1. Uvod

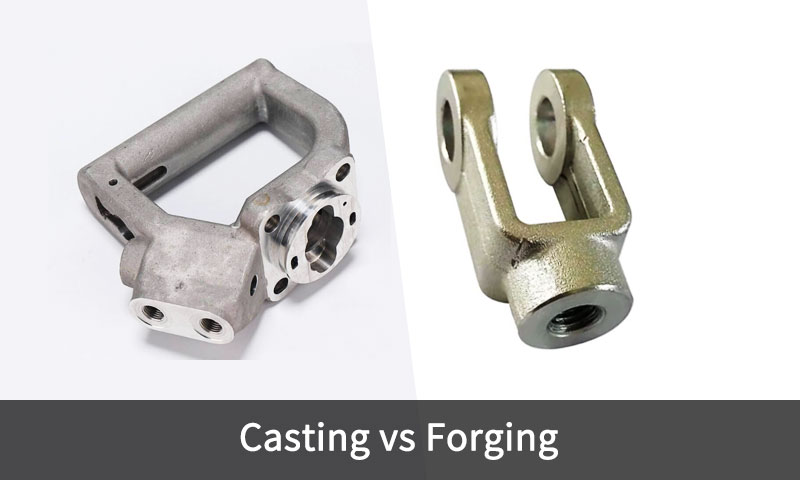

Livenje vs kovanje are two fundamental metal-shaping routes.

Livenje Equell na proizvodnji složenih oblika, internal cavities and large parts with relatively low material waste and low per-part tooling cost for moderate geometries.

Kovanje produces parts with superior mechanical properties, Poboljšana otpornost na umor i bolji protok zrna, Ali obično zahtijeva teže sredstvo i više obrade za složenu geometriju.

Pravi izbor ovisi o mehaničkim zahtjevima aplikacije, složenost geometrije, zapremina, Ciljevi troškova i regulatorna ograničenja.

2. Šta se baca?

Livenje je proizvodni proces u kojem se rastopljeni metal izlije u kalupsku šupljinu u obliku željene komponente.

Nakon što se metal ohladi i učvrsti, Kalup se uklanja da bi otkrio lijevani dio.

Ovaj proces je jedna od najstarijih metoda oblikovanja metala, izlazi iz leđa hiljada godina, i još se široko koristi zbog svoje svestranosti u proizvodnji jednostavnih i vrlo složenih dijelova.

Pregled procesa

- Kreiranje uzorka - replika dela (uzorak) izrađen je od voska, drvo, plastičan, ili metal.

- Priprema kalupa - Kalup se kreira pomoću pijeska, keramika, ili metal, ovisno o načinu lijevanja.

- Topljenje & Izlijevanje - Metalne legure se rastope (obično na 600-1.600 ° C, ovisno o leguru) i izliven u kalup.

- Učvršćenja & Hlađenje – Controlled cooling allows the metal to take the shape of the mold cavity.

- Shakeout & Čišćenje – The mold is broken or opened, and excess material (kapije, rizeri) se uklanja.

- Završna obrada & Inspekcija – Heat treatment, obrada, and surface finishing are applied as required.

Variants of Casting

- Livenje pijeska – Cost-effective, suitable for large and heavy parts; dimensional tolerance typically ±0.5–2.0 mm.

- Investicijska livenja (Izgubljeni vosak) – Produces highly detailed, near-net-shape parts with excellent surface finish (Ra ≈ 1.6–3.2 µm).

- Die Casting – High-pressure injection of molten non-ferrous alloys (Al, ZN, Mg) into permanent molds; excellent for high-volume production.

- Centrifugalno livenje – Used for cylindrical parts like pipes, with high density and minimal defects.

- Kontinuirano livenje – Industrial process for producing billets, ploča, and rods directly from molten metal.

Ključne prednosti

- Ability to produce Složene geometrije, including internal cavities and thin-walled sections.

- Wide range of Fleksibilnost legure (čelici, pegla, aluminijum, bakar, nikl, titanijum).

- Oblik gotovo mreže Mogućnost smanjuje zahtjeve za obradu obrade.

- Isplativo za Veliki dijelovi i Količina niskog do srednjeg.

- Skalabilnost - od prototipa do proizvodne velike količine (posebno sa malim livenjem).

Ograničenja

- Mane livenja poput poroznost, Smanjenje šupljine, uključivanja, i vruće suze.

