Aluminum alloys are indispensable in a wide array of industries, owing to their unique combination of lightweight, durability, and impressive machinability.

Whether it’s aerospace components, automotive parts, or medical instruments,

the selection of the right aluminum alloy can dramatically impact the performance, cost, and longevity of a product.

In this article, we will delve into the different types of aluminum alloys, their distinctive properties, and their primary applications, helping you make an informed decision for your next project.

1. What Is Aluminum Alloy?

An aluminum alloy is a mixture of aluminum with other elements such as copper, magnesium, manganese, silicon, and zinc.

These elements are added to enhance the material’s mechanical properties, including its strength, durability, and resistance to corrosion.

Depending on the alloying elements, aluminum alloys are categorized into different series, each with specific characteristics that make them suitable for a variety of applications.

2. Understanding the Alloy Series

Aluminum alloys are classified into several series, identified by four-digit numbers.

Each series corresponds to the primary alloying element, which defines the alloy’s properties and potential uses. Here’s a breakdown:

- 1xxx Series: Pure aluminum, with a minimum of 99% aluminum content.

It is known for excellent corrosion resistance, workability, and high thermal conductivity. Commonly used in electrical industries (e.g., 1050, 1100). - 2xxx Series: Copper is the primary alloying element, offering high strength and fatigue resistance but lower corrosion resistance.

Primarily used in aerospace applications (e.g., 2024). - 3xxx Series: Manganese alloys provide moderate strength and excellent corrosion resistance. These are used in beverage cans, roofing, and cooking utensils (e.g., 3003, 3105).

- 4xxx Series: Silicon is added to reduce the melting point, making these alloys suitable for welding and brazing applications (e.g., 4032, 4047).

- 5xxx Series: Magnesium alloys are known for good corrosion resistance and weldability. Common in marine environments (e.g., 5052, 5083).

- 6xxx Series: Composed of magnesium and silicon, offering excellent machinability, strength, and corrosion resistance.

Common in construction and automotive industries (e.g., 6061, 6063). - 7xxx Series: Zinc is the primary alloying element, known for high strength and often used in aerospace and high-performance applications (e.g., 7075).

- 8xxx Series: These alloys are for specialized applications and include elements like lithium and iron, used in electrical and foil applications (e.g., 8006, 8090).

3. Recognizing Temper Designations

Recognizing temper designations is crucial for understanding the properties and potential applications of metal alloys, particularly aluminum and steel.

The temper designation provides information about the thermal and mechanical treatments that have been applied to an alloy to achieve specific characteristics

such as hardness, strength, ductility, and formability.

For aluminum alloys, temper designations are typically indicated by a suffix following the alloy number.

These designations can be quite detailed and provide specific information on how the material has been treated. For example:

- F – As fabricated, no special control over thermal or working conditions.

- O – Annealed to obtain the lowest strength condition.

- H – Strain hardened (cold worked) with or without supplementary thermal treatment.

H tempers can be further subdivided into more specific categories depending on the degree of cold work and whether additional heat treatment has been applied. - T – Heat treated to produce stable tempers other than F, O, or H.

The T temper may be followed by one or more digits that specify particular conditions,

such as T3 (solution heat treated, cold worked), T4 (solution heat treated, naturally aged), T6 (solution heat treated, artificially aged), etc.

4. Properties of Aluminum

Aluminum stands out for several key properties that make it an ideal material for diverse applications:

Lightweight

One of the most well-known properties of aluminum is its low density.

At around 2.7 g/cm³, it is roughly one-third the weight of steel, making it ideal for applications where weight reduction is crucial.

This property is especially advantageous in industries like aerospace, automotive, and transportation,

where every kilogram of weight saved can contribute to better fuel efficiency and performance.

Corrosion Resistance

Aluminum has an intrinsic ability to resist corrosion due to the natural formation of a protective oxide layer on its surface when exposed to air.

This oxide layer prevents further oxidation, making aluminum highly resistant to rust and corrosion, particularly in harsh environments.

This resistance can be further enhanced with specific aluminum alloys, coatings, or anodization processes, making it ideal for marine, automotive, and outdoor applications.

Electrical and Thermal Conductivity

Aluminum is an excellent conductor of both electricity and heat.

It is used extensively in the electrical industry for wiring and heat transfer applications like heat exchangers, radiators, and cooling systems.

Its thermal conductivity is 237 W/m·K, making it effective at dissipating heat.

Its electrical conductivity is about 60% that of copper, which makes it a preferred material for electrical cables,

especially in high-voltage applications where weight reduction is also a concern.

