1. Introduction

Ball valves are quarter-turn shut-off devices that combine compactness, low pressure drop and strong sealing capability.

Their straightforward operation and high reliability have made them a default choice for isolation in process plants, pipelines, utilities and cryogenic systems.

Yet beneath the apparent simplicity lies a wide technical variation — seat construction, sealing chemistry, body materials, mounting style and actuation choices determine whether a ball valve will provide decades of trouble-free service or require frequent intervention.

2. What is a Ball Valve

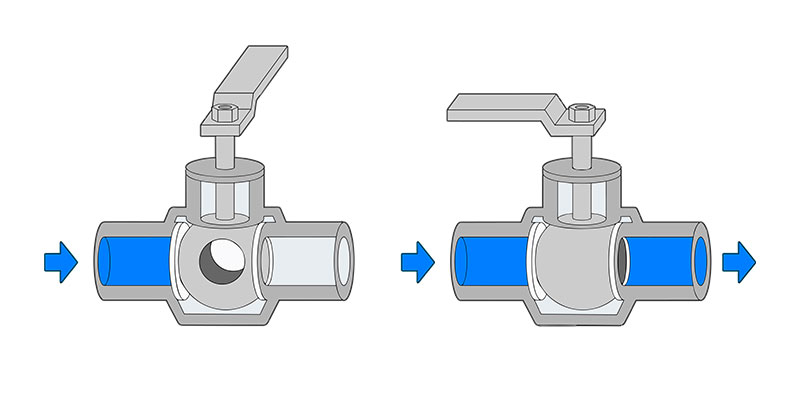

A ball valve is a quarter-turn isolation and flow control device that uses a hollow, ported spherical disc (the “ball”) to regulate fluid passage.

When the ball’s bore aligns with the valve’s inlet and outlet, flow occurs with minimal resistance.

A 90° rotation via the stem, driven manually or by an actuator, misaligns the port, creating a leak-tight shutoff.

According to API 6D (Pipeline Valves), ball valves are primarily on/off isolation valves, but certain designs such as V-port configurations allow controlled throttling with moderate precision.

Their popularity lies in simplicity: typically 5–7 main components (body, ball, seats, stem, actuator, bonnet), which reduces potential failure points while ensuring robust sealing and operational reliability.

Ball valves today account for an estimated 20–25% of the industrial valve market, making them one of the most widely applied valve types across oil & gas, chemical, water, power, and cryogenic industries.

Key Features

- Rapid Actuation: 90° rotation enables full open/close in 1–5 seconds, vs. 30–60 seconds for gate valves—critical for emergency shutdowns (ESDs).

- Low Pressure Drop: Full-bore designs have ΔP <1 psi at 100 gpm for a 2-inch valve (ASME B16.104), 50–70% lower than globe valves of the same size.

- Tight Shutoff: Soft-seated valves achieve ISO 5208 Class VI leakage (<0.0001 cm³/min), equivalent to 1 drop of water every 10 years; metal-seated valves meet Class IV (<0.01 cm³/min).

- Wide Operating Range: Suitable for pressures from vacuum to 15,000 psi and temperatures from -269°C (cryogenic LNG) to 815°C (high-temperature steam).

- High Cycle Life: Soft-seated valves withstand 10,000–50,000 cycles; metal-seated designs exceed 100,000 cycles (API 6D), outperforming gate valves (5,000–20,000 cycles).

Basic Components and Terminology

| Component | Function | Key Terminology & Notes |

| Body | Houses internal components; provides pressure boundary and end connections. | End connections: Flanged (ANSI B16.5), Threaded (NPT), Welded (ANSI B16.25). Pressure ratings: Class 150–2500 / PN 10–420. |

| Ball | Rotating sphere with bore to permit/stop flow. | Port types: Full-bore (port = pipe size), Reduced-bore (port < pipe size). Surface finish: Ra ≤ 0.8 μm for sealing reliability. |

| Seats | Sealing rings ensuring tight shutoff against the ball. | Soft seats (PTFE, RPTFE) → Class VI shutoff. Metal seats (Stellite, WC) → high-temp/high-pressure service. |

| Stem | Connects actuator to ball; transfers torque. | Anti-blowout stem design (API 6D). Packing: graphite/PTFE rings to prevent leakage. |

| Actuator/Handle | Provides motion to rotate the ball. | Manual: lever (≤6″) or gear operator (≥8″). Automated: pneumatic (1–5 s actuation), electric (10–30 s actuation). |

| Bonnet | Covers stem/packing; allows maintenance access. | Bolted bonnet for serviceability. Welded bonnet for high-pressure/corrosive duty. |

