1. ʻO ka hōʻuluʻuluʻana

"E nānā i ka alumini-Magnesium" e pili ana iʻelua mau mea e pili ana iʻelua mauʻohana:

(A) High-MG Drand Alloys (MG-hein Nui alloying e hoʻonui ai i ka paleʻana o ka corrosione e kū'ē ana a me ka ikaika kūikawā no ka marine / kaupaona kaumaha) and (Na B) Al-si-mg canging alloys (Al-si kumu me nā hoʻohui mg mg i hoʻohanaʻia no ka wā paʻakikī a me ka ikaika).

Hāʻawiʻo Al-mg i nā alloys e hoʻopakele i nā pale kū'ē maikaʻi loa (nui loa i nā kaiāulu chrlode), ʻO ka ikaika ikaika-ikaika a me ka paʻakikī maikaʻi, Akāʻo lākou ka pise i ka wā e hoʻokaʻawale ai i nā luʻu no ka mea e pono ai ka mg o mg i nā poosities a hiki ke hoʻolaha i ka poosity inā nāwaliwali ke kaʻina hana.

ʻO ka hapa nui a Al-MG Hand Alloysʻaʻole ikaika loa-paʻakikī - hoʻoikaika i ka hana nui e nā hopena paʻa, ʻO ka mālamaʻana o ka Microstructure a me ka ThermomeCuncical.

2. ʻO ka mea a mākou e manaʻo ai ma ka "carst al-mg" - nāʻohana a me nā helu maʻamau

ʻElua mauʻano hana o nā hana al-mg alloys iʻike pinepineʻia ma kaʻoihana:

- Kālepili A - A - MG Kipi (All M-Mg): ʻO nā alloys ma kahi o ka mg e pono ai ke kiʻekiʻe e hoʻopaʻaʻia i keʻano o keʻano a me ka ikaika a me ka ikaika.

I ka palapala a me nā hale kūʻai hana hana i kēia papa hana maʻamau mg ma ka 3-6 wt% range me nā mea liʻiliʻi shai (≈ x0.5-1.0 %) I ka manawa e pono ai ka hale kūʻai maikaʻi. Hoʻohanaʻia kēia ma kahi o ke kū'ēʻana / ʻO ka paona māmā. - Kākau B - Al-si-mg casting alloys (Al-Si-mgʻohana): kokoke-eatectic al-si was shar cast alloys (SI ≈ 7-12 wt%) e komo pū me ka mg mg (≈0.2-0.8 WT%) eʻae i kaʻeha nui (Mg₂si papai) aʻoi aku ka ikaika kiʻekiʻe ma hope o ka t-type Aging (T6).

Nā hiʻohiʻona e pili ana i nāʻoihana hana hana hana e like me A356 (Al-si-mg) -ʻO kēia mau manawa i kapaʻiaʻo "Al-mg e loaʻa ana i nā hale noho" (akāʻo ka momi mua al-si alloys me MG e like me ka mea hoʻoikaika).

I ka hoʻomaʻamaʻaʻana e kohoʻoe i ka māhele i ka wā i kū ai ke kū'ē (Marine, Kauka Hoʻokani Pūlepa) a me nā haʻahaʻa haʻahaʻa loa; E koho i ka māhele b i ka wā e noho ai, Ponoʻiaʻo Dimensional.

3. Nā hui hoʻohālikelike maʻamau

Pākaukau: Nā Kūlana Kūlana maʻamau (Kāhea kū hāleʻa)

| Ohana / Hoʻoloholo | AL (kaulike) | Mg (wt%) | A (wt%) | Cu (wt%) | Maahua / nā moʻolelo |

| Aloha nui-mg drand al-mg (MAKAINA WAU) | kaulike | 3.0 - 6.0 | 0.0 - 1.0 | ≤ 0.5 | Mn liʻiliʻi mn, Lia; Mua hoʻohui (~ 0.5-1.0%) e hoʻomaikaʻi i ka wai i ka wā e pono ai. |

| Al-si-mg (E.g., A356 / Kāleʻa A357) | kaulike | 0.2 - 0.6 | 7.0 - 12.0 | 0.1 - 0.5 | Mg i kēia manawa e hiki ai iā Mg₂si Unting paʻakikī (T6). |

| Haʻahaʻa-mg al casting (no ka hoʻohālikelikeʻana) | kaulike | < 0.2 | ʻanoʻano | ʻanoʻano | ʻO nā mea make e make ai (A380 etc.) - mg keiki. |

Nā memo

- ʻO nā'ōkuhi ma luna o nā pukaʻenehana hana pono - Pono nā kiko'ī pololei e kuhikuhi i kahi hoʻolālā hoʻonohonoho (Astm / en) a iʻole ka palapala hōʻoia.

