1. エグゼクティブサマリー

アルミニウムダイキャストエンクロージャは、以下の比類のない組み合わせを提供します。 機械的強度, 寸法精度, 熱伝導性と電磁シールド性 単一のニアネット形式で.

熱放散が問題となる多くの電子および電気機械製品の場合, EMIシールドと機械的堅牢性が優先事項です,

アルミニウム HPDC エンクロージャは、エンクロージャがダイカストの制約を考慮して設計されている場合、板金またはプラスチックのハウジングよりも推奨されるソリューションです。 (壁の厚さ, 下書き, rib骨, ボス) 適切な下流側の加工とシーリング.

主なトレードオフは、工具のコストと部品ごとの仕上げ/加工ステップです。; 中量から大量まで, HPDC は非常に経済的です.

2. アルミダイキャスト筐体とは?

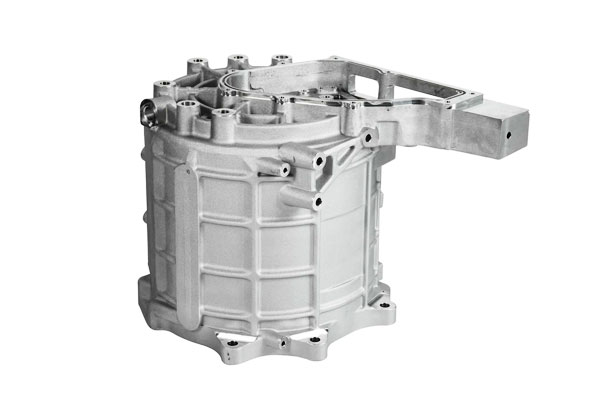

an アルミダイキャスト筐体 主に高圧ダイカストによって製造されるハウジングです。 (HPDC) アルミニウム合金を使用した (例えば。, A380/ADC12ファミリー, A356 バリアントまたは特殊なダイカスト合金) そして機械加工で仕上げました, 表面処理とシーリング.

鋳造部品に統合される典型的な機能には、取り付けボスが含まれます。, 対立, rib骨, ケーブル入口ポート, ねじインサート用ボス, ヒートシンクフィン, ガスケットまたはコネクタ用のフランジ.

ダイカストにより、細かい表面ディテールと再現可能な寸法公差を備えたニアネットシェイプが生成されます。.

エンクロージャにダイカストアルミニウムを選択する理由?

- 高い剛性と耐衝撃性 (電子機器を保護する)

- 優れた熱伝導により受動的な放熱を実現

- 固有の EMI/RFI シールド (導電性の連続金属)

- 構造的特徴と熱的特徴を 1 つの部品に統合する機能

- コーティングと美しい仕上げのための良好な表面品質

- リサイクル可能で広く入手可能

3. 材料 & 合金の選択

アルミニウム合金 ダイカストエンクロージャに使用されるものは、以下に基づいて選択されます。 キャスト性, 機械的強度, 熱伝導率, 耐食性と機械加工性.

以下は、一般的な選択肢とその典型的なパフォーマンス範囲をまとめたコンパクトな表です。 (エンジニアリング ガイダンス - 正確な値についてはサプライヤーのデータシートを確認してください).

| 合金 / 通称 | エンクロージャでの一般的な使用法 | 密度 (g/cm³) | 典型的な引張強度 (MPA) | 代表的な熱伝導率 (W・m⁻¹・K⁻¹) | メモ |

| A380 / alsi9cu3(fe) (ダイカスト標準) | 汎用ダイキャスト筐体 | ~2.68~2.80 | ~150~260 (as-cast) | ~100~140 (合金依存) | 大容量 HPDC に最適; 優れたキャスタビリティとディテール; 中程度の強さ |

| ADC12 (A380に似ています) | 自動車 & 電子ハウジング | 〜2.7 | ~160~260 | ~100~140 | アジアで広く使われている; 優れた薄肉性能 |

| A356 / alsi7mg (重力/PM & 時々HPDC) | より高強度, 熱処理可能なエンクロージャ & ヒートシンク | ~2.65~2.70 | ~200~320 (T6) | 〜120–160 | 熱処理可能 (T6) より良い機械的効果をもたらします & 疲労特性; より高い熱性能と耐圧性が必要な場合によく使用されます。 |

| A413 / AlSi12Cu (キャスティング) | 特殊ハウジング, 熱を要求する部品 | 〜2.7 | ~200~300 | ~110~150 | 強度と導電性のバランス |

メモ: 値は設計見積もりの一般的な範囲です. ダイカスト合金は展伸アルミニウムよりも延性が低く、プロセスによって気孔率が異なります。.

