Popular Finishes for Metal

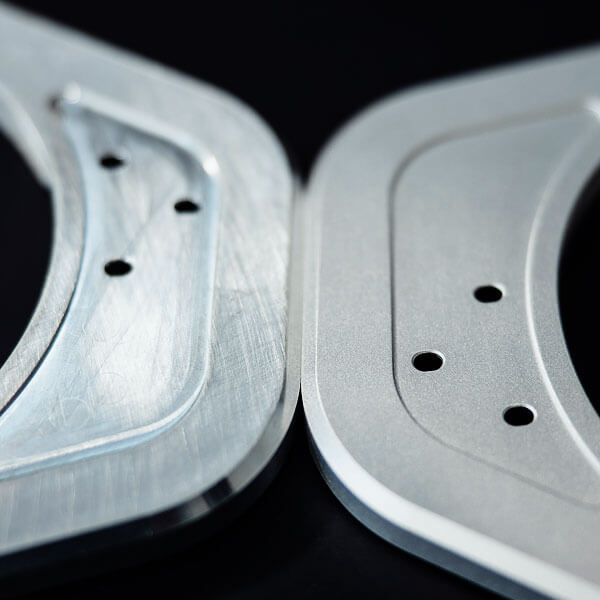

As machined finish is a CNC machined part or parts that come right off the machine, just keep the parts as it is without any other surface finishing involved.

Type II anodize provides increased corrosion resistance and can be used as a base for paint and other finishes. Thickness ranges from .0002”-.0012”. Will conform to MIL-A-8625/MIL-PRF-8625 Type II, Class 2.

Color anodizing involves using dyes to affect the part’s surface color. Anodized colors cannot be matched to specific Pantone or RAL colors. Type II coatings are susceptible to wear and may bleach or fade under prolonged direct sunlight.

Type III hard coat anodize produces a thicker layer of standard anodizing, making it more durable and wear-resistant. It can be used as a base for paint and other finishes. Colors tend to come out slightly dark due to thickness. Anodized colors cannot be matched to specific Pantone or RAL colors. Thickness is generally 0.002” and will conform to MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2.

Electroplating is a widely used electrochemical process that involves depositing a thin layer of metal onto the surface of a part to enhance its properties. The process not only improves the part’s appearance but also boosts its resistance to corrosion, wear, and tarnishing.

Powder coating is a highly effective finishing process that involves applying a dry powder to a metal surface and curing it with heat to form a hard, protective finish. This coating provides excellent durability, resistance to corrosion, and a high-quality aesthetic appearance.