Ductile Iron Machining Services

Ductile iron is a tough, wear-resistant metal known for its excellent strength, impact resistance, and machinability. At LangHe, we provide high-performance ductile cast iron casting services tailored to meet the needs of industries such as automotive, agriculture, heavy equipment, and industrial machinery.

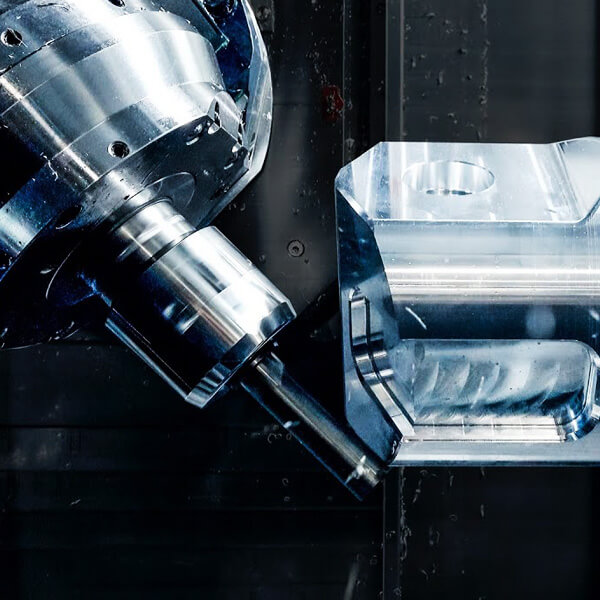

Our capabilities include custom ductile iron casting, precision mold design, CNC machining, heat treatment, surface finishing, and quality inspection to ensure reliable, long-lasting components.

With extensive foundry experience and strict quality control, LangHe delivers ductile iron castings that meet demanding mechanical and dimensional requirements—offering both performance and cost efficiency.