1. Einführung

Kükenventil ist ein vielseitiges Vierteldrehungsventil, das häufig zur Isolierung eingesetzt wird, Umleitung, und gelegentliche Drosselung in Industriesystemen.

Sein einfacher Aufbau – ein zylindrischer oder konischer Stopfen, der sich in einem Ventilkörper dreht – ermöglicht eine schnelle Bedienung, geringer Druckabfall, und robuste Zuverlässigkeit.

Seine Prinzipien verstehen, Materialien, Leistungsmetriken, und Industrieanwendungen ist für die Auswahl des richtigen Ventils für Hochdruck von entscheidender Bedeutung, Schleifmittel, oder platzbeschränkte Dienste.

2. Was ist ein Kükenventil??

A Kükenventil ist ein spezielles Drehventil mit Vierteldrehung, das häufig in industriellen Rohrleitungssystemen zur Strömungsisolierung eingesetzt wird, Umleitung, und gelegentliches Throttling.

Das Kernbetriebsprinzip beruht auf a zylindrischer oder konischer Stopfen in einem Ventilgehäuse untergebracht, Dieser dreht sich, um entweder seinen internen Anschluss mit der Rohrleitung auszurichten und so einen ungehinderten Durchfluss zu gewährleisten, oder um den Durchgang vollständig zu blockieren.

Dieser einfache, aber robuste Mechanismus ermöglicht eine schnelle 90°-Bedienung, bietet sowohl Effizienz als auch Zuverlässigkeit in kritischen Anwendungen.

Kernfunktionen

- Vierteldrehung

Schnelle Betätigung (typischerweise 90°) — ideal für die Notfallisolierung, Umlenkaufgaben und Anwendungen, bei denen ein schnelles Ein-/Ausschalten erforderlich ist. - Einfach, Strömungsweg mit geringer Behinderung

Konfigurationen mit vollem Anschluss bieten nahezu einen Rohrdurchfluss bei minimalem Druckabfall; Optionen mit reduziertem Anschluss tauschen Durchflusskapazität gegen geringeres Drehmoment und geringere Kosten. - Mehrere Portkonfigurationen

Zwei-, drei- und Vier-Wege-Steckeranordnungen ermöglichen eine Umleitung, Mischen, Probenahme und komplexe Leitungsführung ohne mehrere Ventile. - Vielseitigkeit beim Abdichten

Erhältlich mit Metall auf Metall Sitze für Hochtemperatur-/Abrasivanwendungen, robust (PTFE/RPTFE, Elastomere) Sitze für blasendichtes Absperren und niedriges Drehmoment, oder geschmiert Systeme, die die Sitzlebensdauer in schmutzigen oder erosiven Medien verlängern.

3. Klassifizierung von Kükenventilen nach Design

Kükenventile werden basierend auf kategorisiert mechanisches Design, Versiegelungsmethode, und Strömungskonfiguration.

Das Verständnis dieser Klassifizierungen hilft Ingenieuren bei der Auswahl des richtigen Ventils für den Druck, Temperatur, fließen, und Serviceanforderungen.

Basierend auf dem Steckertyp

| Typ | Beschreibung | Vorteile | Typische Anwendungen |

| Zylindrisches Kükenventil | Der gerade zylindrische Plug dreht sich in einer passenden Körperhöhle; einfachste Bauform. | Kompakt, kostengünstig, geringer Druckabfall. | Wasser, Gas, Niederdruck-Chemieleitungen. |

| Konisch (Konisch) Stopfenventil | Konischer Stopfen, der für eine bessere Abdichtung im Gehäuse verkeilt ist. | Hervorragende Abdichtung; bewältigt höheren Druck und Temperatur. | Petrochemisch, Öl & Gas, Dampflinien. |