Ductility and Malleability

Aluminum is a highly ductile and malleable material, meaning it can be easily formed, bent, or rolled into various shapes without cracking.

This is why aluminum is often used for extrusion, allowing manufacturers to create a wide range of complex shapes such as pipes, profiles, and frames.

Its ability to be cold-worked further improves its formability, which makes it versatile for different manufacturing processes.

High Strength-to-Weight Ratio

Despite its lightweight nature, aluminum alloys are capable of achieving a high strength-to-weight ratio,

which makes it strong enough to withstand heavy loads while maintaining its low weight.

By adding different alloying elements, such as copper, magnesium, or zinc, aluminum’s strength can be significantly increased,

making it suitable for demanding applications such as in aerospace (e.g., 7075 aluminum), automotive, and structural components.

Non-Toxic and Biocompatible

Aluminum is non-toxic and biocompatible, making it safe for applications in medical devices and food containers.

It is widely used in food packaging (e.g., aluminum foil, cans) and medical equipment (e.g., surgical tools, implants) due to its safety and inertness in contact with humans.

Recyclability

Aluminum is one of the most recyclable metals.

It retains its inherent properties even after multiple cycles of recycling, which makes it a sustainable material choice for environmentally conscious industries.

Recycling aluminum requires only 5% of the energy used to produce it from raw materials, making it highly cost-effective and energy-efficient in the long term.

The high recyclability of aluminum helps reduce waste and the environmental footprint of products.

Reflectivity

Aluminum is highly reflective, particularly when it is polished or anodized. It reflects about 80% of visible light and up to 98% of infrared radiation.

This property makes aluminum an excellent choice for applications requiring heat or light reflection, such as in lighting, insulation, and solar panels.

Strength and Hardness

Aluminum is relatively soft in its pure form, but it can be significantly strengthened through various alloying techniques and heat treatments.

For example, 6061 and 7075 aluminum alloys provide excellent strength, making them suitable for structural components and high-performance applications.

The hardness of aluminum is also influenced by the alloying elements, with certain grades offering superior resistance to wear and deformation.

Acoustic and Vibration Damping

Aluminum has excellent acoustic properties, meaning it can absorb vibrations and noise effectively,

which makes it useful in soundproofing, vehicle construction, and electronic enclosures.

Its ability to dampen noise and vibrations is a valuable characteristic for improving the comfort and performance of products in various industries.

Surface Finish and Aesthetic Appeal

Aluminum’s ability to undergo processes like anodizing, painting, or polishing provides opportunities for a wide range of aesthetic finishes.

It is often used in applications where both functionality and appearance are important, such as in architectural finishes, consumer electronics, and automotive trim.

5. Common Aluminum Alloy Types Used in Machining

Aluminum alloys are widely used in machining due to their excellent machinability, strength-to-weight ratio, and corrosion resistance.

Various aluminum alloys are tailored to specific applications based on their composition and properties.

Below, we explore some of the most common aluminum alloy types used in machining, along with their key characteristics and typical applications.

Aluminum 6061

Composition: Aluminum 6061 is a combination of aluminum, magnesium, and silicon.

Properties:

- High corrosion resistance, especially after heat treatment.

- Good strength and machinability.

- Excellent weldability, making it suitable for structural applications.

- Moderate to good fatigue resistance.

Applications:

- Widely used in aerospace components, structural parts, and construction materials.

- Bicycle frames, sporting goods, and marine applications.

- Suitable for parts requiring good strength, weldability, and corrosion resistance.

6061 Aluminum parts

Why It’s Common in Machining: 6061Al is one of the most popular aluminum alloys for machining.

It has good machinability, allowing it to be easily cut, drilled, and shaped, making it a go-to choice for both prototyping and high-performance applications.

Aluminum 5052

Composition: Aluminum 5052 contains aluminum, and magnesium as the primary alloying element.

Properties:

- Excellent corrosion resistance, especially in marine environments.

- Good weldability and formability.

- Moderate strength compared to other aluminum alloys but good strength-to-weight ratio.

- High resistance to saltwater corrosion, making it ideal for harsh environments.

Applications:

- Marine industry (boat hulls, decks, marine tanks).

- Automotive (fuel tanks, exhaust systems).

- Storage tanks and pressure vessels.

- Industrial machinery and architectural applications.

Why It’s Common in Machining: 5052 is known for its superior corrosion resistance, making it ideal for harsh environments.

It offers excellent machinability, especially for parts that require high strength and corrosion resistance without needing extreme precision.