鋳造アルミニウム合金の熱伝導率は純アルミニウムよりも低い (237 w/m・k) ただし、プラスチックと比較すると熱管理には有利です.

4. ダイカスト工程 & アルミニウム筐体に関連するバリエーション

アルミニウム ダイキャスト エンクロージャはいくつかの鋳造技術で製造できます.

各プロセスは異なるバランスを提供します。 ジオメトリ機能, 表面の品質, 気孔率 (誠実さ), 機械的特性, コストとスループット.

概要表 - プロセスの概要

| プロセス | 一般的な生産規模 | 典型的な最小壁 (mm) | 相対気孔率 / 誠実さ | 表面仕上げ (ra) | 主な強み | いつ選択するか |

| 高圧ダイキャスティング (HPDC) | 高い→非常に高い | 1.0–1.5 | 適度 (改善できる) | 1.6–6 µm | 非常に高いスループット, 薄い壁, 細かい詳細, 優れた寸法再現性 | 薄い壁と多くの統合機能を備えた大容量エンクロージャ |

| 真空HPDC | 高い (プレミアム) | 1.0–1.5 | 低気孔率 (最良の HPDC バリアント) | 1.6–6 µm | HPDC のすべての利点 + ガスの気孔率が減少し、機械的/疲労挙動が改善されました。 | より高い完全性が必要なエンクロージャ, 圧力シール, または疲労寿命の向上 |

| 低圧ダイキャスティング / 重力低圧 (LPDC) | 中くらい | 2–4 | 低い (良い) | 3–8μm | 良好な誠実さ, 下層乱気流, HPDCよりも優れた機械的特性 | 完全性と機械的特性が重要な中容量 |

| スクイーズキャスティング / レオ / 半固体 | 低→中 | 1.5–3 | 非常に低い気孔率 | 1.6–6 µm | 鍛造に近い特性, 低気孔率, 優れた機械 | より高い強度/耐疲労性が必要なエンクロージャ; より小さいボリューム |

パーマネントモールド / 重力 (PM) |

低→中 | 3–6 | 低い | 3–8μm | 良好な機械的特性, 低気孔率, 砂よりも長いダイ寿命 | 中量, より厚い壁の筐体と構造部品 |

| インベストメント鋳造 | 低→中 | 0.5–2 | 低い (良い) | 0.6–3 µm | 優れたディテールと表面仕上げ, 薄い部分も可能 | 小さい, 複雑な内部形状を備えた高精度のエンクロージャまたは部品 |

| 砂鋳造 (樹脂 / 緑) | 低い | 6+ | より高い (より大きなセクション) | 6–25 µm | ツーリングコストが低い, 柔軟なサイズ | プロトタイプ, 非常に低い音量, 非常に大きな筐体 |

| 泡消失 / 添加剤 (ハイブリッド) | 低い | 1–6 (ジオメトリに依存します) | 変数 | 変数 | 複雑なフォームに対応する迅速なツール, コアの数が少ない | 迅速なプロトタイプ, 設計検証, 少量のカスタマイズされたエンクロージャ |

プロセスの詳細な説明 & 実用的な意味

高圧ダイキャスティング (HPDC)

- 仕組み: 溶融したアルミニウムを高速・高圧でスチール金型に注入します。 (2つの半分), 急速に固化して排出される. 通常のサイクルタイムは短い (数秒から数分).

- 典型的なプロセスパラメータ: 溶融温度 ~680~740℃ (合金に依存する); ダイ温度 ~150~220℃; 速いショット速度と高い増圧圧力により金属を薄い形状に圧縮します.

- パフォーマンス: 優れた寸法精度, 細かい詳細 (ロゴ, rib骨, 薄いヒレ) 大規模化しても単価が低い.

- トレードオフ: HPDC はガス/乱流によって生じる多孔性を捕捉する傾向があり、重力法よりも延性がわずかに劣る微細構造を生成する可能性があります。. 真空HPDC 最適化されたゲート/ベントにより、これらの問題が大幅に軽減されます。.

- 実践的なヒント: シール面の場合は真空 HPDC を指定してください, タップ加工されたボスや疲労寿命は重要です; それ以外の場合は、シンプルなエンクロージャでは従来の HPDC が最もコストが低くなります。.

真空HPDC (真空アシスト)

- 利点: 充填中にキャビティとランナー システムから空気を抜き取ります — 閉じ込められた空気と水素関連の気孔率を低減します, 機械的特性と気密性を向上させます.

- 使用事例: 機械加工されたシール面を備えた IP 定格エンクロージャ, 圧力がかかるコネクタや振動が重要な用途のエンクロージャ.

