1. Hōʻikeʻike

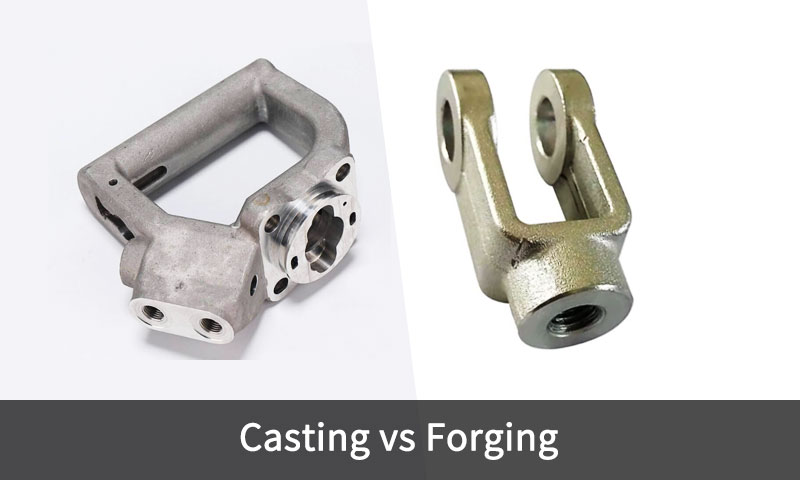

Kauhi vsa Kākau heʻelua mau alanui nui.

ʻO ka hoʻokaʻawaleʻana i nā exmils i ka hanaʻana i nāʻano paʻakikī, Nā cavities kūloko a me nā'āpana nui me nā mea haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa a me ka haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa no nā geometries maikaʻi.

Kākau e hana i nā'āpana me nā waiwai mecharinical, hoʻomaikaʻi i ka paleʻana o ka momona a me ka nui o ka palaoa, akā, koi pinepine i ka hana koʻikoʻi a me ka hana houʻana no keʻano o ka geometry paʻakikī.

ʻO ke koho kūpono e pili ana i nā koina o nā noi, geometry paʻakikī, Volume, nā kumukūʻai kumukūʻai a me nā mea hoʻoponopono regulatory.

2. He aha ke kauʻana?

Kauhi he kaʻina hana hana e pili ana i keʻano molten i nininiʻia i loko o kahi chevity chevity e like me ka mea i makemakeʻia.

ʻO ka manawa a me nā mea momona a me nā mea paʻa, laweʻia ka mold e hōʻike i ka'āpana.

ʻO kēia kaʻina hana kekahi o nā hana kahiko o nā mea hana metala, ʻO ke kauʻana i nā tausani o nā makahiki, a ua hoʻohana pinepineʻia ma muli o konaʻano ma ka hanaʻana i ka hana maʻalahi a me nā'āpana paʻakikī loa.

Ke kaʻina hana hoʻokolohua

- Kumukaha Kahuna - kahi replica o ka'āpana (Kākau) i hanaʻia mai ka wax, Wood, palaki, a iʻole he mea hao paha.

- Mākaukau Mold - Ua hanaʻia kahi mold e hoʻohana ana i ke one, hana, a iʻole he mea hao paha, Ke hilinaʻi nei i ke ala kūʻai.

- Hoʻomālamalama & E ninini ana - ua hoʻoheheʻeʻia nā alloys metal (ka maʻamau ma ka 600-1,600 ° C e pili ana i ka alloy) a nininiʻia i loko o ka'ōpū.

- Kūpuia & Ho'ōla - Uaʻaeʻo ia i ka hōʻoluʻolu i ka mea hao e lawe i keʻano o ka cevity.

- Ka Haakauaoha & ʻO ka hoʻomaʻemaʻe - ua wāwahiʻia a weheʻia paha ka mold, a me nā mea nui (nā'īpuka, 'Anaʻa) laweʻia.

- Ke hoʻopauʻana & Nānā - Hoʻohanaʻia kaʻoliʻoli, machining, a ua hoʻopiliʻia ka pauʻana o ka honua e like me ke koiʻia.

Nāʻano hōʻailona o ka lawaiʻaʻana

- Sand cread - kumukūʻai-kūpono, He kūpono no nā'āpana nui a me nā kaumaha nui; ʻO ka Timmansional Tolerance ma kahi o ± 0.5-2.0 mm.