Aluminum 7075

Composition: Aluminum 7075 contains aluminum with zinc, magnesium, and copper as the primary alloying elements.

Properties:

- Very high strength-to-weight ratio.

- Excellent fatigue resistance, making it suitable for high-stress applications.

- Fair corrosion resistance, which can be improved with coatings or anodizing.

- Lower machinability compared to 6061 due to higher strength.

Applications:

- Aerospace (aircraft structures, landing gears).

- Military (high-performance equipment, tooling).

- Sporting equipment (high-strength bicycle frames, fishing reels).

- Applications requiring high strength and resistance to stress and fatigue.

Why It’s Common in Machining: 7075 aluminum is ideal for heavy-duty applications that require extreme strength and toughness.

While it can be harder to machine than 6061 due to its higher strength, it remains popular for applications where mechanical performance is the priority.

Aluminum 2024

Composition: Aluminum 2024 is primarily composed of aluminum and copper, with small amounts of manganese, magnesium, and other elements.

Properties:

- Excellent strength and fatigue resistance.

- Lower corrosion resistance compared to 6061 and 5052.

- High machinability when treated correctly.

- Known for its ability to handle stress and impact in demanding environments.

Applications:

- Aerospace components (wing skins, fuselage frames, and structural components).

- Aircraft parts require a high strength-to-weight ratio and fatigue resistance.

- Marine applications where strength is crucial, though often coated for better corrosion protection.

Why It’s Common in Machining: 2024 aluminum is highly regarded for its strength and fatigue resistance.

It is often used in aerospace machining due to its superior performance under stress, though it requires special care in machining due to its tendency to be more brittle than other alloys.

Aluminum 3003

Composition: Aluminum 3003 is a relatively pure aluminum alloy with manganese as the primary alloying element.

Properties:

- Excellent corrosion resistance, particularly in mild environments.

- Good workability and formability, but lower strength than other alloys like 6061 or 7075.

- Easy to machine, and well-suited for various sheet and plate applications.

Applications:

- Residential and commercial applications (roofing, siding).

- Cooking utensils, storage tanks, and other everyday products.

- Automotive and HVAC applications.

Why It’s Common in Machining: 3003 is easy to machine, form, and weld, making it an excellent choice for simple, lightweight applications.

It’s ideal for situations where excellent corrosion resistance and high formability are more critical than strength.

Aluminum 6063

Composition: Aluminum 6063 is primarily made of aluminum with magnesium and silicon alloying elements.

Properties:

- High corrosion resistance.

- Good surface finish quality, making it ideal for aesthetic applications.

- High formability and excellent extrusion characteristics.

- Moderate strength, suitable for general engineering applications.

Applications:

- Architectural applications (window frames, door frames, curtain walls).

- Furniture and decorative items.

- Structural applications that require good corrosion resistance and appearance.

Why It’s Common in Machining: 6063 is easy to machine, extrude, and form, and it offers a great balance between strength and aesthetic quality.

Its excellent surface finish and corrosion resistance make it a go-to for many decorative and structural applications.

Aluminum 1100

Composition: Aluminum 1100 is essentially pure aluminum, with a minimum of 99% aluminum content.

Properties:

- Excellent corrosion resistance.

- Very good workability and weldability.

- Low strength compared to other alloys, but lightweight and malleable.

- High thermal and electrical conductivity.

Applications:

- Heat exchangers, chemical equipment, and food processing.

- Cooking utensils, foil, and storage containers.

- Decorative applications and architectural components.

Why It’s Common in Machining: 1100 aluminum is incredibly easy to machine and form, making it ideal for applications requiring intricate shapes and non-structural components.

It’s highly sought after for applications requiring high conductivity or corrosion resistance rather than strength.

6. Considerations for Choosing the Right Aluminum Alloy Type

When selecting an aluminum alloy for machining, several factors must be taken into account:

- Machinability Rating: Alloys like 6061 and 7075 are highly machinable, making them ideal for producing complex parts. 2011 is also noted for its excellent machinability.

- Material Costs and Availability: High-strength alloys like 7075 tend to be more expensive and may be harder to source,

while more common alloys like 6061 are more affordable and widely available. - Heat Treatment: Alloys like 2xxx, 6xxx, and 7xxx can be heat-treated to further enhance their mechanical properties, adding complexity and cost to the process.

- Casting vs. Wrought Alloys: Wrought alloys, processed by rolling, forging, or extrusion, are generally stronger and more uniform than cast alloys, which are solidified from molten metal.

