1. Introduction

Metal bending involves deforming a metal workpiece by applying force to achieve a desired shape, offering a reliable means to shape metal sheets, plates, and tubes without removing any material.

This process is critical in the automotive, aerospace, construction, and metal fabrication industries.

Furthermore, the evolution from manual bending to sophisticated CNC-controlled machines has revolutionized the field, enabling manufacturers to achieve tight tolerances and complex geometries.

In this article, we delve into the principles, techniques, and applications of metal bending, while addressing the challenges and innovations that drive continuous improvement in this vital process.

2. Fundamental Principles of Metal Bending

What is Metal Bending?

Metal bending is the process of plastically deforming a metal workpiece to create curves, angles, or other complex shapes without cutting or removing material.

This process leverages the metal’s ductility—its ability to deform permanently under stress—while accounting for elastic recovery (or springback) once the force is removed.

Material Behavior During Bending

Understanding how materials behave during bending is crucial. When force is applied, the outer fibers of the metal experience tension, while the inner fibers undergo compression.

For instance, ductile materials like aluminum and mild steel exhibit significant elastic recovery, known as springback, which must be anticipated during design.

In contrast, materials with lower ductility, such as certain high-strength steels, require precise control to avoid cracking or wrinkling.

Key Bending Parameters

Several parameters govern the bending process, including:

- Bend Radius and Angle: These determine the curvature and degree of bending.

- Neutral Axis: The theoretical line within the material that experiences no tension or compression.

- Tensile and Compressive Forces: Their balance influences the quality of the bend.

- K-Factor: This ratio helps predict the location of the neutral axis, ensuring accurate calculations for the bend.

3. Common Metal Bending Techniques

Metal bending encompasses a range of techniques designed to form metal into desired shapes while preserving its integrity.

Each method has its unique advantages and is selected based on factors such as the type of metal, part geometry, production volume, and required tolerances.

In this section, we explore the most common metal bending techniques, providing an in-depth look at how each method works, along with their applications and limitations.

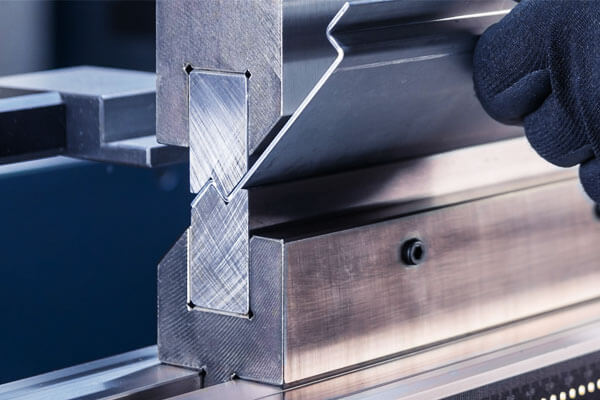

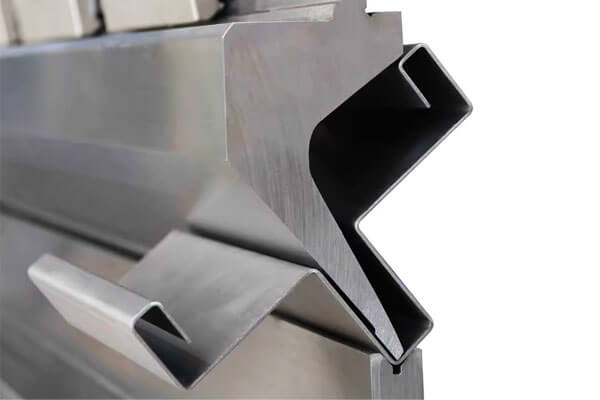

Press Brake Bending

Press brake bending is one of the most widely adopted techniques in metal fabrication.

In this process, a metal sheet is placed between a punch and a die, and an intense force is applied to create a bend. This method offers several variations:

- Air Bending:

In air bending, the punch does not fully force the material against the die. This approach allows for a range of bend angles by varying the depth of the punch. - It is particularly useful when flexibility is required in the bending process. However, controlling the exact bend angle can be challenging due to springback.

- Bottoming:

During bottoming, the metal is forced to fully contact the die, resulting in more consistent and precise bends.

This method minimizes springback, making it ideal for applications where tight tolerances are critical. - Coining:

Coining involves applying extremely high forces to permanently deform the metal, creating very sharp and accurate bends.

