1. Introdução

Ligas de alumínio are widely cast in sand, molde permanente, morrer, gravity or investment processes for automotive, Aeroespacial, consumer and industrial applications.

Compared with ferrous castings, aluminum presents specific metallurgical behaviours—high thermal conductivity, Solidificação rápida, significant sensitivity to hydrogen absorption and a strong tendency to form oxide films—that create unique defect modes.

Understanding the defect mechanisms and controlling melt, gating and solidification are essential to produce reliable castings with predictable mechanical properties.

2. Impact of Defects in Cast Aluminum Parts

Defects in alumínio fundido parts are not merely cosmetic problems — they directly degrade performance, shorten service life, increase cost and can create safety and liability exposures.

Internal and surface defects such as porosity, encolhimento, inclusões, rachaduras, and distortion reduce effective load-bearing area, create stress concentrators, and significantly degrade fatigue life, pressure tightness, precisão dimensional, e resistência à corrosão.

Em aplicações críticas, these defects can lead to premature or catastrophic failure, safety risks, and regulatory or liability exposure.

De uma perspectiva de fabricação, defects increase inspection complexity, scrap and rework rates, custo de produção, and delivery uncertainty, while also introducing large variability in mechanical properties that forces conservative design margins.

Consequentemente, effective control of casting defects is not merely a quality issue but a strategic requirement, demanding prevention-oriented process design, rigorous melt and mould control, simulation-driven engineering, and risk-based inspection and acceptance criteria.

3. Classification of Common Defects

Broadly, casting defects fall into two groups:

- Superfície / visible defects — readily apparent on finished parts: fins/flash, Cold Fechs, Misruns, shrinkage cavities visible at the surface, inclusões de areia, surface porosity, lágrimas quentes, overlap, and dimensional distortions.

- Interno / hidden defects — embedded within the part and often critical to strength: porosidade do gás, internal shrinkage cavities, oxide and dross inclusions, slag entrapment, segregação, and internal cracks.

Both groups can reduce fatigue life, lower tensile strength, cause leak paths in pressure parts, or lead to outright rejection in safety-critical components.

4. Detailed Defect Descriptions

The table below summarizes the most common defects encountered in aluminum castings, their root causes, how they manifest, and practical countermeasures.

| Defeito | Causa(s) | How it affects part | Detection methods | Prevenção / remediation |

| Porosidade do gás (Bolas, microporosity) | Hydrogen dissolved in liquid Al; entrained air due to turbulent pouring; moisture in mould/cores | Internal voids reducing static and fatigue strength; leak paths | Radiografia (Raio-X/Ct), ultrassônico, sectioning | Desgaseificação (rotativo, gás inerte), fluindo, minimize turbulence, pre-dry cores/moulds, control melt temperature, elenco de vácuo, improved gating |

| Shrinkage cavities / porosidade de encolhimento | Volumetric shrinkage on solidification with insufficient feeding; pobre posicionamento do riser; wide freezing ranges in alloy | Large voids, often interdendritic; severe reduction in load capacity | raio X, Ct, sectioning, visual if surface breaks | Solidificação direcional, risers/chills, feeding systems, use of feeders and chills, alloy selection with narrower freezing range |

| Fechado a frio / cold lap | Low metal temperature or slow flow resulting in two streams not fusing | Surface discontinuity, stress concentrator, reduced local strength | Inspeção visual, dye-penetrant for surface cracks | Increase pouring temperature, melhorar o design de bloqueio, reduce abrupt changes in cross-section, increase metal velocity |

Lágrima quente (rachadura quente) |

Thermal contraction constrained during final solidification; high restraint; poor alloy or mould design | Cracks form during solidification — often at corners or thin sections | Visual, penetrant, sectioning | Reduce restraint, redesign geometry (evite cantos afiados), modify solidification path, use grain refiners, control pouring temperature |

| Oxide film entrainment / escória / inclusões | Surface oxides folded into liquid by turbulence; slag entrainment; Pobre limpeza de fusão | Internal inclusions acting as crack initiation sites; porosity adjacent to inclusions | Radiografia, metalografia, sectioning | Skim dross, use ceramic filters, laminar filling, controlled pouring, fluindo, proper furnace practice |

| Sand/slag inclusion | Poor mould integrity, degraded sand, insufficient core washing, slag carryover | Stress risers, Defeitos de superfície, potential corrosion initiation | Visual, raio X, sectioning | Improve sand quality and handling, better mould/core preparation, filtration of melt |