- Mehanička svojstva (zatezna čvrstoća, Otpornost na umora) često su inferiorni od krivotvorenih ekvivalenta zbog dendritičkih mikrostrukture i poroznosti.

- Dimenzionalna tačnost i površinska obrada značajno variraju po procesu.

- Stope hlađenja mogu uzrokovati segregacija i anisotropy u mehaničkim performansama.

3. Šta se formira?

Kovanje je postupak obrade metala u kojem se metal oblikuje u željene geometre kroz Komprezijska sila, obično koriste čekiće, preše, ili umire.

Za razliku od livenja, Tamo gdje se materijal rastopi i učvršćuje, kovanje radi metal u a Slijeto stanje, Poboljšanje njegove strukture zrna i unapređenje mehaničkih svojstava.

Kovanje je jedno od najstarijih metoda u obliku metala, povijesno izvodi kovačice sa jednostavnim ručnim alatima.

Danas, it is a high-precision industrial process widely used in aerospace, automobilski, ulja & plin, Generacija energije, and defense industries.

Pregled procesa

- Grijanje (Neobavezno) – Metal is heated to a plastic state (for hot forging) or left at room temperature (for cold forging).

- Deformacija – The metal is compressed or hammered into shape between flat or shaped dies.

- Obrezivanje – Excess material (bljesak) se uklanja.

- Toplotni tretman (Ako je potrebno) – Normalizing, gašenje, and tempering are applied to optimize strength, tvrdoća, i duktilnost.

- Završna obrada – Machining, Završetak površine, and inspection complete the process.

Types of Forging

- Kovanje otvorenog dim – Large parts shaped between flat dies; used for shafts, diskovi, and large blocks.

- Zatvoren (Utisak) Kovanje – Metal pressed into shaped cavities for near-net shape parts; widely used in automotive and aerospace.

- Hladno kovanje – Performed at room temperature; excellent dimensional accuracy and surface finish.

- Vruće kovanje – Performed above recrystallization temperature; allows shaping of large, tough alloys with reduced work hardening.

- Isothermal & Precizna kovanje - Napredne metode za titanijum, nikl, i zrakoplovne legure, Smanjenje obrade i materijalnog otpada.

Ključne prednosti

- Vrhunska mehanička svojstva Zbog rafinirane strukture zrna i eliminacije unutarnjih praznina.

- Visoko Otpornost na umora i utiče na snagu u odnosu na odlivce.

- Dosljedan tačnost dimenzija U preciznom kovanju.

- Pogodno za Kritične aplikacije kao što su dijelovi zrakoplova, Automobilski radiji, Plodovi pod pritiskom, i nuklearne elektrane.

- Minimalna poroznost i odličan metalurški integritet.

Ograničenja

- Veći trošak nego od kastinga, posebno za složene oblike.

- Ograničena na dijelove koji se mogu formirati deformacijom - manje pogodnim za šuplje, tanki zid, ili vrlo zamršene geometrije.

- Zahtijeva Specijalizirane alate i visoko tonažne preše za velike dijelove.

- Duža vremena vode za prilagođene umire.

4. Mikrostruktura & Grain Flow of Casting vs. Kovanje

Jedna od najosnovnijih razlika između livenja i kovanja leži u Interna mikrostruktura materijala.

Kako se formiraju zrna, usklađen, and distributed during processing directly influences the mechanical strength, žilavost, and fatigue resistance of the final component.

Casting Microstructure

- Solidification Process – In casting, molten metal cools and solidifies inside the mold.

Grains nucleate randomly and grow outward, formiranje izjednačen ili columnar grains depending on cooling conditions. - Grain Orientation – No preferred orientation (isotropic structure), but often heterogeneous. Grain boundaries may be weak points under stress.

- Oštetiti – Possible poroznost, Smanjenje šupljine, uključivanja, and segregation of alloying elements due to uneven cooling. These reduce fatigue resistance and fracture toughness.

- Nekretnine – Adequate for static loads and complex shapes but generally lower tensile strength and fatigue resistance compared to forged parts.

Forging Microstructure

- Plastic Deformation Process – Forging plastically deforms metal in its solid state, breaking up cast dendritic structures and eliminating porosity.

- Grain Flow Alignment – Forging aligns grains in the direction of applied forces, proizvodnja a continuous grain flow that follows the shape of the part.

This improves impact strength and fatigue resistance, especially in components like crankshafts and turbine blades. - Defect Reduction – Forging compacts voids and inclusions, reducing defect size and improving metallurgical integrity.

