1. Introduction

In today’s advanced manufacturing landscape, etching stands as a crucial process for creating intricate microstructures and patterns on substrates.

This process is indispensable in semiconductor fabrication, microelectromechanical systems (MEMS), electronics, and various high-precision industries.

Two primary etching methods dominate the field: dry etching and wet etching.

Each method offers unique advantages and trade-offs, influencing factors such as precision, cost, and environmental impact.

This article provides a comprehensive analysis of both etching techniques, examining their underlying processes, benefits, challenges, and practical applications.

By understanding these differences, engineers and manufacturers can select the optimal etching method to achieve superior product quality and process efficiency.

2. Overview of Etching Methods

Dry Etching

Dry etching employs high-energy reactive ions to remove material from a substrate’s surface.

This method typically uses a radiofrequency (RF) field to convert reactive gases into plasma, a process commonly known as plasma etching.

The resulting ions bombard the substrate, enabling precise material removal.

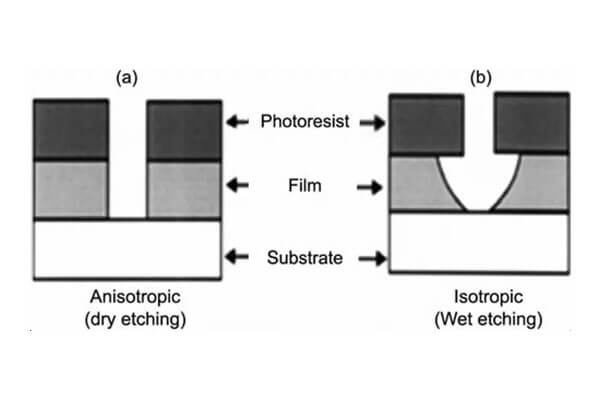

Notably, dry etching allows for both isotropic and anisotropic profiles, offering exceptional control over etch depth and sidewall formation.

For example, Reactive Ion Etching (RIE) combines physical sputtering and chemical reactions to achieve fine, high-aspect-ratio structures.

Additionally, Deep Reactive Ion Etching (DRIE) specializes in creating deep features essential for MEMS applications.

These techniques have become indispensable for producing highly detailed microstructures required in modern integrated circuits.

Wet Etching

Wet etching, in contrast, utilizes liquid chemical solutions to dissolve material from the substrate.

Common etchants, such as hydrofluoric acid (HF) and hydrochloric acid (HCl), selectively remove unprotected regions of the material while a protective mask shields areas that must remain intact.

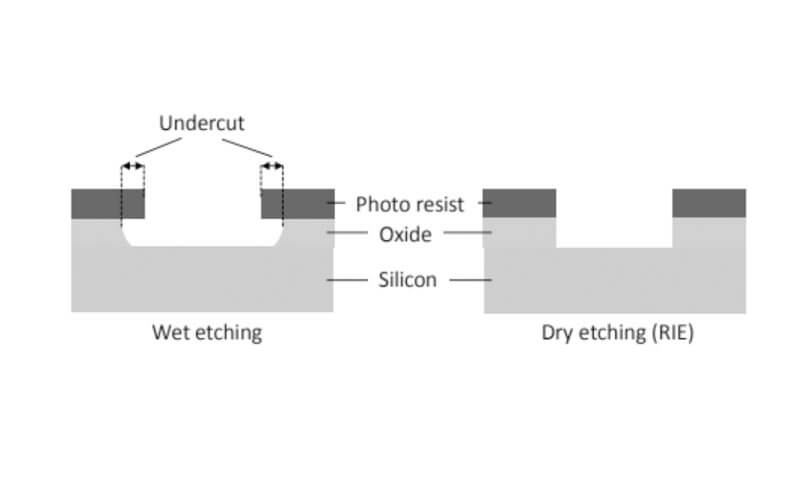

This process is inherently isotropic, meaning it etches material uniformly in all directions.

However, manufacturers have developed advanced techniques to control the etch rate and achieve more directional etching under certain conditions.

The wet etching process generally involves immersing the substrate in a chemical bath or spraying the etchant onto a spinning substrate,

ensuring that the material removal remains consistent across the surface.

This method is highly cost-effective and simple to set up, making it a favored choice for applications where ultra-fine precision is not critical.

3. Key Differences Between Dry Etching and Wet Etching

Dry Etching: Precision Through Plasma Technology

Dry etching operates in a controlled vacuum environment where reactive gases are converted into plasma using radiofrequency (RF) energy.

This high-energy plasma is directed onto the substrate, etching away material through a combination of physical sputtering and chemical reactions.

- Process Medium: Dry etching uses ionized gases, enabling precise control over the etching direction.

