Metal vacuum casting has rapidly emerged as a transformative manufacturing process that combines precision, versatility, and cost-efficiency.

By utilizing a vacuum environment to eliminate air pockets and achieve superior surface finishes, this method produces high-quality metal parts ideal for prototyping and low-volume production.

In this article, we provide a comprehensive analysis of metal vacuum casting from multiple perspectives,

covering its principles, process, material selection, applications, advantages, challenges, and future trends—to offer an authoritative and in-depth understanding of this innovative technology.

1. Introduction

Metal vacuum casting has become an essential tool for engineers and manufacturers striving for high-precision components with intricate geometries.

Unlike traditional casting methods, which often suffer from porosity and inconsistent surface quality,

vacuum casting leverages a controlled, low-pressure environment to yield parts with exceptional detail and durability.

This process has gained popularity in industries such as aerospace, automotive, and electronics, where rapid prototyping and short-run production are crucial.

Moreover, vacuum casting serves as a cost-effective intermediary between 3D printing and mass production methods,

enabling companies to refine designs quickly before committing to large-scale manufacturing.

2. What is Metal Vacuum Casting?

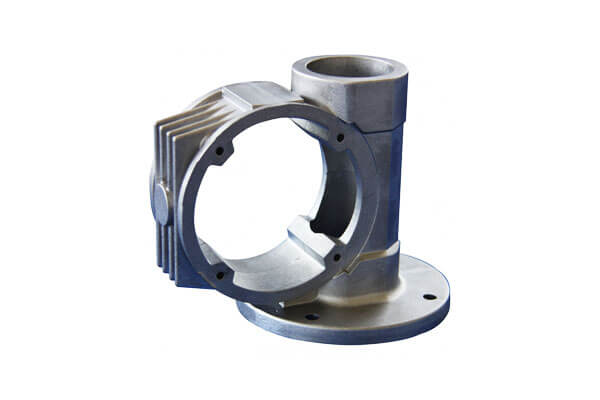

Metal vacuum casting is an advanced casting process used to produce high-quality metal components by utilizing a vacuum environment during the casting procedure.

This technique is particularly beneficial for creating parts that require high precision, excellent surface finish, and minimal porosity or defects.

Process Overview

In metal vacuum casting, the mold and the molten metal are placed within a sealed chamber where a vacuum is applied. The vacuum serves multiple purposes:

- Eliminates Air and Gases: By removing air and gases from the mold cavity before pouring the molten metal,

it prevents the formation of oxides and gas bubbles inside the casting, which can lead to defects. - Improves Metal Flow: The vacuum helps draw the molten metal into the mold cavity more smoothly and evenly, ensuring a complete fill without turbulence that could introduce impurities.

- Enhances Material Properties: This controlled environment contributes to better material properties in the final product,

such as increased strength and durability due to reduced porosity and inclusions.

3. The Metal Vacuum Casting Process

The metal vacuum casting process comprises several key stages, each integral to ensuring optimal quality and performance:

Master Model and Mold Creation

The process begins with the fabrication of a master model, usually produced via CNC machining or advanced 3D printing.

This model must exhibit flawless surface finish and exact dimensions because it dictates the quality of the final part.

Next, the master model is embedded in a mold material—often a high-temperature-resistant silicone or composite—which is then cured to create a detailed, reusable mold.

The resulting silicone mold can typically produce 20 to 30 castings before requiring replacement, a trade-off that balances cost and precision.

Metal Selection and Vacuum Chamber Setup

Choosing the right metal alloy is crucial. Manufacturers often opt for alloys such as aluminum, brass, stainless steel, copper, or titanium

based on the desired mechanical properties, thermal resistance, and application-specific requirements.

Once the appropriate alloy is selected, the mold is positioned within a vacuum chamber.

The chamber is then evacuated to remove air and moisture, setting the stage for a uniform metal pour.

Pouring, Solidification, and Cooling

Under strict vacuum conditions, molten metal is poured into the prepared mold. The vacuum ensures that no air bubbles compromise the integrity of the cast.

Subsequently, the metal is allowed to solidify in a controlled cooling environment.

This phase is critical, as the cooling rate significantly affects the microstructure and, consequently, the mechanical properties of the part.

Engineers carefully manage temperature gradients to prevent defects such as shrinkage or warping.

Demolding and Post-Processing

Once the metal has fully solidified, the part is carefully extracted from the mold. Thanks to the flexibility of silicone, even complex geometries can be demolded with minimal damage.

Post-processing steps—such as trimming, polishing, and heat treatment—are then performed to achieve the desired finish and precise dimensions.