- Nekretnine – Forged parts show superior mechanical properties, especially in dynamic or cyclic load conditions.

5. Typical Mechanical Property of Casting vs. Kovanje

| Nekretnina (na rt) | Livenje (316 SS) | Kovanje (316 SS) |

| Zatezna čvrstoća (MPa) | 485–515 | 560-620 |

| Snaga prinosa (0.2% MPa) | 170-240 | 240-310 |

| Izduženje (%) | 20-30 | 35-40 |

| Tvrdoća (HB) | 135-150 | 150-160 |

| Charpy udar (J) | 60-80 | 100-120 |

| Snaga umora (MPa, 10⁷ Cycles) | ~ 170 | ~ 240 |

6. Sloboda dizajna, Tolerancije, and Surface Finish

U poređenju casting vs forging, one of the most decisive factors is the balance between Fleksibilnost dizajna, Dimenzionalna kontrola, i kvalitet površine.

Svaki proces ima jedinstvene snage i ograničenja, which determine suitability for different applications.

Sloboda dizajna

- Livenje offers unmatched design flexibility. Complex geometries such as internal cavities, tanki zidovi, rešetke, and undercuts can be produced directly in a single pour.

Posebno lijevanje ulaganja omogućava neposredno-neto dijelove oblika, Smanjenje obrade do do do 70%.

Komponente poput rotora pumpe, Oštrice turbine, ili zamršene zagrade gotovo se isključivo izrađuju livenjem jer bi se takvi oblici krivci bili nemogući ili ekonomski zabranjuje. - Kovanje, Suprotno tome, je ograničen na relativno jednostavnije geometrije.

Iako se formiranje zatvorene boje omogućava dijelove u blizini neto, Zamršeni unutarnji odlomci, Fine rešetke konstrukcije, ili oštri podrezi nisu dostižni.

Kovanje ističe kada dio zahtijeva čvrste, Kontinuirana geometrija bez šupljih presjeka, poput osovina, zupčanici, i povezivanje šipki.

Dimenzionalne tolerancije (ISO 8062 Referenca)

| Proces | Tipična klasa tolerancije | Primer (100 MM dimenzija) | Kritična značajka tolerancija (npr., Promjer provrta) |

| Livenje pijeska | CT8-CT10 | ± 0,4 - 0.8 mm | ± 0,2 - 0.4 mm |

| Investicijska livenja | CT4 - CT6 | ± 0,05 - 0.2 mm | ± 0,03 - 0.08 mm |

| Die Casting (Al / Zn / mg) | CT5-CT7 | ± 0,1 - 0.3 mm | ± 0,05 - 0.15 mm |

| Kovanje otvorenog dim | CT10 - CT12 | ± 0,8 - 1.5 mm | ± 0,4 - 0.8 mm |

| Zatvoreni kovanje | CT7-CT9 | ± 0,2 - 0.6 mm | ± 0,1 - 0.25 mm |

Završna obrada (Roughness Ra, μm)

| Proces | As-cast / Krivotvoreni ra (μm) | Ras završne obrade (μm) |

| Livenje pijeska | 10 - 20 | 5 - 10 |

| Investicijska livenja | 1.2 - 5 | 0.8 - 2 |

| Die Casting (Al / Zn / mg) | 2 - 10 | 1.2 - 5 |

| Kovanje otvorenog dim | 10 - 40 | 5 - 10 |

| Zatvoreni kovanje | 5 - 12 | 2.5 - 5 |

7. Secondary Operations and Heat Treatment Impact

Sekundarno poslovanje i toplotni tretman igraju kritičnu ulogu u optimizaciji performansi komponenata proizvedenih lijevanjem ili kovanjem.

Ovi koraci nakon procesa izravno utječu na mehanička svojstva, tačnost dimenzija, Površinski finiš, i dugoročna izdržljivost.

Sekundarne operacije

Obrada:

- Livenje: Komponente lijeva često zahtijevaju značajnu obradu za postizanje uskih tolerancija i kritičnih površina, posebno za rupe, Teme, i parenje lica.

Investicijska livenja smanjuje zahtjeve za obradu zbog mogućnosti u blizini neto oblika, budući da lijevanje pijeska obično zahtijeva opsežnije nakon obrade. - Kovanje: Kovani dijelovi uglavnom zahtijevaju minimalnu obradu, uglavnom za završnu površinu i precizne rupe, Zbog uniformnosti i krajnjih konačnih dimenzija kovanja zatvorenog.

