1. Introduction

Annealing vs tempering are two foundational heat treatment processes that optimize the properties of metals, enabling them to meet the demands of diverse industrial applications.

While both involve controlled heating and cooling, their core objectives, process parameters, and outcomes are fundamentally distinct:

Annealing prioritizes softening, stress relief, and formability, while tempering focuses on reducing brittleness and balancing strength/toughness in previously hardened metals.

Both are essential in modern manufacturing — chosen and controlled to match alloy, geometry, and final service requirements.

2. What Is Annealing?

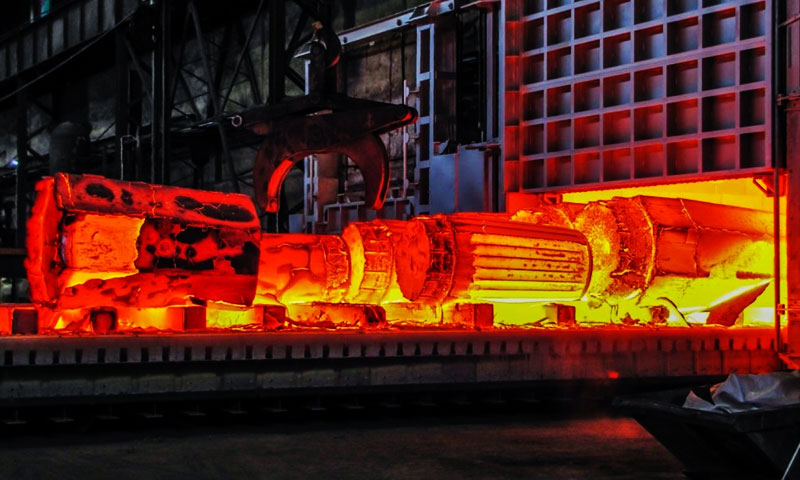

Annealing is a controlled heat-treatment process in which a metal is heated to a specific temperature, held at that temperature for a certain period, and then cooled slowly.

The primary purpose is to soften the metal, relieve internal stresses, and improve ductility and machinability.

Annealing transforms the metal’s microstructure, making it more uniform and easier to work with in subsequent manufacturing operations.

Key Features of Annealing:

- Softens hard or cold-worked metals for easier forming and machining.

- Relieves residual stresses caused by welding, casting, or deformation.

- Refines grain structure and homogenizes alloy composition.

- Improves electrical conductivity for non-ferrous metals like copper and aluminum.

- Enhances dimensional stability and reduces the risk of cracking or warping.

Process Descriptions & Typical Parameters

Annealing can be performed in different ways depending on the metal type, desired mechanical properties, and subsequent use. Below is a summary of common annealing types:

| Anneal Type | Typical Temperature (°C) | Cooling Method | Purpose / Outcome |

| Full Anneal | 750–920 | Furnace slow-cool | Produces soft ferrite + pearlite in steel; maximum ductility and machinability |

| Process / Intermediate Anneal | 450–700 | Air or slow cooling | Restores ductility to cold-worked metals; moderate stress relief |

| Spheroidize Anneal | 650–720 (long soak) | Very slow cooling | Forms spherical carbides in steels for excellent machinability |

| Stress-Relief Anneal | 350–650 | Air cool | Reduces residual stresses from forming/welding without major microstructural change |

| Normalizing (related) | 820–920 | Air cool | Refines grain for uniform mechanical properties |

Soak time guideline: ~15–60 minutes per 25 mm thickness, depending on alloy and furnace.

Material Compatibility & Parameters

Scope: common ferrous and non-ferrous alloys most frequently annealed or tempered in industry (steels, tool steels, cast irons, copper, aluminum, brass, Ti alloys).

Values are typical shop practice ranges — always qualify with supplier data and shop trials.

| Material / Class | Typical Anneal Temp (°C) | Soak Time Guidance | Cooling Method | Purpose / Practical Notes |

| Low-carbon steels (e.g., 1010–1020) | 720–800 (full) | 15–60 min per 25 mm | Furnace slow-cool (furnace or insulated cool) | Softening, stress relief, improve ductility and machinability |

| Medium-carbon steels (e.g., 1045) | 740–820 (full) | 15–60 min per 25 mm | Furnace slow-cool | Reduce hardness, spheroidize if machinability needed |

| High-carbon steels / bearing steels | 650–720 (spheroidize, long soak) | Several hours to 10+ h (long soak) | Very slow cool or hold + slow cool | Produce spherical carbides for best machining; long soak required |

| Alloy steels (Cr, Mo, Ni additions) | 720–900 (alloy dependent) | 20–90 min per 25 mm | Furnace slow-cool | Homogenize, relieve stresses; adjust temp for alloying additions |

| Tool steels (e.g., A2, D2) | 650–800 (softening anneal or sub-critical) | Hours for D2; A2 shorter | Furnace slow-cool; sometimes normalization cycles | Prepare for machining; avoid over-heating to prevent grain growth |

