1. Introduction

In the realm of engineering materials, titanium vs stainless steel frequently stand out as two high-performance metals utilized across a broad range of industries.

Their applications span aerospace, medical, marine, and consumer products, driven by their unique mechanical, chemical, and physical characteristics.

This article delivers a professional, data-driven comparison of these two materials, aiming to inform material selection decisions with authority and clarity.

2. Chemical Composition & Alloy Systems

Understanding the chemical composition and alloy systems of titanium and stainless steel is critical for material selection,

as these factors directly influence mechanical properties, corrosion resistance, thermal behavior, and processability.

Titanium Alloys

It is typically used in two forms:

- Commercially pure titanium (Grades 1–4) – varying oxygen content controls strength and ductility.

- Titanium alloys – mainly Ti-6Al-4V (Grade 5), the industry workhorse.

| Titanium Grade | Composition | Key Characteristics |

| Grade 1 | ~99.5% Ti, very low O | Softest, most ductile, excellent corrosion resistance |

| Grade 2 | ~99.2% Ti, low O | Stronger than Grade 1, widely used in industrial applications |

| Grade 5 (Ti‑6Al‑4V) | ~90% Ti, 6% Al, 4% V | High strength-to-weight ratio, aerospace & biomedical use |

| Grade 23 | Ti‑6Al‑4V ELI (Extra Low Interstitial) | Improved biocompatibility for implants |

Stainless Steel Families

Stainless steels are iron-based alloys with ≥10.5% chromium, forming a passive Cr₂O₃ film for corrosion resistance. They are grouped by microstructure:

| Family | Typical Grades | Key Alloying Elements | Primary Characteristics | Common Applications |

| Austenitic | 304, 316, 321 | Cr, Ni, (Mo in 316), (Ti in 321) | Excellent corrosion resistance, non-magnetic, good formability | Food processing, medical devices, chemical equipment |

| Ferritic | 409, 430, 446 | Cr | Magnetic, moderate corrosion resistance, good thermal conductivity | Automotive exhausts, appliances, architectural trim |

Martensitic |

410, 420, 440A/B/C | Cr, C | High hardness and strength, magnetic, less corrosion-resistant | Knives, turbine blades, tools |

| Duplex | 2205, 2507 | Cr, Ni, Mo, N | High strength, improved chloride stress corrosion cracking (SCC) resistance | Marine structures, oil & gas, bridges |

| Precipitation-Hardening | 17-4PH, 15-5PH, 13-8Mo | Cr, Ni, Cu, Al (or Mo, Nb) | Combines high strength and corrosion resistance, heat-treatable | Aerospace, defense, shafts, valves, nuclear components |

3. Mechanical Properties of Titanium vs Stainless Steel

Selecting between titanium and stainless steel requires understanding their distinct mechanical profiles. The table below outlines the most relevant properties for commonly used grades:

Mechanical Properties Comparison Table

| Property | Titanium Grade 2 (Commercially Pure) | Ti-6Al-4V (Grade 5) | 304 Stainless Steel | 316 Stainless Steel |

| Density (g/cm³) | 4.51 | 4.43 | 8.00 | 8.00 |

| Tensile Strength (MPa) | ~345 | ~900 | ~505 | ~515 |

| Yield Strength (MPa) | ~275 | ~830 | ~215 | ~205 |

| Elongation (%) | ~20 | 10–14 | ~40 | ~40 |

| Hardness (HB) | ~160 | ~330 | 150–170 | 150–180 |

| Elastic Modulus (GPa) | ~105 | ~114 | ~193 | ~193 |

| Fatigue Strength (MPa) | ~240 | ~510 | ~240 | ~230 |

4. Corrosion Resistance & Surface Behavior

Corrosion performance often dictates material choice in demanding environments.

Both titanium and stainless steel rely on passive oxide films—yet their behavior diverges sharply under chlorides, acids, and elevated temperatures.

Passive Film Formation

- Titanium (TiO₂)

-

- Instantly forms a 2–10 nm thick, self‑healing oxide layer

- Re‑passivates rapidly if scratched—even in seawater

- Stainless Steel (Cr₂O₃)

-

- Develops a 0.5–3 nm chromium oxide film

- Effective in oxidizing environments but vulnerable where oxygen is depleted

Key Point: TiO₂ is more stable than Cr₂O₃, granting titanium superior resistance to a wider range of corrosive media.