- Hoʻolei kālā (Nalowale-wax) - hana nui i nā kiko'ī, kokoke-net-mode'āpana me ka hoʻopau maikaʻi loa (Ra ≈ 1.6-3.2 μm).

- Hoolei Make -ʻO ke kumukūʻai kiʻekiʻe o nā moly no nā alloys non-ferrous (AL, Zn, Mg) i loko o nā'ōpū mau; maikaʻi no ka hana kiʻekiʻe.

- ʻO Centricugual kāhea - Hoʻohanaʻia no nā'āpana cylindrical e like me nā piptes, me ka nui o ke kūpaʻa kiʻekiʻe a me nā hemahema liʻiliʻi.

- Ke hoʻomau nei - Ke kaʻina hana no ka hanaʻana i nā billets, sala, a me nā koʻokoʻo pololei mai ka metala mol.

Loaʻa nā kiʻi nui

- Hiki ke hana nā geomet paʻakikī, komo pū me nā'āpana kūloko a me nā'āpana'āpana.

- Lehulehu o Alloy flixibility (nā pāpale, irons, aluminum, keleawe, nickel, Titanium).

- Kokoke i kahi kokoke hoʻemiʻia nā koi machining.

- Kumukūʻai-kūpono no nā'āpana nui and nā helu haʻahaʻa haʻahaʻa haʻahaʻa.

- Scalability - mai nā prototypes i ka hana kiʻekiʻe (ka mea nui me ka hānaiʻana).

PAHUI

- E hoʻolei ana i nā hemahema e like me Potiwale, Nāʻuala, Nā Hoʻohui, He waimaka wela.

- Nā Pīkuhi Propertinies (ikaika ikaika, ʻO ka paleʻana o ka momona) ka haʻahaʻa pinepine i nā mea hoʻohālikelike no nā mea hoʻohālikelike ma muli o nā micstitic micsstructures a me ka poosity.

- ʻO ka pololei o ka dimensional a me ka papa e hoʻopau i ka maʻalahi o ke kaʻina hana.

- Hiki i nā kumukūʻai kaulike ke kumu lihao a me ka anitororopy ma ka hana mechanical.

3. He aha ke kalaʻana?

Kākau he kaʻina hana hana ma keʻano o keʻano o ke kala i loko o nā geomes i makemakeʻia ma o ikaika ikaika, ʻO ka hoʻohana maʻamauʻana i nā hammers, kuʻi, a iʻole nā make.

ʻAʻole like me ka mālamaʻana, kahi e hoʻoheheʻeʻia ai ka waiwai a hoʻoponoponoʻia, e ho'ōla ana i nā hana ma keʻano kūlana paʻa, ka hoʻomaikaʻiʻana i konaʻano grain a me ka hoʻonuiʻana i nā waiwai mechaninical.

ʻO ke kalaʻana kekahi o nāʻano mea kahiko kahiko-shower, Hanaʻia ka mōʻaukala ma nā blacksmiths me nā mea hana uila maʻalahi.

I kēia mau lā, ʻO kahi kaʻina hana maʻamau-kūpono loa i hoʻohana nuiʻia ma Aerospace, aitompetitive, pono & aila, mana pā'āʻu, a me nāʻoihana mālama.

Ke kaʻina hana hoʻokolohua

- Hoʻohui (Koho koho) - Ua hāpaiʻia ka metala i kahi kūlana plastik (No ka ho'ōlaʻana) a i waihoʻia ma ka mahana o ka lumi (No ke kalaʻana).

- Hapa - ke hoʻohālikelikeʻia ka mea hao i keʻano ma waena o nā'āpana a iʻole nā mea e make ai.

- Ho'ākāka - nā mea waiwai (Pū uilani) laweʻia.

- ʻO ka hana wela (Inā makemakeʻia) - ka hanaʻana, Queech, a ua hoʻopiliʻia ka hoʻowalewaleʻana e hoʻomaikaʻi i ka ikaika, paakiki, a me ka defility.

- Ke hoʻopauʻana - Machining, surface finishing, a me ka nānāʻana i ke kaʻina hana.

ʻAno o ke kalaʻana

- E hoʻopau ana i ka holoiʻana - nā'āpana nui i hoʻohālikelikeʻia ma waena o nā make; hoʻohanaʻia no nā shafts, Disc, a me nā poloka nui.

- Pani-make (Manaʻo-make) Kākau - Hoʻokomoʻiaʻo Metal i loko o nā hale noho i loko no nā'āpana likeʻole; hoʻohana nuiʻia ma ka kaʻa a me ka aerospace.