Cast irons (gray, ductile) |

750–900 (stress relief / anneal) | 30–120 min | Furnace slow or air cool (depending on objective) | Reduce residual stress, improve machinability (spheroidize for high-C irons) |

| Copper (pure, OFC) | 300–700 | 15–45 min depending on cold work | Air or furnace cool | Restore ductility and conductivity; watch oxidation |

| Aluminum alloys (e.g., 3003, 6061) | 300–410 (recrystallization/stress relief) | 15–120 min | Air cool (or controlled) | Recrystallize or stress-relief; avoid solution treatments unless specified |

| Brass / Bronze | 300–500 | 10–60 min | Air or furnace slow-cool | Soften for forming; avoid dezincification risk in some brasses |

| Titanium alloys (Ti-6Al-4V) | 650–800 (stress relief) | 30–120 min | Furnace or air cool depending on objective | Use controlled atmosphere to avoid contamination; anneal for stress relief |

Effects on Mechanical Properties

Annealing has a profound impact on the mechanical behavior of metals, transforming their structure and making them more suitable for forming, machining, and further processing.

The changes depend on the material, annealing type, and cycle parameters.

| Property | Effect of Annealing | Practical Implications |

| Hardness | Significantly decreases | Metals become easier to cut, machine, or form; reduces tool wear and surface finish issues |

| Ductility / Elongation | Increases markedly | Enhances ability to undergo bending, drawing, or shaping without cracking |

| Toughness | Generally increases | Reduces susceptibility to brittle fracture under load, especially for cold-worked or high-carbon steels |

| Residual Stress | Significantly reduced | Improves dimensional stability; minimizes warping, distortion, and stress-induced cracking in further processing |

| Yield Strength / Tensile Strength | Typically decreases | Material becomes softer and less resistant to plastic deformation; acceptable for forming, not load-bearing applications |

| Machinability | Improved | Softer, more uniform microstructure allows faster cutting, less tool wear, and better surface finish |

Illustrative Examples:

- Cold-worked low-carbon steel: Hardness can drop from >250 HB to ~120–150 HB after a full anneal, while elongation can increase from 10–15% to 40–50%, making it much easier to form.

- Copper (OFC): Annealing restores ductility and electrical conductivity after cold work; elongation may increase from 20% to >60%.

- Aluminum alloys (e.g., 6061): Recrystallization anneal improves formability and reduces the risk of cracking during bending or stamping.

3. What Is Tempering?

Tempering is a heat-treatment process applied to metals that have already been hardened, most commonly quenched steels.

Its primary purpose is to reduce brittleness, increase toughness, and achieve a balanced combination of hardness and ductility.

Unlike annealing, tempering is performed below the critical transformation temperature, so it does not soften the metal completely but fine-tunes its mechanical properties.

Key features of tempering:

- Reduces brittleness of hardened or quenched metals.

- Increases toughness and impact resistance.

- Adjusts hardness to meet application requirements.

- Relieves residual stresses induced during quenching.

- Stabilizes microstructure and dimensions for critical components.

Process Descriptions & Typical Parameters

Tempering is performed by heating the hardened metal to a controlled temperature, holding it for a defined time, and then cooling, usually in air.

The temperature and soak time determine the final balance between hardness and toughness.

| Tempering Range | Temperature (°C) | Soak Time | Cooling | Mechanical Effect / Use |

| Low-Temperature Tempering | 150–300 | 30–90 min | Air cool | Slight hardness reduction, brittleness reduced; retains wear resistance; suitable for tools and small springs |

| Medium-Temperature Tempering | 300–500 | 30–120 min | Air cool | Balanced hardness and toughness; commonly used for structural components like shafts, gears, and automotive parts |

| High-Temperature Tempering | 500–650 | 30–120+ min | Air cool | Significant toughness increase, moderate hardness loss; used for heavy-load components or parts subjected to impact |

Material Compatibility & Parameters

Tempering is primarily used for hardened steel and cast iron but may also be applied to some high-strength alloy steels. Non-ferrous metals typically use other aging processes instead of tempering.