Misrun / preenchimento incompleto |

Low pouring temperature, blocked gating, overly long flow path | Missing features, weak sections, sucata | Visual, CMM for geometry | Increase pouring temperature, optimize gating, increase sprue/runner size, reduce thin cross-sections |

| Rugosidade da superfície / sand blow / gas scab | Gas evolution at mould surface (umidade, binder decomposition), poor venting | Poor surface finish, early crack initiation | Inspeção visual | Control mould moisture, improve venting, use proper binders and drying |

| Cold lap / laps / folds | Flow velocity too low causing metal to fold over | Surface crack, poor fatigue behaviour | Visual, penetrant | Increase metal temperature/velocity, change gating, reduce abrupt geometry changes |

Dimensional distortion (Vareira, desvio) |

Uneven cooling, non-uniform wall thickness, poor tooling | Out-of-tolerance parts, assembly issues | Cmm, 3D scanning | Espessura uniforme da parede, balanced cooling, proper fettling, design for casting tolerances |

| Segregação (chemical inhomogeneity) | Microsegregation during solidification, ampla gama de congelamento, resfriamento lento | Local mechanical property variations, reduced corrosion resistance | Metalografia, chemical spot tests | Optimized alloy choice, stirring (onde aplicável), solidificação controlada, homogenization heat treatment |

| Internal cracks (delayed cracking) | Hidrogênio, estresse residual, envelhecimento excessivo, improper heat treatment | Catastrophic failure in service | Ultrassônico, dye-penetrant for surface, FRACTOGRAFIA | Reduce hydrogen, alívio do estresse, tratamento térmico controlado, eliminate sharp transitions |

5. Advanced Detection Methods for Cast Aluminum Part Defects

Accurate and efficient defect detection is the core guarantee for qualified cast aluminum parts.

Targeting different defect types and locations, the industry adopts a combination of multiple detection technologies to achieve full-coverage quality control:

Inspeção visual

Applicable defects: Surface blowholes, surface shrinkage cavity/porosity, surface slag inclusion, Inclusão de areia, obvious cracks, cold shut, misrun, surface flash/burrs, excess material, material loss.

Technical characteristics: Conducted by experienced quality inspectors with magnifying glasses (5–10× magnification) for detailed observation; simples, low-cost and efficient, serving as the first-line quality screening method.

Detection standard: Complies with ASTM E186, with surface defect size tolerance controlled within 0.05 mm for precision castings.

Inspeção de raios-X

Applicable defects: Internal blowholes, internal shrinkage cavity/porosity, internal slag inclusion and hidden internal cracks.

Technical characteristics: Uses X-ray penetration to form images of internal structures; defects appear as dark (vazios) or bright (inclusões) spots in the image.

Core advantages: Testes não destrutivos (Ndt), high detection accuracy (defect size ≥0.02 mm can be identified), clear visualization of internal defect distribution and shape.

Compliance standard: Meets ASTM E94, mandatory for critical components in aerospace and automotive industries.

Inspeção penetrante fluorescente (FPI)

Applicable defects: Subsurface and surface micro-cracks, cold shut and tiny porosity that are invisible to the naked eye.

Technical characteristics: Penetrant with high fluorescence is applied to the casting surface; penetrant seeps into defect gaps, and excess penetrant is cleaned; ultraviolet light irradiation makes defects emit bright fluorescence.

Core advantages: High sensitivity, capable of detecting micro-cracks with width <0.01 mm and depth <0.05 mm; suitable for complex-shaped castings.

Compliance standard: Conforms to ASTM E1417, essential for detecting stress-sensitive cracks in high-strength aluminum alloy castings.

