1. Hōʻikeʻike

Nalowale wax casting - ua kāheaʻia Kāhaka kūʻai kūʻai - heʻano hana kūponoʻole e hoʻopili ana i nā mea i hoʻololiʻia i nā mea kūʻai aku i loaʻa i nā mea kiʻekiʻe kiʻekiʻe.

Ka hoʻohuiʻana i nā cedities-kahiko me nā meaʻepekema o kēia mau'ōlelo a me nā'ōnaehana hana, ʻO ka mea kūʻai aku i ka hoʻopiʻiʻana i nā mea kūʻokoʻa e hāʻawi ana i nā geometry paʻakikī, ʻO ka hopena maikaʻi loa a me ka wānana i ka metallirgy ma kahi ākea ākea nui o nā alloys.

Noho ia i ka niche ma waena o ka cotxibility prototype a me ka hana kūpono: ʻO ke kaʻina hana i hāʻawiʻia a me nā mea haʻahaʻa haʻahaʻa haʻahaʻa a me ka haʻahaʻa o ka hanaʻana i ka hanaʻana i nā'āpana e koi pinepine ai.

2. He aha ka mea e nalowale ana?

Nalowale shop, Uaʻikeʻia e like me Kāhaka kūʻai kūʻai, he kaʻina hana kūʻai ma keʻano heʻano hana i kahi hoʻohālike, hana maʻamau i ka wax, hoʻohanaʻia e hana i kahi mokuahi pale.

Ke laweʻia nei keʻano hoʻohālike, Ua nininiʻiaʻo Molten i keʻano i loko o ka lua e hana i ka'āpana hope loa.

ʻO ka weheweheʻana i keʻano o ka paleʻana i ka wana keʻano o keʻano o keʻano a hōʻili: Pono kēlā me kēia hale kūʻai i kahi kumu kūʻai hou, Ke kūpono nei i ka paʻakikī, kūlike, a iʻole nā'āpana kiʻekiʻe e hikiʻole ke hana maʻalahi e hoʻohanaʻia me ka hoʻohana mauʻana i nā molū mau a make paha.

ʻAʻole like me ka cand cand, ka mea e hoʻohana hou ai i nā molū a iʻole nā mea hoʻolimalima akā maʻamau ka palena maʻamau a me nā mea paʻakikī a geometric, Ua loaʻa i nā mea kūʻai akuʻo Wax Wax kokoke-net-mode'āpana me ka pololei o ka dimensional pololei, e kūpono ana i nā noi koʻikoʻi ma ka aerospace, olakino, ikaika, a me nā'āpanaʻoihana.

Nā hiʻohiʻona nui

- Kūʻokoʻa kūʻokoʻa kūʻokoʻa: nā undercuts, Nā Paukū Kuhi, Hiki i nā cavities kūloko a me nā kiko'ī kiko'ī.

- Bigle Alylonge: Mai Alminim a hiki i ke kila kila, Nickel Spehealys a me Titanium.

- ʻO ka maikaʻi kiʻekiʻe a me nā dime aliʻi: palena pinepine a hoʻopau paha i ka pauʻana o lalo.

- Scalable i nā'āpanaʻelua a me nā liʻiliʻi liʻiliʻi-liʻiliʻi-medium: ʻO nā kumukūʻai hana e hoʻohālikelikeʻia me ka nui o ka makeʻana o ke kiʻekiʻe.

3. ʻO ke kaʻina hana Wax Wax Wax

Nalowale shop, a iʻole ka hoʻopukapuka waiwai, he kaʻina hana lehulehu e hoʻololi ai i kahi kumu kūʻai wax i loko o kahi mea i waena.

ʻO kēlā me kēia papa hana he koʻikoʻi e hoʻokō i ka pololei o ka dimensional, ʻO ka maikaʻi kiʻekiʻe, a me ke kūpono kūpono.

'Lelo 1 - Ke hanaʻokoʻa (wax a iʻole keʻano paʻi)

Kumu: hana pololei, ʻO keʻano hoʻohālikelike e wehewehe i ka geometry casting.