Rigorous quality control inspections follow, ensuring that the final product meets both industry standards and specific design requirements.

Time and Cost Considerations

Metal vacuum casting excels in rapid prototyping and small-batch production, often delivering finished parts within 7–10 days.

While it may not be the most economical option for mass production, its low initial tooling costs and high precision make it an ideal choice for prototypes and custom components.

In addition, the ability to produce complex parts without extensive post-processing further reduces overall production time and cost.

4. Materials Used in Metal Vacuum Casting

Material selection is a critical factor in metal vacuum casting, as it directly influences the quality, performance, and longevity of the final product.

By choosing the appropriate alloy, manufacturers can tailor the mechanical properties, thermal stability, and surface finish of the cast part to meet specific application requirements.

In this section, we explore the various materials commonly used in metal vacuum casting and examine how their inherent properties impact the casting process and final product performance.

Common Metal Alloys

Manufacturers rely on a diverse range of metal alloys for vacuum casting, each offering unique advantages.

The selection depends on factors such as strength, weight, corrosion resistance, and thermal performance.

Aluminum:

Aluminum is prized for its lightweight nature, excellent thermal conductivity, and corrosion resistance.

Its low density makes it ideal for aerospace and automotive applications where reducing weight is critical.

In vacuum casting, aluminum alloys produce parts with a smooth finish and can be easily machined post-casting.

For example, aluminum castings often achieve high dimensional accuracy, which is crucial for precision components.

Brass:

Brass combines strength with good machinability and attractive aesthetics.

It offers excellent thermal and electrical conductivity, making it suitable for applications in decorative components and electronic housings.

Its fluidity during casting allows for the accurate reproduction of complex geometries.

Stainless Steel:

Stainless steel is used when high strength and corrosion resistance are necessary.

Its ability to withstand elevated temperatures and harsh environments makes it a common choice for industrial components and marine applications.

Vacuum casting stainless steel parts results in robust components that require minimal surface finishing.

Copper:

Known for its superior thermal and electrical conductivity, copper is ideal for applications that demand efficient heat dissipation and excellent conductivity.

Vacuum-cast copper components are widely used in cooling systems and electrical connectors, where precise control of material properties is essential.

Titanium:

Titanium and its alloys offer an exceptional strength-to-weight ratio combined with excellent corrosion resistance.

Although more expensive, titanium is increasingly popular in high-performance sectors such as aerospace and medical devices.

Its use in vacuum casting enables the production of lightweight, durable parts that perform reliably under extreme conditions.

Impact of Material Properties on Casting

The inherent properties of metal alloys play a significant role throughout the vacuum casting process. Key factors include:

- Melting Point and Flow Rate:

Alloys with lower melting points, such as aluminum, allow for easier flow into the mold, reducing the risk of incomplete filling.

In contrast, high-melting-point materials like stainless steel require precise temperature control to ensure proper flow and complete mold filling. - Cooling Rate and Microstructure:

The rate at which the cast metal cools directly influences its microstructure, impacting properties like tensile strength, ductility, and hardness.

For example, rapid cooling may produce finer grain structures that enhance mechanical properties, while controlled cooling can minimize internal stresses and distortions. - Surface Finish and Texture:

The material’s ability to replicate the mold’s fine details determines the surface quality of the final part.

High-quality surface finishes are particularly important for applications where aesthetics and precise dimensions are critical.

Material Selection Considerations

Selecting the appropriate material involves a careful evaluation of both performance requirements and economic factors. Engineers must consider:

- Mechanical Performance:

Determine whether the part requires high strength, flexibility, or impact resistance.

For instance, aerospace applications might prioritize high-strength, lightweight materials like titanium, whereas automotive components might benefit from the versatility of aluminum. - Environmental Resistance:

Assess the operating environment to choose materials that can withstand corrosive chemicals, high temperatures, or exposure to moisture.

Stainless steel and certain high-performance alloys excel in these areas. - Cost and Availability:

Balance the material’s performance benefits with its cost and availability. While advanced alloys like titanium offer superior performance, they may also drive up production costs.

Often, a trade-off between performance and cost must be managed to achieve the desired outcome.

5. Applications of Metal Vacuum Casting

Metal vacuum casting is particularly valuable for industries that require high-precision components and rapid turnaround times. Its applications span various sectors:

Prototyping and Low-Volume Production

Vacuum casting allows manufacturers to produce high-fidelity prototypes quickly and cost-effectively.

This is essential for automotive components, aerospace parts, and medical devices, where design iterations are frequent and precision is paramount.