- Ke hoʻokokoke aku nei nā huakaʻi kiʻekiʻe-Mg (ʻO ka nānāʻana i ka mana kūpono a me keʻano kūpono).

4. ʻO Microstructure lāuaʻo Phase Chemistry - he aha nā mea e mālama nei

ʻO nā mea pāʻani micstrury mua

- α-al Matrix (cubic cub): ʻO ka hoʻouka kaua mua.

- Mg ma ka hopena paʻa: MG ATOMS FSSOLVE IN α-al; I nā hoʻokolohua haʻahaʻa e hoʻoikaika ai lākou i ka Matrix ma o ka hoʻoikaika paʻaʻana.

- ESTamESTICS / mau lua:

-

- Nāʻenehana mg-waiwai waiwai (Al₃mg₂ / β): hiki ke hana ma nā pae mg kiʻekiʻe a ma nā'āina interdendritic; ko lākou mau morphology a me ka hoʻoiliʻana i keʻano kiʻekiʻe o keʻano kiʻekiʻe a me keʻano o keʻano.

- Mg₂si (I nā al-si-mg alloys): nā puka i ka wā o kaʻeha aʻo ke kumu nui e hoʻomau i ka phase paʻakikī i kaʻohana al-si-mg.

- Nā lā a pau: ʻO nā mea nui i nā intmetallics (Al₅fesi, etc.) e hōʻemi ana i ka dorcility a hiki ke hoʻolaha i ka corrosion kūloko; Hoʻohui pinepineʻiaʻo MN i nā'āpana liʻiliʻi e hoʻololi i nā lā.

Nā hiʻohiʻona Kūnā

- Nā MG Alloys E loaʻa i kahiʻano maʻalahi loa α + ʻO ke ala hana kūpono kūpono akā hiki ke hōʻike i ka segregeation inā he lohi; ʻO ka wikiwiki wikiwiki wikiwiki akā e hāpai i ka hopena o ka pososity ināʻaʻole pono ka hānaiʻana.

- AL-si-mg alloys kū pono me ka mua o ka hahaiʻia e kahi mea etectic α + A; Ua komoʻo MG i nā hopena hope loa (Mg₂si) Inā loaʻa nā meaʻike mg.

Moloka ole → properties pili

- Laulu, nā papaʻelua i hoʻokaʻawaleʻia hāʻawi i ka paʻakikī maikaʻi a pale aku i keʻano brittle.

- ʻO nā intemetallics a iʻole ke kauʻana degrade facigue, ʻO ka hanaʻole a me ka hana noʻonoʻo. Kāohi ma ka hana melt hana, ʻO nā mea paʻa a me nā loiloi a me ka hōʻoluʻolu.

5. Nā hiʻohiʻona hana

Nā Pīkuhi Propertinies (ʻO nā meaʻenehanaʻenehana maʻamau - e hoʻolei i ka moku'āina)

ʻO nā waiwai e like me ka alloy, 'āpana liʻiliʻi, Ke hoʻolei nei i ke kaʻina hana a me ka mālama wela. E hoʻohana i nāʻikepili huahana no nā helu koʻikoʻi.

- Huakai (MAKAINA WAU): ~2.66-2.73 g · gm⁻³ No nā al-mg chore alloys (hoʻonui iki i ka hoʻomaʻemaʻe hoʻomaʻemaʻe al ~ 2.70).

- Ikaika ikaika (e like me-lawe):

-

- Nā Kelepona nui-MG: ~ 150-260 MPA (Ke hilinaʻi nei i nāʻike MG, 'āpana'āpana a hoʻopau).

- Al-si-mg (kiola + T6): ~ 240-320 MPA (T6 AGED A356 Nā Kūlana ma kaʻaoʻao kiʻekiʻe).

