1. Executive summary

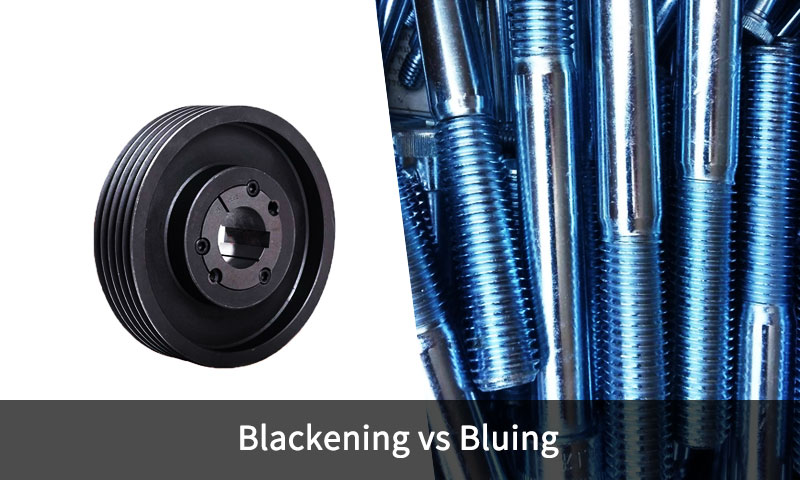

“Blackening” vs “bluing” are terms often used interchangeably in casual conversation, but they refer to overlapping yet distinct families of surface treatments.

Both are intended to produce a dark appearance and some degree of corrosion resistance on ferrous parts, but they differ in chemistry, process temperature, appearance, durability and typical uses.

Bluing historically refers to controlled oxidation processes used on firearms to create a blue-black magnetite film, while blackening is a broader industrial term that embraces conversion coatings (black oxide), phosphating, nitriding and deposited black finishes (electroplate, PVD, powder coat).

Choosing between them depends on substrate, functional requirements (corrosion, wear, dimensional tolerance), cost, production scale and environmental constraints.

2. Introduction

In surface engineering, finishes are selected to achieve one or more goals: corrosion resistance, wear resistance, reduced glare, specific appearance (color/gloss), lubrication, electrical behavior, or to serve as a paint base.

Two common “dark” finishes encountered in industry are bluing and blackening:

- Bluing — traditionally denotes a controlled oxidation of ferrous surfaces to form a thin magnetite (Fe₃O₄) layer.

It is strongly associated with firearms and small arms, where a characteristic blue-black patina is desired for both aesthetics and modest corrosion protection when sealed with oil. - Blackening — a broader term that generally means producing a black or very dark coating on metal.

It can describe conversion coatings (black oxide, black phosphate), deposition finishes (black electroplate, PVD), or thermochemical processes (black nitriding).

Blackening is commonly used in industrial hardware, fasteners, automotive parts and decorative items.

Important: both bluing and many blackening conversions produce a very thin protective film (often sub-micron to a few microns thick); their real corrosion protection depends heavily on post-treatment sealing (oil, wax, lacquer, or polymer topcoat).

There are also deposited black finishes that are intentionally thicker and mechanically more robust; these are technically different from conversion bluing/black oxide.

3. The chemistry and metallurgy behind the finishes

Conversion coatings vs deposited coatings

- Conversion coatings: chemical reaction between the metal substrate and the treating solution/atmosphere.

The coating is integral with the substrate (not an added layer) and very thin.

Examples: black oxide (Fe → Fe₃O₄), phosphate (iron phosphate films), ferritic nitrocarburizing (forming iron nitrides/oxides). - Deposited coatings: layers built on top of the substrate by electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), or paint/powder coating. These can be thicker and provide mechanical barrier protection.

Chemistry of bluing (magnetite formation)

Bluing is essentially a controlled formation of magnetite (Fe₃O₄) on steel.

That magnetite film is formed typically by oxidation in an alkaline salt bath (hot bluing) or by controlled rusting and conversion (rust bluing).

Magnetite is adherent, thin and gives a bluish-black tone because of its optical properties.

The film itself provides only modest corrosion resistance unless sealed; oil or wax fills micro-porosity and improves performance significantly.

Chemistry of common blackening routes

- Hot black oxide (hot bluing / hot blackening): alkaline oxidizing bath converts the iron surface to magnetite quickly and uniformly at elevated temperature (commonly 135–155 °C depending on chemistry). Result: dense Fe₃O₄ layer.

- Cold blackening (chemical blackening): room-temperature solutions (nitrite, nitrate-based) produce a black conversion film through chemical reactions; easier for touch-up or small-batch work but yields a thinner, less robust film.

- Phosphating (Parkerizing): forms iron or zinc phosphate crystals that are porous and excellent at holding oil; can appear gray to black depending on formulation and subsequent treatment.