- Ke hoʻopoinaʻana i ke anuanu - Hanaʻia ma ka mahana o ka lumi; ʻO ka pololei o ka dimensional kūpono a me ka hoʻopauʻana.

- Ua kalaʻia ka wela - Hanaʻia ma luna o ka hoʻonuiʻana i ka mahana; aeʻae i ka nui o ka nui, nā mea paʻakikī paʻakikī me ka hoʻemiʻana i ka hana paʻakikī.

- Isothermal & Ua mālama ka pololei - nā hana holomua no Titanium, nickel, a me ka aerospace alloys, ʻO ka hoʻemiʻana i ka machining a me nā mea waiwaiʻole.

Loaʻa nā kiʻi nui

- ʻO nā waiwai maikaʻi loa Ma muli o ke kiʻiʻana i ka palaoa grain a me ka ho'ēmiʻana o nā palapala kūloko.

- High ʻO ka paleʻana o ka momona a me ka ikaika hopena i hoʻohālikelikeʻia i nā hale kūʻai.

- Ke kaulike nei dimensional pololei I ke kalaʻana.

- Kūpono no nā palapala koʻikoʻi e like me nā wahi mokulele mokulele, Cranomotive CraNkshafts Waiwai, nā ipu koʻikoʻi, a me nā'āpana mana nukle.

- Nā poosity liʻiliʻi a me nā mea maikaʻi maikaʻi maikaʻi loa.

PAHUI

- Uku kiʻekiʻe ma mua o ka hoʻoleiʻana, kūikawā no nāʻano paʻakikī.

- Kaupalenaʻia nā'āpana i hiki ke hanaʻia e ka deformation -ʻokoʻa i ka haʻahaʻa, laki, a iʻole nā geomes kiʻekiʻe.

- Pono ʻO nā hana hana kūikawā a me ke kiʻekiʻe kiʻekiʻe No nā'āpana nui.

- ʻOi aku ka lōʻihi o nā manawa no nā hana maʻamau.

4. Moloka & ʻO ke kaheʻana o ka laweʻana i ka curning vs. Kākau

Kekahi o nāʻokoʻa nui loa ma waena o ka hoʻoleiʻana a me ke kalaʻana i ka hoʻopunipuni ma ka micrstructure kūloko o ka waiwai.

Pehea e hoʻokumuʻia ai nā grains, hui pu, a ka mea e hoʻokaʻawale ai i ka wā o ka hoʻoiliʻana i ka ikaika o ka ikaika, paʻakikī, a me ka hōʻeha o kaʻeha o ka hopena hope loa.

Ka hoʻoleiʻana i nā micrstructure

- Ke kaʻina hana - ma ke kāʻeiʻana, ʻO nā haʻahaʻa haʻahaʻa a me nā mea paʻa i loko o ka mū.

Grains nukleate implely a ulu i waho, hana mea kūlike Oole columnar grains Ke hilinaʻi nei i nā kūlana hoʻomaha. - ʻO ka Orientation Grain -ʻaʻohe mea i makemakeʻia (ʻO ka hana Isotropic), akā pinepine heterogeneous. Hiki i nā palena o Grain nā mea nāwaliwali nāwaliwali ma lalo o ke kaumaha.

- 'Āke - hiki Potiwale, Nāʻuala, Nā Hoʻohui, a me ke kalaʻana i nā mea'ē aʻe Ma muli o ke kūleʻaʻana. Hoʻololi kēia mau mea i ka paleʻana i kaʻeha a me ka paʻakikī.

- Waiwai - lawa no nā ukana static.

Ua poina iā Microstructure

- Kaʻina hana pale - ke kala nei i nā mīkini deformally deformally ma kāna kūlana paʻa, ka wāwahiʻana i nā hana dendritic a me ka hoʻopauʻana i ka pososity.

- ʻO ke kaheʻana o ka palaoa - ke kala nei i nā kīwī i nā mea nui ma ke ala o nā pūʻali noi, e hana ana i Ke kahe nuiʻana o ka palaoa e hahai ana i keʻano o ka'āpana.

Ua hoʻomaikaʻi kēia i ka ikaika o ka hopena a me kaʻehaʻeha, nui loa i nā mea like e like me nā crankshafts a me nā'āpana turbine. - Hōʻike Hōʻailona - ke kalaʻana i nā hana i hoʻohālikelikeʻia, hoʻemi i ka nui o ka nui a me ka hoʻomaikaʻiʻana i ka pono metallurgical.

