Electrophoretic Deposition (EPD), commonly known as E-coating, has revolutionized the field of surface treatment by providing an efficient, uniform, and environmentally friendly method for applying protective and decorative coatings.

In this article, we delve into the principles, processes, applications, and future trends of E-coating, offering a multifaceted, in-depth analysis supported by data and industry insights.

1. Introduction

E-coating represents a significant advancement in coating technology. Originally developed in the 1950s, the method has continuously evolved with innovations in materials science and automation.

Today, it underpins many industrial processes, notably in the automotive, aerospace, and consumer goods sectors.

Recent market analyses indicate that the global E-coating market is growing at a compound annual growth rate (CAGR) of approximately 8%, reflecting its increasing adoption in modern manufacturing.

This growth is fueled by its ability to deliver uniform, high-quality coatings with excellent corrosion resistance and aesthetic appeal.

2. Fundamental Principles of Electrophoretic Deposition

At the heart of E-coating lies the principle of electrophoresis—the movement of charged particles in a colloidal suspension under the influence of an electric field.

In simple terms, particles with a positive or negative charge migrate towards an electrode with the opposite charge.

This basic mechanism drives the deposition process and is influenced by several key factors:

- Voltage and Electric Field: The applied voltage dictates the speed and efficiency of particle migration.

Higher voltages can accelerate deposition but must be carefully controlled to avoid defects. - Particle Size and Charge: Smaller, uniformly charged particles tend to produce more homogeneous coatings.

Research shows that coatings with particle sizes below 1 micron achieve superior surface finishes. - pH and Conductivity: The chemical environment, particularly pH and ionic strength of the bath, directly affects the dispersion stability and mobility of the particles.

- Bath Composition: The solvent type, dispersants, and additives in the coating bath play a critical role in ensuring optimal deposition rates and coating uniformity.

Moreover, E-coating can be performed using either anodic or cathodic methods.

In anodic E-coating, negatively charged particles deposit on the anode, whereas cathodic EPD,

which deposits positively charged particles on the cathode, dominates the industry due to its enhanced corrosion resistance.

Notably, cathodic E-coatings have been reported to reduce corrosion rates by up to 70% compared to untreated substrates.

3. Process of Electrophoretic Deposition

The E-coating process unfolds in several critical stages that together ensure a high-quality, uniform, and durable coating.

Pretreatment and Surface Preparation

Before deposition, substrates must undergo thorough cleaning and activation. First, cleaning and degreasing remove oils, contaminants, and residues that can hinder adhesion.

Then, chemical conversion coatings often follow, which modify the substrate surface to enhance its receptivity.

Recent studies show that proper pretreatment can improve coating uniformity by 15–20%.

This stage is crucial because an activated surface leads to more consistent and robust deposition during subsequent steps.

Electrophoretic Deposition Stage

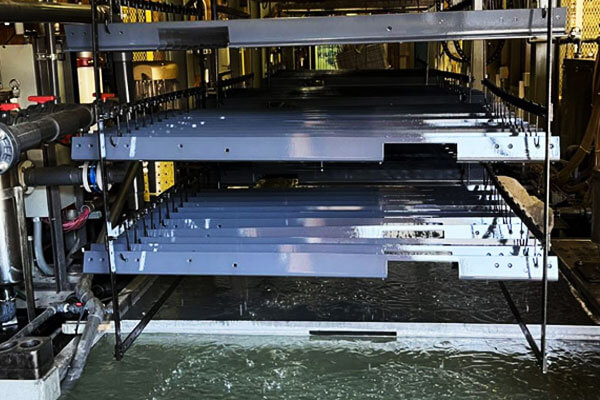

After surface preparation, the deposition stage begins by applying an electric field to the coating bath.

Charged particles within the colloidal suspension migrate toward the oppositely charged substrate.

Manufacturers meticulously control bath composition, solvent type, and dispersants to regulate particle movement and deposition rate.

Modern systems use real-time sensors and automation to maintain optimal conditions, achieving coating thickness variations of less than 5 microns.

This precision is essential for applications that demand uniform, high-performance coatings.

Post-Deposition Rinsing and Drying

Following deposition, substrates are rinsed to remove any excess or loosely bound coating material.

