Why LANGHE for Shell Mold Casting

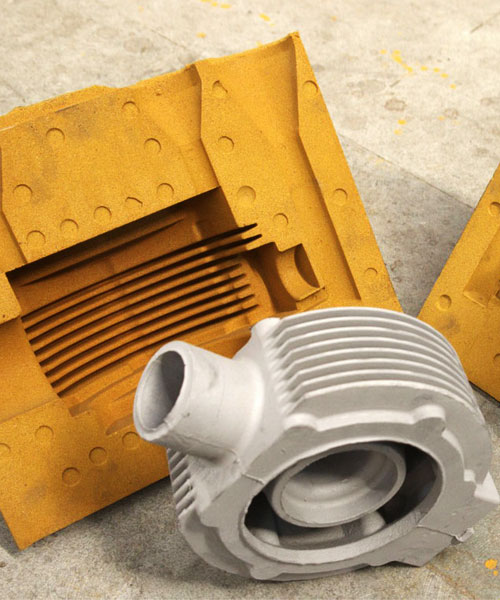

High-Precision Shell Mold Castings with Full-Service Manufacturing and Finishing Capabilities

- Complex, Thin-Walled Parts with Excellent Surface Finish and Dimensional Accuracy

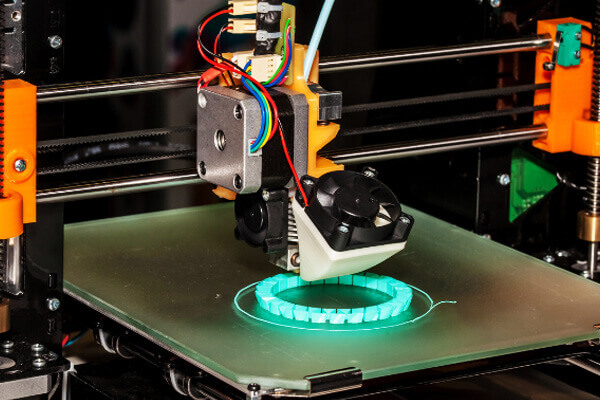

- Rapid Turnaround: Prototype Samples Ready in as Few as 20 Days

- Tight Tolerances Up to ±0.02mm for Critical Components

- Full Support from Tooling Design to Final Inspection

- Ideal for Medium to High-Volume Production of Intricate Metal Parts

- Post-Casting CNC Machining for Threads, Holes, and Tight Features

- Multiple Surface Treatments: Sand Blasting, Painting, Heat Treatment, and More

- Wide Range of Ferrous and Non-Ferrous Alloys Available

- Complete Material Traceability with Certificates of Compliance (CoCs)