Floating vs. trunnion-mounted designs

- Floating ball — ball is free to shift axially under pressure and is pressed into the downstream seat to seal. Simpler and common for small/medium sizes and lower pressures.

- Trunnion-mounted ball — ball is supported (anchored) at top and/or bottom trunnions; seats are spring-loaded toward the ball.

Trunnion design reduces seat load and operating torque and is used for large diameters and high-pressure applications.

3. Types & Variants of Ball Valves

Ball valves have evolved into a wide range of design variants, each tailored to specific service conditions such as flow capacity, temperature, pressure, corrosion resistance, and leakage requirements.

Below is an in-depth look at the most important types:

Full-Bore vs. Reduced-Bore

- Full-Bore (Full-Port):

-

- Bore size equals pipe diameter → minimal pressure drop (ΔP ≈ 0).

- Ideal for pigging pipelines and minimizing turbulence.

- Typically used in oil & gas transmission and slurry transport.

- Reduced-Bore (Reduced-Port):

-

- Bore size is smaller than pipe diameter.

- Lower cost and weight, but higher pressure drop (ΔP ~5–10%).

- Common in process industries where pigging is not required.

V-Port Ball Valves

- Feature a V-shaped bore, enabling controlled throttling.

- Offer linear or equal percentage flow characteristics, suitable for flow control rather than just isolation.

- Widely applied in chemical dosing, pulp & paper, and water treatment.

Seat Variants: Soft-Seated vs. Metal-Seated

- Soft-Seated:

-

- PTFE or RPTFE → bubble-tight shutoff, Class VI leakage.

- Limited to ~200 °C service.

- Metal-Seated:

-

- Stellite or tungsten carbide coatings → withstand up to 815 °C, abrasive media, and Class IV leakage.

- Used in refinery, power plant, and slurry handling.

Multi-Port Ball Valves (3-way & 4-way)

- Allow flow diversion, mixing, or splitting.

- Reduce the need for multiple valves and piping.

- Common in pharmaceutical, water treatment, and food industries.

Cryogenic Ball Valves

- Extended bonnet design ensures stem packing remains above cryogenic zone.

- Operates reliably down to -196 °C (LNG service).

- Must pass BS 6364 cryogenic testing.

High-Pressure & Fire-Safe Ball Valves

- High-Pressure: Designed for pressures up to 15,000 psi (Class 2500). Common in wellhead and hydraulic fracturing.

- Fire-Safe: Equipped with secondary metal-to-metal seals that engage if soft seats burn out. Certified to API 607 / ISO 10497.

Comparative Table of Ball Valve Variants

| Ball Valve Type | Key Features | Typical Pressure Rating | Applications |

| Full-Bore | Zero pressure drop, piggable | Class 150–1500 | Oil & gas pipelines, slurries |

| Reduced-Bore | Economical, compact, higher ΔP | Class 150–600 | Chemical plants, HVAC |

| V-Port | Precision flow control | Class 150–600 | Process industries, water treatment |

| Soft-Seated | Bubble-tight, low temp limit | Class 150–600 | Water, food, pharma |

| Metal-Seated | High temp/abrasion, Class IV shutoff | Class 600–2500 | Refining, power, slurry |

| Multi-Port (3/4-way) | Mixing/diversion, space-saving | Class 150–300 | Pharma, water, food |

| Cryogenic | Extended bonnet, -196 °C | Class 150–900 | LNG, air separation, cryogenics |

| High-Pressure | Up to 15,000 psi, robust seats | Class 1500–2500 | Oilfield, hydraulic fracturing |

| Fire-Safe | Secondary seal post-fire | Class 150–2500 | Petrochemicals, refineries |

4. Materials, Trims, and Sealing Technologies of Ball Valves

The performance and service life of a ball valve are strongly influenced by body material selection, trim (ball, stem, seat) composition, and sealing technology.