- Waiwai - nā'āpana i hōʻikeʻia i nā waiwai maikaʻiʻole, nui loa i nā kūlana paʻakikī.

5. ʻO ka waiwai maʻamau maʻamau o ka casting. Kākau

| Waiwai (at rt) | Kauhi (316 SS) | Kākau (316 SS) |

| Ikaika ikaika (Mpa) | 485-515 | 560-620 |

| Ka ikaika (0.2% Mpa) | 170-240 | 240-310 |

| Ewangantion (%) | 20-30 | 35-40 |

| Hālulu (HB) | 135-150 | 150-160 |

| Nā Kūlana Charpy (J) | 60-80 | 100-120 |

| Ka ikaika momona (Mpa, 10⁷ nā kupu) | ~ 170 | ~ 240 |

6. Hoʻolālā kūʻokoʻa, Aiko, a hoʻopauʻia

Ke hoʻohālikelike nei ʻO ke kalaʻana i ke kalaʻana, ʻO kekahi o nā mea nui loa o nā mea kūpono loa ma waena o Hoʻolālā Hoʻolālā, ʻO ka hoʻokeleʻo Dimensonal, a me ka maikai o ka ili.

Loaʻa i kēlā me kēia kaʻina hana nā ikaika a me nā palena, e hoʻoholo i ka kūpono no nā noi likeʻole.

Hoʻolālā kūʻokoʻa

- Kauhi Hāʻawi i kahi hoʻololi hoʻolālā hoʻolālāʻole. ʻO nā geomet paʻakikī e like me nā lua kūloko, nā pāʻili, ʻO nā hana Latting, a hiki i nā mea undercuts ke hana pololeiʻia i kahi ninini hoʻokahi.

ʻO ka mea kūʻai aku i ka waiwai e pili ana i nā mea e hiki ai i nā'āpana-net-likeʻole, e hōʻemi ana i ka machining e 70%.

Nā mea like e like me nā mea hana pump, Nā'āpana o Turbine, a iʻole e like me nā brackets i hanaʻia ma ka hoʻoleiʻana no ka mea hikiʻole ke hoʻopoina i nāʻano likeʻole. - Kākau, Ma ka hoʻohālikelike, i hoʻopaʻaʻia i nā geometr maʻalahi.

ʻOiai ua hoʻopauʻia ka paleʻana i ka mea e hoʻopau i nā'āpana likeʻole, intricate int ins, ʻO nā hana maikaʻi maikaʻi, a iʻole ka hoʻokōʻana i nā undercuts.

E kala mai i nā excels i ka wā e pono ai ka'āpana, hoʻomau mau geometry me kaʻole o nā'āpana, e like me nā mea like, Kauluhi, a me ka hoʻopiliʻana i nā koʻokoʻo.

Nā mea hana dimensional (ISO 8062 Kamaʻilio)

| Ke kaʻina hana | ʻO ka papaʻaina maʻamau | Hoʻoloholo (100 mm alimension) | ʻO nā mea koʻikoʻi koʻikoʻi (E.g., ʻO ka mea maʻi) |

| Sand cread | Ct8-ct10 | ± 0.4 - 0.8 mm | ± 0.2 - 0.4 mm |

| Hoʻolei kālā | Ct4 - ct6 | ± 0.05 - 0.2 mm | ± 0.03 - 0.08 mm |

| Hoolei Make (Al / zn / mg) | Ct5-ct7 | ± 0.1 - 0.3 mm | ± 0.05 - 0.15 mm |

| E hoʻopau ana i ka holoiʻana | Ct10 - ct12 | ± 0.8 - 1.5 mm | ± 0.4 - 0.8 mm |

| Ua paniʻia ka make-make | Ct7-ct9 | ± 0.2 - 0.6 mm | ± 0.1 - 0.25 mm |

Hoʻopau ʻili (RE, }m)

| Ke kaʻina hana | E like me-lawe / As-resied ra (}m) | Post-hoʻopau ra (}m) |

| Sand cread | 10 - 20 | 5 - 10 |

| Hoʻolei kālā | 1.2 - 5 | 0.8 - 2 |

| Hoolei Make (Al / zn / mg) | 2 - 10 | 1.2 - 5 |

| E hoʻopau ana i ka holoiʻana | 10 - 40 | 5 - 10 |

| Ua paniʻia ka make-make | 5 - 12 | 2.5 - 5 |

7. ʻO nā hanaʻelua a me nā hopena hana wela

ʻO nā hanaʻelua a me ka hana wela e pāʻani ai i kahi hana koʻikoʻi ma ka nānāʻana i ka hana o nā mea i hanaʻia e ka laweʻana.

