1. Introduction

Duplex Stainless Steel (DSS) has become indispensable in applications that require both durability and performance.

Duplex Stainless Steel 2205 (UNS S31803/S32205), with its unique dual-phase microstructure of nearly equal parts austenite and ferrite, offers enhanced mechanical and corrosion-resistant properties.

Engineers and industry experts prioritize 2205 for critical applications in oil & gas, chemical processing, marine environments, and construction due to its balanced performance and economic advantages.

This article explores the evolution, properties, manufacturing techniques, applications, and future trends related to 2205 DSS.

We systematically examine its chemical composition, mechanical behavior, and environmental benefits, along with the challenges manufacturers face and innovations on the horizon.

2. Evolution of Duplex Stainless Steel 2205

The development of Duplex Stainless Steel 2205 represents a critical milestone in the metallurgical evolution of stainless steels.

This section examines the origins, standardization, and industrial adoption of this material, demonstrating how decades of innovation have led to its prominence in demanding engineering applications.

Definition and Classification of Duplex Stainless Steels

Duplex stainless steels are distinguished by their dual-phase microstructure, comprising nearly equal proportions of ferrite (α) and austenite (γ).

This unique configuration grants them a hybrid performance profile—exhibiting both the high strength and chloride stress corrosion cracking resistance of ferritic steels, and the toughness and weldability of austenitic steels.

Duplex steels are generally classified into three categories:

- Lean duplex grades (e.g., 2101, with low nickel and molybdenum content),

- Standard duplex grades (notably 2205),

- Super duplex grades (e.g., 2507, for ultra-aggressive environments).

Among these, Duplex Stainless Steel 2205—standardized under UNS S31803 and improved to UNS S32205—has emerged as the workhorse of the group, balancing performance with economic efficiency.

It complies with key international standards, such as:

- ASTM A240/A240M (plate, sheet, and strip),

- EN 10088-2 (general corrosion-resistant stainless steel),

- ISO 15156-3/NACE MR0175 (materials for use in H₂S-containing oil and gas environments).

Historical Development and Metallurgical Refinement

The concept of duplex stainless steels dates back to the early 1930s, with the first patents filed in Sweden by Avesta (now Outokumpu).

However, early duplex alloys suffered from poor toughness and weldability due to high carbon and insufficient control over nitrogen content.

It was not until the 1970s and 1980s that significant metallurgical breakthroughs,

especially the controlled addition of nitrogen and low-carbon processing, allowed the emergence of commercially viable grades like 2205.

The deliberate inclusion of ~0.14–0.25% nitrogen not only strengthened the austenitic phase but also delayed the formation of detrimental intermetallic phases such as sigma (σ).

The transition from S31803 to S32205 came after metallurgical optimization in the 1990s, with the latter offering:

- Enhanced phase balance (more stable austenite),

- Improved pitting resistance (PREN ≥ 35),

- Better toughness and weldability.

As such, Duplex 2205 became an industry standard by the early 2000s, replacing many austenitic grades in aggressive environments where both strength and corrosion resistance were critical.

Technological Influence and Standardization

The adoption of Duplex 2205 also influenced the evolution of fabrication practices.

New welding techniques—such as gas tungsten arc welding (GTAW) with controlled heat input—and enhanced thermal treatments were developed to maintain the optimal duplex phase balance.

This innovation ecosystem spurred the integration of 2205 into advanced structural components, heat exchangers, and reactor vessels.

Moreover, the push for global standardization helped build industry trust and broadened market access.

International standards like ASME SA-240, DNV-GL RP F112, and API 5LD specifically include guidelines for the use of 2205 DSS, highlighting its recognized reliability in pressure-bound and safety-critical applications.

3. Chemical Composition and Microstructural Design

The performance excellence of Duplex Stainless Steel 2205 lies in its meticulously engineered chemical composition and its finely balanced dual-phase microstructure.

This synergy not only enhances mechanical and corrosion resistance properties but also enables the alloy to operate efficiently in challenging environments where traditional stainless steels often fall short.