This rinsing step prevents defects that might otherwise develop during curing. Next, a controlled drying process, typically involving heat curing, solidifies the coating and enhances adhesion.

Optimized curing protocols can increase the coating’s mechanical strength by around 20%, ensuring durability and resistance to environmental stresses.

This final stage locks in the coating’s properties, resulting in a product that meets strict industry standards.

4. Types of E-coating Coatings and Materials

Electrophoretic Deposition supports a diverse array of coating systems, enabling manufacturers to tailor surfaces according to specific performance, durability, and aesthetic requirements.

By selecting the appropriate material system, companies can optimize their coating processes to achieve excellent corrosion resistance, wear properties, and environmental stability.

Below, we delve into the major categories of EPD coatings, elaborating on their characteristics, advantages, and application areas.

Organic Coatings

Organic coatings are widely used due to their robust protective properties and appealing finishes.

These coatings are particularly favored in industries such as automotive, consumer electronics, and appliances.

- Acrylics, Epoxies, Polyesters, and Urethanes:

These materials offer a balance between mechanical strength and flexibility.

Acrylics and polyesters are valued for their clarity and color retention, while epoxies provide excellent adhesion and chemical resistance.

Urethanes are notable for their durability and abrasion resistance. - Rapid Curing and Low-Temperature Processing:

Many organic E-coating systems cure quickly under controlled heat conditions, reducing cycle times and enhancing throughput.

This rapid curing minimizes production downtime and allows for high-volume manufacturing. - Aesthetic Versatility:

Manufacturers can choose from a broad spectrum of colors, gloss levels, and textures, which makes organic coatings ideal for decorative and consumer-facing applications. - Performance Data:

In the automotive sector, the application of organic EPD coatings has been shown to reduce corrosion-related failures by up to 70%,

thereby extending the lifespan of critical components and reducing maintenance costs.

Inorganic Coatings

Inorganic coatings cater to applications that demand enhanced durability, high-temperature stability, or specific electrical properties.

These coatings are critical in industries such as electronics, biomedical devices, and high-performance machinery.

- Ceramic Coatings:

These coatings are renowned for their wear resistance and high-temperature performance. Ceramic particles can form a dense barrier, significantly reducing surface degradation.

For instance, ceramic EPD coatings can improve the wear resistance of biomedical implants by approximately 15%, offering extended service life in challenging environments. - Bioactive Coatings:

In biomedical applications, bioactive inorganic coatings, such as hydroxyapatite, enhance the biocompatibility of implants.

They promote faster osseointegration, which is critical for the success of dental and orthopedic devices. - Composite Systems:

By combining inorganic particles with binders, composite coatings achieve superior mechanical properties and corrosion resistance.

These composites are tailored for high-stress applications where single-component systems may fall short. - Electrical and Thermal Stability:

In electronics, inorganic EPD coatings serve as dielectrics or protective layers, ensuring device reliability under varying operational conditions.

The inherent stability of these coatings makes them indispensable in high-performance circuit boards and semiconductor devices.

Hybrid and Functionalized Coatings

Hybrid and functionalized coatings represent the cutting edge of E-coating technology, merging the best attributes of both organic and inorganic systems.

These advanced formulations open up new possibilities for performance enhancement and specialized applications.

- Nanocomposite Formulations:

Incorporating nanoparticles into the coating matrix can dramatically improve barrier properties, mechanical strength, and thermal stability.

For example, nanocomposites can reduce permeability and enhance scratch resistance, thereby prolonging the coating’s protective function. - Smart Coatings:

These innovative systems feature self-healing or anti-fouling properties, which are particularly beneficial in harsh environmental conditions.

Smart coatings actively respond to damage or contamination, maintaining the integrity of the substrate over extended periods. - Tailored Functionalities:

Hybrid coatings can be engineered to meet precise industry specifications.

In aerospace and renewable energy applications, coatings are customized to resist extreme temperatures, UV exposure, and chemical corrosion. - Integrated Performance Enhancements:

Recent research has shown that functionalized coatings can improve overall durability by as much as 25%, translating into significant cost savings and reduced downtime in industrial operations.