Basierend auf der Portkonfiguration

| Porttyp | Beschreibung | Vorteile | Typische Anwendungen |

| Durch den Hafen (Vollständiger Port) | Der Anschluss entspricht dem Rohrleitungsdurchmesser; Fließweg gerade durch. | Minimaler Druckabfall; hohe Durchflusskapazität. | Massentransport von Flüssigkeiten, Pipelines, Güllehandhabung. |

| Reduzierter Port | Anschluss kleiner als Rohrbohrung. | Geringeres Betriebsdrehmoment; kostengünstig. | Systeme mit mittlerem Durchfluss, Instrumentenlinien. |

| Multi-Port (Drei- oder Vier-Wege) | Ermöglicht eine Flussumleitung, Mischen, oder Probenahme über mehrere Ports. | Ersetzt mehrere Ventile; flexible Streckenführung. | Probenahme, Umleitungspflichten, Chemische Reaktoren. |

Basierend auf Plug-Unterstützung

| Unterstützungstyp | Beschreibung | Vorteile | Einschränkungen |

| Schwimmender Stecker | Der Stecker liegt zwischen den Sitzen und dreht sich frei. | Selbstausrichtend; einfacher Aufbau. | Höheres Drehmoment bei großen Größen; begrenzter Hochdruckeinsatz. |

| Zapfenmontierter Stecker | Dübel mit oberen und/oder unteren Lagern verankert. | Reduziert das Betriebsdrehmoment; stabil bei Hochdruck- oder Großanwendungen. | Komplexeres Design; höhere Produktionskosten. |

Basierend auf dem Dichtungsdesign

Verlängerte Sitzlebensdauer; reibungsloser Betrieb in schmutzigen oder erosiven Flüssigkeiten.

Regelmäßige Wartung; nicht ideal für Sanitäranwendungen.

Lymer-Sitze sorgen für eine dichte Abdichtung.

| Dichtungstyp | Beschreibung | Vorteile | Einschränkungen |

| Metall-auf-Metall | Harter Sitz hat direkten Kontakt zum Stecker. | Hohe Temperatur, Hochdruck, Schleifservice. | Erfordert ein höheres Drehmoment; Ohne Schmierung kann es zu Fressverschleiß kommen. |

| Belastbare Sitze (Ptfe, Rptfe)

</td> |

Elastomer oder Po | Niedriges Drehmoment; Blasendichte Absperrung; chemische Beständigkeit. | Begrenzter Temperaturbereich; mögliche Verschlechterung durch aggressive Medien. |

| Lubr |

4. Hauptkomponenten und Materialien des Kükenventils

Die Leistung eines Kükenventils, Haltbarkeit, und die Eignung für bestimmte Anwendungen hängen davon ab Komponenten und Materialien.

Jedes Teil ist so konstruiert, dass es Druck standhält, Temperatur, Korrosion, und Erosion und sorgt gleichzeitig für einen reibungslosen Betrieb und eine leckagefreie Abdichtung.

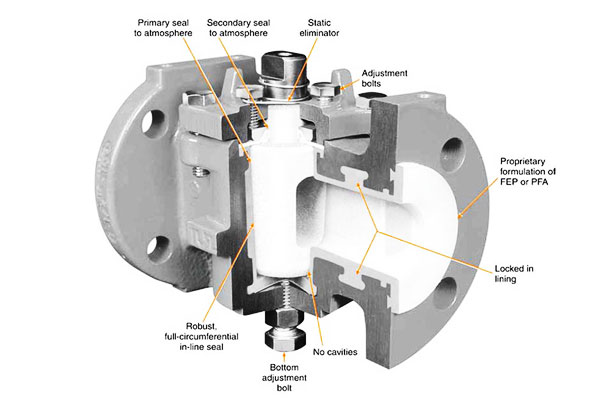

Hauptkomponenten

| Komponente | Beschreibung | Funktion |

| Ventilkörper | Das äußere Gehäuse, das den Stecker und die Anschlüsse enthält. | Unterstützt Druckbelastungen, stellt den Strömungsweg bereit, und verbindet sich mit der Pipeline. |

| Stecker | Zylindrisches oder konisches rotierendes Element mit einer oder mehreren Öffnungen. | Steuert den Fluss durch Ausrichten oder Blockieren des Ports(S); primäres Flusskontrollelement. |