Performance in Aggressive Environments

| Environment | Ti‑6Al‑4V | 316 Stainless Steel |

| Chloride‑bearing solutions | No pitting at Cl⁻ up to 50 g/L at 25 °C | Pitting threshold ~ 6 g/L Cl⁻ at 25 °C |

| Seawater Immersion | < 0.01 mm/year corrosion rate | 0.05–0.10 mm/year; localized pitting |

| Acidic media (HCl 1 M) | Passive up to ~ 200 °C | Severe uniform attack; ~ 0.5 mm/year |

| Oxidizing acids (HNO₃ 10%) | Excellent; negligible attack | Good; ~ 0.02 mm/year |

| High‑temperature oxidation | Stable to ~ 600 °C | Stable to ~ 800 °C (intermittent) |

Localized Corrosion Susceptibility

- Pitting & Crevice Corrosion

-

- Titanium: Pitting potential > +2.0 V vs. SCE; essentially immune under normal service.

- 316 SS: Pitting potential ~ +0.4 V vs. SCE; crevice corrosion common in stagnant chlorides.

- Stress‑Corrosion Cracking (SCC)

-

- Titanium: Virtually SCC‑free in all aqueous media.

- Austenitic SS: Prone to SCC in warm chloride environments (e.g., above 60 °C).

Surface Treatments & Coatings

Titanium

- Anodizing: Enhances oxide thickness (up to 50 nm), allows color marking.

- Micro‑Arc Oxidation (MAO): Creates a 10–30 µm ceramic‑like layer; boosts wear and corrosion resistance.

- Plasma Nitriding: Improves surface hardness and fatigue life.

Stainless Steel

- Acid Passivation: Nitric or citric acid removes free iron, thickens Cr₂O₃ film.

- Electropolishing: Smooths microscale peaks and valleys, reducing crevice sites.

- PVD Coatings (e.g., TiN, CrN): Adds a thin hard barrier for wear and chemical attack.

5. Thermal Properties & Heat Treatment of Titanium vs Stainless Steel

Thermal behavior influences material choice for components exposed to temperature swings or high‑heat service.

Titanium vs stainless steel differ significantly in heat conduction, expansion, and treatability.

Thermal Conductivity & Expansion

| Property | Ti‑6Al‑4V | 304 Stainless Steel |

| Thermal Conductivity (W/m·K) | 6.7 | 16.2 |

| Specific Heat Capacity (J/kg·K) | 560 | 500 |

| Coefficient of Thermal Expansion (20–100 °C, 10⁻⁶/K) | 8.6 | 17.3 |

Heat‑treatable vs. non‑hardenable grades

Martensitic stainless steels are heat-treatable and can be hardened and tempered to achieve desired mechanical properties.

Austenitic stainless steels are non-hardenable by heat treatment, but their strength can be increased through cold working.

Duplex steels rely on controlled heat input during welding, with no further hardening.

Titanium alloys, such as Ti-6Al-4V, can be heat-treated to optimize their mechanical properties, including solution annealing, aging, and stress relieving.

High‑Temperature Stability & Oxidation

- Titanium resists oxidation up to ~ 600 °C in air. Beyond this, embrittlement from oxygen diffusion can occur.

- Stainless Steel (304/316) remains stable to ~ 800 °C intermittently, with continuous use up to ~ 650 °C.

- Scale Formation: SS forms protective chromia scales; titanium’s oxide adheres strongly, but thick scales can spall under cycling.

6. Fabrication & Joining of Titanium vs Stainless Steel

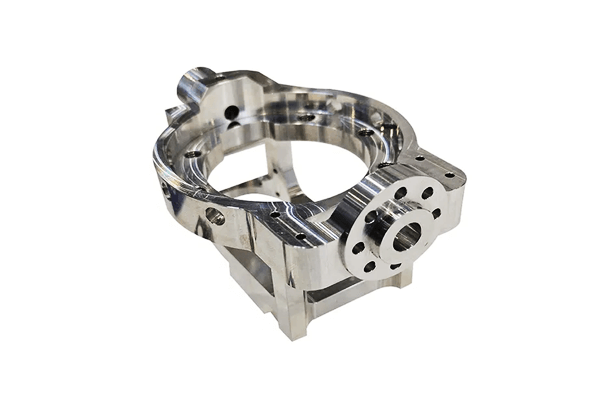

Formability and machinability

Austenitic stainless steels are highly formable and can be easily shaped using processes like deep drawing, stamping, and bending.

Ferritic and martensitic stainless steels have lower formability. Titanium is less formable at room temperature due to its high strength, but hot-forming techniques can be used to shape it.

Machining titanium is more difficult than stainless steel due to its low thermal conductivity, high strength, and chemical reactivity, which can lead to rapid tool wear.