低圧ダイキャスティング / 重力低圧 (LPDC)

- 仕組み: 溶融金属は、下からの低い正圧によって閉じた金型内に押し込まれます。 (または重力によって満たされる), 穏やかな充填と低乱流を実現.

- パフォーマンス: HPDCよりも健全性が高く、気孔率が少ない; より優れた微細構造と疲労寿命.

- 使用事例: 機械的な完全性が重要であるが、HPDC の経済性は必要とされない中程度の量.

スクイーズキャスティング / 半固体 (レオ / 神)

- 仕組み: 半固体のスラリーまたは金属を閉じた金型内で圧力下で固化させます。. 結果はほぼ完全な密度と微細な微細構造になります。.

- パフォーマンス: 鍛造に近い特性 (高強度, 低気孔率), 従来の鋳物よりも優れた表面仕上げ.

- 使用事例: 高い機械的/疲労性能を必要とするが、適度な容積のエンクロージャ.

永久型 / 重力が死ぬ

- 仕組み: 再利用可能な金型は重力によって充填されます; HPDC より遅いが、穏やかな充填.

- パフォーマンス: 低気孔率, HPDC より優れた機構; 限られた複雑性と HPDC の比較.

- 使用事例: より高い整合性が要求される中量のボリューム (例えば。, より大きな壁セクションを備えたハウジング).

インベストメント鋳造 (ロストワックス, シリカソル)

- 仕組み: パターン (ワックス/3Dプリント) セラミックシェルでコーティングされた, 脱蝋およびセラミックシェル焼成, その後、溶融金属で満たされます (通常は真空中/反応性合金の場合は不活性).

- パフォーマンス: 優れた表面仕上げと薄肉性能; 複雑な内部機能; スループットが遅くコストが高い.

- 使用事例: 小型精密ハウジング, 内部の複雑なチャネル, または最高の外観仕上げ/機能の忠実性が必要な場合.

砂鋳造 (グリーン/樹脂)

- 仕組み: 模様の周囲に形成される消耗品の砂型; 柔軟だが粗い表面と寸法変化.

- パフォーマンス: 薄い部分や粗い仕上げでは気孔率が高くなるリスクが高くなります; ツーリングコストが低い.

- 使用事例: プロトタイプ, 非常に低い音量, 非常に大きなエンクロージャ、または工具への投資が法外な場合.

泡消失 / アディティブハイブリッド

- 仕組み: フォームパターンまたは 3D プリントされたパターンは砂にコーティングまたは埋め込まれています; 注ぐと金属が蒸発するパターン; 迅速な NPI のために、添加剤から鋳造までのハイブリッド ワークフローが増加しています.

- パフォーマンス & 使用: 複雑な形状や少量のカスタマイズに適しています; プロセス制御に応じて完全性が変化する.

プロセスの選択がエンクロージャの属性に与える影響

- 壁の厚さ & 特徴: HPDCは薄い外壁と一体型ボスに優れています; PMと投資は厚いほうが良い, ストレスを抱える上司.

- 気孔率 & 気密性: 真空HPDC, LPDC, スクイーズキャスティングとパーマネントモールドにより気孔が最も少なくなります; 真空を使用しない HPDC では、重要な面にシールや設計上の余裕が必要になる場合があります.

- 機械 & 疲労強度: 一般に、スクイズ/半固体および永久成形部品は、疲労が重要な用途において標準 HPDC よりも優れた性能を発揮します。.

ヒップ (ポストキャスト熱間静水圧プレス) 非常に信頼性の高い部品の内部気孔を閉じるためのオプションです (しかし高価な). - 表面仕上げ & 詳細: 投資キャスティング > HPDC > 永久型 > 砂鋳造. 素晴らしいロゴ, HPDC とインベストメント鋳造を使用すると、テクスチャリングと目に見える化粧品が最も簡単になります.

- ツーリング & ユニットエコノミクス: HPDC ツールのコストは最も高いが、大量生産では単価が最も低くなります。.

砂と投資により工具コストは低くなりますが、量産時の部品あたりの価格は高くなります. パーマネントモールドツールは、.

5. 機械, サーマル, および電気的性能

密度: ~2.68 ~ 2.80 g/cm3 — 約 1/3 鋼の, 製品の軽量化.

剛性 / 弾性率: ~68–72 GPa (アルミクラス) — 鋼鉄よりも低い, ただし、リブと肉厚を考慮して設計されている場合は十分です。.

典型的な引張強度 (ダイキャスト): ~150~260MPa (HPDC合金); 熱処理された A356 T6 の場合は最大 ~300 MPa.