Nā hana: injection wax i loko o nā make metal; Hoʻolaha i nā mea i paʻiʻia 3D i paʻiʻia a iʻole Palymer i nā hiʻohiʻona no nā prototypes / haʻahaʻa haʻahaʻa.

Nā pale nui / 'Kākoʻoʻana:

- E hoʻohana i nā mea hao politika no nā papa o nā cosmetic costical.

- Mālama i ka mahana o ka heleʻana a me ke kaomiʻana i ke kaomi e pale aku ai i nā hana a me nā pōkole pōkole.

- No nā hiʻohiʻona paʻi, E nānā pono i kaʻaoʻao a me ke kaʻina hana-dimensional (holoi / ho'ōla) E like me ka mea e pono ai.

Mauʻoiaʻiʻo: Wax Melt point ~ 60-90 ° C (hilinaʻi i ka hana); Hoʻokomoʻia ka loaʻaʻana o nā kekona → Nā minuke e pili ana i ka nui o ka pana.

'Lelo 2 - Kākoʻo Hou, ke aloha a me ka hana

Kumu: E hana i kahiʻoihana hānai (Kumulāʻau) e kū pono ai i nā kahe maikaʻi maikaʻi a me ke ala kūmole.

Nā pale nui / 'Kākoʻoʻana:

- ʻO nā lā hoʻolālā e hānai i nā'āpana mānoanoa mua a pale i ke kaheʻana i nā helehelena koʻikoʻi.

- Minor Turbulence ma o ka hoʻohanaʻana i nā gates streamched a me kaʻaoʻao ma lalo.

- E koho i nā mea hānai / Riser nodes e hoʻolaha i ka hōʻoiaʻana i ke kuhikuhiʻana i ka punawai.

Papa kuhikuhi loiloi: ʻO ka helu kaulike o nā hiʻohiʻona ma kēlā me kēia kumu me nā palena lima lima a me ka nui.

'Lelo 3 - Kahaā (cemic cheating a stucco)

Kumu: kūkulu i kahi ikaika, ʻO ka'ōpū o ka cheramic cemik a puni ka lāʻau wax.

Ke kaʻina hana: Nā mea e pono ai (maikaʻi loa) Me Stucco (ʻO ke one) nā papa.

Nā hiʻohiʻona maʻamau & alakaʻi alakaʻi:

- Nā Koko: maʻamau 6-12 mau moku (Hiki i nā mea hou no nā alloys kaumaha).

- Hāliu: ~4-12 mm Nui (ʻO nā'āpana no nā'āpana alumina liʻiliʻi, Kahi no ke kiʻekiʻe kiʻekiʻe-Temp).

- Kāleka: Hoʻomaka me ka slurry maikaʻi / stucco no ka fuditity o kaʻaoʻao; ka holomuaʻana i ka sourser stucco no ka ikaika.

- Haunaele: Eʻae i ka maloʻoʻana ma waena o nā lole; E kāohi i ka hoʻohaʻahaʻa / mahana e pale ai i kaʻokiʻana.

Kikowaena: E hoʻopaʻa a hoʻopaʻa i ka Slurry Slirry Viscosity, ʻO Stucco Grain ka nui o nā manawa a me ka maloʻoʻana i nā manawa - Shell Consistency ka mea hoʻokele mua o ka laweʻana i nā mea kūʻai aku.

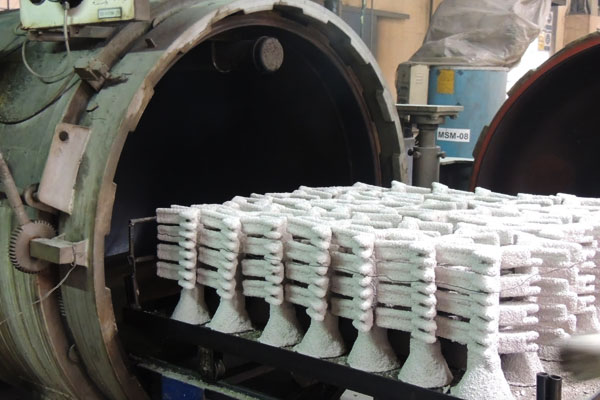

'Lelo 4 - Pue (wax lawe)

Kumu: E haʻalele i ka wax e waiho i kahi pale pale e pili ana i ka'āpana o ka geometry'āpana.