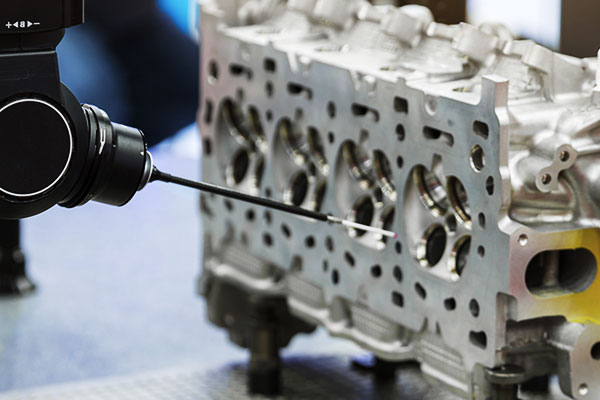

Endoscope Inspection

Applicable defects: Internal cavity flash, internal surface slag inclusion and dimensional deviation of complex internal cavities.

Technical characteristics: Flexible or rigid endoscopes with high-definition cameras are inserted into the casting’s internal cavity to capture real-time images of the inner surface.

Core advantages: Não destrutivo, can detect complex internal structures that are inaccessible to other methods; supports precise positioning of internal defects.

Application scenario: Mandatory for cast aluminum parts with complex inner cavities (Por exemplo, engine cylinder heads, hydraulic valve bodies).

3D Scanning Technology

Applicable defects: Core shift, mismatch, casting deformation and dimensional deviation beyond design tolerance.

Technical characteristics: Uses laser or structured light 3D scanners to collect full-surface point cloud data of castings; compares with 3D design models to analyze dimensional deviations with high precision.

Core advantages: High measurement accuracy (± 0,005 mm), full-dimensional detection, digitized data output; can quantify deformation degree and position of castings.

Compliance standard: Meets ISO 10360, critical for precision cast aluminum parts requiring tight dimensional tolerances (± 0,01-0,05 mm).

6. Key Prevention Measures for Common Defects in Cast Aluminum Parts

Abaixo está um compacto, engineering-oriented set of preventive measures keyed to the dominant defect mechanisms in aluminum casting.

Qualidade de fusão & metal treatment

- Desgaseificação: use rotary or vacuum degassing and monitor effectiveness (density-index or equivalent). Target consistently low dissolved-gas levels before pouring.

- Fluxo & deslizando: remove dross and oxidized surface films routinely; use appropriate flux chemistry and skimming practice to minimize non-metallic inclusions.

- Filtração: install ceramic/foam filters in the gating system (appropriate pore rating for alloy and flow) to trap dross and inclusions.

- Temperature control & superheat: maintain repeatable melt and pouring temperatures with narrow control limits (appropriate superheat above liquidus for the alloy) so fill and fusion are reliable without excessive gas pickup.

- Alloy chemistry control: hold composition to specification limits to avoid wide freezing ranges and undesirable solidification behaviour; perform frequent sample analysis and retain heat traceability.

Bloqueio, riser & mould filling design

- Laminar filling: design gates and runners to promote smooth, fluxo laminar (bottom or well-designed ingates, tapered runners) to avoid oxide folding and air entrapment.

- Controlled fill velocity: avoid turbulent splash that entrains air; use flow modelling to set runner dimensions and pour rates.

- Solidificação direcional: place risers/feeders and chills to establish a predictable solidification front and prevent internal shrinkage.

- Adequate risering: size and locate feeders to ensure sufficient metal head and feeding during the final solidification stage; consider insulated risers or exothermic sleeves where beneficial.

Moulds, cores and pattern practice

- Dry, well-cured cores/moulds: maintain low moisture and proper binder cure to prevent gas evolution (sand blow) and scabbing.

- Ventilação & permeabilidade: provide vents and vent channels at high-gas zones, and control sand permeability to suit the alloy and casting section thickness.

- Clean mould surfaces & Revestimentos: use appropriate washes/coatings to control metal-mould reactions and improve surface finish; verify compatibility of coatings with billet temperature and pouring practice.

- Tool maintenance: replace worn patterns or dies to prevent excessive flash/parting-line defects.

Filling & pouring practice

- Bottom-or controlled-bottom filling: onde aplicável, use bottom or submerged gating to reduce surface oxide entrainment.

- Minimize turbulence at pour points: use tapered gate entries, well-designed pouring cups and steady pour techniques.