| Sitze | Metallische oder elastische Oberflächen, gegen die der Stopfen abdichtet. | Gewährleistet eine blasendichte Absperrung und erhält die Dichtungsintegrität langfristig aufrecht. |

| Stängel / Handhaben | Welle oder Hebel zum Drehen des Steckers. | Überträgt das Drehmoment vom manuellen oder automatisierten Stellantrieb auf den Stecker. |

| Schmiermittelkammer (optional) | Ein mit Schmiermittel gefülltes Reservoir zwischen Stopfen und Gehäuse (für geschmierte Kükenhähne). | Reduziert die Reibung, verlängert die Lebensdauer des Sitzes, und verhindert Abrieb oder Korrosion. |

| Lager / Zapfen (für Zapfenstecker) | Unterstützt oben und/oder unten am Stecker. | Reduziert das Betätigungsdrehmoment und stabilisiert den Kegel in großen Ventilen oder Hochdruckventilen. |

| Drüse / Verpackung | Dichtungselement um die Schaft- oder Griffschnittstelle. | Verhindert Leckagen entlang des Stiels/Griffs; ermöglicht eine reibungslose Drehung. |

Materialauswahl

| Komponente | Typische Materialien | Schlüsseleigenschaften |

| Körper & Motorhaube | Kohlenstoffstahl (A216 WCB), Edelstahl (304, 316), Duplex, Legierung 20, Nickellegierungen | Stärke, Korrosionsbeständigkeit, Temperaturtoleranz |

| Stecker | Wie Körper oder mit Hartbeschichtung (Stelliten, WC-Auflage) | Resistenz tragen, Dimensionsstabilität, Chemische Kompatibilität |

| Sitze | Metall (Stelliten, Monel), PTFE/RPTFE, UHMWPE | Dichtheit, chemische Beständigkeit, geringe Reibung |

| Stängel / Handhaben | Edelstahl, Legierungsstahl | Stärke, Torsionssteifigkeit, Korrosionsbeständigkeit |

| Schmiermittel | Mineralöl, synthetisches Fett, oder von der FDA zugelassene Schmiermittel | Reduziert die Reibung und schützt vor Korrosion bei geschmierten Ventilen |

5. Strömungseigenschaften und hydraulisches Verhalten

Durchflussfähigkeit (Cv) — typische Bereiche

- Kleine Kükenhähne in Instrumentengröße (¼ – 1) vielleicht haben Lebenslauf ~ 0,1–5.

- Gängige Prozessgrößen (2–6) typischerweise Bereich Lebenslauf ~ 5–200 je nach Portdesign (voller Port vs. reduzierter Port).

- Kükenhähne mit großem Durchmesser (8+) können sehr hohe Cv-Werte erreichen, vergleichbar mit Kugelhähnen und übertrifft oft Kugelventile derselben Größe.

Druckabfall und Drosselung

- Kükenhähne sind in erster Linie dafür konzipiert Ein/Aus oder Umlenker Service.

Sie können zwar zur Drosselung genutzt werden, sie sind weniger ideal als Kugelventile für eine präzise Modulation aufgrund möglicher nichtlinearer Strömungseigenschaften und Sitzverschleiß bei Drosselung unter hohem ΔP. - Der Druckabfall steigt mit dem Durchfluss und nimmt mit der Anschlussgröße ab; Der Betrieb mit hohem ΔP erfordert spezielle Verkleidungen (Mehrstufen- oder Druckreduzierstopfen) um Lärm und Erosion zu vermeiden.