Nā hana: Steam Autoclave, ove mentout, a iʻole e hoʻopau i ka extravent no nā waxes kūikawā.

Nā hiʻohiʻona maʻamau & 'Kākoʻoʻana:

- Steam Autoclave ʻo ia ka mea maʻamau-steam / condensate melts wax wax wikiwiki a lawe aku ia ia mai ka.

- Hōʻalo i nā mea wela wela e wāwahi ai; kāohiʻia, Hoʻokuʻuʻiaʻo DOWAX i nā pōʻino shell.

- E hōʻiliʻili a me ka recycle wax ma kahi hiki.

Nā hopena: ʻO ka lua maʻemaʻe a hoʻemi i nā mea noho kūlohelohe ma mua o ka puhiʻana.

'Lelo 5 - fream / ʻokiʻoki

Kumu: E hoʻopau i nā koena o ke koena / wax residies a me ka lawehala i ka pale i ka ikaika a me ke kumu hoʻohālike.

Nā Kūlana maʻamau & Hoʻopaʻa nā:

- Kaumaha i nā wela: maʻamau 600-1000 ° C, ʻoi aku ka kiʻekiʻe no ka hana hana (ʻO kaʻaihue Chemistry hilinaʻi).

- Nā manawaʻehā: mau hola e pili ana i ka nui o kaʻili a me keʻano ikaika.

- Hopena: hoʻomaikaʻi hou i ka ikaika shemit, hoʻonohonoho i ka permeability no ke kaheʻana o ke kahe a me ke kai.

Kikowaena: ʻO ke kiʻiʻana i ka hanaʻana i nā kope me ka alloy a me ke ala nui.

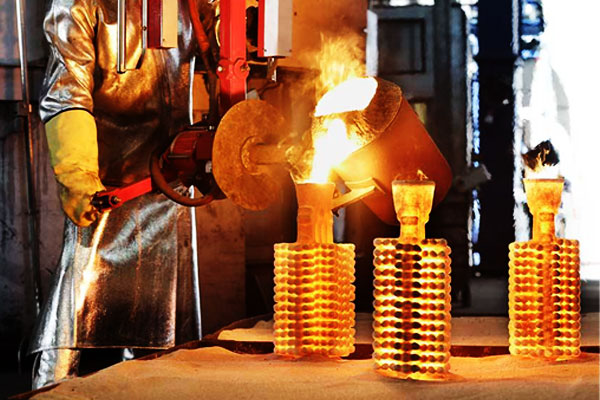

'Lelo 6 - metal metting a me ka nininiʻana (Hoʻopihaʻana)

Kumu: melt alloy e kuhikuhi ai a hōʻike iā ia i loko o ka pūpū me ke kaheʻana o ke kaheʻana.

Nā hana hoʻohālikelike: ke komoʻana (ʻO ka hakahaka a iʻole ka lewa), ahi-ahi, ʻO keʻano hoʻomaha no ka reactive / kiʻekiʻe-kiʻekiʻe-waiwai.

No kaʻenehana: ʻO ka nui o Gravity Poir, VIEUMAM-kōkua, a iʻole ke kōkua (haʻahaʻa haʻahaʻa / counter-singress) Ke hilinaʻi nei i ka alloy a me ke kāheaʻana i nā pono kūpono.

Manaʻo maʻamau & No nāʻikepili (hōʻikeʻike):

- Aluminum: Mel ~ 650-750 ° C

- Nā mea kanu lāʻau: Melt ~ 1450-1600 ° C

- Nickel mau: Melt ~ 1350-1500 ° C

- Pour CROTHERS: minerheat minimized e hōʻemi i ka oxidation / dross; He mea nui nā kiʻi a me nā detrasinging no nā'āpana haʻahaʻa haʻahaʻa.

Hana maikaʻi loa: preheat shells e hōʻemi i ka pīhoihoi o ka thermal a me nā kuhi hewa; E hoʻohana i nā kānana cemic a me nā degasing (argon / argon-bubbling, rotartsgaling) E like me ka mea e pono ai.