5. Available Materials for E-coating

E-coating works best on parts that are composed of materials with conductive surfaces and robust mechanical properties.

Manufacturers select substrate materials that can endure the rigorous pre-treatment, deposition, and curing processes. Here are the key material types suited for E-coating:

Ferrous Metals

- Carbon Steel, Stainless Steel, and Galvanized Steel:

These materials are widely used in industries such as automotive and industrial manufacturing.

They offer a durable base for E-coating, providing excellent adhesion and corrosion resistance.

The process is especially effective in reducing corrosion-related failures, making these metals a top choice for long-term performance.

Non-Ferrous Metals

- Aluminum and Its Alloys:

Aluminum parts are common in aerospace, electronics, and consumer products due to their lightweight and excellent corrosion resistance.

When properly prepared, aluminum surfaces accept E-coating well, ensuring a uniform finish and enhanced durability.Electrocoating Aluminum - Copper and Its Alloys:

While less common, certain copper components can also undergo E-coating.

Process adjustments ensure that these materials maintain their conductive properties and adhere properly to the coating.

Other Conductive Substrates

- Pre-Treated Non-Metals:

In some cases, non-metallic parts can be made conductive through surface pre-treatment.

Although this application is less widespread, it offers flexibility for coating components in specialized industries.

6. Advantages and Limitations of E-coating

Electrophoretic Deposition offers numerous advantages that have made it a popular choice in surface coating applications, yet it also presents certain limitations that manufacturers must consider.

Below, we explore both aspects in depth.

Advantages of E-coating

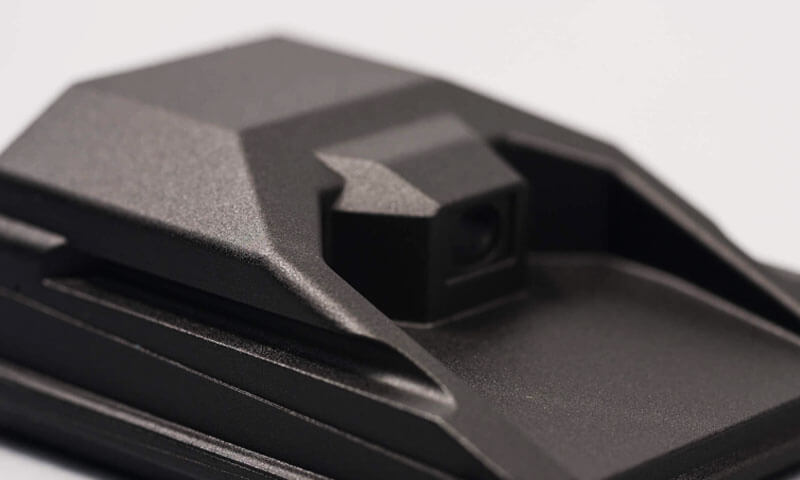

- Uniform Coating Thickness:

E-coating produces a consistent and even coating across complex geometries, ensuring high-quality finishes.

Studies indicate that variations in coating thickness can be reduced to less than 5 microns in optimized processes. - Enhanced Corrosion Resistance:

With proper formulations, E-coating coatings can reduce corrosion-related failures by up to 70%, making them ideal for automotive, aerospace, and industrial components. - Efficient Material Utilization:

The process maximizes material usage by depositing only the necessary amount on the substrate, thereby reducing waste and lowering production costs. - Scalability and Automation:

E-coating systems integrate well with automated production lines, making them suitable for high-volume manufacturing without compromising quality. - Environmental Benefits:

Compared to traditional methods, E-coating generates minimal volatile organic compounds (VOCs) and produces less waste, aligning with increasingly strict environmental regulations.

Limitations of E-coating

- High Initial Investment:

The setup and equipment for E-coating can be costly, which may deter smaller companies or those with limited budgets.

This includes investments in specialized tanks, power supplies, and real-time monitoring systems. - Sensitivity to Process Conditions:

The quality of the deposited coating heavily depends on strict control over bath composition, pH, voltage, and temperature. Even minor fluctuations can lead to defects or uneven coatings. - Thickness Limitations:

While E-coating excels at producing thin, uniform layers, achieving very thick coatings remains challenging. This limitation can restrict its use in applications requiring high buildup. - Complex Pretreatment Requirements:

The success of E-coating is largely contingent upon meticulous substrate preparation.