- Avoid re-melting of dross: do not pour from the surface skim into the mold; position ladles and tapping to draw from clean metal.

- Consistent operator procedures: enforce standard operating procedures (POPS) for furnace, ladle, and pour that include checklist verification (degassing completed, filter installed, pour temp logged).

Controle de solidificação & Gerenciamento térmico

- Chills and thermal controls: apply chills to promote directional solidification; place them based on simulation output.

- Reduce section thickness variations: design components with uniform wall thickness and generous fillets to avoid hot spots and stress concentrations.

- Control cooling rates: where feasible, use controlled cooling fixtures or molds to reduce thermal gradients and residual stress that lead to hot tearing and distortion.

Alloy-specific and metallurgical measures

- Refinamento de grãos / inoculação: use appropriate grain refiners or modifiers (Por exemplo, Sr for Al-Si systems) to improve feeding and reduce hot-tearing susceptibility.

- Hydrogen control: use degassing and dry crucibles/liners to minimize hydrogen sources; control moisture in fluxes, coatings and cores.

- Homogeneização / solucionando: for castings that permit heat treatment, apply homogenization or solution anneal cycles to reduce segregation and dissolve detrimental phases.

Process simulation, design for castability & DFCAST

- Mold-fill and solidification simulation: run CFD/solidification models early in design to identify risky zones (cold spots, turbulence regions, shrinkage hot spots) and iterate gating, feeder and chill layouts.

- Design for castability (DFCAST): incorporate uniform section thickness, generous radii, avoidance of abrupt section changes, and castable features (drafts, accessible machining allowance) at the design stage.

Foundry practice, Inspeção & in-process controls

- Process parameters logging: record melt chemistry, degassing metrics, temperatura de derramamento, filter/flux usage and mold drying status for every heat/shift.

- Layered NDT strategy: define inspection tiers based on part criticality — visual → dye-penetrant for surface cracks → radiography/CT or phased-array UT for internal volumetric defects.

- Acceptance criteria tied to function: specify allowable porosity size, location and volume fraction relative to service loads (not just “pass/fail” surface counts).

- On-line monitoring: sempre que possível, use inline hydrogen monitoring, melt cleanliness indices and pour temperature alarms to stop non-conforming pours.

Post-cast remediation & verification

- Prensagem Isostática a Quente (QUADRIL): specify HIP for high-value or fatigue-critical castings to close internal porosity when permitted.

- Qualified repair procedures: weld or braze repairs only with controlled procedures and subsequent NDT and mechanical verification.

- Final machining & Teste funcional: remove surface defects by machining where acceptable; apply pressure/leak testing for pressure parts.

7. Conclusão

Aluminum casting defects arise from metallurgical, thermal and process interactions.

Proactive control—starting with clean melt practice, careful gating and riser design, drying and venting of moulds/cores, and well-defined NDT strategies—substantially reduces defect incidence.

For mission-critical parts, invest in advanced inspection (Ct, phased-array UT), process simulation and, when warranted, post-casting HIP to assure structural integrity and long service life.

Perguntas frequentes

What is the single most common root cause of internal porosity in aluminum castings?

Hydrogen absorption and entrapment during solidification, exacerbated by turbulent fill and inadequate degassing, is the most common cause of internal gas porosity.

Can all porosity be removed by heat treatment?

Não. Conventional heat treatment does not eliminate gas or shrinkage porosity. Pressionamento isostático quente (QUADRIL) can close internal porosity for high-value parts.

Which NDT is best for detecting small internal pores?

Ct (computed tomography) provides the best 3-D sensitivity and sizing accuracy; radiography and phased-array UT are also effective and more economical depending on defect size and accessibility.

How should I specify acceptance criteria for porosity?

Acceptance should be application-driven: specify maximum allowable defect size, volume fraction, or critical location limits (Por exemplo, no through-wall porosity in sealing surfaces), and mandate the inspection method used to verify.

Is aluminum casting always more defect-prone than steel casting?

Not inherently — each metal has its own dominant defect mechanisms.

Aluminum’s sensitivity to hydrogen, oxide films and its wide freezing range require specific controls; with proper process discipline, defect rates can be as low as other alloys.

Referências: Aluminum and Aluminum Alloys Subject Guide Overview