熱伝導率: 典型的な鋳造合金 ~100 ~ 160 W/m·K (合金と気孔率に依存). これはプラスチックよりもはるかに優れており、受動的冷却を助けます。.

電気伝導率 & EMIシールド: 連続アルミニウムシェルは効果的な導電性バリアです; ベースラインシールドに適しています, 特にガスケットと導電性界面が制御されている場合.

意味するところ:

- アルミニウム製の筐体はパワー エレクトロニクスの構造保護と熱拡散を実現します。.

- 機械的な堅牢性のために, リブとフランジを使用 - ダイカストによりそれらを簡単に統合.

- EMI性能について, 連続的な導電性表面と継ぎ目での良好な接触 (導電性ガスケットまたはオーバーラップフランジ付き) 不可欠です.

6. ダイキャストの設計 - ジオメトリ, 特徴, および DFM ルール

優れたダイカスト設計が決め手. 以下は、実際的な設計ガイドラインの表と設計者が従うべき重要なルールです。.

DFM の主要なルール (まとめ)

- 壁の厚さ: 均一の壁を目指す. 一般的な HPDC 最小値: 1.0–1.5 mm 単純な形状の場合; 実用的なエンクロージャの外壁はしばしば 1.5–3.0 mm. 厚い島を避ける - 局所的な厚みの増加ではなくリブを使用します.

- 抜き勾配角度: 提供する 1–3° すべての垂直面の抜き勾配 (より深い機能についてはさらに詳しく).

- rib骨: リブを使用して補強します — リブの厚さ ≈ 0.5–0.8× 公称壁厚; 閉じたセクションを作成するリブを避ける.

- ボス / 対立: ボス外壁 ≒ 1.5–2.0× 主肉厚; ボスと壁の間の半径を含む; 通気用のドレン/ゲージ穴が含まれています; 収縮を避けるために適切なルートの厚さを組み込みます.

- 切り身 & 半径: トランジション部分にたっぷりのフィレットを使用する (≧1~2×壁厚) ストレス集中と摂食の問題を軽減するため.

- アンダーカット: アンダーカットを最小限に抑える; 必要に応じてスライドまたは分割ダイを使用すると、工具コストが増加します.

- シール面: 少し大きめにキャストし、平らになるまで機械加工します。; 表面仕上げを指定してください (ra) ガスケットシール用.

- スレッド: 繰り返し組み立てる場合は成形ねじを避けてください。機械加工ねじまたはヒートセット/インサートねじを推奨します。 (セクションを参照 10).

- ベント & ゲーティング: シール面とボスの気孔を最小限に抑えるためにゲートと通気口を配置します。; ゲート計画については鋳造工場と調整する.

コンパクトなDFMテーブル

| 特徴 | 代表的なガイドライン |

| 最小壁厚 (HPDC) | 1.0–1.5 mm; 剛性のために ≥1.5 mm を推奨 |

| 典型的な壁の厚さ (囲い) | 1.5–3.0 mm |

| 抜き勾配角度 | 1–3° (外部の) |

| ボス径:最小壁比 | ボス外径 3~5×肉厚; ボス厚み 1.5~2×肉厚 |

| リブの厚さ | 0.5–0.8×肉厚 |

| フィレット半径 | ≧1~2×壁厚 |

| シール面の機械加工取り代 | 0.8–2.0mmの追加ストック |

| ねじのかみ合い | 2.5× アルミニウムのネジ径 (またはインサートを使用します) |

これらは経験則です。最適化とシミュレーションについては、早めにダイキャスターに相談してください。.

7. シーリング, 侵入保護, およびガスケット戦略

電子エンクロージャは多くの場合、IP 定格を満たす必要があります. 重要な考慮事項:

- ガスケット溝の設計: ガスケットの圧縮に適したサイズの長方形またはアリ溝を使用します (例えば。, 20–30%圧縮). 連続した溝形状を提供し、デッドスペースを回避します.

- 面の平坦度 & 仕上げる: シール面を平坦になるように機械加工し、Ra を指定します (例えば。, ra≤ 1.6 µm) エラストマーの接着力を高めるため.

- ファスナー & 圧縮シーケンス: ボルトのトルクを指定する, 間隔, ガスケットのはみ出しを防ぐための脱落防止ネジまたはネジ付きインサートの使用. 均一な圧縮のために複数の小さなネジを検討してください.

- ガスケット材質: シリコンを選ぶ, EPDM, 温度/化学物質への曝露と硬度に基づくネオプレンまたは特殊なフルオロシリコン (ショア A 40 ~ 60 通常). EMIシールドには導電性エラストマーガスケットを使用してください.