- Etch Profile: It offers both isotropic and anisotropic etching; however, it is most celebrated for its anisotropic capabilities,

which yield vertical sidewalls and fine, high-aspect-ratio structures. - Precision and Control: Advanced techniques such as Reactive Ion Etching (RIE) and Deep Reactive Ion Etching (DRIE) allow for excellent resolution and minute feature definition.

- Environmental Impact: This method typically produces less chemical waste and uses fewer hazardous materials, though it requires high energy consumption and specialized equipment.

Wet Etching: Simplicity and Cost-Effectiveness

Wet etching involves immersing or spraying a substrate with a liquid chemical etchant, such as hydrofluoric acid or hydrochloric acid, to selectively remove material.

Protective masks are applied to preserve regions that should remain intact.

- Process Medium: Wet etching relies on liquid solutions, making it simpler and generally less expensive to set up than dry etching.

- Etch Profile: It is inherently isotropic, which means it removes material uniformly in all directions.

While this can lead to undercutting, advanced techniques have improved its directional control in specific cases. - Cost Efficiency: The process is cost-effective and well-suited for large-scale production, especially in applications where ultra-high precision is not critical.

- Environmental Impact: Wet etching typically uses more chemicals and produces more waste, requiring careful waste treatment and recycling protocols.

Comparative Analysis: Key Differences

| Parameter | Dry Etching | Wet Etching |

|---|---|---|

| Etching Medium | Uses ionized gases (plasma) in a controlled vacuum environment | Uses liquid chemical solutions (e.g., acids such as HF or HCl) |

| Etch Profile | Offers high anisotropy, allowing precise, vertical sidewalls; can also be isotropic based on settings | Inherently isotropic, resulting in uniform material removal in all directions, which may cause undercutting |

| Precision & Resolution | Achieves superior precision and high-resolution features, making it ideal for microfabrication and MEMS | Provides less directional control; better suited for applications where ultra-fine precision is not critical |

| Equipment & Cost | Requires sophisticated, high-cost equipment and a tightly controlled environment | Utilizes simpler, less expensive equipment; lower capital costs make it more accessible for large-scale production |

| Process Control | Offers advanced control over etch rate and profile through techniques like Reactive Ion Etching (RIE) and DRIE | Relies on chemical reaction parameters; easier setup but may need additional steps to enhance uniformity |

| Environmental Impact | Produces minimal chemical waste but consumes more energy due to vacuum and plasma generation | Involves larger quantities of chemicals and waste, necessitating robust waste treatment and recycling processes |

| Typical Applications | Essential for semiconductor fabrication, MEMS, and high-resolution microstructuring | Commonly used in PCB production, bulk etching, and applications where uniform material removal suffices |

4. Benefits and Drawbacks

Understanding the benefits and drawbacks of different etching methods is essential for selecting the right process for specific applications. Below, we explore the key advantages and disadvantages of dry etching and wet etching, highlighting how each method impacts precision, cost, and environmental factors.

4.1. Benefits

Dry Etching

- High Precision and Control:

Dry etching offers excellent anisotropic control, allowing for vertical sidewalls and intricate, high-resolution features.

This makes it indispensable in semiconductor fabrication and MEMS production. - Superior Resolution:

The use of plasma and ion beams facilitates the creation of fine details with minimal lateral etching, ensuring that even micro-scale patterns are accurately defined. - Process Versatility:

Dry etching techniques can be adapted for multilayer structures, enabling selective material removal and preserving underlying layers. This is crucial for complex integrated circuits. - Lower Chemical Waste:

By utilizing reactive gases in a controlled environment, dry etching generates less hazardous waste compared to methods that use large volumes of chemical solutions.

Wet Etching

- Simplicity and Cost-Effectiveness:

Wet etching employs straightforward processes and simpler equipment, making it a more economical choice, especially for large-scale production. - Ease of Setup:

The process involves immersing or spraying the substrate with chemical etchants, which reduces the complexity of setup and lowers operational costs. - Uniform Material Removal:

Wet etching generally removes material uniformly across the substrate, which is beneficial for bulk material removal and applications where precision is less critical. - Broad Material Compatibility:

Wet etching is versatile, effectively processing a wide range of materials. This makes it suitable for applications where the substrate is sensitive to high-energy processes.

4.2. Drawbacks

Dry Etching

- High Equipment and Operational Costs:

Dry etching requires sophisticated machinery, such as RF plasma generators and vacuum systems, which increases both capital and operating expenses. - Complex Process Control:

The need for precise control over reactive gas flow, ion energy, and etch time demands specialized expertise. Inadequate control may lead to substrate damage. - Potential Substrate Damage:

The high-energy ion bombardment inherent in dry etching can cause physical damage to sensitive substrates

if not properly managed, potentially affecting the performance of the final product.

Wet Etching

- Lack of Directional Control:

Wet etching is inherently isotropic, which means it removes material uniformly in all directions. This can lead to undercutting and imprecise feature definition, making it less suitable for high-resolution applications. - Slower Etching Rates:

In many cases, wet etching processes take longer to achieve the desired material removal compared to the rapid ion bombardment in dry etching. - Environmental and Safety Concerns:

Wet etching uses aggressive chemicals that require careful handling and disposal.