ʻO kēia mau hana hana i hana ponoʻia e pili pono ana i nā waiwai mechanical, dimensional pololei, paulapua, a me ka lōʻihi lōʻihi.

ʻO nā hanaʻelua

Machimen:

- Kauhi: E hoʻolei pinepine nā māhele i ka machining nui e hoʻokō ai i nā mea hana paʻa a me nā papahele koʻikoʻi, nui no nā lua, KauwaiHua, a me nā maka maka.

ʻO ke kūʻai akuʻana i ka hoʻolimalimaʻana i nā koi machining ma muli o nā mea hiki ke kokoke mai, Ma kahi o Sand Sanding e koi pinepine ai i ka post-Machinging Post-Machining. - Kākau: Pono nā'āpana i nā'āpana machimal machining, ʻO ka hapa nui no ka hoʻopauʻana i nā papahele a me nā luaʻelua, Ma muli o nāʻano likeʻole a kokoke i ka hope o ka paniʻana o nā mea i paniʻia.

Hoʻopau ʻili:

- Pohō a me ke kālaiʻana: Hoʻonui i ka maikaʻi o ke kino, hoʻemi i ka paʻakikī, a wehe i nā hemahema liʻiliʻi. Hiki i nā mea kūʻai aku i nā mea kūʻai aku < 1.5 μM ma hope o ka mīkini a iʻole ke electrophinging.

- Pana pua / Hoʻopaʻa ʻana i ka Bead: Hoʻohanaʻia e hoʻoneʻe, Pū uilani, a hoʻomaikaʻi i ka lole kūlohelohe.

- Nā pāpale a me nā pale: Kaahu'āina lua (E.g., e hoʻolauna no ka kila kila, zinc a iʻole nickel e pale ana i ka pale o ka corrosonition) ua hoʻohana pinepineʻia i ka post-machining.

Kāhea & Pono:

- Koʻikoʻi no nā māhele me nā'āpana he nui, e like me nā lāʻau, Pins, a iʻole nā poʻe impea. ʻO nā hana hoʻoponopono kūpono e hōʻoia pono ai i ka hoʻomaʻemaʻe kūpono, ho'ōkiu, a me ka hana hana.

ʻO ka hana wela

Kumu:

ʻO ka hana wela hanaʻia e hoʻonui i nā waiwai mechanical e like me ka ikaika, paakiki, kumaikalua, a kau pale. ʻO kona mau hopena e like me nā mea i kauʻia ma waena o nā mea i kauʻia a me nā'āpana.

- Kauhi:

-

- E hoʻolei pinepineʻia nā kila kila a me nā haʻahaʻa haʻahaʻa haʻahaʻa Hoʻoholo hōʻoluʻolu, Ke kaumaha nei ke kaumaha, Oole Age paʻakikī e hōʻemi i nā kaumaha kūlohelohe, homogenize microstructure, a hoʻomaikaʻi i ka machindability.

- Pono e mālamaʻia e pale i ka hoʻokaʻawaleʻana i ka hoʻokaʻawaleʻana a iʻole ka palaoa i nā'āpana liʻiliʻi, i loko o nā hale kūʻai waiwai.

- Kākau:

-

- ʻO nā mea i ukuʻia mai hana maʻamau Oole ʻO ka huhū a me ka hoʻowalewale No ka hoʻopaʻaʻana i keʻano grain a hoʻonui i ka hana mechanical.

- E kala mai i nā mea i hanaʻia, ʻoi aku ka nui o nā mictruncture, No lailaʻoi aku ka maikaʻi o ka mālama wela i ka paʻakikī a me ke kaumaha kaumaha ma mua o ka hoʻomakaʻana no nā hemahema.

Holomua

- Hip hiki ke pani i ka postity kūloko i loko o nā hale kūʻai, e lawe mai ana i nā waiwai kokoke i nā mea i hanaʻia / hanaʻia ma ke kumukūʻai kiʻekiʻe.

- Nā mea kino kino (ʻO ka panaʻana, nitriding, carpurize) E hoʻomaikaʻi i ke ola momona a me nā pale pale.

