Easy to understand how solution aging & precipitation hardening transform metals—learn process steps, microstructural mechanisms.

In the world of metal heat treatment, two terms often appear together—solution aging & precipitation hardening.

While they may seem interchangeable at times, their subtle distinctions and synergistic roles are key to understanding modern alloy strengthening mechanisms.

Let’s break down these concepts, clarify the confusion, and uncover the metallurgical magic behind them.

1. What Is Solution Aging and How Does It Relate to Precipitation Hardening?

Many engineers and metallurgists encounter these terms in heat treatment protocols.

One moment, a manual calls for solution aging, and the next, a specialist refers to precipitation treatment—leaving even experienced professionals puzzled.

In truth, the two are closely connected but not identical.

- Solution aging refers to the heat treatment process, consisting of two main stages: solution treatment followed by aging.

- Precipitation hardening, on the other hand, refers to the microstructural and strengthening mechanism that occurs during aging. It focuses on the formation of fine precipitates that enhance material strength.

Thus, while solution aging is the process, precipitation hardening is the result.

2. Solid Solution Treatment: Enabling a “Fusion Party” for Alloy Phases

Definition & Purpose

Solution treatment (also called solution quenching) involves heating an alloy into its single‑phase field, above the solvus (solid‑solution) line but below the solidus,

holding it long enough to dissolve all secondary phases, then quenching rapidly to “freeze in” a supersaturated solid solution.

This metastable state contains far more solute atoms in the matrix than equilibrium allows at room temperature,

setting the stage for controlled precipitation and peak mechanical properties during subsequent aging.

Key Steps

- Heating to the Single‑Phase Region

-

- Temperature Selection: Typically 20–50 °C below the solidus to avoid partial melting.

- Homogenization Soak: Duration determined by diffusion kinetics (t ≈ L²/π²D), where L corresponds to half the maximum diffusion distance (e.g., grain size or section half‑thickness).

- Rapid Quenching

-

- Media Choices: Water, polymer solution, oil, or forced air, selected to balance cooling rate with risk of distortion or cracking.

- Objective: Prevent any premature re‑precipitation of dissolved phases, thus preserving maximum supersaturation.

Thermodynamic Considerations

- Supersaturation: The quench traps a high‑temperature composition into a room‑temperature matrix, creating a driving force for later precipitation.

- Metastability: Though metastable, this supersaturated solid solution is prime for nucleating fine, uniformly dispersed precipitates under controlled aging.

Processing Parameters & Control

| Parameter | Typical Range | Effect if Mis‑Controlled |

|---|---|---|

| Solution Temp. | Al alloys: 480–550 °C Ti alloys: 930–995 °C Ni‐base: 1,020–1,060 °C Steels: 1,000–1,050 °C |

Too high → grain coarsening, incipient melting Too low → incomplete dissolution |

| Soak Time | 30 min–8 h (depending on section thickness) | Under‑soak → residual undissolved particles Over‑soak → excessive grain growth |

| Quench Medium | Water, polymer, oil, air | Slow quench → partial precipitation during cooldown Fast quench → distortion, cracking in thick sections |

| Quench Agitation | Stirred bath or spray | Improves uniformity of cooling; reduces gradients |

Easy to Understand: The “Fusion Party” Analogy

Imagine each alloy phase as a distinct party guest.

At high temperature, the room becomes so warm and energetic that every guest (solute atom) mingles freely with the host phase, forming one homogeneous crowd.

The moment the music stops (rapid quench), nobody has the energy or time to regroup into separate clusters—everyone remains uniformly distributed.

Super Down‑to‑Earth: “Ice and Fire” Metaphor

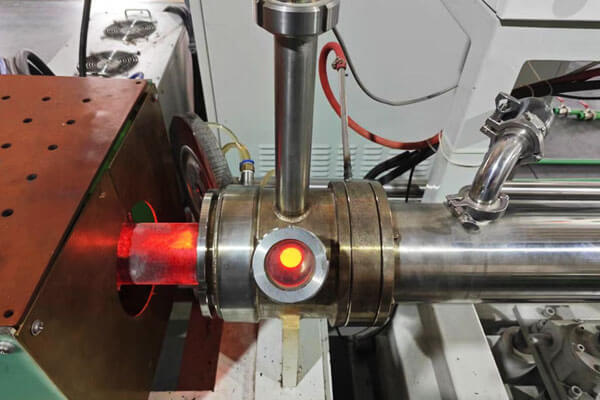

If you prefer a more visceral image, think of heating the metal “red‑hot” (fire) and then plunging it into water or oil (ice).