- Ferritic nitrocarburizing / black nitriding: thermochemical diffusion introduces nitrogen and carbon into the surface, producing hard nitride layers and sometimes an oxide topcoat that is black (used for wear resistance plus corrosion resistance).

- Deposited black finishes (electroplated black chrome, black nickel, PVD, powder coat): these are not conversions but added layers; thickness and barrier properties vary by process — often far more protective against corrosion and wear than thin conversion films.

4. Principal Processes

Surface treatments that produce dark finishes on ferrous metals are widely used for aesthetic, corrosion resistance, and functional purposes.

The choice of method depends on substrate, desired appearance, dimensional tolerance, corrosion/wear requirements, and production scale.

Hot Bluing / Hot Black Oxide

- Process Overview: Steel parts are immersed in an alkaline oxidizing bath (typically sodium hydroxide with oxidizing salts) heated to 135–155 °C. Oxygen reacts with iron to form a thin, adherent magnetite layer (Fe₃O₄).

- Key Features:

-

- Produces a uniform blue-black finish with subtle iridescence.

- Thickness is typically 0.5–2 µm, resulting in negligible dimensional change—suitable for precision components like firearm barrels and slides.

- Film is porous; therefore, post-treatment sealing with oil, wax, or lacquer is required for corrosion resistance.

- Advantages: High-quality, repeatable finish; good color depth; minimal dimensional impact.

- Limitations: Requires temperature-controlled baths, proper ventilation, and careful handling of caustic chemicals.

Cold Bluing / Chemical Blackening

- Process Overview: Room-temperature chemical solutions, often nitrite- or nitrate-based, react with the steel surface to produce a thin black oxide layer.

- Key Features:

-

- Film thickness is extremely thin (<1 µm).

- Primarily used for small parts, touch-ups, and maintenance rather than production-scale applications.

- Appearance: dull black, less rich than hot bluing; uneven application possible if not carefully controlled.

- Advantages: Convenient, low-cost, no need for hot baths; can be applied in situ.

- Limitations: Lower corrosion and wear resistance; shorter lifespan without maintenance or sealing.

Rust Bluing / Fume Bluing

- Process Overview: Traditional, multi-step process:

-

- Controlled rusting of the steel surface (formation of red Fe₂O₃).

- Conversion to black magnetite (Fe₃O₄) through boiling, chemical reduction, or exposure to fumes.

- Repetition of cycles to build depth and consistency.

- Key Features:

-

- Produces a deep, lustrous blue-black finish highly valued in firearms and collector-grade components.

- Time-intensive; requires careful monitoring of humidity, temperature, and chemical exposure.

- Advantages: Premium aesthetic; durable when maintained properly with oil.

- Limitations: Labor-intensive, low throughput; not suitable for mass production.

Black Phosphating (Parkerizing)

- Process Overview: Steel is immersed in an acid phosphate bath, producing a crystalline iron or zinc phosphate layer.

Parameters such as bath concentration, temperature (88–95 °C), and immersion time control crystal size and color (gray to black). - Key Features:

-

- Film thickness: 5–25 µm, slightly thicker than black oxide.

- Porous layer holds oil exceptionally well, improving corrosion resistance.

- Matte appearance reduces glare, commonly used in military and tactical equipment.

- Advantages: Economical for large batches; compatible with oily or lubricated applications.

- Limitations: Porous surface can be mechanically weak; oiling required to prevent corrosion.

Ferritic Nitrocaburizing / Black Nitriding

- Process Overview: Thermochemical diffusion process introducing nitrogen and carbon into the surface at 500–600 °C, forming a thin, hardened compound layer.

A black oxide surface forms naturally on top (black nitriding). - Key Features:

-

- Thickness: 5–50 µm, combination of compound layer and diffusion zone.

- Improves wear resistance, fatigue strength, and moderate corrosion protection.

- Slight dimensional growth may occur (~0.02–0.05 mm).

- Advantages: Excellent for high-wear parts such as gears, shafts, fasteners.

- Limitations: Requires specialized equipment and careful temperature control.

Deposited Black Coatings (Electroplating, PVD, Powder Coat)

- Process Overview: Layers are deposited onto the substrate rather than chemically converted:

-

- Electroplating: black chrome, black nickel.

- PVD: thin metallic or ceramic layers applied under vacuum.

- Powder coating: polymer-based finishes cured on the substrate.

- Key Features:

-

- Thickness: 5–100+ µm, depending on method.

- High uniformity, gloss or matte finishes.

- Superior corrosion and wear resistance compared to thin conversion coatings.

- Advantages: Excellent aesthetics, functional coatings, wider color/finish options.

- Limitations: Can alter dimensions significantly; adhesion depends on pretreatment; higher cost.

5. Visual, dimensional and mechanical differences

Appearance (color, gloss and uniformity)

- Bluing (hot/rust bluing): bluish-black to deep blue; slightly iridescent when new; prized aesthetic on firearms.

