction surfaces and RF/microwave dielectric applications. - They are complementary, not interchangeable. Many robust engineering solutions combine both materials (e.g., PTFE sealing faces on PEEK backup rings, PTFE liners in PEEK housings, filled variants of each to tailor properties).

FAQs

Can PTFE be substituted by PEEK in seals?

Only when the seal requires structural stiffness and low creep — PEEK can work in some engineered seals but will have higher friction. For conformable, low-pressure seals PTFE is often superior.

Can PEEK and PTFE be bonded together?

Bonding PTFE to anything is difficult; special surface treatments and primers are needed. PEEK bonds to many adhesives after surface prep.

Which polymer is safer at very high temperatures?

Both decompose eventually. PEEK tolerates higher mechanical service temperature; PTFE can survive chemically at high T but can release toxic decomposition products if overheated — both require thermal management.