- Ka ikaika: ahu 0.5-0.8 × Pili Ma keʻano he alakaʻi.

- Ewangantion:5-15% Ke hilinaʻi nei i ka alloy a me ka hoʻoiliʻana - nā hale kūʻai kiʻekiʻe-mg-mg maʻamau e hōʻike pinepineʻia (smet-prose tendency), Al-si me corsane si e hōʻike i lalo o ka elongation haʻahaʻa ināʻaʻole i hoʻololiʻia.

- Momona a me ka paʻakikī: maikaʻi ke kaniʻana o ka moloka; ʻO ka hana momona i ka hana i ka nānāʻana i nā hemahema.

Ke kū'ē neiʻo Corrosionion

- Nā Kelepona nui-MG hōʻike Ke kū'ē nei i ka paleʻana o ka'āina, ka mea nui ma nā wahi a alkaline a me alkanaline.

- No nā mea waiwai chrlode-waiwai, Al-mg alloys pinepine i nā mea i waho alluys akāʻoi aku ka haʻahaʻa o nā mea nānā i nā kinikini a me nā pale pale i nā hihia koʻikoʻi.

Nā'lelo Thermal

- ʻO ka mālamaʻana o ka Thermal of Al-Mg Alloys e noho kiʻekiʻe (≈ 120-1480 mala · m ⁻¹ · k⁻¹ Ke hilinaʻi nei i ka alloying a me nā microstructure), Ke hana nei lākou i nā mea kūpono no nā hale kūʻai a me nā'āpana wela.

Mea hana & Welding

- Nā hana kīwī: Sand cread, mau loa, ʻO Gravity Died-singing a me kekahi mau kiʻekiʻe kiʻekiʻe (me ka leʻaleʻa maikaʻi) hoʻohanaʻia.

- Wawahua: ʻO nā all-mg alloys maʻamau maʻamau (Gtaw, Kāmaʻa kikomua), akā,ʻo ka ukiukiʻana o nā'āpana hopu e pono ai e nānā i ka pososity a me ka post-weld corrosion (E hoʻohana i nā alloys filler kūpono a me ka hoʻomaʻemaʻeʻana i ka hoʻomaʻemaʻe).

- Markinpalibility: Kūpono; nā koho koho a me nā wikiwiki i hoʻoponoponoʻia no nā alloys Aluminum.

6. ʻO ka hana wela wela a me ke kaʻina hana

ʻO nā alloys pane i ka hopena wela?

- Al-si-mg chore alloys (Kauohaa B) 'Ekā ʻO ka wela-mālama (Hedget-paʻakikī): Mālamalamaʻo Roms (T6) hana i ka ikaika nui i hoʻonuiʻia ma ka hoʻomakaʻana o mg₂si.

Nā papa maʻamau T6 no A356 / A357: Solution ~ 495 ° C, makahiki ma 160-180 ° C no kekahi mau hola (E hahai i ke alakaʻi pilikino). - High-MG Drand Alloys Af-MG (CHITITAT) 'Ekā ʻaʻole maʻamau i ka hopena-paʻakikī i ka pae like: Mg he mea ikaika-solud e hoʻoikaika a me nā mea kiʻekiʻe kiʻekiʻe-MG kiʻekiʻe ma mua o ka hana a me keʻano o nāʻano hana maʻamau.

ʻO ka hana wela no ka laweʻana i nā mea e hele ai i nā my:

-

- Homekangation e hōʻemi i ka hoʻokaʻawaleʻana (ʻO ka haʻahaʻa haʻahaʻa haʻahaʻa e hoʻoponopono ai i ka retistrist).

- Sysfe-relief anneal e hoʻoneʻe i nā kaumaha (hoʻohālikelike maʻamau: Nā Kūlana Kūlana 300-400 ° C - E hilinaʻi pono i nāʻano a me nā'āpana).

- Hoʻolilike ka hoʻonāʻana i ka palekana: Ua hoʻohanaʻia ma kahi koho no kekahi mauʻano al-mg, Akā e hoʻolaha paha i nā mea i loaʻaʻole i keʻano o keʻano o keʻano.