- Cold blackening / black oxide: can be matte to semi-gloss black; often slightly browner or slate compared to classic bluing.

- Phosphate: matte, granular surface (dull black/gray); non-reflective.

- Black nitriding / PVD / powder coat: can be deep black and uniform; PVD and powder coat can achieve high gloss or matte finishes on demand.

Thickness and dimensional change

- Conversion bluing/black oxide/phosphate:very thin — typically sub-micron to a few microns.

Negligible dimensional change (advantageous for precision parts and tight tolerances). - Nitriding: creates diffusion layer that can be several microns thick plus compound layer — small but measurable dimensional change.

- Electroplating / PVD / powder coat: deposited layers commonly range from microns to tens/hundreds of microns; significant for tight tolerances.

Wear resistance and hardness

- Bluing / black oxide: minimal added hardness; mainly cosmetic + mild corrosion resistance; wear resistance poor without additional coatings or lubricants.

- Black nitriding: increases surface hardness substantially (benefit for wear-critical parts).

- Deposited coatings: wear resistance depends on coating (hard PVD or ceramic coatings >> black oxide).

6. Corrosion protection and durability

Baseline corrosion protection

- Bluing / black oxide alone: thin and porous; provides minimal barrier protection by itself. Typical protection relies on post-seal (light oil, wax, polymer topcoat). Without sealing, corrosion will start relatively quickly, especially in aggressive environments.

- Phosphate + oil: good corrosion resistance when impregnated with oil; widely used where parts see periodic handling/oiling.

- Black nitriding: good corrosion resistance due to compact compound/diffusion layers.

- Deposited coatings: best corrosion barrier when thick, dense, and defect-free (e.g., black chrome or high-quality powder coat).

Real-world durability

- In benign, dry environments, a well-sealed blued or black-oxide part can be serviceable for years with occasional oiling. In marine or high-humidity conditions, conversion films require more robust sealing or better choice of coating (nitriding or deposited coating). Engineering selection must consider expected exposure, maintenance regimen and acceptable lifetime before recoating.

7. Practical engineering considerations and applications

Firearms and small arms (classic use-case)

- Bluing (hot or rust bluing) is traditional — favored for aesthetics, acceptable protection when oiled, and dimensional stability. Cold bluing is used for spot repairs only.

- Phosphate (Parkerizing) is common for military firearms because of durable, matte surface and oil retention.

Fasteners, hardware and automotive parts

- Black oxide (hot or cold) is often used for fasteners and general hardware where cost and low dimensional change matter; post-oil or lacquer improves corrosion resistance.

- Ferritic nitrocarburizing is used on gears, shafts and engine parts when wear resistance and fatigue life are needed.

Decorative and architectural items

- PVD, powder coat, or electroplated black finishes are used for consistent aesthetic appearance and better weather resistance.

Tooling and dies

- Nitriding gives wear resistance; sometimes followed by black oxide/PVD for combined performance and appearance.

Manufacturing/throughput and cost

- Hot bluing / hot blackening requires controlled baths and more safety infrastructure but gives consistent results at scale.

- Cold bluing is low-cost and flexible but inferior in durability.

- Deposited finishes are costlier but offer superior protection and a wider palette of finishes.

8. Environmental, safety and regulatory aspects

- Hot alkaline bluing baths and cold chemical bluing solutions contain caustic, oxidizing, or nitrite-based chemistries.

They pose inhalation, skin burn, and disposal hazards; facilities must provide fume control, proper PPE, and wastewater neutralization/treatment. - Phosphate baths are acidic and create spent sludges that must be managed.

- Electroplating may involve hazardous heavy metals or hexavalent chromium in certain systems — strict disposal and worker-safety rules apply.

- Black nitriding involves high temperatures and ammonia or other reactive gases; exhaust treatment is required.

- Safer alternatives: improved waste treatment, water-based coatings, or non-toxic deposited coatings (some PVD systems) reduce environmental impact but often at higher capital cost.

9. Quality control, testing and maintenance

Tests and QC metrics

- Salt spray (ASTM B117-style): comparative corrosion resistance. Conversion coatings typically fare lower unless sealed.

- Adhesion (crosshatch / tape pull): checks coating adhesion (applies more to deposited coatings).

- Thickness measurement: micrometer-based or eddy-current gauges; conversion coatings are very thin (near detection limit for some gauges).

- Color and gloss measurement: spectrophotometry or gloss meters for cosmetic control.

- Visual inspection and microscopy: check for uniformity, micro-porosity, and substrate reaction.

Maintenance

- Blued / black-oxide parts: periodic oiling or waxing prolongs life; remove surface moisture and reapply light oil after cleaning.

- Phosphate-treated parts: re-oil after cleaning; phosphate is porous and relies on oil impregnation.