8. Nā'Āpana Hana Kūlana: Keʻano kūpono e pono ai

Ka hoʻoleiʻana a me ka hoʻopoinaʻana i nā'āpana kūʻokoʻa kūʻokoʻa e pili ana i ko lākou mau mea paʻakikī ikaika-geometry paʻakikī, ʻO ka hana mechanication, Pono nā koina, a me nā kumu kūʻai.

Ke hoʻolaunaʻana i nā noi

Kaʻa kaʻa:

- Nā poloka mīkini: Ua hoʻohana nuiʻiaʻo Sand Canding no nā poloka mīkini hao, E noho ana i nā pahu wai a me nā lua o loko.

- Nā poʻo Cylinder: Hoʻolālā ka hoʻolimalimaʻana i nā mea kūʻai aku i nā channel channel a me nā geomet i nā geometries i nā mīkini kiʻekiʻe.

- Nā huila alumini: E make i ka mea kūʻai aku i ka hana kiʻekiʻe-Volume me ka hana maikaʻi loa a me ka hana dimensional.

Aerospace:

- Nā'āpana o Turbine: Ke kūʻai neiʻo Shopsments o nā Superalys e like me ka incontel 718 hoʻokō i nā geomel geomet o nā geomet.

- Hoʻololi Waʻa EIN: Ua kākoʻoʻo Sand Canding o nā Alluinum Alloys i nā kukui kukui me nā mea paʻakikī me ka paʻakikī.

Pono & Aila:

- Nā Hale Hōʻikeʻike: ʻO ka one i ke kīʻana o ka hao hao a iʻole snael i hāʻawi i ka robust, nā hopena kūpono-kūpono no ka laweʻana i ka wai.

- Nā kino valve: Ke kūʻai aku nei ka waiwai kūʻai aku ma ka steel stivelss i ka steel intel.

Kūkulu hoʻi & Hewakai:

- Uhi kuikahi: Ua hāʻawiʻo Sand ma ka pahu Ductile i hao i ka ikaika kiʻekiʻe a me ka nui.

- Pipet complees & Nā'āpana: ʻO ka makeʻana e hānai ana i ka alumini a iʻole keleawe e hāʻawi i ka māmā, ʻO nā hoʻonā Corrosionion-resistant no ka wai a me nā hui uila.

E kala mai i nā noi

Kaʻa kaʻa:

- Lihao: Ua paniʻia ka make-make i ka AISI 4140 ʻO Steel Enries High Favering Fireigue Resistivance a me Sun Suin Glole no nā mea hana hana.

- Ka hoʻopiliʻana i nā rods: Hana mai 4340 ʻO Steel no ka ikaika a me ka paʻakikī ma lalo o ka hoʻopiliʻana i ka Dynamic.

Aerospace:

- ʻO nā'āpana'āina: Hoʻopili i nā mea i hōʻokiʻia i loko o nā allnium alloys e hui pū ana i ka nui o ka nui o ka momona.

- Mīkiniʻoni: E hoʻopau i ka makeʻana o nā pilikia 625 Hoʻokumu nā mea i nā mea i kauʻia i nā kiʻekiʻe kiʻekiʻe a me nā kaumaha.

Pono & Aila:

- Nā Kūloko: ʻO ka holoi holoiʻana i ke kalaʻana ma Aisi 4145h Steel e hōʻoia i ka hoʻomauʻana o ka hoʻomanawanui.

- Nā lāʻau lāʻau: ʻO ka mea i hoʻopaʻaʻia i ka hanaʻana o 316l stainless steel reeel i ka hōʻoia a me ka paleʻana.

NA KAHIKI & Mea hana hana:

- Gear Blanks: Ua paniʻia ka make-make i ka AISI 8620 Loaʻa ka Steel i ka paʻakikī kiʻekiʻe a me nā pale pale no ka hoʻounaʻana i ka mana.

- ʻO nā cylinders hydraulic & Nā papahele: E hoʻopau i nā mea e kalaʻana i ka mea hana a A36 e hōʻoia i ka paʻakikī a me ka hopena hopena no nā hana kaumaha.

9. ʻO ka hoʻohālikelikeʻana o ke kāheaʻana i ka mālamaʻana. Kākau

ʻO ke kāheaʻana i ke kalaʻana i nā hana hana waiwai, ʻO kēlā me kēia me nā mea ponoʻole, PAHUI, a me nā hihia e hoʻohana pono ai.