| Material / Class | Typical Temper Range (°C) | Soak Time Guidance | Cooling Method | Typical Outcome / Notes |

| Low-carbon quenched steels (hardened condition) | 150–300 (low temper) | 30–90 min | Air cool | Small hardness drop; reduce brittleness; retain wear resistance |

| Medium-carbon quenched steels (e.g., 4140) | 250–450 (medium temper) | 30–120 min | Air cool | Balance hardness/toughness for shafts, gears |

| High-carbon / alloy tool steels (e.g., W-, Cr-, Mo-bearing) | 150–200 (first) → 500–600 (re-temper depending on spec) | 30–120 min per temper step; often double temper | Air cooling; sometimes inert or vacuum | Tool steels often double-temper to stabilize dimensions & properties; over-tempering reduces wear life |

Spring steels (hard + temper) |

200–400 (as required for spring rate) | 30–60 min | Air cool | Set spring properties (resilience, fatigue life) |

| Cast irons (quenched & tempered, e.g., HT cast) | 300–550 | 30–120 min | Air cool | Improve toughness after austempering/quenching |

| Stainless martensitic grades (e.g., 410, 420) | 150–400 (depending on desired hardness and corrosion requirement) | 30–120 min | Air or forced air | Temper for toughness; note sensitization concerns for higher temps in some SS |

Effects on Mechanical Properties of Tempering

Tempering has a direct and predictable impact on the mechanical properties of hardened metals, primarily steels.

By carefully controlling the tempering temperature and time, manufacturers can achieve the desired balance between hardness, toughness, and ductility.

| Property | Effect of Tempering | Practical Implications |

| Hardness | Decreases from the as-quenched maximum | Softens overly brittle metals while retaining sufficient strength for functional use; higher temper temperatures lead to greater hardness reduction |

| Toughness / Impact Strength | Increases significantly | Reduces brittleness, making metals more resistant to cracking, impact, and sudden loads |

| Ductility / Elongation | Improves moderately | Metals can deform slightly under stress without fracturing, important for springs, tools, and structural components |

Residual Stress |

Partially relieved | Reduces warping or cracking during service, enhancing dimensional stability |

| Strength / Tensile Properties | Slightly reduced compared to quenched state | Ensures a balance between hardness and toughness suitable for practical applications |

| Wear Resistance | Retained at lower tempering temperatures; decreases with high-temperature tempering | Low-temperature tempering preserves hardness for wear-critical components like cutting tools, while higher temperatures favor toughness over wear resistance |

Illustrative Examples:

- High-carbon quenched steel: HRC 63 (as-quenched) → tempered at 200–250 °C → HRC 58–60, toughness significantly improved for springs or hand tools.

- Medium-carbon alloy steel (e.g., 4140): HRC 58 → tempered at 400 °C → HRC 45–50, achieving a good balance of strength, toughness, and fatigue resistance for shafts and gears.

- Tool steel (e.g., D2): Double tempering at 525 °C reduces internal stresses, stabilizes hardness (HRC 60–62), and improves impact resistance for dies and molds.

4. Industrial Applications: When to Use Each Process

Tempering and annealing serve distinct purposes in metalworking, and selecting the right process depends on the desired mechanical properties, subsequent manufacturing steps, and application requirements.

Annealing Applications

Annealing is primarily used to soften metals, relieve internal stresses, and improve ductility, making it ideal for metals that will undergo forming, machining, or shaping.

| Industry / Application | Typical Use Case | Why Annealing is Chosen |

| Automotive | Sheet metal for body panels, structural components | Softened metal allows stamping, bending, and drawing without cracking |

| Aerospace | Aluminum alloy panels, copper wiring | Reduces work hardening; improves formability and electrical conductivity |

| Electronics | Copper and brass components | Enhances ductility for complex shapes and improves electrical conductivity |

| Metal Fabrication / Machining | Steel bars, rods, sheets | Softening makes subsequent machining more efficient and reduces tool wear |

| Construction / Infrastructure | Steel beams, rebar | Relieves residual stresses after rolling or welding; improves dimensional stability |

Tempering Applications

Tempering is used after hardening to optimize the balance between hardness and toughness, making metals suitable for load-bearing, wear-resistant, or impact-prone applications.