- 排水 & ベント: 圧力を均一にするために水抜き穴または通気膜を設ける; 通気性のある通気口を使用してIPを維持しながら結露を防ぎます.

- 密閉型コネクタ & ケーブルグランド: IP67/68用途向けに認定されたケーブルグランドを使用してください. 過酷な環境向けにポッティングまたは成形オーバーモールドを検討してください.

資格: IP67/68 については、IEC に準拠した浸漬および防塵テストを指定 60529 および詳細なテスト条件 (深さ, 間隔, 温度).

8. 熱管理と放熱戦略

アルミダイカスト製エンクロージャは、以下の用途によく使用されます。 構造用ヒートシンク.

デザイン戦略:

- 発熱部品の直接取り付け エンクロージャのベースまたは専用のボス領域に熱を伝え、本体に熱を伝えます。.

サーマルインターフェースマテリアルを使用する (TIM), サーマルパッド, または接触を改善するための熱伝導性接着剤. - フィンを統合し、表面積を増加 外面に; HPDC は、ダイ設計が許せば、複雑なフィン形状を形成できます。.

フィンは破損を避けるのに十分な厚さでありながら、対流冷却のために十分に薄い必要があります。. 一般的なフィンの厚さは 1 ~ 3 mm、エアフローのために最適化された間隔. - 内部導電パスを使用する: 熱を外側シェルに伝える内部リブと厚みのあるパッド.

- 熱伝導を考慮した表面仕上げ: マットまたは陽極酸化された表面は放射率を変える可能性があります; 陽極酸化処理により、コーティングが存在する箇所の熱接触伝導率が低下します。伝導冷却を設計する際には、それを考慮してください。.

- 強制対流: 吸気口/排気口の設計 (粉塵用フィルター付き) ファンまたは送風機の取り付け機能を提供します. IP定格エンクロージャの場合, 通気口を避けるために伝導冷却またはヒートパイプを検討してください.

- 熱モデリング: CFDを使用して伝導のバランスをとる, 対流と放射; 熱シミュレーションでは PCB レイアウトを考慮する必要があります, 電力損失マップと最悪の周囲環境.

経験則: アルミニウム製エンクロージャの伝導パスは通常、プラスチック製エンクロージャと比較して PCB ホットスポット温度を大幅に低下させます。; 熱抵抗で数値化する (℃/W) 目的のアセンブリ用に.

9. エミ / RFI シールドと接地に関する考慮事項

アルミニウム製の筐体は導電性バリアを提供しますが、高いシールド効果を得るには慎重な設計が必要です:

- シームコントロール: 縫い目の接触表面積が十分であることを確認し、必要に応じて接合部に導電性ガスケットを適用します。. 導電性ファスナー圧縮を備えたオーバーラップフランジが効果的.

- 表面仕上げ & メッキ: クロム酸塩変換, ニッケルメッキまたは導電性塗料により耐食性が向上し、導電性が維持されます。.

非導電性コーティング (いくつかの絵の具) 接点がコーティングされないままになるか、導電性パスが提供されない限り、シールドが減少します。. - ガスケットの選定: 導電性エラストマーガスケット (銀またはニッケルを含浸させたシリコン) 継ぎ目とアクセス パネルの周囲に EMI シールを提供します.

- ケーブル & コネクタ貫通: フィルタ付きフィードスルーまたはシールド付きコネクタを使用する; 360°のシールド連続性を維持.

- グラウンディング戦略: グランドループを避けるために、スター接地を備えた 1 つ以上のグランドポイントを指定します。; 外部接地点には非脱落型スタッドまたは溶接ラグを使用します.

- テスト: シールド効果を測定する (SE) IEEE あたり 299 またはMIL-STD-285; 適切に設計された典型的なアルミニウム製エンクロージャは、適切なガスケットを使用することで、関連する周波数帯域にわたって 60 ~ 80 dB の SE を提供できます。.

10. 機械加工, 挿入, および組立方法

鋳造後の機械加工 通常は面の合わせに必要です, ネジ穴, コネクタの取り付け領域と精密な機能.

- 加工代: 鋳造部品の加工代を指定する (0.8–2.0 mm(プロセスに応じて異なる)) 重要な表面上で.

- スレッド: ヘリコイルまたはスチールインサートを使用 (例えば。, ペム, クリンチナットまたはネジ付きブッシュ) 繰り返し組み立てが予想される場所.

薄肉ボスの場合は、トルクを制御したタッピンねじまたはインサートナットを使用してください。. - ねじのかみ合い: アルミニウムへのねじ径の 2.5 倍以上の嵌合を目指すか、スチールインサートを使用してください.