ʻO ka papaʻaina ma lalo nei e hōʻuluʻulu i nāʻano nui o nā mea nui ma nā'āpana he nui, ka hāʻawiʻana i kahi alakaʻi ma-a-grice no nā mīkini, Manaʻoʻia, a me nā luna hana:

| Aspect | Kauhi | Kākau |

| Kaʻina hana | Ua nininiʻo Molten i nā mea hao i loko o kahi mū a hoʻopaʻaʻia | Ua hoʻokaʻawaleʻia ma lalo o ka ikaika kūpono, ʻO ka maʻamau ma ke kiʻekiʻe kiʻekiʻe |

| ʻO ka hoʻohanaʻana i ka waihona | Hoʻololi i ka hoʻemiʻana i ke kiʻekiʻe kiʻekiʻe i ka hoʻopukapukaʻana / make; ʻO kekahi mau geting / Riser Bear | Loaʻa nā waiwai nui loa; minimal scrap i ka wā i hoʻolālā ponoʻia ai |

| Hoʻolālā kūʻokoʻa | Maikaʻi loa no nā geomet paʻakikī, nā pāʻili, Nā Passing kūloko, nā undercuts | Kaupalenaʻia i nāʻano e hiki ke hana; E koi i nā cavinitinitinies i ka hana machining a iʻole nā hanaʻelua |

| Dimensional pololei | Kāhaka kūʻai kūʻai: ± 0.05-0.3 mm; Sand cread: ± 0.5-1.0 mm | Ua paniʻia ka make-make: ± 0.1-0.8 mm; E hoʻopau ana i ka holoiʻana: ± 0.5-2.0 mm |

| Hoʻopau ʻili | Ke kūʻai aku neiʻo Casting Ra 1.6-6.3 μM; Sand Canding Ra 6.3-25 μm | Pani-make i ke kalaʻana i ka rain 3.2-12.5 μm; E holoi i ka holoiʻana i ka RACEDE RA 6.3-50 μm |

| Nā Pīkuhi Propertinies | Ikaika; ʻO nā waiwai Isotropic ma nā hale kūʻai maʻalahi; ʻO nā pale haʻahaʻa haʻahaʻa ma muli o ka pososity | Ka ikaika a me ka paʻakikī; Ua hoʻomaikaʻiʻo ke kaheʻana i ka palaoa i ka momona a me ka hopena hopena |

ʻO ka hoʻohālikelikeʻana wela |

Kūpono loa; E hōʻoluʻolu i nā kaumaha kūloko a hoʻomaikaʻi i nā microstoructure | Pili kūpono; Ua ho'ōla i ka hanaʻana i nā'āina hana-paʻakikī a me keʻano o ke kīʻana i ka palaoa i hoʻonui i nā waiwai mechanininininini |

| Ka Hoʻohuiʻana & Kālā | ʻO ka hana hoʻolālā kiʻekiʻe (make / kūʻai kūʻai kūʻai) hoʻemi i ka uku uku; Hiki ke kūʻaiʻia ka haʻahaʻa haʻahaʻa | Haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa nui loa; Hiki i ke kumukūʻai kiʻekiʻe ke kūʻai aku ma muli o nā mea hana a me ka paʻiʻana i nā uku |

| Nā noi maʻamau | ʻO nā mea pāʻani pump, nā kino valve, Nā poloka mīkini, Nā'āpana o Turbine | Lihao, ka hoʻopiliʻana i nā rods, Nā papahele, Nā Kūlana Kūlana, nā mea hoʻomaʻamaʻa kiʻekiʻe |

| Ka manawa o waena o ka hoʻomaka a i ka wā pau | Loli; Hiki i nā papa haʻahaʻa a me ke kūkuluʻana i nā pule | Lohi loa; Ua pono ke kalaʻana i nā make i ka hoʻolālā pololei a me ka machining |

| ʻO ka pōmaikaʻi | ʻO nāʻano paʻakikī, kokoke i kahi kokoke, ka machining, Hiki i nā Pass Passings | Ikaika ikaika, ʻO ke kū'ē kū'ē, Ke kaheʻana o ka palaoa, paʻakikī maikaʻi loa |

| Cons | ʻO ka hana mechanic haʻahaʻa, mea kūpono, shrinkage, ʻO ka hana palena kiʻekiʻe loa | Kaupalena piha geometric, ʻO nā kumukūʻai kiʻekiʻe, Hoʻohana pinepineʻiaʻo ka mahana o ka lua |

10. Hopena

ʻAʻole nā mea kūʻai aku i nā mea hoʻokūkū a me ke kalaʻana akā nā mea e hoʻopihapiha ai:

- E koho i ka mālamaʻana inā: Ponoʻoe i nā geomex paʻakikī, haʻahaʻa haʻahaʻa haʻahaʻa no ka haʻahaʻa haʻahaʻa, a iʻole nā'āpana i hanaʻia mai Brittle metals (hae hao).