ʻO ke alakaʻiʻana i ka hana hoʻomaʻamaʻa wela

- No ka AL-Si-MG SPARESS manaʻo no ka ikaika, e hoʻolālā no hopena + Quetch + ʻEhā (T6) a hoʻolālāʻia me nā'āpana'āpana e kū pono ana.

- No ka nā hale aliʻi kiʻekiʻe, E wehewehe maopopo homogesation a me ka kaumaha nā mea hana e hoʻokūkū ai i nā microstructure a me ka dimensional kūpaʻa; Mai manaʻo e loaʻa i nā nui o nā makahiki he nui.

7. Loaʻa nā hana loaʻa a me nā hoʻoponoponoʻana i nā noʻonoʻo

ʻO ka paleʻana a me ka paleʻana

- Kaohi magnesium: Mg smidises e maʻalahi i mgo. E hoʻohana i nā pale pale pale pale (ʻO ka paʻakai paʻakai), kāohiʻia supherhaat, a ho'ēmi i ka hana drome.

- Ka wela wela: E mālama i loko o nā mea i manaʻoʻia no ka alloy i kohoʻia; Hoʻonui nui loa ka superheat nui i nā poho a me ka hana oxide.

- ʻO ke kiʻekiʻe a me ka filtration: Wehe i nā hydrogen a me nā orides (rotartsgaling, Nā kānana FAMIC FAM) E hōʻemi i ka pososity a hoʻomaikaʻi i ka hana mechanical / corrosione.

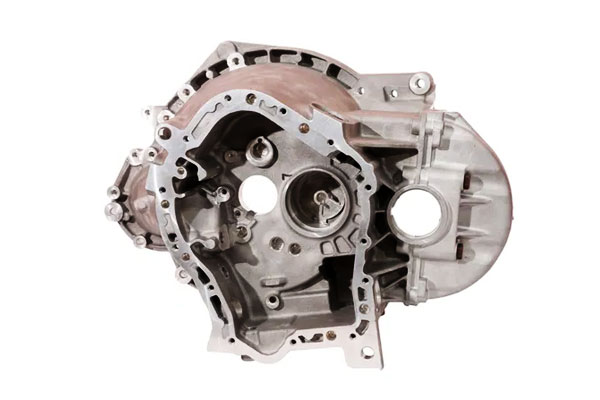

Nā hana kīwī

- Sand cread & hui mau-mau: maʻamau no nā alloys kiʻekiʻe-mg a no nā'āpana nui.

- ʻO ka mālamaʻana i ka nui / ʻO ka hoʻohaʻahaʻa haʻahaʻa haʻahaʻa: hana i nā microstructure maikaʻi a me ka hoʻopauʻana; maikaʻi no nā'āpana hoʻonohonoho.

- ʻO keʻano nui o ke koʻikoʻi: hoʻohana nuiʻia no nā alloys as al-si; ka makaʻala me nāʻikepili kiʻekiʻe-mg ma muli o ka mg oxidation a me ke kino.

Nā hemahema maʻamau & miomi

- Potiwale (ʻO ke kai / shrinkage): hoʻemiʻia e ka degasing, Kapalakula, ʻO ka hoʻolālā maikaʻi a me ka hoʻolālāʻana, a me ka kāohiʻana i ka helu hōʻoia.

- ʻO Oxied / bifilm maikaʻi: E hoʻomoʻi i ka paleʻana i ka turbulence a me ka hoʻohanaʻana.

- 'Āʻia wela: hoʻokele ma o ka hoʻolālā (Hōʻalo i nā hoʻololi o ka pauʻana) a mālama i ka hānaiʻana / paʻa.

8. Nā noi maʻamau o ka laweʻana i nā alloys alumnim

Hūnā.-ʻO nā alloys Afloys e noho ana i kahi'āina waena nui i loko o kaʻenehana māmā-metal: hoʻohui lākou i nāʻano haʻahaʻa haʻahaʻa a hoʻomaikaʻi aku i ke kū'ēʻana i nā mea e pili ana i nā alloys he nui a me nā mea e pono ai a me ka paʻakikī maikaʻi.