'Lelo 7 - ka hōʻoluʻolu a me ka hoʻoponopono

Kumu: E kāohi i ke ala paʻa e hōʻemi ai i nā hemahema shrinkige a hoʻonohonoho i nā microstructure.

Hoʻopaʻa nā & 'Kākoʻoʻana:

- E hoʻohana i nā mea hana hou / Riser e hoʻolālā ma ka lāʻau Wax e hōʻoia i ka hōʻoiaʻana i ka hōʻoia.

- Eʻae i ka manawa nui i ka manawa ma mua o nā molds ma mua o ke kīwī i ke kīwī no nā'āpana liʻiliʻi; Pono nā'āpana nui e pono ai nā manawa nui.

- Hoʻokomo ka helu maʻalahi i ka nui palaoa; Hiki ke noho i ke kikowaena.

Nā manawa kūpono maʻamau: mai kekona a i nā minuke he nui e pili ana i ka nui; E hoʻolālā no ka marmal a me ka mānoanoa.

'Lelo 8 - Shell Wehe (kulaʻi)

Kumu: E hoʻokaʻawale i nā meaʻoki a hōʻike i nā hale kūʻai.

Nā hana: puiahuhu (viguration, tumbling, BlaSTLO), NA NUI WOLOHE, a iʻole ka hoʻokaʻawaleʻana.

Nā Pono Hoʻolālā: reclaim a me recycle semic stucco kahi i hiki ai; E hoʻokele i ka lepo a me nā mea hoʻopiʻi.

'Lelo 9 - ʻoki, Ke hoʻopauʻana, ʻO ka hana wela

Kumu: E hoʻohuli i nā hale kaʻa kaʻa i loko o ka dimension pololei, Nā'āpana kūpono-no-lawelawe.

NA HUI NUI: Hoʻopau i nā'īpuka / Sprues; grinde / hoʻopau i nā papa; mālama i ka wela (hopena + ʻEhā, Annae, huhū) E like me ka mea e pono ai; Nā hiʻohiʻona mana (shem, nā maka).

Alakaʻi alakaʻi: ʻO ka mīkini ma hope o ka wela wela o ka wela o ka wela a me ke kaumaha e pale ai i ka distortion; mālama i ka traceability (hoʻoheheʻe nui, Hana i ka papa inoa).

'Lelo 10 - nānā, ʻO ka ho'āʻoʻana a me ka pena

Kumu: E hōʻoia i ka hoʻokūkū e pili ana i ka kiko'ī.

Mau manaʻo maʻamau: nānā'ōwaho, huahuai (Cmm), Ndt (Kālā hoʻokūkū / X-Ray, Ultrasinatic), Hoʻolālā Metal, ʻO ka paʻakikī paʻakikī a me ka hanaʻana, ʻO ka ho'āʻoʻana / ka hoʻokeleʻana no nā'āpana i hoʻopaʻaʻia.

Ho'ōla: Nā hōʻike hōʻike, Nā Palapala Kūʻai, Nā palapala hōʻoia o ka hoʻokōʻana.

4. ʻO ka mālamaʻana

ʻO ka hoʻounaʻana i ka post-shove e hoʻohuli i kahi waiwai kūʻai aku i kahi hana hana. NA HUI NUI:

- ʻO ka hana wela: Hoʻohui, ʻEhā, Annalile, a iʻole ka huhūʻana - e pili ana i nā waiwai a me nā waiwai i koiʻia.

- Ke hoʻopauʻana: shot blast, bead blast, kūhā, Kāleka, kemika o ke kahe, Hoʻololi, adizing a pena paha.

- Maki: Nā papa wai, KauwaiHua, Ke lawe nei i nā papa i hoʻopaʻaʻia ma hope o ka mālamaʻana i ka wela a me ke kaumaha kaumaha.

- Ndt a me ka hōʻoia: hoʻoili pūnaewele, Ultrasinatic, DENA PEVERETRAT, a me ke koʻikoʻi e hōʻike ana i nā'āpana i hoʻopaʻaʻia.

- ʻO ka'ōlelo waena a me ke kaulike: ʻO ke kaulikeʻo Dynamic no nā'āpana hoʻololi, ʻO ka hōʻoia o Fixture, Hōʻike Manaʻo.