| Industry / Application | Typical Use Case | Why Tempering is Chosen |

| Toolmaking | Hand tools, dies, punches | Reduces brittleness of hardened steel while retaining wear resistance |

| Automotive & Aerospace | Gears, shafts, springs | Ensures toughness and impact resistance for parts subjected to cyclic loads |

| Heavy Machinery | Cutting blades, industrial molds | Balances hardness and toughness for durability under high stress |

| Structural Components | Beams, connecting rods, fasteners | Increases toughness without significant loss of strength, improving safety and reliability |

| Springs & High-Load Components | Coil springs, suspension parts | Provides elasticity while maintaining strength and fatigue resistance |

5. Common Misconceptions & Clarifications

“Tempering is a Type of Annealing”

False. Tempering is a post-hardening process that only follows quenching, while annealing is a standalone process for softening/stress relief.

They have opposite objectives (tempering retains strength; annealing reduces it).

“Higher Tempering Temperature = Better Performance”

False. Tempering temperature is application-dependent: low temper (200–300°C) maximizes hardness for tools; high temper (500–650°C) maximizes toughness for structural parts.

Excessive tempering (≥650°C) reduces strength to unacceptable levels.

“Annealing Works for All Metals”

False. Non-ferrous metals (aluminum, copper) do not undergo phase changes like steel—their annealing only causes recrystallization (softening) without microstructure transformation.

“Tempering Eliminates All Residual Stress”

False. Tempering relieves 70–80% of quenching residual stress—for critical applications (e.g., aerospace parts), additional stress relief annealing may be required.

6. Key Differences — Annealing vs Tempering

The table below provides a clear, side-by-side comparison of annealing vs tempering, highlighting their objectives, processes, and effects on metal properties.

| Aspect | Annealing | Tempering |

| Purpose | Soften metal, relieve internal stress, improve ductility and machinability | Reduce brittleness, increase toughness, balance hardness after hardening |

| Heat Level | Above critical transformation temperature (austenitizing for steels) | Below critical transformation temperature |

| Typical Metals | Steels, copper, aluminum, brass, bronze | Hardened steels, tool steels, martensitic stainless steels, cast iron |

| Cooling Method | Slow furnace cooling (sometimes controlled air for non-ferrous metals) | Air cooling (usually), sometimes controlled or inert atmosphere |

| Effect on Hardness | Significantly decreases | Moderately decreases (from as-quenched hardness) |

| Effect on Toughness | Slightly improved, mainly by stress relief | Significantly improved, reduces brittleness |

Effect on Ductility / Elongation |

Strongly increases | Moderately increases |

| Effect on Residual Stress | Relieved | Partially relieved (after quenching-induced stress) |

| Microstructural Change | Homogenizes grains, soft phases (ferrite/pearlite in steel, recrystallized grains in non-ferrous metals) | Tempered martensite in steel; stabilizes microstructure without fully softening |

| Typical Industrial Use | Forming, bending, drawing, machining, stress-relief | Tools, gears, springs, structural components, wear-resistant parts |

| Cycle Duration | Long (hours depending on thickness and alloy) | Shorter (minutes to hours, depending on temp and section size) |

7. Conclusion

Annealing vs tempering are cornerstone processes in metalworking.

Annealing prepares metals for forming, machining and safer downstream processing by softening and stress-relieving.

Tempering refines the properties of hardened parts, converting as-quenched brittleness into serviceable toughness while retaining useful strength.

Effective use requires matching alloy chemistry, section thickness, heating/soak times and cooling strategy — and verifying outcomes with hardness, microstructure and mechanical tests.

FAQs

Can the same furnace be used for both annealing and tempering?

Yes — most heat-treatment furnaces can be programmed for different cycles and atmospheres, but process control (temperature uniformity, atmosphere) must meet the requirements for each operation.

Which process is more energy-intensive?

Annealing is generally more time- and energy-consuming because of higher soak times and slow cooling (furnace dwell); tempering cycles are typically shorter.

How are results verified?

Common verification methods: hardness tests (Rockwell, Vickers, Brinell), tensile tests, impact (Charpy) tests, metallography (optical/SEM) and residual stress measurements (XRD/hole drilling).

Is tempering used on non-steel metals?

The term “tempering” is most appropriate for steels (martensite tempering).

Non-ferrous alloys use different heat-treatment families (age hardening, annealing, solution treatment) with analogous goals.

Typical temper temps for common outcomes?

(Approximate, alloy-dependent) — 150–250 °C retains higher hardness (tooling wear resistance), 300–450 °C is a balanced hardness/toughness window for structural parts, 500–650 °C maximizes toughness at cost of hardness.