Marine a me nā mea hana kaʻa

- Nā Hale Hōʻikeʻike, nā kino valve a me nā mea hanaʻole no ka lawelawe hou / brackish wai

- Deck fittys, Nā Kūlana Pūnaewele, gustsuts a me nā shrous ma Splash / Spiray Zones

- Pipet complees, ʻO nā mea hoʻonaninani a me nā pā kaua

Autoomotive a me ka halihali

- Nā Kūlana Kūlana a me nā subframes (nā'āpana haʻahaʻa haʻahaʻa)

- Kino ma nā'āpana keʻokeʻo, loko a me nā pā kaua

- ʻO nā mea wela wela-sint a me nā papa lawe kaʻa no nā uila uila (I nā evs)

Pumps, nā valves a me nā fludi (Kahahana)

- Nā mea hana a me nā mea hana no keʻano o ke kahe a me ka wai wai

- Nā kino valve, nā hale noho a me nā mea hana hana

ʻO nā leʻaleʻa wela a me nā mea uila

- Nā leʻaleʻa uila, nā pālahalaha a me nā wahi kaʻa kaʻa kaʻa (Ev traction / inverters)

- ʻO nā mea wela wela e hele ai kahi mea nui a me ka haʻahaʻa haʻahaʻa

Aerospace (ʻO nā hana maʻamau non-kumu mua a me nā'āpanaʻelua)

- Nā pale pale, urowing, nā mea i hoʻopiliʻia, ʻO nā papa hana hana non-kumu mua a me nā kaulike

Kālā & Nā huahana hāmeʻa, mea uila

- Nā māmā māmā, pale kāʻei, Nā Hale Hōʻike Hou, nā'āpana uila (ʻAʻole koʻikoʻi), nā kino

Nā mīkini hanaʻenehana a me nā mea piliʻo HVAC

- Mau hale leʻaleʻa, nā mea kanu pua, ʻO nā mea kūʻai aku i hoʻopauʻia, Nā kukui māmā māmā

Nā noi kūikawā

- Nā lako hana cryogic (kahi e ukuʻia ai ka haʻahaʻa haʻahaʻa akā pono nā alloys no ka paʻakikī haʻahaʻa)

- Offukalike nolsings, Nā'āpana Subesa Spallot (me ka palekana kūpono)

9. Loaʻa a loaʻa nā hemahema

Loaʻa i nā hana o ka hoʻoleiʻana i nā alloys aluminum-Maganim

- Ke kū'ē neiʻo Corrosion Corrosiotion (nui loa ma nā wahi moana)

- Haʻahaʻa haʻahaʻa a me ka ikaika kiʻekiʻe kiʻekiʻe no nā noi koʻikoʻi-koʻikoʻi

- ʻO ka pāʻoihana maikaʻi loa no nā kīʻaha koʻikoʻi a me nā'ōnaehana i hoʻopaʻaʻia

- ʻO ka manikini maikaʻi no ka hoʻopauʻana

Loaʻa i nā hemahema o ka laweʻana i nā alloys aluminum-Maganim

- ʻO ka hanaʻana i ka hanaʻana me ka hana wela wela a me keʻano haʻahaʻa haʻahaʻa a me ka haʻahaʻa haʻahaʻa

- Ka hopena oxidation a me ka slag incountation e koi ana i nā lewa pale

- ʻO nā kumukūʻai hana kiʻekiʻe loa ma muli o ke kaʻina hana a me nā uku waiwai

- Hoʻopiliʻia ka helu helu helu helu helu i nā'āpana kiʻekiʻe

10. Hoʻohālikelike hoʻohālikelike: Thost al-mg vs. Nā hoʻokūkū hoʻokūkū

ʻO ka papaʻaina ma lalo nei kiola aluminum-Lagyemium alloys (Hoʻolei al-mg) me nā mea e hoʻokūkū pinepine ai i nā mea kūʻai aku i hoʻohanaʻia ma nā māmā māmā a me nā noi.