Welding and brazing challenges

Welding stainless steel is a well-established process, with various techniques available. However, care must be taken to prevent issues such as corrosion at the weld site.

Welding titanium is more challenging as it requires a clean environment and inert gas shielding to prevent contamination from oxygen, nitrogen, and hydrogen, which can degrade the mechanical properties of the weld.

Brazing can also be used for both materials, but different filler metals and process parameters are required.

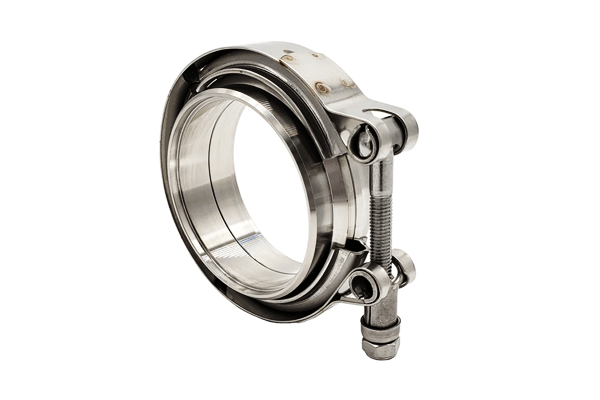

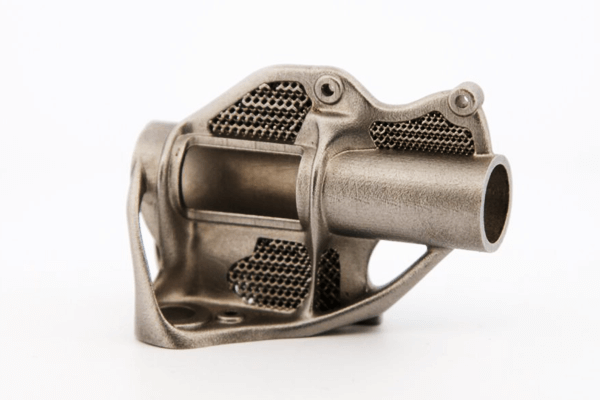

Additive manufacturing (3D printing) readiness

Both titanium and stainless steel are suitable for additive manufacturing.

Titanium’s high strength-to-weight ratio makes it attractive for aerospace and medical applications produced via 3D printing.

Stainless steel is also widely used in 3D printing, especially for producing complex geometries in consumer goods and medical instruments.

Surface finishing (polishing, passivation, anodizing)

Stainless steel can be polished to a high shine, and passivated to enhance its corrosion resistance.

Titanium can be polished and anodized to create different surface finishes and colors, as well as to improve its corrosion and wear resistance.

7. Biocompatibility & Medical Use

In medical applications, tissue compatibility, corrosion resistance in body fluids, and long‑term stability determine material suitability.

Titanium’s Implant History & Osseointegration

- Early Adoption (1950s):

-

- Research by Per-Ingvar Brånemark revealed that bone bonds directly to titanium (osseointegration).

- First successful dental implants used CP titanium, demonstrating > 90% success rates at 10 years.

- Osseointegration Mechanism:

-

- Native TiO₂ surface layer supports bone cell attachment and proliferation.

- Roughened or anodized surfaces increase bone–implant contact area by 20–30%, improving stability.

- Current Uses:

-

- Orthopedic implants: Hip and knee joints (Ti‑6Al‑4V ELI)

- Dental fixtures: Screws, abutments

- Spinal devices: Cages and rods

Stainless Steel in Surgical Tools & Temporary Implants

- Surgical Instruments:

-

- 304L and 316L stainless steels dominate scalpels, forceps, and clamps due to ease of sterilization and high strength.

- Autoclave cycles (> 1,000) induce no significant corrosion or fatigue failures.

- Temporary Fixation Devices:

-

- Pins, screws, and plates crafted from 316L offer sufficient strength for fracture repair.

- Removal within 6–12 months minimizes concerns over nickel release or sensitization.

Nickel Allergy Considerations

- Nickel Content in 316L SS: ~ 10–12% by weight

- Prevalence of Nickel Sensitivity: Affects 10–20% of the population, leading to dermatitis or systemic reactions.

Mitigation Strategies:

- Surface Coatings: Parylene, ceramic, or PVD barriers reduce nickel ion release by up to 90%.

- Alternative Alloys: Use nickel‑free stainless (e.g., 2205 duplex) or titanium for allergy‑prone patients.

