1. Introduction

Aluminum alloys are pivotal in modern manufacturing, providing solutions to numerous industries like automotive, aerospace, and electronics.

Known for their lightweight nature, high strength, and corrosion resistance, aluminum alloys are preferred in many applications.

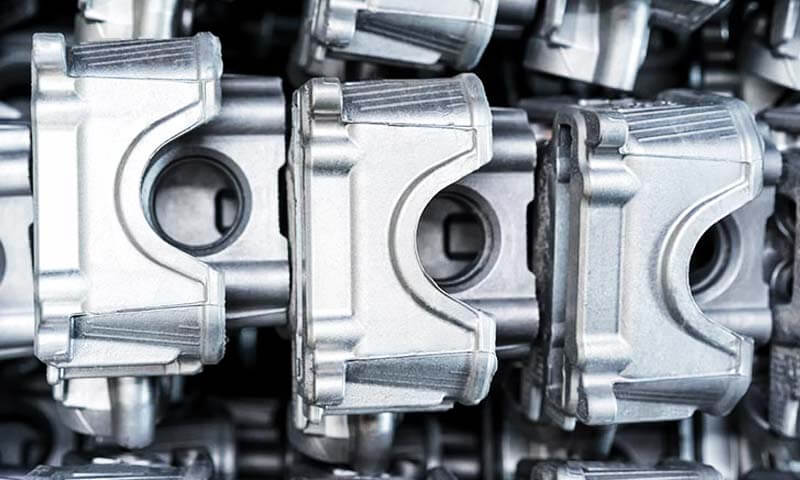

One notable alloy in this category is ADC12, renowned for its performance in die-casting processes.

Die casting, which enables the mass production of intricate parts with high precision, benefits from the unique properties of ADC12,

making it a popular choice in industries requiring complex, high-volume production.

2. What is ADC12 Aluminum Alloy?

ADC12, also referred to as A383.0 or JIS-AC4C is a high-silicon, low-copper aluminum alloy primarily used for die casting.

The alloy’s outstanding fluidity and mechanical properties make it highly favored in automotive, consumer electronics, and other precision industries.

Composition:

- Silicon (Si): 9.6 – 12.0% – Enhances fluidity, reduces shrinkage, and improves wear resistance.

- Copper (Cu): 1.5 – 3.5% – Increases tensile strength but may slightly reduce corrosion resistance.

- Iron (Fe): ≤ 1.3% – Contributes to strength and hardness but can reduce ductility.

- Manganese (Mn): ≤ 0.5% – Improves toughness and refines the grain structure.

- Other elements (Mg, Zn, Ni): Present in trace amounts, contributing to specific mechanical properties such as hardness and overall strength.

Density: With a density of 2.74 g/cm³, ADC12 maintains a balance of lightweight properties while providing the necessary strength for a variety of applications.

Melting Point: Typically around 549°C, with some variance depending on composition and casting conditions.

Historical Context: Originally developed to meet the rigorous demands of the Japanese automotive industry, ADC12 gained widespread adoption internationally. Its precision and versatility in producing complex parts have made it a standard in high-volume manufacturing processes worldwide.

3. Key Properties of ADC12

Mechanical Properties:

- Tensile Strength: Approximately 310 MPa, offering sufficient strength for most structural applications.

- Yield Strength: Around 160 MPa, providing a good balance of flexibility and rigidity.

- Elongation: Although not highly ductile, ADC12 offers a modest elongation range of 1.5-3%, making it suitable for most casting applications.

- Hardness: Approximately 75 HB, ensuring the alloy is durable enough for wear-resistant applications.

Thermal Properties:

- Thermal Conductivity: About 96 W/m·K, ideal for heat-sensitive components like heat sinks.

- Coefficient of Thermal Expansion: Around 23.5 μm/m·K, offering moderate expansion properties that ensure dimensional stability with temperature fluctuations.

Corrosion Resistance:

ADC12 exhibits strong resistance to general corrosion, especially in non-marine environments. To enhance corrosion resistance in more aggressive settings, surface treatments like anodizing are recommended.

Weldability and Machinability:

- Welding: Not typically welded due to the risk of cracking; however, with preheating and specialized techniques, TIG welding can be used if necessary.

- Machining: ADC12 is easy to machine and can be processed with standard cutting tools. Its machinability, similar to that of free-machining brass, enables cost-effective, high-precision manufacturing.

Formability and Castability:

- Fluidity: High fluidity ensures that ADC12 can fill intricate molds with excellent detail, making it suitable for the most complex geometries.

- Filling Characteristics: The alloy’s fluidity contributes to reduced porosity and improved surface finish, resulting in high-quality, defect-free castings.

- Shrinkage and Porosity: Proper mold design and controlled cooling rates can minimize these issues, ensuring optimal casting quality.