Završetak površine:

- Poliranje i mljevenje: Poboljšajte kvalitetu površine, smanjiti hrapavost, i uklonite manju površinu oštećenja. Investicijske odljeve mogu doći do RA < 1.5 μm nakon mehaničkog ili elektropolja.

- Pucanj / Peskanje perla: Used to remove scale, bljesak, and improve surface uniformity.

- Premazi i oblaganje: Secondary coatings (npr., Pasivacija za nehrđajući čelik, zinc or nickel plating for corrosion protection) are often applied post-machining.

Montaža & Fitting:

- Critical for components with multiple parts, such as bushings, pinovi, or hinge assemblies. Proper secondary operations ensure proper clearance, interference, and functional alignment.

Toplotni tretman

Svrha:

Toplotni tretman is employed to enhance mechanical properties such as strength, tvrdoća, duktilnost, i otpornost na habanje. Its effects vary between cast and forged components.

- Livenje:

-

- Cast stainless steel and low-alloy steels often undergo Rješenje žarenje, Oslobođenje stresa, ili Ovrtanje starosti to reduce residual stresses, homogenizirati mikrostrukturu, and improve machinability.

- Care must be taken to avoid partial melting or grain coarsening in thin sections, particularly in investment castings.

- Kovanje:

-

- Forged components benefit from normalizacija ili quenching and tempering to refine grain structure and maximize mechanical performance.

- Forging inherently produces a denser, Uniformna mikrostruktura, so heat treatment mainly optimizes hardness and stress relief rather than compensating for defects.

Advanced post-processing

- Hip can close internal porosity in castings, bringing properties closer to wrought/forged material at high cost.

- Površinski tretmani (pucanj, nitrizam, karburizacija) improve fatigue life and wear resistance.

8. Industrijske aplikacije: Matching Method to Need

Casting and forging dominate distinct industrial sectors based on their inherent strengths—geometry complexity, Mehaničke performanse, Zahtevi za količinu, i ograničenja troškova.

Casting Applications

Automobilski:

- Blokovi motora: Sand casting is widely used for iron engine blocks, accommodating complex water jackets and internal cavities.

- Glave cilindra: Investment casting enables precision cooling channels and intricate geometries in high-performance engines.

- Aluminum Wheels: Die casting allows high-volume production with excellent surface finish and dimensional consistency.

Vazdušni prostor:

- Oštrice turbine: Investment casting of superalloys like Inconel 718 achieves complex airfoil geometries essential for efficiency and high-temperature resistance.

- Kućišta motora: Sand casting of aluminum alloys supports lightweight structures with moderate complexity.

Ulja & Plin:

- Kućišta pumpe: Sand casting of cast iron or steel provides robust, cost-effective solutions for fluid handling.

- Tijela ventila: Investment casting in 316L stainless steel achieves tight tolerances and corrosion resistance for critical valves.

Izgradnja & Infrastruktura:

- Navlake za šahtove: Sand casting in ductile iron offers high strength and durability.

- Pipe Fittings & Komponente: Die casting aluminum or brass provides lightweight, corrosion-resistant solutions for water and gas networks.

Forming aplikacije

Automobilski:

- Radilice: Closed-die forging in AISI 4140 steel ensures high fatigue resistance and superior grain flow for performance engines.

- Connecting Rods: Forged from 4340 steel for strength and toughness under repeated dynamic loading.

Vazdušni prostor:

- Landing Gear Components: Closed-die forging in titanium alloys combines high strength-to-weight ratio with excellent fatigue life.

- Engine Shafts: Open-die forging of Inconel 625 produces components resistant to high temperatures and stresses.

Ulja & Plin:

- Drill Collars: Open-die forging in AISI 4145H steel ensures high-pressure endurance in harsh downhole environments.

- Valve Stems: Closed-die forging of 316L stainless steel guarantees dimensional accuracy and corrosion resistance.

Teška mehanizacija & Industrijska oprema:

- Gear Blanks: Closed-die forging in AISI 8620 steel achieves high hardness and wear resistance for power transmission.

- Hydraulic Cylinders & Osovine: Open-die forging in A36 steel ensures toughness and impact resistance for heavy-duty operations.

9. Comprehensive Comparison of Casting vs. Kovanje

Casting vs forging are foundational manufacturing methods, each with distinct advantages, ograničenja, and ideal use cases.