Nā hoʻohālikelike hoʻohālikelike ʻO ka hoʻoholoʻana i nā hoʻoholo hoʻoholo Ma mua o nā mea waiwai nominal, e hiki ai i nā koho koho pono.

| ʻAno / Loko | Thost al-mg alloy | Thost al-si alloy | Kāhea iā Magnesium Moley | Hoʻolei iā stienceless kila |

| Huakai | Hoʻohaʻahaʻa (≈1.74-1.83 G · Cm⁻³) | Loli (≈2.65-2.75 G · Cm⁻³) | Haʻahaʻa loa (≈1.75-1.85 g · camp⁻³) | High (≈ 6.7- 8.0 8 cm⁻³) |

| Ke kū'ē neiʻo Corrosionion | Maikaʻi loa (ʻoi akuʻo Marine / Splash) | Maikaʻi e maʻalahi (hilinaʻi iā si a cu) | Loli (koi i ka pale) | Kūpono (ʻO nā helu chrlode-resistant) |

| Ikaika ikaika (e like me-lawe / Hanaʻia) | Kūpono | Ke kiʻekiʻe kiʻekiʻe (me ka wela wela) | Haʻahaʻa haʻahaʻa | High |

| Paʻakikī / hopena kū'ē | Maikaʻi loa | Kūpono i ka maikaʻi (Hiki ke loaʻaʻo Britle SU) | Kūpono | Kūpono |

| ʻO ka hiki ke kiʻekiʻe | Paʻa (≤150-200 ° C i maʻamau) | Loli (Al-si-cua maikai) | Ilihune | Kūpono |

| Whola | Maikaʻi loa | Kūpono (maikaʻi loa) | Maikaʻi loa | Loli |

| ʻO Polosity Sentitivity | Kūpono (koi i ka hoʻokele hoʻoheheʻe) | Kūpono | High | Haʻahaʻa haʻahaʻa |

| Markinpalibility | Maikaʻi loa | Kūpono | Kūpono | Kūpono |

| Ka HōʻaʻO Kokua | High | High | High | Hoʻohaʻahaʻa |

| Koikuomahma | Loli (Pono e hoʻokaʻawale) | Loli | Ilihune | Kūpono |

| Ke hoʻopau nei i nā koho | Maikaʻi loa (aodize, Nā pāpale) | Kūpono | Paʻa | Kūpono |

| Kālā (pili pili) | Kūpono | Haʻahaʻa haʻahaʻa | Kūpono | High |

| Nā noi maʻamau | Ma haole featty, Nā Hale Hōʻikeʻike, nā kukui māmā | Nā hale kaʻa kaʻa, urowing, Nā'āpana mīkini | Nā Huakuai Mīkini, Nā'āpana kaulike maikaʻi | Nā Vilves, nā'āpana ikaika, nā wahi kūlike |

ʻO ka helu koho koho

Koho E hoʻolei i ka alumini-Magnesium alloys I ka wa māmā māmā, Ke kū'ē neiʻo Corrosionion, a me ka ikaika kūpono koiʻia ma nā wela wela.

No nā mea nui loa (ʻO ka hapalua kiʻekiʻe, Ka paipai, a iʻole nā mea kanu lāʻau), kila kohu ʻole e noho ana ma luna, oiai Al-SI Alloys E hoʻopaʻa i ka wā ʻO ka paʻakikī o ke kauʻana i ka geometry a me nā pono kūpono he paramika.

11. Nā hopena - Nā Hale Hana Hana Hoʻohana

- Hoʻolei iā alloys al-mg hoʻolako i kahi hui maikaʻi loa o ka haʻahaʻa haʻahaʻa, ʻO ka paleʻana a me ka ikaika kūpono no nā noi he nui - akāʻo lākou ʻaʻole kahi mea hoʻokahi; ʻO nāʻohana kiʻekiʻe-mg i nāʻohana mai Al-si-mg wela-mg wela.

- Kaʻina hana aʻo: ʻO ka pale melt, He mea pono ke kūleʻa a me ka filtration e hoʻokō ai i ka hana mechanical a me ka hana corrosion.

- ʻO nā mea hoʻonaninani wela: Al-si-mg chore alloys pane maikaʻi i ka hoʻonā + ʻEhā (T6) a hāʻawi i nā ikaika kiʻekiʻe; Loaʻa i nā huakaʻi hele kiʻekiʻe-MG i loaʻa i ka nui o ka hoʻokūkūʻana a hilinaʻi hou i ka mana o Microptructure.

- Hoʻolālā no ka hoʻolauʻana: E kāohi i ka mānoanoa, ka hānaiʻana a me ke kiʻiʻana e pale i nā hemahema o nā hemahema e pili ana i ka hapanui o kaʻeha a me ka hana corrosione.