Common Body Materials

- Carbon Steel (ASTM A216 WCB): Widely used in oil & gas, water, and general service up to 425 °C. Cost-effective but requires corrosion allowance.

- Stainless Steel (ASTM A351 CF8M / CF3M): Excellent corrosion resistance, suitable for chemical, food, and pharma industries. Operates from cryogenic (-196 °C) to 815 °C.

- Duplex & Super Duplex (ASTM A995 Gr. 4A/6A): High strength and superior chloride resistance. Used in offshore and subsea valves.

- Nickel Alloys (Hastelloy, Inconel, Monel): For highly corrosive media (acids, sour gas, seawater). High cost but superior reliability.

- Bronze & Brass: For low-pressure water, HVAC, and marine service. Economical, but limited pressure/temperature capacity.

Trim Materials (Ball, Stem, Seats)

- Ball:

-

- Standard: Stainless steel (AISI 316/304) for corrosion resistance.

- Coatings: Chrome plating, ENP (electroless nickel plating), tungsten carbide for wear/abrasion resistance.

- Stem:

-

- Stainless steel or high-strength alloy steel with anti-blowout design.

- Surface hardening (nitriding) to resist galling in high-cycle service.

- Seats:

-

- Soft Seats (PTFE, RPTFE, PEEK): Provide bubble-tight sealing (Class VI). Limited to ~200 °C (PTFE) or 250 °C (PEEK).

- Metal Seats (Stellite, WC, Cr3C2): Withstand 600–815 °C, abrasive media, steam. Class IV shutoff performance.

- Composite Seats: PTFE + graphite blend for improved chemical resistance and extended temperature range.

Sealing Technologies

- Primary Sealing (Ball-to-Seat):

-

- Resilient sealing with PTFE for low torque and tight shutoff.

- Metal-to-metal seating for fire-safe and abrasive conditions.

- Secondary Sealing (Fire-Safe Design):

-

- If soft seats burn away, a backup metal seal engages (API 607 certified).

- Stem Sealing:

-

- Packing sets with graphite, PTFE, or elastomers.

- Anti-blowout stems per API 6D to prevent ejection under pressure.

- Cavity Relief & Double Block-and-Bleed (DBB):

-

- Self-relieving seats release trapped pressure in cavity.

- DBB feature allows pressure monitoring and maintenance safety.

Comparative Table: Materials, Trims & Sealing

| Component | Material Options | Operating Range | Typical Applications |

| Body | WCB (carbon steel), CF8M (SS 316), Duplex, Inconel | -46 °C to 815 °C, up to Class 2500 | Oil & gas, chemicals, power, subsea |

| Ball | SS 316, ENP-coated, WC-coated | Cryogenic to 600 °C | Abrasive service, corrosive fluids |

| Stem | SS 410/316, Alloy steel (nitrided) | -196 °C to 600 °C | High-torque, high-cycle valves |

| Seats | PTFE/RPTFE (soft), PEEK, Metal (Stellite, WC) | PTFE: ≤200 °C; PEEK: ≤250 °C; Metal: ≤815 °C | General service, cryogenic, high-temp steam |

| Sealing | PTFE (resilient), Metal-to-metal, Fire-safe | Vacuum to 15,000 psi | Refineries, LNG, power plants |

5. Manufacturing Routes and Quality Control of Ball Valves

Ball valves are safety-critical components in industrial fluid systems, and their manufacturing process requires strict adherence to design standards (API, ASME, ISO) and quality assurance protocols.

The production route depends on valve size, pressure class, and application.

Manufacturing Routes

- Casting

-

- Sand Casting (ASTM A216 WCB, A351 CF8M): Used for medium to large body sizes (>DN 50) and pressure classes ≤ 600.

- Investment Casting: Provides tight dimensional tolerances (ISO 8062-CT6 to CT8) and fine surface finish for small to medium valves (DN 15–DN 100).