The table below summarizes the key differences across multiple dimensions, providing an at-a-glance guide for engineers, Dizajneri, and production managers:

| Aspekt | Livenje | Kovanje |

| Process Principle | Molten metal poured into a mold and solidified | Metal deformed under compressive force, usually at high temperature |

| Upotreba materijala | Moderate to high scrap reduction in investment/die casting; some gating/riser waste | Very high material efficiency; minimal scrap when properly planned |

| Sloboda dizajna | Excellent for complex geometries, tanki zidovi, Unutarnji odlomci, Podrezi | Limited to shapes that can be forged; internal cavities require machining or secondary operations |

| Dimenzionalna tačnost | Investiciono livenje: ± 0,05-0,3 mm; Livenje pijeska: ± 0,5-1,0 mm | Zatvoreni kovanje: ±0.1–0.8 mm; Open-die forging: ±0.5–2.0 mm |

| Završna obrada | Investment casting Ra 1.6–6.3 μm; sand casting Ra 6.3–25 μm | Closed-die forging Ra 3.2–12.5 μm; open-die forging Ra 6.3–50 μm |

| Mehanička svojstva | Umjerena čvrstoća; isotropic properties in simple castings; lower fatigue resistance due to porosity | Superior strength and toughness; aligned grain flow improves fatigue and impact resistance |

Heat Treatment Compatibility |

Fully compatible; may relieve internal stresses and improve microstructure | Compatible; forging produces work-hardened regions and directional grain flow that enhance mechanical properties |

| Volumen proizvodnje & Trošak | Proizvodnja visokog volumena (die/investment casting) reduces per-part cost; low-volume may be costly | Low-to-medium volume most economical; high-volume can be expensive due to tooling and press costs |

| Tipične aplikacije | Complex pump housings, Tijela ventila, blokovi motora, Oštrice turbine | Radilice, Povezivanje šipki, osovine, Sredstvo za slijetanje, high-stress mechanical components |

| Vrijeme vođenja | Umjeren; mold and pattern development can take weeks | Umjereno do dugo; forging dies require precise design and machining |

| Prednosti | Složeni oblici, Neto oblik, manje obrade, internal passages possible | Visoka čvrstoća, Vrhovni otpor umora, Protok usmerenog zrna, Izvrsna žilavost |

| Konzultati | Lower mechanical performance, potencijalna poroznost, skupljanje, limited high-stress performance | Limited geometric complexity, higher tooling costs, secondary machining often needed |

10. Zaključak

Casting vs forging are not competitors but complementary tools—each optimized for specific manufacturing needs:

- Choose Casting If: You need complex geometries, low upfront cost for low volume, or parts made from brittle metals (liveno gvožđe).

Investment casting excels at precision, sand casting at cost, and die casting at high-volume non-ferrous parts. - Choose Forging If: You need high strength, Otpornost na umora, or tight tolerances for simple-to-moderate shapes. Closed-die forging is ideal for high-volume, Dijelovi visokog stresa; open-die forging for large, low-volume components.

The most successful manufacturing strategies leverage both methods—e.g., a car engine uses cast blocks (složenost) and forged crankshafts (snaga).

By aligning process selection with part function, zapremina, i trošak, engineers can optimize performance, reduce TCO, i osigurati dugoročnu pouzdanost.

FAQs

Can forging produce parts with internal cavities?

No—forging shapes solid metal, so internal cavities require secondary machining (bušenje, dosadan), which adds cost and reduces strength.

Livenje (especially sand or investment) is the only practical method for parts with internal features (npr., engine water jackets).

Which process is more sustainable for steel parts?

Forging is more sustainable for high-volume, Dijelovi visokog stresa: it uses 30–40% less energy than sand casting, produces less waste (10–15% vs. 15-20%), and forged parts have longer service life (reducing replacement cycles).

Sand casting is more sustainable for low-volume, Složeni dijelovi (lower tooling energy).

What is the maximum size for casting vs. kovanje dijelovi?

- Livenje: Sand casting can produce parts up to 100 Tons (npr., ship propellers); investment casting is limited to ~50 kg (Precizni dijelovi).

- Kovanje: Open-die forging can produce parts up to 200 Tons (npr., power plant shafts); closed-die forging is limited to ~100 kg (Dijelovi visokog volumena).

Why are aerospace turbine blades cast instead of forged?

Turbine blades have intricate airfoil geometries and internal cooling channels—impossible to forge.

Investiciono livenje (using single-crystal superalloys like Inconel 718) produces these features with the required precision, while heat treatment optimizes strength for high-temperature service.