Complex Geometries and Intricate Parts

The process excels in producing parts with fine details, internal channels, and thin walls—features that are challenging to achieve with traditional casting or machining.

These complex geometries are critical in electronics, specialized tooling, and precision instruments.

Industry-Specific Examples

- Aerospace: Production of lightweight structural components and intricate engine parts.

- Automotive: Custom prototypes and functional parts for engine components, transmission systems, and trim.

- Medical: High-precision, biocompatible parts for surgical tools and diagnostic devices.

- Consumer Electronics: Custom casings, enclosures, and high-quality prototypes for gadgets and appliances.

- Industrial Equipment: Functional machine parts that require excellent surface finish and dimensional accuracy.

6. Advantages of Metal Vacuum Casting

Vacuum casting offers several significant advantages that make it a preferred method for prototyping and low-volume production:

- High Precision and Detail:

The vacuum environment minimizes defects, ensuring that every cast part accurately replicates the master model with minimal surface imperfections.

This precision is crucial for applications that demand tight tolerances. - Material Versatility:

Manufacturers can choose from a wide range of metal alloys, enabling them to tailor the mechanical and thermal properties of the final product to specific application needs. - Superior Surface Finish:

The elimination of air bubbles during the casting process results in smooth surfaces that often require little to no post-processing, reducing overall production time and cost. - Cost-Effective for Low-Volume Runs:

With lower tooling costs compared to injection molding, vacuum casting offers an economical solution for small production runs and rapid prototyping. - Rapid Turnaround:

The process enables faster production cycles, often completing prototypes within 7–10 days, which is critical in fast-paced industries where time-to-market is essential.

7. Challenges and Limitations of Metal Vacuum Casting

Despite its many benefits, metal vacuum casting faces several challenges that must be addressed:

- Material Limitations:

Not all metal alloys are ideal for vacuum casting. High-melting-point metals may require advanced equipment and tighter process controls, limiting the range of materials that can be used.

- Production Volume Constraints:

Vacuum casting is best suited for low-volume production.

The need to replace silicone molds every 20–30 cycles makes it less economical for mass production compared to injection molding or CNC machining. - Dimensional Accuracy Issues:

Slight shrinkage during the curing process, typically around 0.2–0.5%, can affect the dimensional accuracy of the final product.

This is particularly problematic for parts that require extremely tight tolerances. - Vacuum Integrity and Equipment Maintenance:

Maintaining a consistent vacuum is critical for eliminating air pockets.

Equipment leaks or fluctuations in vacuum pressure can lead to defects, emphasizing the importance of rigorous maintenance and quality control. - Higher Costs for Larger Batches:

Although cost-effective for small production runs, vacuum casting can become expensive for larger volumes due to frequent mold replacements and increased manual labor.

8. Innovations and Future Trends in Metal Vacuum Casting

Metal vacuum casting is undergoing transformative advancements driven by material science, digitalization, and sustainability. Here are key innovations and trends shaping its future:

Advanced Alloys and Material Innovations

- High-Performance Alloys: Development of superalloys (e.g., nickel-, cobalt-, or titanium-based) for extreme environments in aerospace, energy, and medical sectors.

- Metal Matrix Composites (MMCs): Integration of nanoparticles (e.g., carbon nanotubes, ceramics) to enhance strength, wear resistance, or thermal properties.

- Recycled and Sustainable Metals: Use of reclaimed metal powders/scraps to reduce environmental footprint.

- Biocompatible Metals: Titanium and magnesium alloys optimized for medical implants with improved osseointegration.

Integration with Additive Manufacturing (AM)

- 3D-Printed Wax/Resin Patterns: AM (e.g., SLA, FDM) accelerates production of intricate patterns for investment casting, enabling rapid prototyping of complex geometries.

- Direct Ceramic Mold Printing: Binder jetting or stereolithography to create ceramic molds directly, bypassing traditional pattern-making and reducing lead times.

- Hybrid Processes: Combining AM-produced cores with vacuum casting for multi-material or hollow structures (e.g., turbine blades with internal cooling channels).

Automation and Smart Manufacturing

- Robotic Pouring Systems: Precision automation for molten metal handling, improving consistency and safety.

- AI-Driven Process Optimization: Machine learning models predict defects (e.g., porosity, shrinkage) and optimize parameters like pouring temperature, cooling rates, and vacuum levels.

- IoT-Enabled Monitoring: Sensors track real-time data (temperature, pressure, gas levels) to ensure process stability and quality control.

Sustainability and Circular Economy

- Energy-Efficient Melting: Induction furnaces and microwave-assisted melting reduce energy consumption.