- Casting Tolerances: Typical ±2.0 mm for sand casting, ±1.0 mm for investment casting.

-

- Used for high-pressure (Class 900–2500) and critical service valves.

- Forged carbon steel or stainless steel billets are machined to final geometry.

- Superior grain flow improves mechanical strength and toughness.

-

- Precision machining of body, ball, stem, and seat pockets.

- Ball surface finish often required at Ra ≤ 0.4 μm to achieve Class VI leakage.

- Tolerances: ±0.02 mm for sealing surfaces, ±0.1 mm for general dimensions.

- Surface Treatments

-

- ENP (Electroless Nickel Plating), Hard Chrome, Tungsten Carbide, or HVOF Sprays on ball surfaces.

- Improves wear resistance, extends cycle life beyond 100,000 cycles in severe service.

- Assembly

-

- Cleanroom assembly for valves used in oxygen or pharmaceutical service.

- Controlled torque application for seat/stem packing installation.

Quality Control and Testing

Ball valve quality is verified through multi-stage inspection and compliance with API 598, API 6D, and ISO 5208:

- Chemical & Mechanical Testing:

-

- Spectrochemical analysis (PMI) to confirm alloy composition.

- Tensile, impact (Charpy V-notch at -46 °C), and hardness tests.

- Non-Destructive Testing (NDT):

-

- Radiography (RT), Ultrasonic Testing (UT) for cast/forged bodies.

- Magnetic Particle (MT) & Dye Penetrant (PT) for surface crack detection.

- Dimensional Inspection:

-

- CMM (Coordinate Measuring Machines) ensure tolerance compliance.

- Ball roundness within ±0.01 mm critical for sealing.

- Pressure Testing (per API 598 / ISO 5208):

-

- Hydrostatic Shell Test: 1.5 × rated pressure (10–30 min).

- Seat Leakage Test: 1.1 × rated pressure, leakage must meet class requirements (Class IV–VI).

- Low-Pressure Air Test: 0.6 MPa to detect micro-leakage.

- Special Tests (for critical service):

-

- Cryogenic Test (BS 6364) at -196 °C.

- Fire-Safe Test (API 607 / ISO 10497).

- Fugitive Emission Test (ISO 15848, API 641).

6. Key Performance Metrics and Typical Data

Ball valves are evaluated on several critical performance metrics that determine suitability for specific industrial applications.

These include size (DN), pressure rating, flow capacity (Cv), operating torque, and leakage class.

| Valve Type | DN / NPS | Pressure Rating | Cv Range | Operating Torque (Nm) | Leakage Class |

| Floating Soft-Seat | 15–200 mm / ½”–8″ | Class 150–600 | 10–1,200 | 5–150 | ISO 5208 Class VI |

| Trunnion-Mounted Metal-Seat | 100–1,400 mm / 4″–56″ | Class 900–2500 | 1,200–25,000 | 150–3,000 | ISO 5208 Class IV |

| V-Port Flow Control | 15–300 mm / ½”–12″ | Class 150–600 | 5–800 | 10–200 | ISO 5208 Class VI |

| Cryogenic | 15–600 mm / ½”–24″ | Class 150–900 | 10–2,500 | 10–500 | ISO 5208 Class VI |

| High-Pressure / Fire-Safe | 15–1,000 mm / ½”–40″ | Class 1500–2500 | 50–15,000 | 250–3,500 | ISO 5208 Class IV / VI |

7. Common failure modes and root-cause mitigation

| Failure mode | Typical cause | Mitigation |

| Seat leakage | Seat wear (abrasion/erosion), chemical attack, particulate damage | Use metal seats or hard coatings for abrasive service; upstream filtration; select compatible seat chemistry |

| Stem leakage / fugitive emissions | Packing degradation, thermal cycling, incorrect installation | Live-loaded packing, proper installation torque, use low-emission packing systems |

| High breakaway torque / stuck ball | Corrosion/galling, solidified deposits, cold start | Use corrosion-resistant coatings, anti-seize treatments, pre-heat or purging in cryogenic service |

| Ball scouring / surface degradation | Cavitation, two-phase flow, erosive particulates | Avoid cavitation by proper sizing; harden ball surface; use metal seats for erosive fluids |

| Actuator failure / insufficient torque | Undersized actuator, poor maintenance, temperature effects | Size actuator for worst-case torque; include margin; routine actuator servicing |

| Fire damage (soft seats) | External fire causes polymer seat burn | Fire-safe design with secondary metal seating per fire-test standards |