Sterilization & Long‑Term Tissue Response

| Sterilization Method | Titanium | Stainless Steel |

| Autoclave (steam) | Excellent; no surface change | Excellent; requires passivation check |

| Chemical (e.g., glutaraldehyde) | No adverse effect | May accelerate pitting if chloride‑contaminated |

| Gamma irradiation | No impact on mechanical properties | Slight surface oxidation possible |

- Titanium exhibits minimal ion release (< 0.1 µg/cm²/day) and elicits a mild foreign‑body response, forming a thin, stable fibrous capsule.

- 316L SS releases iron, chromium, nickel ions at higher rates (0.5–2 µg/cm²/day), potentially provoking local inflammation in rare cases.

9. Applications of Titanium vs Stainless Steel

Stainless steel vs titanium are both widely used engineering materials known for their corrosion resistance and strength,

but their application fields differ significantly due to differences in weight, cost, mechanical properties, and biocompatibility.

Titanium Applications

Aerospace and Aviation

- Airframes and landing gear components

- Jet engine parts (compressor blades, casings, discs)

- Spacecraft structures and fasteners

Rationale: High strength-to-weight ratio, excellent fatigue resistance, and corrosion resistance in extreme environments.

Medical and Dental

- Orthopedic implants (hip and knee replacements)

- Dental implants and abutments

- Surgical instruments

Rationale: Exceptional biocompatibility, non-toxicity, and resistance to body fluids.

Marine and Offshore

- Submarine hulls

- Heat exchangers and condenser tubing in seawater

- Offshore oil and gas platforms

Rationale: Superior corrosion resistance in chloride-rich and saltwater environments.

Chemical Processing Industry

- Reactors, vessels, and piping for handling corrosive acids (e.g., hydrochloric, sulfuric acid)

Rationale: Inert to most chemicals and oxidizing agents at high temperatures.

Sports and Consumer Goods

- High-performance bicycles, golf clubs, and watches

Rationale: Lightweight, durable, and premium aesthetics.

Stainless Steel Applications

Architecture and Construction

- Cladding, handrails, structural beams

- Roofing, elevator doors, and facade panels

Rationale: Aesthetic appeal, corrosion resistance, and structural strength.

Food and Beverage Industry

- Food processing equipment, tanks, and sinks

- Brewery and dairy equipment

Rationale: Hygienic surface, resistance to food acids, easy to sterilize.

Medical Devices and Tools

- Surgical instruments (scalpels, forceps)

- Hospital equipment and trays

Rationale: High hardness, corrosion resistance, and ease of sterilization.

Automotive Industry

- Exhaust systems, trim, and fasteners

- Fuel tanks and frames

Rationale: Corrosion resistance, formability, and moderate cost.

Industrial Equipment and Chemical Processing

- Pressure vessels, heat exchangers, and tanks

- Pumps, valves, and piping systems

Rationale: High-temperature resistance and resistance to a broad range of chemicals.

10. Pros and Cons of Titanium vs Stainless Steel

Both stainless steel and titanium offer excellent corrosion resistance and strength, but they diverge in areas such as cost, weight, machinability, and biocompatibility.

Pros of Titanium

- High Strength-to-Weight Ratio

Titanium is about 45% lighter than stainless steel while offering comparable or even superior strength. - Excellent Corrosion Resistance

Especially resistant to chlorides, saltwater, and many aggressive acids—ideal for marine and chemical environments. - Superior Biocompatibility

Non-toxic, non-reactive with bodily fluids—preferred in medical implants and surgical applications. - Fatigue and Creep Resistance

Performs well under cyclic loading and high-temperature stress over time. - Thermal Stability

Retains mechanical properties at elevated temperatures (>400°C) better than most stainless steels.

Cons of Titanium

- High Cost

Raw material and processing costs are significantly higher than stainless steel (up to 10× or more). - Difficult to Machine and Weld

Low thermal conductivity and work-hardening behavior increase tool wear and require specialized techniques. - Limited Availability of Alloys

Fewer commercial grades and alloy options compared to the stainless steel family. - Lower Wear Resistance

In uncoated conditions, titanium may gall or wear under friction-intensive conditions.

Pros of Stainless Steel

- Cost-Effective

Widely available and much cheaper than titanium, particularly in grades like 304 or 430. - Excellent Corrosion Resistance

Especially in oxidizing environments and mild acids; grades like 316 excel in chloride-rich settings. - High Strength and Toughness

Good load-bearing capability with options tailored for hardness, ductility, or strength. - Good Fabrication Properties

Readily welded, machined, and formed using standard tools—ideal for high-volume production. - Versatile Alloys and Finishes

Dozens of commercial grades and surface finishes for diverse applications.