6. Leistungsmetriken und -klassen

| Metrisch | Typische Sorge / Reichweite |

| Druckklasse | ANSI 150–2500 allgemein; höher bei geschmiedeten Designs |

| Temperaturbereich | Kryogen (mit geeigneten Materialien) bis zu ≈400–600°C in gängigen Legierungen; Speziallegierungen erweitern das Sortiment |

| Leckage | Metallsitze: geringe Leckage, aber nicht in allen Fällen blasendicht; elastische Sitze: blasendicht (praktisch keine Leckage) |

| Zyklusleben | Geschmierte Metallsitze: lange Lebensdauer im sauberen Betrieb; elastische Sitze: Tausende bis Zehntausende Zyklen |

| Flüchtige Emissionen | Mit Blasebalg mildern, Live-Verpackung, und nachgiebige Schaftdichtungen |

| Standards & Tests | Prüfung des Schalen-/Sitzdrucks, Dichtheitsprüfung des Sitzes, NDT an kritischen Teilen (Radiographie, Mpi) |

7. Herstellungsprozess des Kükenventils

Bei der Herstellung von Kükenhähnen kommt es auf Präzision an Casting, Bearbeitung, Montage, und testen um die Haltbarkeit zu gewährleisten, dichte Abdichtung, und zuverlässigen Betrieb unter verschiedenen industriellen Bedingungen.

Gießen oder Schmieden des Körpers und des Steckers

Das Ventil Gehäuse und Stecker bilden den strukturellen Kern des Kükenventils. Sie können hergestellt werden über:

- Sandguss: Üblich für mittel- bis hin zu Großventilen. Bietet Flexibilität bei komplexen Geometrien, einschließlich Multi-Port-Aufbauten, und ermöglicht eingebettete Funktionen wie Zapfenstützen.

Eine Wärmebehandlung nach dem Guss reduziert die Restspannung. - Feinguss (Lost-Wachs): Bietet außergewöhnliche Maßhaltigkeit und glatte Oberflächen, Ideal für Präzisionsventile oder kleinere Ventile mit engen Toleranzen.

- Schmieden: Produziert dicht, Hochfeste Komponenten für Hochdruck- oder kritische Anwendungen. Geschmiedete Ventile haben weniger Hohlräume und eine überlegene Ermüdungsbeständigkeit, Geeignet für API 6D-Pipeline-Standards.

Präzisionsbearbeitung

Nach dem Gießen oder Schmieden, Komponenten unterziehen sich CNC- und manuelle Bearbeitung um exakte Toleranzen und glatte Oberflächen zu erreichen:

- Bohren und Schleifen von Stopfen: Stellt sicher, dass sich der Stopfen frei drehen kann und gleichzeitig eine dichte Abdichtung gegen den Sitz gewährleistet.

- Sitzbearbeitung: Metall- oder elastische Sitze werden mit Toleranzen im Mikrometerbereich bearbeitet, um eine blasendichte Absperrung zu gewährleisten.

- Portausrichtung: Entscheidend für Mehrwegeventile, um korrekte Durchflusswege zu gewährleisten und den Druckabfall zu minimieren.

- Oberflächenveredelung: Länen, Polieren, oder Honen verringert die Reibung, verhindert Fressen, und verbessert die langfristige Zuverlässigkeit der Dichtung.

Panzerungen und Beschichtungen

Zur Verbesserung der Haltbarkeit Schleifmittel, erosiv, oder korrosive Medien, Stecker und Sitze können sein:

- Hartgeprägt mit Stelliten, Wolfram -Carbid, oder Nickelbasislegierungen, Erhöhung der Verschleißfestigkeit und Verlängerung der Lebensdauer.

- Beschichtet mit korrosionsbeständigen Schichten wie PTFE, Nickelbeschichtung, oder Epoxidharz.

- Geschmiert in speziellen Ventilen, um einen Betrieb mit niedrigem Drehmoment aufrechtzuerhalten, Festfressen verhindern, und verlängern die Lebensdauer der Dichtung, insbesondere bei Hochdruck-Schlammanwendungen.

Montage und Montage

Die Montage ist ein Präzisionsvorgang, der eine ordnungsgemäße Montage gewährleistet Ausrichtung, sanfte Betätigung, und Dichtungsintegrität:

- Einsetzen des Steckers: Sorgfältig im Körper platziert; bei Bedarf geschmiert.