The need for robust waste management systems can add to the environmental impact and operational complexity. - Post-Processing Requirements:

Often, wet etching requires additional cleaning and surface finishing to remove residues and ensure the desired surface quality, potentially increasing production time and costs.

5. Applications in Various Industries

Semiconductor Fabrication

In semiconductor manufacturing, dry etching dominates due to its ability to create extremely fine, high-aspect-ratio features on silicon wafers.

Techniques like RIE and DRIE enable the production of intricate circuit patterns critical for modern microelectronics.

Wet etching also plays a role in bulk material removal and cleaning processes.

Printed Circuit Board (PCB) Production

Wet etching finds widespread application in PCB fabrication, where it efficiently removes copper layers from substrates.

Its simplicity and cost-effectiveness make it a preferred method for large-scale PCB production, although precision requirements sometimes necessitate additional processing steps.

Optical and Precision Instruments

High-resolution optical components and precision instruments benefit from dry etching’s superior directional control, which enables the creation of intricate patterns with minimal feature distortion.

These applications demand exacting tolerances that only dry etching can consistently provide.

MEMS and Microfabrication

Deep reactive ion etching (DRIE), a form of dry etching, is indispensable in the fabrication of MEMS devices.

Its ability to produce deep, narrow trenches with precise control makes it critical for the development of micro-scale sensors and actuators.

6. Factors to Consider When Choosing an Etching Method

Selecting the most appropriate etching method for a specific application involves evaluating several critical factors.

The right choice can significantly impact the quality, cost, and efficiency of the manufacturing process. Below are key considerations to guide this decision:

Material Properties

- Type of Material: Different materials (e.g., metals, semiconductors, ceramics) respond differently to various etching methods.

For instance, wet etching is often suitable for silicon but may not be ideal for harder or more resistant materials. - Material Thickness: Thicker materials might require more aggressive etching techniques, while thinner materials could deform under harsh conditions.

Precision and Resolution Requirements

- Feature Size: High-resolution requirements demand methods capable of producing fine details, such as plasma etching or reactive ion etching (RIE).

- Aspect Ratio: Deep structures with high aspect ratios may necessitate deep reactive ion etching (DRIE) for precise and vertical sidewalls.

Cost Considerations

- Initial Setup Costs: Some advanced etching techniques, like DRIE, involve significant initial investments in equipment and facilities.

- Operational Costs: Continuous costs related to chemical usage, waste disposal, and maintenance should be considered.

Wet etching typically has lower operational costs compared to dry etching methods.

Environmental Impact

- Chemical Usage: Wet etching uses large quantities of chemicals that require careful handling and disposal.

Dry etching methods generally produce less hazardous waste but consume more energy. - Sustainability Practices: Increasingly, manufacturers look for eco-friendly options, including recycling systems for etchants or adopting green chemistry principles.

Production Volume and Speed

- Batch vs. Continuous Processing: Batch processing suits smaller production runs, whereas continuous processes are better for high-volume manufacturing.

- Etching Rate: Faster etching rates reduce production time but must balance against achieving desired quality and resolution.

Surface Finish and Quality

- Surface Roughness: Different etching methods result in varying surface finishes.

For example, isotropic wet etching tends to create smoother surfaces than anisotropic dry etching. - Uniformity: Ensuring uniform etching across the entire surface area is crucial for maintaining product quality.

Safety Concerns

- Handling Hazardous Materials: Both wet and dry etching involve potentially hazardous substances.

Proper safety measures, including protective gear and ventilation systems, are necessary. - Risk of Damage: Certain etching methods pose a higher risk of damaging delicate components or substrates.

Compatibility with Other Processes

- Integration into Manufacturing Lines: The chosen etching method should integrate seamlessly with other steps in the manufacturing process, minimizing downtime and inefficiencies.

- Post-Etching Treatments: Consider whether additional treatments (e.g., cleaning, coating) are required after etching and how these affect overall workflow.

7. Conclusion

In conclusion, both dry etching and wet etching play pivotal roles in material fabrication, each offering unique benefits tailored to specific applications.

Dry etching excels in producing high-precision, anisotropic features essential for advanced electronics and MEMS,

while wet etching provides a simpler, cost-effective solution for bulk material removal and applications where isotropic etching suffices.

By carefully considering factors such as selectivity, etch rate, uniformity, and environmental impact, manufacturers can select the optimal etching method to meet their production needs.

As technology advances, both etching processes will continue to evolve, incorporating innovations such as AI-driven process optimization and eco-friendly chemical solutions.

Embracing these advancements will enable the industry to achieve even higher precision, efficiency, and sustainability in material fabrication.