Although this technique results in excellent repeatability and minimal springback, it requires specialized tooling and higher energy input.

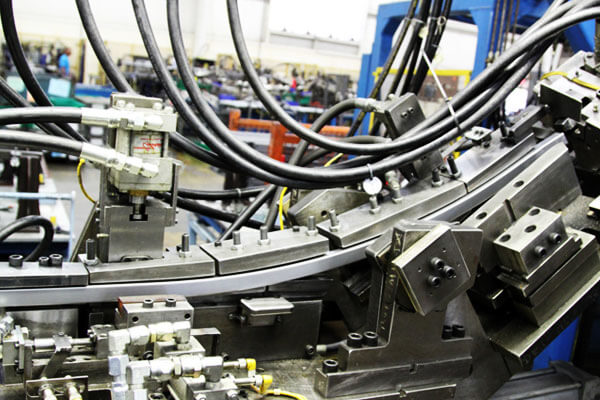

Roll Bending

Roll bending uses a series of rollers to gradually curve a metal workpiece into a cylindrical or conical shape.

This method is predominantly used for creating pipes, tubes, and large sheet metal structures. Key considerations in roll bending include:

- Roller Alignment and Configuration:

Ensuring that rollers are correctly aligned is essential to achieve uniform curvature.

Both three-roll and four-roll bending machines are available, with each configuration offering distinct benefits for controlling force distribution across the metal. - Force Distribution:

Even distribution of bending force prevents defects such as twisting or uneven curvature, especially when working with materials of varying thicknesses.

Roll bending is particularly efficient in high-volume production settings, as it can continuously process long lengths of metal with minimal human intervention.

Data from the metal forming industry shows that roll bending can achieve production speeds up to 25% faster than traditional press brake methods for certain applications.

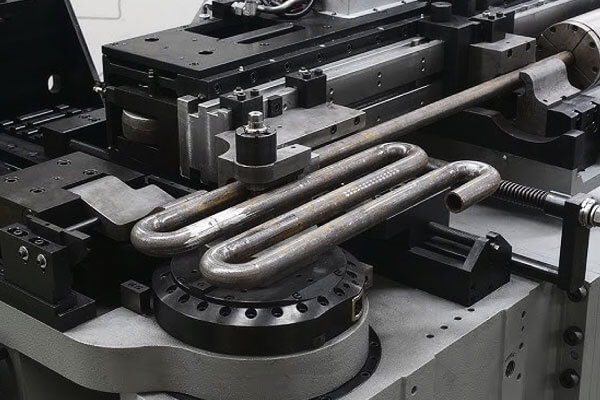

Rotary Draw Bending

Rotary draw bending specializes in bending tubes and pipes, a process that demands both precision and care to avoid wrinkling or flattening of the material.

The key feature of rotary draw bending is the use of a mandrel, which is inserted inside the tube to support it during bending.

This support prevents the tube from collapsing and maintains its cross-sectional shape.

- Mandrel Support:

The mandrel is crucial for high-quality bending, as it ensures that the tube’s interior remains smooth and free from wrinkles. - Draw Bending Mechanism:

As the tube is drawn around a bend die, the combination of external and internal forces results in a uniform bend with minimal distortion.

Rotary draw bending is extensively used in industries such as aerospace and automotive, particularly for exhaust systems and structural tubing.

The precision offered by this method allows manufacturers to achieve tolerances within ±0.5 mm, even for complex curves.

Stretch Bending

Stretch bending involves both stretching and bending the metal simultaneously to achieve a precise and controlled curve while minimizing springback.

This technique is particularly effective for large components where maintaining dimensional accuracy is essential.

- Dual Force Application:

By applying a tensile force along with the bending force, the process counteracts elastic recovery (springback), ensuring that the final shape closely matches the intended design. - Applications:

Stretch bending finds extensive use in the aerospace and construction industries, where large structural frames and components require accurate curves and robust mechanical properties.

Recent innovations in stretch bending have led to improved automation and process control, reducing cycle times by approximately 20% in high-volume production environments.