- 圧入 & スナップフィット: 内部保持が可能, ただし、アルミニウムの熱サイクルとクリープを考慮してください。.

- 締結トルク: ボスの剥がれを避けるために最大トルクを指定します. 組み立て時にトルク制限ツールを使用する.

- 表面実装機能: コネクタと頻繁な取り扱いをサポートするボス補強とガセット.

品質管理: なくなる, 平面度とねじゲージ; 重要な形状の CMM 検査; 加工中にデータムを維持する.

11. 表面仕上げ, コーティングと腐食防止

ダイキャストエンクロージャの一般的な仕上げ:

- クロム酸塩変換 (アロジン/化学フィルム): 耐食性と塗料の密着性を向上させます; 環境規制は非六価プロセスを支持していることに注意してください.

- 陽極酸化処理: 装飾および腐食防止; 厚い陽極酸化により誘電体絶縁が強化され、界面での熱伝導が低下する可能性があります。取り付けパッドはコーティングされていない、または熱接触のためのコーティングが除去された状態で計画してください。.

- パウダーコーティング / ペイント: 優れた美観と腐食防止; EMIに対する継ぎ目の導電率を管理する必要がある (導電性ガスケットまたはマスクされた接触面を使用する).

- エレクトロレスニッケル / ニッケルメッキ: 耐摩耗性と耐腐食性を向上させます; 導電性を維持します.

- 機械仕上げ: ビーズブラスト, タンブリング, 化粧仕上げのための研磨.

選択メモ: EMIクリティカルな設計の場合は、シール面をコーティングしないままにするか、フランジ/ガスケット領域に導電性ペイント/メッキを施します。. 屋外で使用する場合は、耐食性コーティングと適切なシールを選択してください。.

12. テスト, 資格, と規格

一般的に適用される主要なテストと標準:

- 侵入保護 (IP) テスト: IEC 60529 (防塵および防水に対する IPxx 定格). 代表的なターゲット: IP54, IP65, IP66, IP67(環境による).

- 塩スプレー / 腐食: コーティング用の ASTM B117; 実際の使用条件では、浸漬または繰り返し腐食試験が必要になる場合があります。.

- サーマルサイクリング & ショック: 熱疲労と寸法安定性を検証する (例えば。, MIL-STD-810 に準拠).

- 振動 & ショック: IEC 60068-2, 用途に応じて自動車規格またはMIL規格.

- EMC / EMI試験: FCCによる, CE EMC指令, MIL-STD-461 (軍隊), IEEE 299 シールド効果を高めるために.

- 機械的テスト: 落とす, コネクタの衝撃およびトルク試験.

- プレッシャー / リークテスト: ハウジングが加圧またはポッティングされている場合, 漏れとシールの完全性をテストする.

- Rohs / REACH準拠: 材料の選択とコーティングは対象市場の規制要件を満たさなければなりません.

13. 製造業の経済学, リードタイム, およびボリュームに関する考慮事項

- ツーリングコスト: 金型コストが高い (複雑さとキャビティに応じて数十から数百,000USD) — 中量から大量に適しています.

- 単価: HPDC は大規模な場合でも部品あたりのコストを低く抑えることができます; 少量のプロトタイプのオプションには 3D プリント パターンが含まれます, 砂型鋳造またはCNC機械加工アルミニウム.

- サイクル時間: HPDCサイクルが短い (秒から分), 高スループットを可能にする.

- 後処理コスト: 機械加工, 熱処理, 表面仕上げ, インサートの取り付けと組み立ては部品ごとのコストが増加します; コストのかかる二次操作を最小限に抑える設計.

- とんとん: 通常、年間生産量が数千部品を超えるとダイカストが経済的になります, しかしこれは大きく異なります.

サプライチェーンのヒント: ダイキャスターとの早期の連携により、反復が削減されます, 部品のモジュール化 (インナーフレームとアウターカバー) ツールの複雑さを軽減できる可能性がある.

14. 環境, 健康 & 安全性とリサイクル性

- リサイクルバリティ: アルミニウムはリサイクル性が高く、一次生産と比べて再溶解にかかるエネルギーコストが低い. ダイカストスクラップおよび使用済みハウジングはスクラップ価値が高い.

- コーティング環境コンプライアンス: 非六価化成皮膜と ROHS/REACH に準拠した塗料化学を好む.

- ファウンドリH&s: 溶融金属の制御, ほこり, 仕上げとコーティング中に煙を発生させます; 適切な換気と PPE が必要です.

- ライフサイクル上の利点: 軽量の筐体により輸送量が削減され、モバイル用途でのエネルギー消費が削減される可能性があります.