Why ADC12 is the Preferred Choice for Die Casting

- Superior Castability: The high silicon content of ADC12 offers outstanding fluidity, allowing it to flow smoothly into molds and fill intricate designs with precision.

- Dimensional Accuracy and Surface Quality: ADC12 achieves tight tolerances and smooth surfaces, reducing the need for secondary processing and improving production efficiency.

- Repeatability in Mass Production: The alloy’s consistency in casting ensures reliable quality across large production volumes, making it a preferred option for manufacturers needing reliable, high-quality parts.

4. Advantages of ADC12 Aluminum Alloy

- Dimensional Stability: ADC12 maintains its dimensions and shape under varying temperatures, making it suitable for applications in industries where dimensional accuracy is critical, such as automotive or aerospace.

- Corrosion Resistance: While not the most corrosion-resistant aluminum alloy, ADC12’s resistance is sufficient for most environments. Additional surface treatments like anodizing can further enhance its durability.

- Complex Mold Filling: The alloy’s excellent fluidity and low shrinkage make it perfect for producing detailed castings with minimal defects, reducing the need for post-production adjustments.

- Lightweight Strength-to-Weight Ratio: ADC12’s low density, combined with its strength, makes it ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

- Cost-Effectiveness in Mass Production: Due to its easy casting and machining characteristics, ADC12 is highly cost-effective in high-volume production, driving down unit costs.

- Environmental Sustainability: Fully recyclable, ADC12 offers an eco-friendly manufacturing solution by reducing waste and conserving resources during production.

5. Common Applications of ADC12 Aluminum Alloy

Automotive Industry:

- Engine Components: ADC12’s thermal properties make it perfect for engine blocks and cylinder heads, where heat dissipation and durability are essential.

- Transmission and Powertrain Parts: ADC12’s strength and dimensional stability ensure precision and reliability in critical automotive components.

- Chassis and Suspension Parts: Its lightweight yet strong nature is beneficial for improving vehicle fuel efficiency and overall performance.

Consumer Electronics:

- Heat Sinks and Enclosures: ADC12’s high thermal conductivity ensures efficient heat dissipation in electronics, protecting sensitive components from overheating.

- Internal Components: Precision machining makes it ideal for connectors and other internal components requiring high durability.

Industrial Equipment:

- Valves, Pumps, and Fittings: The alloy’s corrosion resistance and strength are key attributes for these essential industrial components.

- Structural Parts: Its combination of lightness and strength makes ADC12 ideal for structural and functional components in industrial machinery.

Household Applications:

- Appliances: ADC12 is found in kitchen appliances like refrigerators and ovens, where heat conductivity and corrosion resistance are important.

- Lighting Fixtures: The alloy’s durability and lightweight characteristics also make it ideal for lighting components.

6. Limitations and Considerations

- Not Ideal for High-Temperature Environments: Due to its relatively low melting point, ADC12 is unsuitable for extreme heat conditions, where alloys like 356 or 380 would perform better.

- Limited in High-Stress Applications: While ADC12 has good mechanical properties, it may not be the best choice for applications that require higher tensile and yield strengths under heavy loads.

- Surface Treatment Needs: To maintain optimal performance, ADC12 often requires anodizing, painting, or other surface treatments to boost corrosion resistance and improve aesthetics.

7. Comparison with Other Alloys

- A356.0: Better thermal conductivity than ADC12, suitable for automotive engine components and heat exchangers.

- A380.0: Offers superior tensile and yield strengths, though it sacrifices some fluidity compared to ADC12.

- A383.0: Shares similarities with ADC12, with a slightly higher copper content providing better mechanical properties but slightly reduced corrosion resistance.

8. Conclusion

ADC12 is a versatile aluminum alloy offering excellent casting capabilities, dimensional stability,

and cost-effectiveness for industries such as automotive, electronics, and industrial manufacturing.

Its combination of properties makes it a preferred material for producing complex, high-precision parts.

With its solid performance in casting, strength-to-weight ratio, and environmental benefits,

ADC12 remains a top choice for manufacturers aiming to optimize production while maintaining high-quality standards.

FAQs

What makes ADC12 different from other aluminum alloys?

ADC12 stands out with its high silicon content, which enhances fluidity and castability, making it ideal for die casting.

Other alloys, like A356.0 and A380.0, cater to specific needs like higher thermal conductivity or tensile strength.

Can ADC12 be used in high-temperature applications?

Due to its lower melting point, ADC12 is not suitable for high-temperature environments. For such applications, consider alloys like 356 or 380 for their superior thermal stability.

Are there any safety concerns when working with ADC12?

As with all metals, ADC12 requires safe handling practices, including PPE and ventilation, to prevent injuries or exposure to fumes during machining and welding.

How should ADC12 be stored and handled?

Store ADC12 in a clean, dry environment and handle it carefully to avoid contamination and oxidation, ensuring the material remains in optimal condition for use.