Inadequate cleaning or surface activation can compromise adhesion, leading to reduced performance and durability.

7. Key Applications of E-coating

E-coating finds widespread use across numerous industries due to its versatility and reliability.

Automotive and Transportation

In the automotive sector, E-coating is indispensable for applying corrosion-resistant finishes on car bodies, chassis, and other components.

High-performance E-coatings not only enhance durability but also contribute to the overall aesthetic of vehicles.

Moreover, aerospace and marine industries benefit from E-coatings that withstand extreme environmental conditions, thereby extending the service life of critical components.

Industrial and Consumer Goods

For industrial applications, E-coating provides protective layers for appliances, machinery, and consumer goods.

Durable finishes ensure that products maintain their appearance and performance over time, reducing maintenance costs and enhancing customer satisfaction.

Biomedical Applications

E-coating plays a transformative role in biomedical engineering.

The process is employed to deposit hydroxyapatite coatings on dental and orthopedic implants, significantly improving biocompatibility and promoting faster osseointegration.

Recent clinical studies have reported a 25% reduction in implant failure rates when using E-coated components.

Electronics and Semiconductor Industry

In the electronics sector, dielectric E-coatings improve insulation and reliability in microelectronic devices.

E-coating is also used in the manufacturing of circuit boards and capacitors, where precision and uniformity are crucial.

These applications underscore E-coating’s critical role in ensuring electronic components’ performance and longevity.

Energy and Environmental Applications

E-coating is making strides in energy storage and renewable energy.

For instance, lithium-ion battery electrodes produced via E-coating exhibit enhanced conductivity and uniformity, contributing to improved battery performance.

Additionally, functional coatings applied to solar cells and fuel cells help maximize energy conversion efficiency, further highlighting the versatility of E-coating in emerging technologies.

8. Comparison with Other Surface Treatments

E-coating is one of many surface treatment methods used to enhance the durability, corrosion resistance, and aesthetics of components.

To better understand its strengths and weaknesses, we compare EPD with other common surface treatment techniques, including powder coating, electroplating, and spray painting.

| Criteria | EPD (E-coating) | Powder Coating | Electroplating | Spray Painting |

|---|---|---|---|---|

| Coating Uniformity | Excellent, even on complex shapes | Good, struggles with recessed areas | Moderate, thickness varies | Low, depends on manual skill |

| Film Thickness | Thin (10–40 microns) | Thick (50–150 microns) | Thin (varies by metal) | Variable, often thin |

Corrosion Resistance |

High, widely used in automotive | High, depends on pre-treatment | Varies by metal type | Moderate, prone to chipping |

| Material Suitability | Steel, aluminum, copper | Mostly metals | Only conductive metals | Almost all materials |

| Application Efficiency | 95–99% (minimal waste) | ~60–80% (overspray loss) | ~70–90% (metal deposition) | ~30–50% (high overspray) |

| Durability | High, excellent adhesion | High, thick durable coat | High, but depends on plating type | Moderate, can chip or peel |

Curing Process |

Heat curing required | Heat curing required | No curing, electrochemical reaction | Air drying or baking |

| Automation & Scalability | Fully automated, scalable | Automated, but less efficient | Complex process, not easily scalable | Requires skilled labor |

| Environmental Impact | Low VOCs, eco-friendly | No solvents, but overspray waste | Uses hazardous chemicals | High VOC emissions, solvent-based |

9. Conclusion

In conclusion, E-coating stands as a transformative technology in modern surface treatment.

Its precise, efficient, and versatile approach has cemented its role across a broad range of industries—from automotive and aerospace to electronics and biomedical applications.

With ongoing innovations in nano-enhancements and sustainable formulations, E-coating is poised to expand its influence even further.

As research continues to push the boundaries of what is possible, the future of E-coating looks not only promising but essential for advancing manufacturing and environmental sustainability.

LangHe is the perfect choice for your manufacturing needs if you need high-quality E-coating services.