In this section, we will delve into the elemental composition of 2205 and the significance of its microstructural design, followed by a comparative analysis with other stainless steel families.

Chemical Composition of Duplex 2205

Duplex Stainless Steel 2205, primarily standardized under UNS S32205, features a carefully optimized blend of elements designed to stabilize both ferritic and austenitic phases.

The typical composition range (in weight%) is as follows:

| Element | Content (%) | Function |

|---|---|---|

| Chromium (Cr) | 21.0 – 23.0 | Enhances general corrosion and oxidation resistance |

| Nickel (Ni) | 4.5 – 6.5 | Stabilizes the austenitic phase, improves toughness and weldability |

| Molybdenum (Mo) | 2.5 – 3.5 | Increases pitting and crevice corrosion resistance |

| Nitrogen (N) | 0.14 – 0.20 | Strengthens the austenitic phase, suppresses intermetallic phase formation |

| Manganese (Mn) | ≤ 2.0 | Deoxidizer, improves hot working properties |

| Silicon (Si) | ≤ 1.0 | Enhances oxidation resistance during welding |

| Carbon (C) | ≤ 0.030 | Kept low to minimize carbide precipitation and intergranular corrosion |

| Iron (Fe) | Balance | Base element providing structural matrix |

Dual-Phase Microstructural Architecture

At the core of 2205’s performance is its duplex microstructure, typically consisting of approximately 50% ferrite and 50% austenite after solution annealing.

This two-phase structure is achieved through precise control during hot working and heat treatment processes, usually at temperatures ranging from 1040°C to 1100°C, followed by rapid quenching.

➤ Ferrite (α) Phase

Provides high strength, magnetic properties, and superior resistance to stress corrosion cracking (SCC) and chloride-induced corrosion.

➤ Austenite (γ) Phase

Contributes to toughness, ductility, and enhanced resistance to fatigue and impact loading, especially at lower temperatures.

This microstructural balance imparts a tensile strength of ≥ 620 MPa, yield strength of ≥ 450 MPa, and elongation of 25–30%, far surpassing many conventional stainless steels.

Additionally, the dual-phase nature delays the onset of localized corrosion and improves resistance to sulfide stress corrosion cracking, making 2205 ideal for sour gas applications.

4. Physics, Mechanical, and Corrosion Properties of Duplex Stainless Steel 2205

Duplex Stainless Steel 2205 (UNS S32205) is renowned for its exceptional physical, mechanical, and corrosion-resistant properties.

In this section, we will analyze the physical attributes, mechanical strength, and corrosion behavior that define the material’s engineering superiority.

Physical Properties

The fundamental physical characteristics of 2205 make it a robust candidate for environments requiring thermal stability, dimensional consistency, and magnetic response.

| Property | Value |

|---|---|

| Density | 7.8 g/cm³ |

| Melting Range | 1350 – 1400°C |

| Specific Heat Capacity (20°C) | ~460 J/kg·K |

| Thermal Conductivity (at 20°C) | 19 W/m·K |

| Electrical Resistivity | ~0.8 µΩ·m |

| Magnetic Behavior | Ferromagnetic due to ferrite |

| Thermal Expansion Coefficient | ~13.7 x10⁻⁶ /°C (0–100 °C) |

Mechanical Properties

One of the standout features of Duplex 2205 is its impressive mechanical performance,

which bridges the gap between ferritic strength and austenitic ductility.

The alloy demonstrates high tensile strength, excellent yield strength, and reliable fatigue performance.

| Mechanical Property | Typical Value |

|---|---|

| Tensile Strength | ≥ 620 MPa |

| Yield Strength (0.2% offset) | ≥ 450 MPa |

| Elongation at Break | ≥ 25% |

| Modulus of Elasticity | ~200 GPa |

| Hardness (Brinell) | ~290 HB |

| Impact Toughness | > 100 J (at -40 °C) |

| Fatigue Strength (10⁷ cycles) | ~275 MPa (air) |

Weldability and Toughness

Unlike many high-strength materials, Duplex 2205 maintains excellent impact toughness down to sub-zero temperatures,

and when welded properly, retains its mechanical integrity.