This sudden plunge locks the atoms in place, like instantaneously freezing a flowing lava sculpture into a rigid, glass‑like form.

That “ice and fire” thrill is exactly what creates the supersaturated matrix for your alloy’s next act: fine precipitate strengthening.

3. Aging Treatment: The “Growth and Transformation” of Metals

Definition & Purpose

Aging treatment follows solution quenching to deliberately precipitate fine second‑phase particles from the supersaturated solid solution.

By holding the alloy at a controlled temperature—either at room temperature (natural aging) or at an elevated but moderate temperature (artificial aging),

solute atoms diffuse and nucleate nanoscale precipitates that impede dislocation motion and substantially increase strength and hardness.

Key Steps

- Natural Aging

-

- Conditions: Ambient temperature (20–25 °C).

- Time Frame: Hours to days (e.g., 4–7 days for Al‑Mg‑Si alloys).

- Mechanism: Slow diffusion forms extremely fine clusters (GP‑zones) that gradually evolve into coherent precipitates.

- Artificial Aging

-

- Conditions: Elevated temperatures, typically 100–200 °C for aluminum alloys; 400–600 °C for steels and titanium alloys.

- Time Frame: Minutes to several hours, depending on temperature and alloy system.

- Mechanism: Accelerated diffusion produces controlled nucleation and growth of semi‑coherent precipitates (e.g., θ′ in Al‑Cu, γ′ in Ni superalloys).

Kinetic Considerations

- Nucleation Rate (I): Peaks at an intermediate undercooling; overly high temperature reduces driving force, while overly low temperature slows diffusion.

- Growth Rate (G): Increases with temperature but risks coarsening; optimal aging requires balancing I and G to maximize particle density and minimize size.

Microstructure–Property Evolution

- Under‑Aged State: Few, very small precipitates → modest strength gain, high ductility.

- Peak‑Aged State: High density of coherent precipitates → maximum yield strength, moderate toughness.

- Over‑Aged State: Precipitates coarsen and lose coherence → slight strength drop, improved ductility.

Easy to Understand: The “Bread Rising” Analogy

Think of solution‑quenched metal as dough that’s been mixed and kneaded—uniform but not yet reaching its full potential.

- Natural Aging is like letting the dough rise slowly on the counter: it eventually forms structure on its own, but takes time.

- Artificial Aging is like placing the dough in a warm proofing box: it rises faster and more predictably.

Super Down‑to‑Earth: The “Time‑Release” Candy Metaphor

Imagine a candy with flavor crystals embedded inside. Initially, you have a “supersaturated” candy with all the sugar mixed in.

Over time (or with a bit of warmth), tiny sugar crystals emerge just beneath the surface—giving bursts of sweetness when you bite down.

Aging treatment is the metallurgical equivalent: time (and heat) coax out minute “sugar” precipitates that make the metal stronger and more “flavorful.”

4. Precipitation Hardening: The “Secret Weapon” of Metal Strengthening

Definition & Scope

Precipitation hardening (also called age hardening) is the process by which a supersaturated solid solution is transformed—under carefully controlled temperature and time,

into a finely dispersed network of second‑phase particles that dramatically impede dislocation motion and boost yield strength and hardness.

Core Steps

- Supersaturation Preparation

-

- Through solution treatment and rapid quenching, the matrix traps an excess of alloying atoms well beyond their equilibrium solubility at ambient temperature.

- Controlled Precipitation (Aging)

-

- At room temperature (natural aging) or at elevated temperatures (typically 400–800 °C for steels, 150–200 °C for aluminum alloys), those solute atoms diffuse and nucleate as nanoscale particles.

- Dispersion Strengthening

-

- The uniform dispersion of coherent or semi‑coherent precipitates generates local stress fields;

dislocations must either cut through or bow around each obstacle, requiring substantially higher applied stresses.

- The uniform dispersion of coherent or semi‑coherent precipitates generates local stress fields;

Strengthening Mechanisms

- Coherency Strain Hardening: Coherent precipitates distort the surrounding lattice, creating elastic stress fields that repel dislocations.

- Order Hardening: Highly ordered precipitates require dislocations to cut through an ordered lattice, raising the critical shear stress.

- Orowan Bypassing: Larger, semi‑coherent or incoherent particles force dislocations to bow and loop between them, generating a significant back‑stress.

Industrial Examples

- PH Stainless Steels (e.g. 17‑4 PH): After solution or cold work, aging at 480–620 °C precipitates copper‑rich clusters, achieving tensile strengths > 1,200 MPa while retaining corrosion resistance.

