Bronze CNC Machining Services

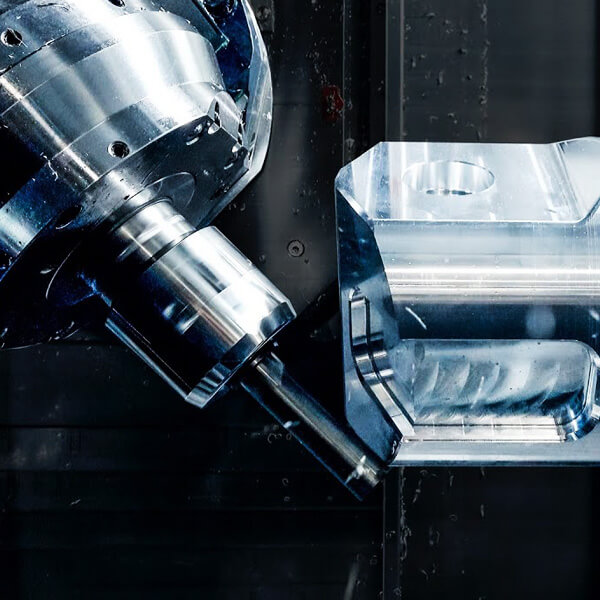

LangHe’s CNC machining services excel in the production of custom bronze parts, utilizing advanced CNC lathes and both 3-axis and 5-axis CNC milling machines. We work with a variety of common bronze grades, such as C932, C954, and other bronze alloys, to satisfy the demanding requirements of industries including marine, automotive, industrial machinery, and electronics.

Focusing on precision and durability, LangHe delivers high-quality bronze components ideal for applications like bushings, bearings, valves, and decorative hardware.

Whether you need prototypes or large-scale production, LangHe is your reliable partner for expert bronze CNC machining services tailored to your exact specifications.