- Installation von Vorbau und Zapfen: Zur Reduzierung des Betriebsdrehmoments und zur Stabilisierung großer Stopfen unter hohem Druck sind Lager und Zapfenstützen eingebaut.

- Anpassung der Packung und der Stopfbuchse: Verhindert Leckagen entlang des Schafts und sorgt gleichzeitig für eine reibungslose Drehung.

- Siegel- und Sitzüberprüfung: Metall- oder elastische Sitze werden auf korrekte Kompression überprüft, Ausrichtung, und Oberflächenkontakt.

Prüfung und Qualitätskontrolle

Jedes Kükenventil wird strengen Tests unterzogen, um die Anforderungen zu erfüllen API, ISO, und ASTM-Standards:

- Hydrostatische und pneumatische Druckprüfungen: Überprüfen Sie die Integrität von Gehäuse und Sitz unter Nennbetriebsdrücken und maximal zulässigen Drücken.

- Sitzdichtheitstests: Blasendichten Verschluss nach ISO bestätigen 5208 oder API 598.

- Dimensionale Überprüfung: CNC-Koordinatenmessgeräte (CMM) stellen Sie sicher, dass die Designvorgaben eingehalten werden.

- Betriebsdrehmomentmessung: Sorgt für eine reibungslose Drehung ohne übermäßige Krafteinwirkung, Kritisch für automatisierte oder fernbetätigte Ventile.

- Nicht-zerstörerische Tests (Ndt): Techniken wie Farbeindringmittel, Magnetpartikel, oder Ultraschallprüfungen erkennen Mikrorisse, Porosität, oder Gussfehler.

8. Vorteile und Einschränkungen

Hauptvorteile des Kükenventils

- Beständigkeit gegen abrasive Flüssigkeiten: Exzentrische Stopfen mit Wolframcarbid-Sitzen zuletzt 300% länger als Kugelhähne in Bergbauschlämmen (pro Mining Engineering Journal).

- Niederdruckabfall: Vollständig geöffnete Kükenventile reduzieren den Energieverbrauch der Pumpe um 10–15 % gegenüber. Globusventile (EPA Energy Star-Daten).

- Schnelle Bedienung: Design mit Vierteldrehung (0.5–2s für automatisierte Ventile) – entscheidend für Notabschaltungen (Z.B., Ölquellenausbrüche).

- Vielseitigkeit: Behandelt Flüssigkeiten, Gase, und Schlämme bei -196 °C bis 815 °C – ein Ventiltyp für mehrere Prozessströme.

- Leckdichtleistung: Weichsitzventile erreichen die Leckageklasse VI (≤0,00001 %) – verhindert den Verlust teurer/giftiger Flüssigkeiten.

Einschränkungen des Kükenventils

- Hohe Drehmomentanforderungen: Ungeschmierte Ventile mit Metallsitz benötigen zwei- bis dreimal mehr Drehmoment als Kugelhähne – größere Ventile erfordern kostspielige pneumatische/hydraulische Antriebe.

- Wartungsbedürfnisse: Bei geschmierten Ventilen ist eine vierteljährliche Fetteinspritzung erforderlich – eine versäumte Wartung führt zum Blockieren der Stopfen (Ausfallzeit 4–8 Stunden pro Vorfall).

- Hochtemperaturgrenzen: Weiche Sitze (Ptfe) Zersetzung über 260 °C – beschränkt auf den Einsatz bei niedrigen Temperaturen (Z.B., Lebensmittelverarbeitung).

- Kosten: Exzenter- und Hochleistungskegelhähne kosten 20–50 % mehr als Kugelhähne – nur bei rauen Bedingungen gerechtfertigt.

- Schlämme mit großen Feststoffen: Multiport- und zylindrische Stopfen verstopfen durch Feststoffe >5 mm – erfordern Siebe oder exzentrische Ausführungen.

9. Anwendung des Kükenventils

Kükenventile überzeugen in rauen Industrieumgebungen, in denen andere Ventile versagen.