However, excessive heat input during welding must be avoided to prevent the formation of embrittling intermetallic phases such as the sigma phase.

Corrosion Resistance

Duplex 2205 exhibits superior corrosion resistance, particularly in aggressive environments rich in chlorides and sulfides.

Its high PREN (Pitting Resistance Equivalent Number) of 35–40 is largely attributed to its chromium (21–23%), molybdenum (2.5–3.5%), and nitrogen (~0.15%) content.

Pitting and Crevice Corrosion Resistance

The alloy offers significant protection against localized corrosion, such as pitting and crevice corrosion.

In ASTM G48 ferric chloride tests, Duplex 2205 resists pitting at temperatures up to 35–40 °C, which is significantly higher than 316L (typically up to 25–30 °C).

Stress Corrosion Cracking (SCC)

A major advantage of the duplex structure is its exceptional resistance to chloride-induced SCC, a common failure mode in austenitic stainless steels.

The ferritic phase hinders crack propagation, even in harsh environments like seawater, brine, and caustic chemical streams.

General Corrosion and Erosion Resistance

Duplex 2205 resists general corrosion in a wide range of acidic and basic environments. Its performance is particularly effective in:

- Seawater (pH ~8.1) with chloride levels above 20,000 ppm

- Sour gas conditions (containing H₂S)

- Phosphoric and acetic acids

- Erosive slurry transport systems

High-Temperature and High-Pressure Performance

Although Duplex 2205 is not typically used in extreme high-temperature service (above 300 °C), it maintains good structural stability under moderate heat and high pressure.

- Temperature Limit: Up to ~300 °C for continuous service due to risk of phase embrittlement.

- Pressure Capabilities: Excellent in high-pressure pipelines and pressure vessels due to its high yield strength.

5. Manufacturing and Processing: Precision-Critical Considerations

The exceptional properties of Duplex Stainless Steel 2205—namely its high strength, superior corrosion resistance, and balanced toughness,

are only fully realized through carefully controlled manufacturing and processing techniques.

The material’s dual-phase structure makes it especially sensitive to thermal cycles, alloying precision, and mechanical treatments.

In this section, we examine the methods, challenges, and critical considerations involved in producing and processing 2205 to meet demanding performance standards.

Production Methods and Metallurgical Integrity

The production of Duplex 2205 typically begins with electric arc furnace (EAF) melting, followed by argon oxygen decarburization (AOD) or vacuum oxygen decarburization (VOD) to refine the alloy.

These advanced refining steps are vital for controlling carbon, sulfur, and nitrogen levels—elements that can strongly influence phase balance and corrosion behavior.

For critical applications, secondary melting processes such as:

- Vacuum Arc Remelting (VAR)

- Electroslag Remelting (ESR)

They are employed to enhance homogeneity, reduce non-metallic inclusions, and ensure consistent microstructure across large cross-sections.

These methods are often used in components for offshore, chemical, and nuclear industries, where reliability under extreme conditions is non-negotiable.

Hot Working and Thermomechanical Processing

Hot working of Duplex 2205 must occur at temperatures between 1100–1250 °C.

Careful temperature control is essential to avoid the formation of intermetallic phases such as sigma (σ) or chi (χ), which can embrittle the steel and severely degrade its corrosion resistance.

Once forged or rolled, rapid cooling—preferably water quenching—is necessary to preserve the desired duplex microstructure.

Delays in cooling can promote phase separation, leading to weakened mechanical integrity.

► Key Hot Working Considerations:

- Avoid processing below 950 °C to prevent phase imbalance.

- Reheat as needed during extended forging to maintain thermal consistency.

- Final heat treatment (solution annealing at ~1050–1100 °C) ensures dissolution of detrimental phases and restores corrosion resistance.

Cold Working and Machining Behavior

While Duplex 2205 offers superior strength, it is more difficult to machine than austenitic stainless steels due to its higher hardness and work-hardening rate.

Compared to 316L, the machinability rating of 2205 is approximately 60–65%, requiring tool materials with high wear resistance and optimized cutting parameters.