- Deposited coatings: repair by re-plating or touch-up paints; powder coat requires sanding and repainting for damage.

10. Common Misconceptions & Clarifications

“Blackening and Bluing Are the Same Process”

False. Blackening forms a thicker (0.5–1.5 μm) black Fe₃O₄ layer for durability; bluing forms a thinner (0.1–0.5 μm) blue-black layer for aesthetics.

“Bluing Is Only for Firearms”

False. Hot bluing is used for tools and decorative parts; cold bluing is for restoration—firearms are just a high-profile application.

“Blackening Is More Expensive Than Bluing”

Partially true. Hot blackening requires heating equipment (higher upfront cost) but lower per-part cost for high volume.

Cold bluing has no upfront costs but higher per-part cost for repeated coats.

“Unsealed Blackening/Bluing Provides Adequate Protection”

False. Unsealed layers are porous—provide <24 hours of corrosion resistance (ASTM B117). Sealing with oil/wax is mandatory for real-world use.

“Both Processes Work on Non-Ferrous Metals”

False. Blackening and bluing only work on ferrous metals (steel, iron). Non-ferrous metals (aluminum, copper) require plating or anodizing.

11. Comprehensive Comparison: Blackening vs Bluing

Blackening and bluing are both widely used surface treatments for ferrous metals, but they differ significantly in chemistry, appearance, functional properties, and industrial applications.

| Feature | Bluing | Blackening |

| Chemistry / Mechanism | Controlled oxidation of iron to form magnetite (Fe₃O₄) | Varies: chemical conversion (black oxide, phosphate), thermochemical (nitriding), or deposited coatings (PVD, electroplate) |

| Substrate | Carbon or alloy steel | Mostly ferrous; some processes applicable to stainless steel or non-ferrous metals (via deposition) |

| Type of Coating | Conversion coating | Conversion or deposited coating |

| Appearance | Blue-black, sometimes slightly iridescent | Dark gray to black; matte, semi-gloss, or glossy depending on process |

| Film Thickness | 0.5–2 µm (hot bluing) | Thin: <25 µm (oxide/phosphate); Moderate: 5–50 µm (nitriding); Thick: 5–100+ µm (PVD/electroplating) |

| Dimensional Change | Negligible | Minimal for chemical conversions; moderate to significant for deposited coatings/nitriding |

| Corrosion Resistance | Low alone; improved with oil/wax sealing | Moderate to high; depends on process (phosphate + oil, nitriding, PVD) |

| Wear Resistance | Minimal | Moderate (oxide/phosphate) to high (nitriding, PVD) |

| Typical Applications | Firearms, collector-grade steel, aesthetic parts | Industrial hardware, fasteners, automotive, aerospace, tooling, decorative parts |

| Maintenance | Requires regular oiling or waxing | Varies: thin conversion coatings need maintenance; deposited coatings require minimal upkeep |

| Cost & Complexity | Moderate (hot bluing) to low (cold bluing); bath and temperature control required | Low-cost (oxide/phosphate) to high-cost (nitriding, PVD); complexity depends on method |

| Aesthetic Value | High; rich, deep blue-black finish prized in collectors | Moderate; can be tailored (matte, glossy, uniform black) for industrial or decorative purposes |

12. Conclusion

Bluing and blackening are complementary surface treatment strategies.

Bluing excels in aesthetics and precision applications, while blackening provides versatile solutions for corrosion, wear, and industrial performance.

Substrate type, functional requirements, visual goals, production scale, and maintenance expectations should guide the choice between them.

By understanding the chemistry, process, and application differences, engineers and designers can make informed, durable, and cost-effective choices for a wide range of metal components.

FAQs

Is bluing the same as black oxide?

Functionally they are similar (both produce iron oxide films), but “bluing” traditionally refers to the historic firearm treatments (hot, rust, fume bluing) and often has a bluish hue; “black oxide” is a broader industrial hot/cold conversion chemistry that yields a black finish.

Can you blacken stainless steel or aluminium the same way?

No. Traditional bluing/black oxide targets ferrous metals.

Stainless and aluminium require special conversion chemistries or deposited coatings (PVD, anodizing for aluminium, or black oxide processes developed specifically for some stainless grades).

Which finish provides the best corrosion protection out of the box?

Deposited coatings (properly applied) and nitride treatments generally provide superior corrosion protection.

Conversion bluing and black oxide require sealing to have reasonable corrosion resistance.

Will bluing affect part dimensions or tolerances?

Bluing and black oxide impart negligible dimensional change (sub-micron to a few microns) — suitable for tight tolerance parts.

Deposited coatings may require allowance if thickness matters.

Is cold bluing as good as hot bluing?

Cold bluing is convenient for touch-ups but produces a thinner, less durable film than hot bluing; hot bluing gives a more uniform, longer-lasting finish when properly sealed.