Nachfolgend sind die wichtigsten Sektoren und Anwendungsfälle aufgeführt:

Öl & Gas

- Stromaufwärts (Bohrlöcher): API 6A-geschmierte Kükenhähne (1000 Bar, 350° C) Regulierung von Rohöl und Sauergas – die Einhaltung von NACE MR0175 schützt vor H₂S-Korrosion.

- Mittelstrom (Pipelines): Exzentrische Kükenventile (6d Feuer) fungieren als Absperrventile für Erdgas (Durchflussraten bis zu 10,000 m³/h) – Ein geringer Druckabfall reduziert den Energieverbrauch des Kompressors.

- Stromabwärts (Raffinerien): Metallisch dichtende Kükenhähne verarbeiten Schweröl und Asphalt (400° C) – Wolframkarbidstopfen widerstehen dem Abrieb von Kokspartikeln.

Wasser- und Abwasserbehandlung

- Schlammbehandlung: Exzentrische Kükenventile (weiche Sitze, Klasse VI) Behandeln Sie Schlamm mit 20–30 % Feststoffen – kein Verstopfen, 60% weniger Ausfallzeiten als Kugelhähne.

- Chemikaliendosierung: Ungeschmierte Kükenhähne (PTFE -Sitze) Kontrollieren Sie die Chlor-/Fluoriddosierung – Leckagen der Klasse VI verhindern eine Wasserverunreinigung.

- Entsalzung: 316L-Kegelventile sind für Salzwasser geeignet (538° C) – Korrosionsbeständigkeit gewährleistet 10+ Jahr Lebensdauer.

Chemie und Pharma

- Säureverarbeitung: Griff für Kükenventile aus Hastelloy C276 98% Schwefelsäure (650° C) – Keine Korrosion, trifft ISO 15848-1 Klasse AH.

- Pharmazeutika: Kükenhähne mit PTFE-Auskleidung (ASME BPE) Regulierung der API-Dosierung – Leckage der Klasse VI und CIP-Fähigkeit verhindern Kreuzkontamination.

Stromerzeugung

- Thermalanlagen: Metallisch dichtende Kükenhähne steuern den überhitzten Dampf (540° C, 200 Bar) – Wird in Turbinen-Bypass-Systemen verwendet.

- Kernkraftwerke: 316L-Kegelventile mit Metallbalgpackung verarbeiten borhaltiges Kühlmittel – keine Leckage (Klasse VI) verhindert die Freisetzung von Strahlung.

Bergbau und Mineralien

- Gülletransport: Exzentrische Kükenventile (Sitze aus Wolframcarbid) Umgang mit Bergbaurückständen (30% Feststoffe) - - 300% längere Lebensdauer als gummierte Kugelhähne.

- Flotationsprozesse: Kegelventile mit Gummisitz steuern die Schaumflotationschemikalien – niedrige Kosten und einfache Wartung für abgelegene Standorte.

10. Vergleich mit anderen Ventilen

Kükenventile sind einer von mehreren Ventiltypen, die in der industriellen Flüssigkeitskontrolle eingesetzt werden.

Das Verständnis ihrer relativen Stärken und Grenzen hilft Ingenieuren bei der Auswahl des am besten geeigneten Ventils für eine bestimmte Anwendung.

Die folgende Tabelle vergleicht Kükenhähne mit anderen häufig verwendeten Ventilen:

| Ventiltyp | Design & Betrieb | Schlüsselvorteile | Einschränkungen | Typische Anwendungen |

| Stopfenventil | Rotierender zylindrischer oder konischer Stopfen mit Anschluss; Vierteldrehung | Einfach, kompakt, Blasendichte Absperrung; geringer Druckabfall; Vielseitig für Multiport-Durchfluss | Das manuelle Betätigungsdrehmoment kann bei großen Größen hoch sein; Schmierung oft erforderlich; Begrenzte Drosselung | Schlämme, Öl & Gas, chemische Prozesslinien, Strömung umleiten, Probenahme |