- Closed-Loop Recycling: Reclaiming and reusing metal scraps and ceramic mold materials.

- Eco-Friendly Binders: Water-soluble or biodegradable binders for ceramic molds to minimize waste.

Enhanced Process Precision

- Vacuum-Assisted Degassing: Improved removal of dissolved gases (e.g., hydrogen) to eliminate porosity and enhance mechanical properties.

- Controlled Solidification: Directional solidification and single-crystal growth techniques for critical components like turbine blades.

- Micro-Casting: Ultra-fine vacuum casting for micro-scale metal parts (e.g., medical devices, microelectronics).

Digital Twin and Simulation

- Virtual Process Modeling: Software (e.g., MAGMASOFT, ProCAST) simulates mold filling, solidification, and stress distribution to preempt defects.

- Digital Twins: Real-time digital replicas of casting systems for predictive maintenance and process refinement.

9. Metal Vacuum Casting vs. Other Metal Casting Methods

Metal vacuum casting stands out among various casting techniques, especially when high precision, exceptional surface finish, and rapid prototyping are required.

However, each casting method offers distinct advantages and limitations depending on the application.

Below is a comprehensive analysis of metal vacuum casting compared with

sand casting, die casting, and investment casting, enriched with a comparative table to clearly illustrate the differences.

Overview of Casting Methods

Metal Vacuum Casting involves pouring molten metal into a mold under vacuum conditions, which effectively removes air bubbles and defects, resulting in highly detailed and smooth parts.

This method excels in rapid prototyping and low-volume production, making it an ideal choice for industries that require iterative design changes.

Sand Casting is one of the oldest casting methods, where molten metal is poured into a sand-based mold.

Although it is cost-effective for large, heavy parts, the process typically results in lower precision and a rougher surface finish.

Die Casting uses high-pressure to force molten metal into a steel mold, producing parts with excellent surface finish and consistency.

It is highly suited for mass production but involves significant upfront tooling costs and less flexibility for design changes.

Investment Casting (lost wax casting) is known for its ability to reproduce intricate details and achieve high dimensional accuracy.

Despite its excellent finish, the process is more time-consuming and costly, making it best suited for low to medium production volumes.

Comparative Analysis of Casting Methods

The table below summarizes key performance parameters across different casting methods:

| Casting Method | Precision & Surface Finish | Production Volume | Tooling Cost | Lead Time | Material Versatility | Typical Applications |

|---|---|---|---|---|---|---|

| Metal Vacuum Casting | High precision; excellent surface finish; minimal defects due to vacuum conditions. | Ideal for low-volume production and prototyping. | Low tooling costs; minimal investment for short runs. | Fast turnaround (7–10 days). | Supports a broad range of metal alloys (e.g., aluminum, brass, stainless steel, copper, titanium). | Aerospace prototypes, automotive components, medical devices, custom industrial parts. |

| Sand Casting | Lower precision; rougher surface finish; may require extensive post-processing. | Suitable for high-volume production of large parts. | Low tooling costs; inexpensive molds. | Moderate lead times. | Limited to metals that can be easily molded in sand. | Heavy industrial components, engine blocks, large machine parts. |

| Die Casting | High precision; smooth, detailed surfaces; consistent quality. | Best for mass production. | High tooling costs; expensive steel molds. | Short cycle times for high-volume runs. | Extensive for plastics and certain metals; limited in metal alloy variety. | Consumer products, automotive parts, electronics housings. |

| Investment Casting | Very high precision; excellent detail reproduction; superior dimensional accuracy. | Low to medium volumes. | High tooling and production costs; complex process. | Longer lead times due to detailed mold-making. | Broad range of metals; ideal for complex geometries. | Jewelry, high-precision aerospace components, intricate tooling. |

10. Conclusion

Metal vacuum casting stands as a robust and versatile manufacturing method, offering high precision, excellent surface finishes, and cost-effective solutions for low-volume production.

It serves as a vital link between rapid prototyping and mass production, enabling companies to refine designs and validate performance before scaling up.

Although challenges such as material limitations and scalability exist, continuous innovations in materials,

process automation, and sustainability are poised to further enhance the capabilities of vacuum casting.

As industries continue to demand faster product development cycles and higher quality components, metal vacuum casting will play an increasingly important role in modern manufacturing.

Embracing these advancements will help businesses maintain a competitive edge and achieve superior product performance in an ever-evolving market.

If you’re looking for high-quality metal vacuum casting services, choosing LangHe is the perfect decision for your manufacturing needs.