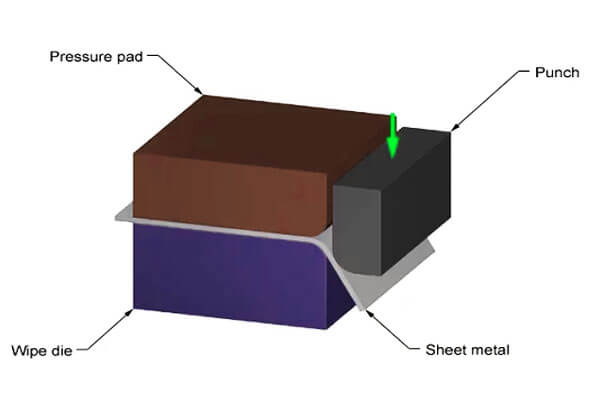

Wipe Bending

Wipe bending is a process where a metal sheet is bent over a fixed die edge, commonly used in mass production for its high repeatability and ease of setup.

The process involves clamping the metal sheet and then applying a controlled force that causes the metal to wipe over the die.

- Consistency and Repeatability:

Wipe bending is renowned for its ability to produce consistent and uniform bends, making it ideal for high-volume applications in industries such as automotive panel production. - Efficiency:

This method minimizes setup time and allows for rapid production cycles, although it is generally limited to simpler, less complex bend geometries.

Hot vs. Cold Bending

The temperature at which metal bending is performed significantly influences the outcome:

- Cold Bending:

Cold bending takes place at room temperature and is ideal for ductile metals that do not require additional heat to deform.

This method preserves the material’s mechanical properties and is commonly used for precision parts in electronics and automotive applications. - Hot Bending:

In hot bending, the metal is heated before bending. This process reduces the required force, minimizes the risk of cracking, and allows for the bending of thicker or less ductile materials.

Hot bending is frequently used in the construction and heavy machinery sectors. Heating temperatures can vary but typically range from 300°C to 500°C, depending on the material.Hot Bending

4. Equipment Used in Metal Bending

Modern metal bending relies on specialized equipment that ensures precision, efficiency, and repeatability in the manufacturing process.

Advances in technology have led to the development of machines that can handle complex geometries and varied material properties, significantly enhancing productivity.

In this section, we explore the key equipment used in metal bending, detailing their functions, benefits, and the technological innovations that drive the industry forward.

Press Brakes

Press brakes are among the most widely used machines in metal bending. They operate by using a punch and a die to bend metal sheets into the desired shape.

- Types of Press Brakes:

Modern press brakes come in several variants, including hydraulic, mechanical, and CNC-controlled models.

Hydraulic press brakes are known for their power and flexibility, while CNC-controlled machines offer exceptional precision and repeatability.

Mechanical press brakes, although less advanced, remain popular for smaller production runs due to their cost-effectiveness. - Technological Advancements:

Recent developments in CNC technology have improved the accuracy of press brakes by reducing setup times by up to 40%.

These machines also feature advanced control systems that adjust force and speed in real time, ensuring consistent bend angles and minimizing defects like springback.

Roll Bending Machines

Roll bending machines are designed to curve metal sheets, plates, or tubes using a series of rollers.

These machines are essential for producing cylindrical or conical shapes in applications such as piping and large structural components.

- Roller Configurations:

Roll bending machines typically come in three-roll or four-roll configurations.

Three-roll machines are preferred for standard applications due to their simplicity,

while four-roll machines offer improved flexibility and better control over the bending process, especially for thicker materials. - Efficiency and Throughput:

Roll bending allows continuous processing, which can boost production speeds by up to 25% compared to traditional press brake methods for certain applications.

The ability to process long lengths of metal with minimal manual intervention makes roll bending highly efficient in high-volume production environments.

Tube and Pipe Benders

Tube and pipe bending machines are specifically designed to form curves in tubular materials without compromising their cross-sectional integrity.

These machines play a crucial role in industries such as aerospace, automotive, and HVAC.

- CNC Tube Benders:

CNC-controlled tube benders offer high precision and repeatability. They use advanced software to control the bending process, ensuring that curves meet strict dimensional tolerances.

This precision is particularly important in the aerospace industry, where even minor deviations can affect performance. - Manual vs. Automated Systems:

While manual tube benders are still used for small-scale or repair work, automated systems have become the norm in high-volume manufacturing.

Automated benders not only increase production rates but also reduce operator fatigue and minimize the risk of human error.

Specialized Bending Tools

In addition to large-scale machinery, specialized bending tools play a vital role in achieving precise bends in specific applications. These tools include:

- Dies and Punches:

Custom-designed dies and punches are critical for achieving the correct bend radius and angle.