| Ballventil | Kugelförmige Kugel mit Bohrung; Vierteldrehung | Schneller Betrieb; Blasendichte Abdichtung; gut für hohen Druck/Temperatur; niedriges Drehmoment | Begrenzte Multi-Port-Konfigurationen; nicht ideal für erosive Medien | Wasser, Gaspipelines, chemische Leitungen, Ein/Aus-Anwendungen |

| GATENVENTIL | Schiebetor zwischen den Sitzen; lineare Bewegung | Minimaler Druckabfall bei vollständiger Öffnung; bidirektional; geeignet für große Durchmesser | Langsamer Betrieb; schlechte Drosselung; sperrig; mögliche Vibrationen oder Rattern | Dampf, Wasser, Ölpipelines; Isolationspflichten |

Globusventil |

Lineare Bewegung von Stecker/Sitz oder Scheibe/Sitz; Drosselndes Design | Hervorragende Durchflussregulierung; genaue Kontrolle; robuste Abdichtung | Höherer Druckabfall; komplexer; langsamerer Betrieb; höhere Kosten | Prozesskontrolle, chemische Pflanzen, Stromerzeugung, Drosselungspflichten |

| Schmetterlingsventil | Rotierende Scheibe; Vierteldrehung | Leicht, kompakt; mäßiges Throttling; kostengünstig für große Durchmesser | Unter hohem Druck eingeschränkte Dichtigkeit; nicht für abrasive Flüssigkeiten geeignet | HVAC, Wasserbehandlung, Niederdruck-Chemieleitungen |

| Nadelventil | Konische Nadel und Sitz; lineare Bewegung | Feine Durchflusskontrolle; präzise Dosierung | Nicht für hohen Durchfluss; langsamer Betrieb; kleine Größe | Instrumentierung, Probenahme, Laboranwendungen |

Wichtige Erkenntnisse:

- Versiegelungsleistung: Kükenhähne bieten Blasendichte Absperrung Ähnlich wie Kugelhähne, kann jedoch den Durchfluss mit mehreren Anschlüssen effizienter bewältigen.

- Drosselfähigkeit: Linearventile wie Kugel- und Nadelventile zeichnen sich durch eine präzise Durchflussregelung aus; Kükenventile eignen sich besser für Auf/Zu- und Umleitungsaufgaben als für Feindrosseln.

- Druckabfall: Küken- und Kugelhähne haben niedrig Δp in vollständig geöffneten Positionen; Kugel- und Schieberventile können zu einem erheblichen Druckabfall führen.

- Wartung und Haltbarkeit: Geschmierte Kükenhähne erfordern eine regelmäßige Inspektion in abrasiven oder korrosiven Medien; Kükenhähne mit Metallsitz bieten langfristige Zuverlässigkeit unter rauen Bedingungen.

- Vielseitigkeit: Kükenventile mit Konfigurationen mit mehreren Anschlüssen können mehrere Ventile austauschen im Umsteller, Mischer, oder Probenahmesysteme, Reduzierung der Rohrleitungskomplexität.

11. Abschluss

Kükenhähne sind robust, kompakte Drehgeräte, ideal zum Ein-/Ausschalten, Ablenkung und viele Isolationsaufgaben.

Ihre Leistung hängt von der sorgfältigen Auswahl der Steckerunterstützung ab (schwebend gegen Trunnion), Sitztyp (Metall vs. belastbar), Materialien und Betätigung.

Sie sind nicht die beste Wahl für Präzisionsdrosselung, aber wenn schnelle Aktion, Einfache Konstruktion und robuster Umgang mit schmutzigen oder abrasiven Flüssigkeiten sind erforderlich, Kükenventile sind oft die praktischste Lösung.

Moderne Materialien, Beschichtungen und digitale Aktoren erweitern ihre Anwendbarkeit immer weiter.

Kundenspezifische Ventilbaugruppen von LangHe

Langhe Angebote kundenspezifische Lösungen für die Ventilmontage, Spezialisiert auf maßgeschneiderte Komponenten für spezifische industrielle Anforderungen.