8. Industry Applications of Ball Valves

Ball valves are tailored to diverse industries, with case examples highlighting their performance:

Oil & Gas

- Application: Subsea wellhead isolation (Gulf of Mexico).

- Valve Specs: 10-inch trunnion ball valve, duplex 2205 body, Stellite seats, ANSI Class 1500 (3,600 psi), API 607 fire-safe.

- Challenge: Withstand 3,000 psi pressure, H₂S corrosion (NACE MR0175), and 10-year maintenance intervals.

- Outcome: Operated for 12 years without failure; reduced downtime by 80% vs. gate valves.

Petrochemicals

- Application: Polyethylene reactor isolation (Texas refinery).

- Valve Specs: 6-inch full-bore ball valve, 316L body, RPTFE seats, ANSI Class 600 (1,440 psi).

- Challenge: Bubble-tight shutoff (Class VI) to prevent monomer leakage; handle 180°C process fluid.

- Outcome: Achieved zero leakage for 5 years; reduced monomer loss by $50,000 annually.

Power Generation

- Application: Boiler feedwater control (coal-fired plant, Indiana).

- Valve Specs: 4-inch V-port ball valve, alloy steel (A182 F91) body, Stellite seats, ANSI Class 900 (2,160 psi).

- Challenge: ±2% flow accuracy; withstand 350°C water.

- Outcome: Maintained feedwater flow within ±1% of setpoint; reduced boiler efficiency losses by 2%.

Water Treatment

- Application: Municipal water distribution (Los Angeles).

- Valve Specs: 12-inch reduced-bore ball valve, ductile iron (epoxy-coated) body, EPDM seats, ANSI Class 150 (285 psi).

- Challenge: Low cost, corrosion resistance (chlorinated water), and easy operation.

- Outcome: Installed in 500+ locations; 15-year service life with minimal maintenance.

Pharmaceuticals

- Application: Sterile vaccine production (Boston biotech).

- Valve Specs: 2-inch sanitary ball valve, 316L electropolished (Ra ≤0.4 μm) body, PTFE seats, tri-clamp connections, FDA 21 CFR Part 177.

- Challenge: Zero dead zones (prevent bacterial growth); Class VI shutoff; CIP/SIP compatibility.

- Outcome: Passed 10,000+ CIP cycles; no contamination incidents.

Cryogenic

- Application: LNG storage tank isolation (Qatar).

- Valve Specs: 8-inch cryogenic ball valve, 316L body, modified PTFE seats (-269°C), extended stem, ANSI Class 300 (740 psi).

- Challenge: Operate at -162°C (LNG boiling point); maintain Class VI shutoff.

- Outcome: Zero leakage for 8 years; enabled safe LNG transfer at 10,000 gpm.

9. Ball Valves vs. Other Valve Types

Ball valves are widely used for on/off and throttling applications, but their performance and suitability differ from gate, globe, butterfly, and plug valves.

The following table provides a comparative overview:

| Feature / Metric | Ball Valve | Gate Valve | Globe Valve | Butterfly Valve | Check Valve |

| Operation | Quarter-turn (90°) | Linear rising/non-rising stem | Linear lift stem | Quarter-turn disc | Flow-driven automatic |

| Shutoff Tightness | Soft-seat: Class VI; Metal-seat: Class IV | Class IV–VI | Class IV–VI | Soft-seat: Class VI; Metal-seat: Class IV | Class IV–VI |

| Flow Characteristics | Near-full bore; minimal ΔP; V-port for throttling | Full open: minimal ΔP; throttling not recommended | Excellent throttling; linear flow | Good for on/off and modulating; 30–50% ΔP at partial opening | Prevents backflow; not for throttling |