They are often made from high-strength tool steel to withstand repeated use and maintain precision over time. - Mandrels:

Mandrels are used in rotary draw bending and tube bending processes to support the interior of the tube during the bending process.

They help prevent wrinkling and collapse, ensuring that the final product maintains its intended cross-sectional shape. - Clamping and Fixture Systems:

To secure parts during bending, manufacturers use advanced clamping systems that hold the metal in place, reducing the risk of slippage and ensuring consistent force distribution.

Integration with Simulation and Monitoring Software

Modern bending equipment increasingly incorporates simulation software and real-time monitoring systems.

These technologies enable manufacturers to predict deformation, adjust process parameters on the fly, and reduce defects.

For example, finite element analysis (FEA) software models the bending process, allowing engineers to optimize the bending sequence and minimize issues like springback.

Real-time sensors and feedback loops further enhance quality control, ensuring that every bend meets precise specifications.

5. Summary of Common Metal Bending Materials

Steel:

Widely used for its high strength and durability, steel is ideal for structural applications in automotive and heavy machinery.

However, its strength demands significant force during bending, and springback must be carefully managed.

Aluminum:

Valued for its lightweight and high ductility, aluminum excels in aerospace and automotive applications.

Its ease of bending allows for smooth curves, though designers must account for springback (up to 10%) to achieve precise dimensions.

Copper:

Known for excellent electrical and thermal conductivity, copper’s high ductility makes it suitable for electrical components and heat exchangers.

Its softness, however, requires precise control to prevent deformation.

Titanium:

Titanium offers a superior strength-to-weight ratio and exceptional corrosion resistance, making it a top choice for aerospace and medical components.

Due to its lower ductility, specialized hot bending techniques are often necessary to avoid cracking.

Other Materials

In addition to the primary metals mentioned above, other materials are occasionally used in metal bending:

- Stainless Steel: Valued for its corrosion resistance and aesthetic appeal, stainless steel is often used in architectural and consumer applications.

Its bending behavior requires careful attention to minimize springback and maintain dimensional accuracy. - Brass: Combining good ductility with an attractive appearance, brass is used in decorative and precision applications.

However, its lower strength compared to steel necessitates careful process control to avoid over-bending. - Special Alloys: Custom alloys, engineered for specific performance characteristics, are sometimes employed in high-tech or specialized applications.

These materials may offer unique benefits such as enhanced thermal stability or resistance to extreme environments, but can also pose challenges in bending due to non-standard properties.

6. Challenges in Metal Bending and Solutions

Metal bending, though widely adopted, presents several challenges that can affect the quality and consistency of the final product.

Addressing these challenges is critical for achieving precise, durable, and cost-effective results.

Below, we outline the main challenges encountered during metal bending along with effective solutions.

Springback Control

Challenge:

Springback occurs when a bent metal partially returns to its original shape after the force is removed. This elastic recovery can lead to inaccuracies in the final dimensions.

Solutions:

- Over-Bending: Intentionally over-bend the material by 5-10% to compensate for anticipated springback.

- Coining and Stress Relief: Apply localized coining or heat treatments after bending to reduce residual stresses.

- Computer Simulation: Utilize finite element analysis (FEA) software to predict springback and adjust bending parameters accordingly.

Material Cracking and Wrinkling

Challenge:

Excessive bending force or an improper bend radius can cause material cracking or wrinkling, particularly in brittle or high-strength metals.

Solutions:

- Optimized Bend Radii: Design with appropriate radii that respect the material’s ductility.

- Gradual Bending: Implement incremental bending processes to distribute strain evenly and minimize the risk of cracks.

- Lubrication: Use high-quality lubricants to reduce friction and lower the force required for bending, thus preventing wrinkling.

Maintaining Dimensional Accuracy

Challenge:

Variations in material properties and inconsistencies in the bending process can lead to deviations from target dimensions, impacting product functionality.

Solutions:

- Precision Tools and Equipment: Employ CNC-controlled machines and high-precision measuring instruments to monitor and adjust bending parameters in real time.

- Process Simulation: Use advanced simulation software to forecast deformation and optimize the bending sequence before production.

- Quality Control Systems: Implement rigorous in-line quality checks to identify and correct deviations during production.

Managing Material Heterogeneity

Challenge:

Different metals and even variations within the same metal can react unpredictably to bending forces, leading to inconsistent outcomes such as uneven bending or localized failures.

Solutions:

- Material Testing: Conduct thorough testing to understand the behavior of the specific alloy under bending stresses.