ʻO ka hoʻopukapukaʻana i nā mea kūʻai aku ma mua, ʻO ke kauʻana ma ke kumukūʻai, a make i ka hānaiʻana i nā wahi kiʻekiʻe. - E koho i ke kalaʻana inā: Ponoʻoe i ka ikaika kiʻekiʻe, ʻO ka paleʻana o ka momona, a iʻole nā mea i hoʻopaʻaʻia no nāʻano maʻalahi loa. ʻO ke kūleʻaʻana i ke kalaʻana no ka paleʻana no ke kiʻekiʻe kiʻekiʻe, nā'āpana kiʻekiʻe; E holoi ana i ka holoiʻana i ka nui, nā'āpana haʻahaʻa haʻahaʻa.

ʻO nā mea hana kūleʻa maikaʻi loa e hoʻohana ai i nā hana maʻamau-e.g., ʻO kahi kaʻa kaʻa e hoʻohana ai i nā poloka (huanui) a me nā crankshafts (ikaika).

Ma ke kohoʻana i ke kohoʻana i ke kaʻina hana me ka hana mahele, Volume, a me ke kumukuai, Hiki i nā meaʻenehana ke hoʻonui i ka hana, hoʻemi i ka TCO, A e hōʻoia i ka hilinaʻi lōʻihi.

FaqS

Hiki ke hoʻopoina i nā'āpana i nā'āpana kūloko?

ʻAʻole e kala mai i nā mea hao paʻa, Pono nā poʻe kūloko i loko (hoʻomālamalama, hānai), e hoʻohui i ke kumukūʻai a hōʻemi i ka ikaika.

Kauhi (ʻO ka Sand a iʻole ka hoʻopukapuka kālā) ʻo keʻano pono wale nō no nā'āpana me nā hiʻohiʻona o loko (E.g., ʻO ka wai kai wai).

ʻO ke kaʻina hana eʻoi aku ka nui o nā'āpana kila?

Uaʻoi aku ka maikaʻi o ke kalaʻana no ka nui-Volume, nā'āpana kiʻekiʻe: Hoʻohana ia 30-40% i ka nui o ka ikehu ma mua o ke kauʻana, hana i ka pauʻole (10-15% vs. 15-20%), Ua loaʻa i nā'āpana i nā lawelawe lawelawe (hōʻemi i nā alaloa hoʻololi).

ʻOi aku ka nui o nā Sand Canding no ka haʻahaʻa haʻahaʻa, nā'āpana paʻakikī (ʻO ka ikehu haʻahaʻa haʻahaʻa).

He aha ka nui o ka nui no ka mālamaʻana i ka casting vs. Kākau Nā'āpana?

- Kauhi: Hiki i ke Sand Canding ke hana i nā'āpana a hiki i 100 Tons (E.g., Nā Kahu Pūnaewele); Ua kaupalenaʻia ka hoʻopukapuka kālā ma ~ 50 kg (Nā'āpana 2.).

- Kākau: ʻO ka holoiʻana i nā kala e hana ai e hiki ke hana i nā'āpana i 200 Tons (E.g., nā mea kanu kanu); Ua hoʻopauʻia ka paleʻana i ke kalaʻana iā ~ 100 kg (nā'āpana nui).

No ke aha he mea nuiʻo Aerospace Turbine ma mua o ka hanaʻana?

Ua hoʻohālikelikeʻo Turbine i nā geomel o nā geomelil a me nā channels i loko.

Kāhaka kūʻai kūʻai (Ke hoʻohana nei i nā mea i hana likeʻole e like me ka inconal 718) hana i kēia mau hiʻohiʻona me ka mea i koiʻia, ʻOiai ka hana wela o ka wela i ka hoʻoikaikaʻana i ka ikaika no ka lawelawe kiʻekiʻe.