Cold forming operations such as bending or stamping must be carefully controlled, as the higher yield strength (typically 2x that of 304/316) results in spring-back and elevated forming loads.

► Recommended Machining Tips:

- Use carbide tooling with low cutting speeds.

- Apply copious lubrication to reduce heat buildup.

- Optimize feed rates to minimize work hardening near the surface.

Welding and Fabrication: Balancing Metallurgy and Performance

Welding is one of the most challenging aspects of Duplex 2205 processing.

While the material is weldable, special techniques are necessary to maintain a balanced ferrite-austenite ratio and avoid the formation of intermetallic compounds.

► Recommended Welding Techniques:

- GTAW (TIG), GMAW (MIG), and SAW (Submerged Arc Welding) are commonly used.

- Heat input must be kept within a narrow range (typically 0.5–2.5 kJ/mm).

- Interpass temperatures should not exceed 150 °C.

- Use matching or over-alloyed filler metals (e.g., ER2209) to maintain phase balance.

Post-weld heat treatment is generally not required for most applications, but in critical service, pickling and passivation are essential to restore corrosion resistance.

Quality Control and Industry Standards

Ensuring the long-term reliability of 2205 components demands rigorous quality control across every stage of manufacturing. The alloy is governed by several international standards, including:

| Standard | Description |

|---|---|

| ASTM A240 / A240M | Specification for 2205 plate, sheet, and strip |

| ASTM A789 / A790 | Seamless/welded tubes and pipe specifications |

| EN 10088-3 | European specification for stainless steel bars |

| ISO 15156-3 (NACE MR0175) | Materials for use in H₂S-containing oilfield environments |

Non-destructive testing (NDT) methods such as ultrasonic testing (UT), liquid penetrant testing (PT), and radiographic testing (RT) are employed to ensure weld integrity and detect internal or surface flaws.

Additionally, microstructural verification using optical microscopy or SEM (Scanning Electron Microscopy) ensures that the target 50:50 austenite-ferrite balance is achieved post-fabrication.

6. Pros and Cons of Duplex Stainless Steel 2205

Pros of Duplex Stainless Steel 2205

Superior Strength-to-Weight Ratio

Duplex 2205 offers a remarkable strength enhancement over conventional austenitic grades.

With typical yield strengths ranging from 450 to 620 MPa, it allows engineers to design with thinner sections without compromising structural integrity.

This improvement translates into significant weight savings, which is critical for applications in offshore platforms, pressure vessels, and transportation.

Outstanding Corrosion Resistance

One of the key benefits of 2205 is its enhanced resistance to localized corrosion.

The alloy’s carefully balanced composition—including approximately 22% chromium, 3–3.5% molybdenum, and about 5–6% nickel—results in a Pitting Resistance Equivalent Number (PREN) of 35–40.

This makes Duplex 2205 highly effective against pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-rich environments such as marine, chemical, and desalination applications.

Cost Efficiency over Lifecycle

Although the initial cost of Duplex 2205 can be higher than that of some carbon steels or austenitic grades,

Its extended service life and reduced maintenance requirements yield significant lifecycle cost savings.

Moreover, its lower nickel content compared with austenitic stainless steels helps stabilize raw material expenses, making it economically attractive over the long term.

Good Weldability and Fabricability

When appropriate welding practices and controlled heat input are applied, Duplex 2205 can be effectively welded using techniques like TIG (GTAW) and MIG (GMAW).

Its dual-phase structure mitigates hot cracking and enhances weld zone strength, provided that factors such as interpass temperature (<150 °C) and proper filler metals (e.g., ER2209) are rigorously controlled.

Environmental Sustainability

In addition to performance benefits, Duplex 2205 is recognized for its environmental advantages.

Its long service life, recyclability (over 90%), and reduced maintenance all contribute to a lower overall environmental footprint.

As industries increasingly adopt green manufacturing practices, 2205 stands out as a sustainable material option.

Cons of Duplex Stainless Steel 2205

Processing Sensitivity and Heat Treatment Complexity

Maintaining the precise 50:50 balance of austenite and ferrite is imperative for achieving the desired mechanical properties.