| Pressure Drop | Very low | Low | High | Moderate | Low–Moderate |

| Cycle Life | 10k–50k (soft), >100k (metal) | Moderate (5k–20k) | Moderate | High (20k–50k) | High |

| Size & Pressure Suitability | DN 15–1400, Class 150–2500 | DN 15–2000, Class 150–2500 | DN 15–500, Class 150–1500 | DN 50–2000, Class 150–600 | DN 15–1200, Class 150–2500 |

| Maintenance / Service | Low; easy seat/stem replacement | Moderate; stem & wedge inspection | Moderate; bonnet access needed | Low; simple stem/seat replacement | Low; typically maintenance-free |

| Typical Applications | Oil & gas, petrochemicals, power, water, cryogenic | Pipelines, water, slurry | Steam, chemical dosing, process control | HVAC, water, pulp & paper, slurry | Water, pumps, pipelines, HVAC |

10. Innovation, Digitalization and Sustainability Trends

The ball valve industry is evolving to meet demands for smarter, more sustainable solutions:

Digitalization (Smart Ball Valves)

- IoT Integration: Valves equipped with pressure, temperature, and vibration sensors (e.g., Emerson Rosemount 3051) transmit real-time data to SCADA systems.

AI algorithms predict failures (e.g., seat wear) 2–3 months in advance, reducing unplanned downtime by 30% (Emerson, 2024). - Wireless Actuation: Battery-powered electric actuators (10-year life) enable remote operation in subsea/offshore locations, eliminating wiring costs ($50,000+ per valve).

- Digital Twins: Virtual replicas of valves (AVEVA E3D) simulate performance under variable conditions (pressure/temp), optimizing maintenance schedules and reducing overhauls by 20%.

Advanced Materials

- Graphene-Enhanced Seats: PTFE seats with 0.1% graphene additive increase wear resistance by 50%, extending cycle life from 50,000 to 75,000 cycles (MIT Material Science Lab, 2023).

- Additive Manufacturing Alloys: 3D-printed Inconel 718 ball valves (SLM process) have 30% less weight than forged valves while maintaining strength—ideal for aerospace/automotive.

- Self-Healing Polymers: RPTFE seats embedded with microcapsules that release sealant when damaged, reducing leakage by 90% and extending seat life by 3x.

11. Conclusion

Ball valves deliver fast actuation, compact installation and excellent shut-off, which makes them indispensable in modern process and utility systems.

Their successful deployment depends on selecting the correct variant (floating vs trunnion), seat material, body metallurgy and actuation strategy relative to service conditions.

Key engineering tasks are to size for Cv and torque, protect against particulates and cavitation, and specify testing and traceability.

Emerging technologies — smart actuators, advanced materials and additive manufacturing — are improving reliability and reducing lifecycle costs, but basic disciplines (accurate service definition, correct materials, filtration and surge management) remain decisive for long-term performance.

FAQs

When should I choose a trunnion-mounted ball valve vs a floating ball?

Choose trunnion for large diameters (>~6–8″) and/or high pressures where seat load and torque would otherwise be excessive.

Floating balls are simpler and effective for small to medium sizes under moderate pressure.

Can I use a ball valve for throttling?

Standard ball valves are not ideal for precise throttling. Use a V-port ball if you require limited control, or select a globe/control valve for accurate modulation.

What seat material is best for abrasive slurries?

Metal seats with hardfacing (Stellite, tungsten carbide) are preferred; soft polymer seats erode quickly in abrasive services.

How do I size an actuator for a ball valve?

Obtain the manufacturer’s breakaway torque at full differential pressure and temperature.

Add a safety margin (commonly 25–50%), include gearbox efficiency, and select an actuator with required duty cycle and environmental protection.

What tests should I require in a purchase order for critical valves?

Minimum: material test reports (MTRs), hydrostatic shell test (1.5× rating), seat leakage test (per API 598/ISO 5208), functional cycling and, if applicable, fire-safe testing (API 607/ISO 10497) and fugitive emission testing (ISO 15848 / API 624).