- Tailored Process Parameters: Customize bending settings—such as force, speed, and temperature—based on the material’s characteristics.

- Supplier Collaboration: Work closely with material suppliers to ensure consistent quality and properties that match the production requirements.

7. Advantages of Metal Bending

Metal bending offers several compelling benefits:

- Cost-Effectiveness: Since the process does not remove material, it minimizes waste and reduces material costs.

- High Efficiency: Automated bending processes have significantly reduced production times, making them ideal for high-volume manufacturing.

- Precision: Modern CNC machines and simulation software enable the production of complex shapes with tight tolerances.

- Material Conservation: Bending preserves the intrinsic strength and integrity of the original material, making it perfect for structural applications.

- Versatility: A wide range of metals can be bent, catering to diverse industrial needs.

8. Applications of Metal Bending in Various Industries

Metal bending finds widespread use across multiple sectors:

- Automotive: Used in chassis, exhaust systems, and structural components to improve performance and reduce weight.

- Aerospace: Critical for forming fuselage structures, tubes, and frames, where precision and strength are paramount.

- Construction and Architecture: Bending techniques shape metal frames, bridges, and decorative facades, contributing to both form and function.

- Heavy Machinery: Employed for structural reinforcements and hydraulic components to enhance durability.

- Electronics and Consumer Goods: Used to create metal casings, brackets, and enclosures that require both precision and visual appeal.

9. Comparison with Other Metal Forming Processes

Below is a comparison table that highlights the key differences between metal bending and other common metal forming processes, including stamping, welding, and machining.

This table outlines each process’s impact on material integrity, production efficiency, cost, waste, and typical applications.

| Process | Material Integrity | Production Efficiency | Cost Efficiency & Waste | Key Applications |

|---|---|---|---|---|

| Metal Bending | Preserves the original material with minimal removal; maintains structural strength and continuity. | High efficiency with automated CNC systems; ideal for continuous curves and angles. | Low material waste; cost-effective for high-volume production. | Automotive chassis, aerospace fuselages, architectural frames, heavy machinery. |

| Stamping | Involves cutting and shaping; removes excess material, which can weaken structural integrity if not optimized. | Very fast cycle times; excellent for intricate shapes in large production runs. | Generates more waste due to material removal; high material costs. | High-volume components such as electronic housings, automotive panels, and appliances. |

Welding |

Joins separate metal pieces; may create weak points at the joints; often requires additional finishing. | Moderate speed; complexity increases with multi-joint assemblies and quality control requirements. | Higher operational costs due to labor and post-weld processing; potential for material stress. | Construction, shipbuilding, automotive assembly, heavy machinery. |

| Machining | Subtractive process that removes material, potentially compromising strength and causing high scrap rates. | Slower process; high precision but often requires multiple passes. | High energy consumption and significant material waste; higher operational costs. | Precision components, molds, and parts requiring tight tolerances, especially in aerospace and medical devices. |

10. Future Trends and Innovations in Metal Bending

The future of metal bending looks promising, driven by ongoing technological advancements:

- Automation and CNC Control: Enhanced automation reduces human error and improves repeatability.

Data indicates that CNC bending machines can increase production efficiency by up to 30% compared to manual methods. - Simulation Software: Advanced modeling tools predict deformation and optimize bending parameters, reducing material waste and minimizing defects.

- Smart Materials: Research into flexible metals with improved bendability promises to expand the possibilities of metal bending in innovative applications.

- Eco-Friendly Methods: Manufacturers are increasingly adopting energy-efficient processes and waste reduction strategies.

The integration of green technologies is expected to reduce the carbon footprint of metal bending operations significantly.

11. Conclusion

Metal bending remains a fundamental process in modern manufacturing, offering a blend of efficiency, precision, and cost-effectiveness.

Its ability to shape metal without material loss, coupled with advancements in automation and simulation, makes it indispensable in industries such as automotive, aerospace, and construction.

As new technologies and sustainable practices continue to evolve, metal bending will undoubtedly play a critical role in meeting the demands of future manufacturing challenges.

By embracing these innovations, manufacturers can optimize their processes, reduce waste, and ensure high-quality production while maintaining a competitive edge in the global market.

LangHe is the perfect choice for your manufacturing needs if you need high-quality metal bending services.

Pingback: How to Set Up Your CNC Roll Bender for Accurate Results? - CNCRB