Cons of Stainless Steel

- Heavier than Titanium

Nearly 60% denser—unsuitable for weight-sensitive applications (e.g., aerospace, implants). - Susceptibility to Chloride Pitting

Especially in lower grades (e.g., 304) in marine or salt-spray environments. - Lower Biocompatibility (Some Grades)

Can cause allergic reactions or leach nickel—less preferred in long-term implantable devices. - Magnetism (in Some Grades)

Ferritic and martensitic stainless steels may be magnetic, which could interfere in sensitive applications.

11. Standards, Specifications & Certification

Titanium Standards

- ASTM F136: Ti‑6Al‑4V ELI for implants

- AMS 4911: Aerospace titanium

- ISO 5832-3: Implants—unalloyed titanium

Stainless Steel Standards

- ASTM A240: Plate, sheet

- ASTM A276: Bars and rods

- EN 10088: Stainless steel grades

- ISO 7153-1: Surgical instruments

12. Comparison Table: Titanium vs Stainless Steel

| Property / Characteristic | Titanium (e.g., Ti-6Al-4V) | Stainless Steel (e.g., 304, 316, 17-4PH) |

| Density | ~4.5 g/cm³ | ~7.9 – 8.1 g/cm³ |

| Specific Strength (Strength-to-Weight) | Very high | Moderate |

| Tensile Strength | ~900–1,100 MPa (Ti-6Al-4V) | ~500–1,000 MPa (depending on grade) |

| Yield Strength | ~830 MPa (Ti-6Al-4V) | ~200–950 MPa (e.g., 304 to 17-4PH) |

| Elastic Modulus | ~110 GPa | ~190–210 GPa |

| Corrosion Resistance | Excellent (especially in chlorides and seawater) | Excellent (varies by grade; 316 > 304) |

| Oxide Layer | TiO₂ (very stable and self-healing) | Cr₂O₃ (protective but susceptible to pitting in chlorides) |

| Hardness (HV) | ~330 HV (Ti-6Al-4V) | ~150–400 HV (grade dependent) |

| Thermal Conductivity | ~7 W/m·K | ~15–25 W/m·K |

Melting Point |

~1,660°C | ~1,400–1,530°C |

| Weldability | Challenging; requires inert atmosphere | Generally good; care needed to avoid sensitization |

| Machinability | Difficult; causes tool wear | Better; especially with free-machining grades |

| Biocompatibility | Excellent; ideal for implants | Good; used in surgical tools and temporary implants |

| Magnetic Properties | Non-magnetic | Austenitic: non-magnetic; Martensitic: magnetic |

| Cost (Raw Material) | High (~5–10× stainless steel) | Moderate |

| Recyclability | High | High |

13. Conclusion

Titanium and stainless steel each have distinct advantages. Titanium is ideal where lightweight strength, fatigue resistance, or biocompatibility are mission-critical.

Stainless steel, by contrast, offers versatile mechanical properties, easy fabrication, and cost efficiency.

Material selection should be application-specific, considering not just performance, but also long-term cost, manufacturability, and regulatory standards.

A total-cost-of-ownership approach often reveals titanium’s true value, particularly in demanding environments.

FAQs

Is titanium stronger than stainless steel?

Titanium has a higher specific strength (strength-to-weight ratio) than stainless steel, meaning it provides more strength per unit mass.

However, some hardened stainless steel grades (e.g., 17-4PH) can exceed titanium in absolute tensile strength.

Is stainless steel magnetic while titanium is not?

Yes. Austenitic stainless steels (e.g., 304, 316) are non-magnetic, but martensitic and ferritic grades are magnetic.

Titanium, in contrast, is non-magnetic, making it ideal for applications like MRI-compatible medical devices.

Can both titanium and stainless steel be welded?

Yes, but with different requirements. Stainless steel is easier to weld using standard methods (e.g., TIG, MIG).

Titanium welding requires a fully inert atmosphere (argon shielding) to avoid contamination and embrittlement.

Which material is better for high-temperature applications?

Stainless steel, particularly heat-resistant grades like 310 or 446, performs well at sustained high temperatures.

Titanium resists oxidation up to ~600°C, but its mechanical properties degrade beyond that.

Can titanium and stainless steel be used together in assemblies?

Caution is advised. Galvanic corrosion can occur when titanium and stainless steel are in contact in the presence of an electrolyte (e.g., water), especially if stainless steel is the anodic material.