This balance is sensitive to thermal cycles; inadequate or inconsistent heat treatment can lead to the formation of embrittling intermetallic phases such as the sigma phase.

Consequently, tight process control during fabrication and welding is essential, requiring specialized equipment and expertise.

Limited High-Temperature Service

Duplex 2205 is best suited for service temperatures up to about 300 °C (572°F).

Beyond this threshold, the material’s properties may deteriorate due to phase transformations,

making it less appropriate for applications demanding sustained high-temperature performance, such as certain power generation components.

Reduced Cold Work Formability

While 2205 exhibits excellent strength and corrosion resistance,

its higher yield strength means that its formability under cold working conditions is somewhat limited compared to more ductile austenitic stainless steels.

This characteristic may lead to higher forming loads, increased spring-back effects, and a need for specialized tooling in production.

Welding Challenges

Even though Duplex 2205 can be welded, the process demands rigorous control.

Excessive heat input or improper cooling rates may upset the delicate phase equilibrium and generate residual stresses.

In practice, this translates into a need for skilled operators and stringent adherence to welding standards,

which can add complexity and cost during fabrication.

Market Availability and Application Awareness

Despite its advantages, Duplex 2205 is not as ubiquitously available as some traditional stainless steel grades.

In some regions and applications, there may be limited sizes or forms available,

and market adoption can lag in conservative industries more familiar with austenitic steels.

7. Applications of Duplex Stainless Steel 2205

Oil & Gas Industry: A Critical Backbone

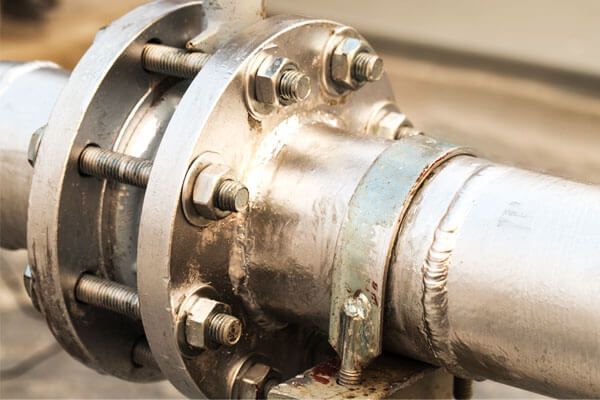

- Pipelines & Pressure Vessels: Its high yield strength (~450 MPa) allows for thinner wall constructions, reducing overall weight without compromising safety.

- Subsea Systems & Offshore Platforms: 2205 offers superior resistance to chloride stress corrosion cracking (SCC) and pitting corrosion, vital in deep-sea and saltwater environments.

- Heat Exchangers & Separators: With its high PREN (Pitting Resistance Equivalent Number) typically between 35–40, Duplex 2205 outperforms 304/316 stainless steels in aggressive chemical media.

Marine & Desalination: Corrosion Resistance at Sea

- Shipbuilding & Marine Hardware: It is commonly used in rudders, shafts, propeller systems, and anchor chains, thanks to its exceptional fatigue strength and corrosion resistance.

- Desalination Plants: 2205 is increasingly replacing traditional materials in evaporators, pressure vessels, and brine heaters, where salt-induced corrosion is a major concern.

- Seawater Cooling Systems: With lower susceptibility to crevice corrosion, 2205 ensures long-term reliability in high-salinity environments.

Chemical Processing & Refining: Durability in Aggressive Media

- Acidic and Alkaline Media: It withstands sulfuric, phosphoric, acetic, and nitric acids better than many standard stainless grades.

- Reactors, Columns & Tanks: It is widely used in distillation towers, scrubbers, and storage tanks where both structural strength and chemical resistance are needed.

- Urea and Fertilizer Production: Urea plants benefit from the alloy’s resistance to intergranular attack and chloride pitting.

Infrastructure & Architecture: Strength Meets Aesthetics

- Bridge Components & Structural Supports: Its high yield strength and fatigue resistance make it ideal for load-bearing structures and bridge girders.