7. Applications of Aluminum Alloys

Aluminum alloys find applications in numerous industries due to their lightweight, durability, and resistance to corrosion. Some of the key sectors include:

Aerospace Industry

In aerospace, aluminum alloys have been used extensively due to their lightweight and high-strength properties.

Alloys such as 2024 and 7075 are favored for aircraft structures because they provide the necessary strength and fatigue resistance required in critical components.

The use of aluminum alloys helps reduce the overall weight of aircraft, which in turn leads to lower fuel consumption and increased efficiency.

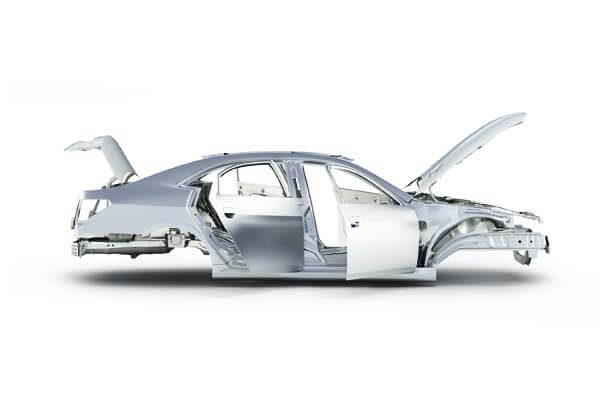

Automotive Industry

The automotive industry has increasingly turned to aluminum alloys to reduce vehicle weight, improve fuel economy, and enhance performance.

Modern vehicles, including electric cars like Tesla and NIO ES8, utilize aluminum bodies to achieve significant weight reductions,

sometimes up to 30-40% compared to traditional steel bodies.

Aluminum alloys are also used in engine blocks, wheels, suspension systems, and other parts where durability and lightness are important.

Marine Applications

For marine applications, aluminum alloys are selected for their ability to withstand saltwater corrosion.

They are commonly used in the construction of boat hulls, superstructures, and various fittings.

Alloy series such as 5xxx are particularly suitable for these environments due to their magnesium content, which improves corrosion resistance.

Construction

Aluminum alloys are widely used in architectural and structural applications, including window frames, roofing, siding, and decorative elements.

Their ability to be easily formed into complex shapes and their natural resistance to weathering make them ideal for both aesthetic and functional purposes in building design.

Electrical Transmission

Due to their excellent electrical conductivity and low weight, aluminum alloys are often used in power transmission lines.

Although not as conductive as copper, aluminum’s lighter weight makes it more cost-effective for overhead power lines.

Consumer Goods

Consumer products ranging from kitchen utensils to sports equipment frequently incorporate aluminum alloys.

Items like cookware benefit from aluminum’s superior thermal conductivity, while bicycles and golf clubs leverage its lightweight nature to improve performance.

Packaging

Aluminum foil and cans are ubiquitous examples of aluminum alloy usage in packaging.

The material provides an effective barrier against light, oxygen, and moisture, preserving the quality of food and beverages over long periods.

Renewable Energy

In renewable energy sectors, aluminum alloys play a vital role in solar panel frames and wind turbine components.

Their lightness and durability contribute to the efficiency and longevity of these technologies.

8. Conclusion

Understanding the different types of aluminum alloys and their respective grades is crucial for selecting the most suitable material for your project.

Each alloy series offers distinct properties, allowing manufacturers to choose the best match based on specific application needs, performance requirements, and cost considerations.

If you need help determining the right aluminum alloy for your project or require high-precision aluminum machining, LangHe is here to assist.

We offer customized machining solutions tailored to your exact specifications, ensuring your project is a success from start to finish.

Contact us today to learn more about our comprehensive services and expert solutions.

FAQs

Q: What is the difference between 6061 and 7075 aluminum?

A: 6061 offers good corrosion resistance and is easier to weld, while 7075 provides higher strength but is more challenging to weld.

Q: What is the most corrosion-resistant aluminum alloy?

A: Alloys in the 5xxx series, such as 5052, offer excellent corrosion resistance.

Q: Which aluminum alloy is best for outdoor use?

A:5052 is excellent for outdoor applications due to its high resistance to corrosion.

Q: What aluminum alloy is best for machining?

A:6061 and 7075 are among the most commonly used for machining due to their excellent machinability and mechanical properties.

Q: Can all aluminum alloys be heat-treated?

A: No, only certain alloys, such as 2xxx, 6xxx, and 7xxx, can be heat-treated to increase strength.