Nutzen Sie fortschrittliches Casting, Präzisionsbearbeitung, und Materialkompetenz, LangHe bietet Kükenhähne an, Steuerventile, und andere Ventilbaugruppen mit:

- Benutzerdefinierte Materialien: Kohlenstoffstahl, Edelstahl, Duplex, Nickellegierungen, und Hochleistungswerkstoffe für korrosive oder Hochtemperaturanwendungen.

- Maßgeschneiderte Designs: Single-Port, Multiport, geschmiert, oder metallisch dichtende Kükenventile, die nach Kundenspezifikationen gefertigt werden.

- Präzisionsbearbeitung: CNC-gefertigte Gehäuse und Stopfen mit engen Toleranzen für reibungslosen Betrieb und leckagefreie Abdichtung.

- Montage und Test: Komplett montierte Ventile, Hydrostatisch und funktionsgeprüft nach ISO, API, oder Kundenstandards.

LangheDie maßgeschneiderten Dienstleistungen ermöglichen Branchen wie Öl & Gas, Chemische Verarbeitung, Wasserbehandlung, und Stromerzeugung Ventile zu integrieren, die sich treffen einzigartig betriebsbereit, räumlich, und Leistungseinschränkungen, Gewährleistung der Zuverlässigkeit, Effizienz, und langes Lebensdauerleben.

Kontaktieren Sie LangHe noch heute um Ventilkomponenten zu entwerfen und herzustellen, die genau auf Ihre Spezifikationen zugeschnitten sind.

FAQs

Was ist der Unterschied zwischen einem Kükenhahn und einem Kugelhahn??

Kükenventile verwenden einen zylindrischen/konischen Küken (Exzentrische Designs reduzieren den Verschleiß), während Kugelhähne eine sphärische Kugel verwenden.

Kükenventile eignen sich hervorragend für abrasive/korrosive Flüssigkeiten (300% längere Lebensdauer in Schlämmen), während Kugelhähne günstiger sind, wenn sie nicht abrasiv sind, Anwendungen mit hohem Durchfluss.

Welcher Kükenventiltyp eignet sich am besten für abrasive Schlämme??

Exzentrische Kükenventile mit Wolframkarbid-Sitzen (85–90 HRC) sind am besten.

Das exzentrische Design hebt den Stopfen vom Sitz ab (kein Schleifkontakt), und Wolframcarbid widersteht dem Verschleiß durch Feststoffe – verlängert die Lebensdauer auf 1–2 Jahre im Vergleich zu. 3–6 Monate für Kugelhähne.

Wie oft sollten geschmierte Kükenhähne geschmiert werden??

Vierteljährlich bei normalem Betrieb (Öl & Gas, Wasser); monatlich für abrasive Flüssigkeiten (Bergbau). Automatische Schmiersysteme (pneumatische Injektoren) kann die Intervalle auf 6–12 Monate verlängern.

Kann hohe Temperaturen vertragen?

Ja. Metallisch dichtende Kükenhähne (Stelliten 6, Hastelloy C276) bis zu 815°C belastbar (Kernkraftwerke/Kraftwerke). Weichsitzende Ventile (Ptfe) sind auf 260°C begrenzt.

Was ist die Leckageklasse von Kükenventilen??

Weichdichtende Kükenhähne (PTFE/Viton) Erreichen Sie ANSI FCI 70-2 Klasse VI (≤0,00001 % Leckage) – entscheidend für giftige/teure Flüssigkeiten.

Metallisch dichtende Ventile erreichen die Klasse IV (≤0,01 % Leckage) – geeignet für den Einsatz bei hohen Temperaturen.

Wie reduziere ich die Drehmomentanforderungen für Kükenhähne??

Verwenden Sie geschmierte Stopfen (Graphit-PTFE-Fett reduziert die Reibung um 50%); Wählen Sie exzentrische Designs (Hebt den Stecker vom Sitz ab); Stellen Sie sicher, dass die Rohrleitungen richtig ausgerichtet sind (vermeidet Bindung).