15. 典型的な業界アプリケーション & 事例

- パワーエレクトロニクス / インバータ (太陽, EV, モータードライブ): エンクロージャは熱を伝導し、放散します; EMIと環境保護を満たさなければなりません.

- 通信基地局 & ラジオヘッズ: EMIシールドと耐候性.

- 自動車 ECU & パワーモジュール: 構造的役割と熱的役割を組み合わせたもの; 振動と温度サイクルが重要.

- 産業用制御 & 計装: エンクロージャは過酷な環境でもコントローラを保護します (IP66バージョン共通).

- 医療機器 & イメージングエレクトロニクス (非インプラント): 衛生的な仕上げとEMI制御が必要.

- アウトドアIoT / スマートシティノード: 一体型フランジとアンテナマウントを備えた小型ダイキャストハウジング.

16. アルミニウムダイキャストエンクロージャ vs. 代替案 — 比較表

以下はコンパクトです, エンジニアリング指向の比較 アルミダイキャストエンクロージャ (HPDC) 一般的な代替材料/プロセスとの比較.

| 材料 / プロセス | 密度 (g・cm⁻³) | 熱伝導率 (W・m⁻¹・K⁻¹) | 典型的な引張強度 (MPA) | EMIシールド | 一般的な表面仕上げ | 相対コスト (ユニット, 中音量) | 最適な使用例 |

| アルミニウム HPDC (A380 / ADC12) | 〜2.7 | ~100 – 140 | ~150 – 260 | とても良い (連続金属シェル) | 滑らかな鋳放し → 塗装 / 粉 / 陽極酸化します | 中くらい | 薄壁を必要とする大容量電子エンクロージャ, 統合されたボス, 基本的な熱放散とEMIシールド |

| アルミニウム (A356 T6, 重力 / 真空HPDC) | ~2.65 | ~120 – 160 | ~200 – 320 (T6) | とても良い | 良好 → 加工可能 & 陽極酸化 | 中程度 | より高度な機械的完全性が必要なエンクロージャ, 疲労/熱性能または圧力シールの向上 |

| 板金鋼 (刻印された / 折りたたまれた) | 〜7.85 | ~45 – 60 | ~300 – 600 (グレード依存) | とても良い (連続した縫い目がある & ガスケット) | 塗装済み / 粉体塗装 | 低メディウム | 低コストのエンクロージャ, 大型パネル, シンプルな形; 重量はそれほど重要ではなく、靭性が必要な場合 |

| ステンレス鋼 (シート) | ~7.7~8.1 | ~15 – 25 | ~450 – 700 | 素晴らしい (導電性, 耐食性) | ブラシ / 電動済み | 高い | 腐食性または衛生的な環境, 高強度 & 耐食性が必要 |

プラスチック 射出成形 (パソコン, ABS, PPO) |

~1.1~1.4 | ~0.2 – 0.3 | ~40 – 100 | 貧しい (金属化されていない限り) | スムーズ, テクスチャーのある | 低い | 低コスト, 誘電体エンクロージャ, 屋内用家電製品, EMI が重要ではないアプリケーション |

| 亜鉛ダイカスト (重荷) | ~6.6~7.1 | ~100 – 120 | ~200 – 350 | 良い | 非常に細かい表面のディテール; 簡単なメッキ | 中くらい | 小さい, 重量はそれほど重要ではなく、高い詳細が必要な詳細なハウジング; 装飾仕上げ |

| マグネシウムダイカスト | ~1.8 | ~70 – 90 | ~200 – 350 | とても良い | 良好なキャスト; 機械加工/塗装が可能 | 中程度 | 優れた熱伝導性を備えた超軽量筐体 (自動車, 航空宇宙エレクトロニクス) |

| 押し出し / アルミニウム加工品 (シート/押出成形品 + 機械加工) | 〜2.7 | 〜205 (純粋なアル), 合金の下位 | 200 - 400 (合金に依存する) | とても良い | 素晴らしい (陽極酸化します, 機械加工仕上げ) | 中程度 | 精密エンクロージャ, ヒートシンク一体型部品, 低い- NPI で中規模の実行まで & 工具のコストを制限する必要がある |

| 金属積層造形 (alsi10mg / 316l) | 2.7 / 8.0 | 100 (アル) / 10–16 (316) | 250–500 (材料に依存する) | とても良い | 完成状態→機械加工済み & 仕上げる | 高い | 低音量, 複雑な内部チャネル, 迅速な反復プロトタイプ, 高度に最適化された熱経路 |

メモ & 選択ガイダンス

- 重さ: アルミニウム (≈2.7g・cm⁻³) スチールや亜鉛と比較して、重量と剛性のバランスを最適化します。; マグネシウムはさらに軽量ですが、コスト/プロセスに制限があります.