- Austenitic Precipitation‑Hardened Steels: Aging in the 400–500 °C or 700–800 °C windows produces intermetallic phases for applications demanding ultra‑high strength.

- Nickel‑Base Superalloys: Solution‑treat above the γ′ solvus, then age at 700–800 °C to precipitate Ni₃(Al,Ti) cuboids—critical for creep resistance in turbine blades.

Easy to Understand: The “Two‑Stage Workout” Analogy

Think of precipitation hardening as a fitness regimen for metals:

- Warm‑Up (Solution Treatment): Loosening stiff muscles—dissolving all rigid phases into a single, pliable mass.

- Strength Training (Aging): Introducing carefully calibrated resistance—tiny precipitates—that force the metal’s internal “fibers” (dislocations) to work harder, building strength and rigidity.

Super Down‑to‑Earth: The “Waffle Iron” Metaphor

Imagine pouring batter (the supersaturated solution) into a hot waffle iron (aging temperature).

As the iron heats and presses the batter, crisp pockets form in a uniform grid.

These crispy ridges are like nano‑precipitates—they give the waffle (the metal) its extra rigidity and bite, just as precipitates bolster the alloy’s mechanical “crispness.”

5. Why Not Just Age Without Solution Treatment?

At first glance, skipping the solution treatment step and proceeding directly to aging might seem more efficient.

However, this shortcut undermines the very foundation of precipitation hardening. Here’s why solution treatment is essential before aging in most alloy systems:

To Achieve a Supersaturated Solid Solution

The key to effective precipitation hardening lies in creating a supersaturated solid solution—a non-equilibrium state where solute atoms are present in the matrix at levels far beyond their solubility at room temperature.

- Without solution treatment, much of the second phase (e.g., intermetallic compounds or eutectic phases) remains undissolved, locked at grain boundaries or within segregated zones.

- These undissolved coarse particles cannot be re-precipitated uniformly during aging, and as such, strengthening is severely limited.

To Ensure Precipitate Fineness and Uniform Distribution

Solution treatment dissolves the coarse second-phase particles, allowing for controlled reprecipitation during aging:

- This results in fine, uniformly distributed precipitates, which are far more effective in impeding dislocation motion.

- Skipping this step typically yields large, incoherent particles that offer little strengthening and may even promote brittleness or reduce toughness.

To Enhance Workability Before Final Hardening

Solution-treated alloys are generally softer and more ductile, which is ideal for forming, machining, or other post-processing steps:

- After shaping is complete, aging then hardens the alloy to its final strength.

- If aging were done first without solution treatment, the part would remain brittle and hard to process, increasing the risk of cracking or failure during manufacturing.

To Activate the Right Precipitation Sequence

Many alloys—especially precipitation-hardenable aluminum and titanium systems—follow a precise aging sequence (e.g., GP zones → θ” → θ’):

- Solution treatment resets the microstructure, making the alloy responsive to this sequence.

- Skipping solution treatment often bypasses the formation of the most effective strengthening phases.

Easy to Understand: The “Baking a Cake” Analogy

Imagine trying to bake a cake by simply leaving raw dough at room temperature for a few days instead of baking it first:

- Sure, it might dry out or harden slightly—but it will never have the structure, flavor, or integrity of a properly baked cake.

- Solution treatment is the baking; aging is the cooling and setting phase where the structure matures.

In Summary:

Solution aging and precipitation hardening are two perspectives—process vs. mechanism—on the same two‑step heat‑treatment that underpins the high strength of countless modern alloys.

By mastering both stages, metallurgists tune strength, ductility, and toughness to exacting specifications.

FAQs

How does solid solution austenite dissolve the second phase?

When the alloy is heated into the single‑phase (austenite) region, the solubility of alloying elements increases sharply.

This drives the existing second‑phase particles to dissolve back into the austenitic matrix, creating a uniform, supersaturated solution.

Why do tiny precipitates strengthen the metal so effectively?

Fine precipitates are like a dense forest of pinning points for dislocations.

As dislocations try to slip past, they must either cut through or bow around each precipitate—requiring much higher applied stress and thus increasing yield strength.

Why does aluminum‑alloy solution treatment reduce hardness, while steel quenching increases hardness?

- Aluminum alloys form no martensite; solution quenching simply creates a soft, supersaturated solid solution, so initial hardness is low until aging.

- Low‑carbon steels form martensite upon quenching—a hard, distorted phase—so quenching itself yields high hardness (but low toughness).