- Façades and Public Infrastructure: Due to its clean surface finish and resistance to atmospheric corrosion, it is often used in cladding, railings, and urban sculptures.

Energy and Power Generation: High Strength for Harsh Conditions

- Boilers & Heat Exchangers: With a tensile strength exceeding 620 MPa, it performs well under cyclic thermal and pressure stresses.

- Geothermal and Renewable Energy: In geothermal plants, where hot, corrosive fluids are extracted from deep underground, 2205 offers stability and longevity.

Food & Beverage and Pharmaceutical Industries

- Dairy Equipment, Breweries & Wineries: 2205 can resist lactic and acetic acids found in fermentation processes.

- Pharmaceutical Vessels: It maintains cleanliness while resisting corrosion from sanitizing agents like chlorine-based disinfectants.

8. International Equivalents of Duplex Stainless Steel 2205

| Country/Region | Standard Organization | Designation / Grade | Standard Number | Notes |

|---|---|---|---|---|

| USA | ASTM / UNS | UNS S32205 / S31803 | ASTM A240 / ASTM A789 / A790 | Widely used in pressure vessels and piping |

| Germany | DIN / EN | 1.4462 | EN 10088-1 / EN 10216-5 | Also known as X2CrNiMoN22-5-3 |

| UK | BS / EN | 2205 | BS EN 10088 | Covered under BS standards harmonized with EN |

| France | AFNOR | Z2CND22-05AZ | NF EN 10088 | Similar to EN 1.4462 |

| Japan | JIS | SUS S32205 | JIS G4304 / G4305 | Based on international UNS system |

| Sweden | SS | 2377 | SS 14 23 77 | Based on Sandvik’s duplex technology |

| China | GB / CNS | 022Cr22Ni5Mo3N / S31803 | GB/T 21832, GB/T 14975 | Chinese equivalent standard designation |

| Russia | GOST | 03Х21Н5М3Н | GOST R 5632 | Cyrillic grade equivalent |

| India | IS | X2CrNiMoN22-5-3 | IS 5522 | Aligned with European standard EN 1.4462 |

| Australia | AS | S32205 / 2205 | AS 2837 | Mirrors ASTM and EN standards |

9. Comparative analysis with similar materials

Core Comparison Table

| Criteria | Duplex 2205 | 316L (Austenitic) | 430 (Ferritic) | 2507 (Super Duplex) | 1.4573 (Free-Machining) |

|---|---|---|---|---|---|

| Structure | Duplex (50% α / 50% γ) | Fully Austenitic | Fully Ferritic | Super Duplex (α/γ) | Austenitic + Cu, S |

| Yield Strength (MPa) | 450–620 | 200–300 | 250–350 | 550–750 | 230–350 |

| Tensile Strength (MPa) | 620–850 | 500–700 | 450–600 | 750–1000 | 550–750 |

| Elongation (%) | ≥25 | 40–50 | 20–30 | ≥25 | ~35–40 |

| PREN (Corrosion Index) | 35–40 | 25–30 | ~18 | 40–45 | ~26 |

| Chloride Resistance | Excellent | Moderate | Poor | Superior | Moderate |

Weldability |

Moderate (needs control) | Excellent | Poor | Challenging | Excellent |

| Machinability | Fair | Good | Moderate | Difficult | Excellent |

| Initial Cost | Moderate | Moderate–High | Low | High | Moderate |

| Lifecycle Cost | Low | Higher | High | Low | Moderate |

| Best Use Case | Corrosive + structural | General corrosion | Decorative, low-cost | Severe chloride environments | High-speed machining |

10. Conclusion

Duplex Stainless Steel 2205 exemplifies how microstructural engineering and alloy optimization can result in superior materials that meet and exceed modern industrial demands.

Its compelling combination of strength, corrosion resistance, and cost efficiency makes it a strategic choice for the future.

As industries shift toward sustainable, high-performance materials, the ongoing innovations and proven capabilities of 2205 DSS position it at the forefront of global material solutions.

LangHe is the perfect choice for your manufacturing needs if you need high-quality duplex stainless steel products.