- 熱管理: アルミニウム合金は、プラスチックやステンレス鋼よりも大幅に優れた熱伝導を実現します。これが、パワー エレクトロニクスにダイカスト アルミニウムを選択する主な理由です。.

- EMI性能: 金属ハウジング (アルミニウム, 鋼鉄, 亜鉛, マグネシウム) 本質的に優れたEMIシールドを提供します; プラスチックには、適合するメタライゼーションまたは導電性ガスケットが必要です.

- 構造的完全性 & 気孔率: HPDC 部品は多孔性を示す場合があります - 使用してください 真空HPDC, LPDC, またはA356 (T6) 漏れが気密なルート, 疲労寿命または機械加工されたシール面が重要です.

- 表面仕上げ & 腐食: ダイカストアルミニウムは幅広い仕上げに対応します (パウダーコート, ペイント, 無電解ニッケル, クロム酸塩変換, 陽極酸化します). ステンレスは優れた地金耐食性を提供します.

- 経済: HPDC は工具コストが高いが、量産単価は低い. シートメタルは、少量の場合は工具の面で安価ですが、複雑な統合機能には劣ります. AM は部品ごとに高価ですが、比類のない形状の自由度を実現します.

17. 結論

アルミニウム ダイキャスト エンクロージャは、エンジニアに統合された強力なプラットフォームを提供します。 機械的保護, 熱伝導とEMIシールド 単一の製造可能なパッケージ内で.

うまく使用するには、早めに焦点を当てる必要があります。 ダイカスト用DFM, 正しい合金とプロセスの選択 (完全性と熱性能が重要な場合は真空 HPDC または A356 T6), クリアシーリングとEMI対策, 明確に指定された仕上げとテスト.

正しく設計され、指定されている場合, ダイカストアルミニウムエンクロージャにより、組み立ての複雑さが軽減されます, 信頼性を向上させ、プレミアムを提供します, 現代の電子機器に適した耐久性のあるハウジング.

FAQ

板金エンクロージャよりもダイカストアルミニウムの方が望ましいのはどのような場合ですか?

統合されたリブ/ボスが必要な場合は、ダイカストアルミニウムを推奨します。, 優れた熱伝導, より高い機械的堅牢性, およびEMIシールド. 非常に低い工具コストで優れたシートメタルを実現, 薄型でシンプルな形状.

塗装されたダイキャストエンクロージャを使用してもEMI要件を満たすことができますか??

はい - ただし、継ぎ目でのガスケットによる導電性接触を確保してください, または、コーティングされていない導電性接触パッドを提供します. フランジ部分に導電性塗料やメッキを施すことも効果があります。.

成型/アルミニウム製の筐体は防水性があります?

シール面が平坦になるまで機械加工されている場合には、可能性があります。, 適切なガスケットとケーブルグランドが使用されている, 設計はテストされ、意図された IP 定格に適合することが確認されています。.

ガスケットのクリープと圧縮永久歪みを時間の経過とともに防ぐにはどうすればよいですか?

耐久性のあるガスケット材質を指定してください, 適切な圧縮を実現する設計 (20–30%), ボルトパターンとトルクを維持する, ファスナーが頻繁に循環される場合はインサートを選択します.

生産ツールの一般的なリードタイムはどのくらいですか??

ツーリングのリードタイムは複雑さによって異なります。通常は 6–20週間. サプライヤーの早期関与と製造容易性を考慮した設計により、反復と生産までの時間が短縮されます。.

アルミニウム ダイキャスト エンクロージャはどのようにして EMI シールドを実現するのか?

EMI シールドは次の方法で実現されます。: 1) アルミニウム固有の導電性 (50 dBベースライン); 2) 統合された内部シールドリブ (40 ~ 60 dB を追加); 3) 導電性表面処理 (無電解ニッケル, 導電性塗料, 15 ~ 30 dB を追加).

アルミニウム ダイカスト エンクロージャの最大 IP 定格はどれくらいですか??

アルミダイキャスト筐体でIP68を実現 (水没を超えて 1 メートル) 真空ダイカストで (気孔率 <1%) 精密なシール溝設計 (公差±0.1mm) バイトンOリングと組み合わせる.

アルミダイカストエンクロージャは高温用途で使用できますか?

はい - 標準エンクロージャ (A380/ADC12) 最大 125°C で動作; 高温合金 (6061) 硬質陽極酸化処理により 150 ~ 200°C に耐えることができます (エンジン搭載電子機器に適しています).