5. Nāʻano likeʻole a me nāʻohana

ʻO Wax Wax Casting ke kaʻina hana, a i ka manawa, Ua puka mai nāʻano kiʻi kūikawā e hālāwai ai me nā mea likeʻole, huanui, a me nā koi hana.

| Lihiloli | Nā hiʻohiʻona Core | Mea waiwai | Nā noi maʻamau |

| ʻO ka paleʻana o ka'ōpū | Kahua'āina; hoʻohana iā Anumina / Silica Curramit Well i hiki i nā kiʻekiʻe kiʻekiʻe | Hualaola, Titanium, kila kohu ʻole | ʻO Aerospace Turbine Blades, Nā Kūlana Kūʻai Kūʻai Nui, NA KEKI ANA |

| Pākuʻi Morold Kahuila | Hoʻohana i ka loaʻaʻana o ka loaʻa kālā; ua hoʻolakoʻia no nā haʻahaʻa haʻahaʻa haʻahaʻa a me nā'āpana liʻiliʻi | Aluminum, Nā pāpale keleawe, nā metala koʻikoʻi (gula, dala, Papa) | Kōhai, ʻO kaʻike moʻolelo, Hopoi |

| Haka Hoʻolei kālā | Dewaxing a me / a iʻole ka nininiʻana ma lalo o ka hakahaka e hōʻemi i nā poosity | Titanium, nā mea kanu nckel (Actoel), nā alloys kiʻekiʻe | Nā Kūlana Kūlana Kūʻai Kūʻai, nā leka detal, ʻO nā'āpana Arosprity kiʻekiʻe kiʻekiʻe |

| E hoʻokaʻawale i nā wana wax / Nā hiʻohiʻona paʻi | ʻO Wax a iʻole Palymer i hana pololeiʻia ma o ka paʻi 3D; ʻAʻole koiʻia nā mea i hoʻopaʻaʻia | Kila kohu ʻole, Titanium, aluminum | Rapid prototyping, nā polokalamu lapaʻau haʻahaʻa haʻahaʻa haʻahaʻa, Nā hoʻolālā hoʻokolohua paʻakikī |

6. Nā mea waiwai a me ka hoʻohuiʻana i ka hoʻololiʻana o ka wana wax

Koho o ka alloy kūpono kūpono nā koina mechanical, Ke kū'ē neiʻo Corrosionion, Holo Maʻaleʻa, a me nā mea pili kūpono.

| Kālana uila | Nā helu maʻamau | Huakai (g / cm³) | ʻO ka ikaika maʻamau maʻamau (Mpa) | ʻO keʻano maʻamau (° C) | Nā memo |

| Apana Apana Aluminum | A356, A413, 319 | 2.6-2.8 | 140-320 | 650-750 | ʻO ka Castability maikaʻi loa, Ke kū'ē neiʻo Corrosionion, ʻO ka wela-mālama pono no ka hana mechanical. Kūpono no ke kaʻa uila māmā, AerERPPACE, a me nā'āpanaʻoihana. |

| keleawe Alloys / Bronze | C954, C932, Nā mea kūʻai nui | 8.2-8.9 | 200-500 | 1000-1100 | ʻO ke kūpaʻa maikaʻi, Kāleʻa Kūʻai Nui. Hoʻohanaʻia ma kaʻoihana, Marine, a me nā noi hoʻonaninani. |

| Nā mea kanu lāʻau | 304, 316, 17-4Ph | 7.7-8.0 | 400-900 | 1450-1600 | Ke kū'ē neiʻo Corrosionion, incrutural integrity, a me ke kūlana kiʻekiʻe. Kūpono no aerospace, olakino, a me nā meaʻai meaʻai. |

Nickel mau |

Actoel 718, 625 | 8.2-8.9 | 600-1200 | 1350-1500 | ʻO ka ikaika kiʻekiʻe a me keʻano o ka ikaika kiʻekiʻe. Hoʻohana nuiʻia ma Turbine Enginenes a me nā noi hana kiʻekiʻe. |

| Alloys Kekahi | Shoultite series | 8.3-8.6 | 500-1000 | 1350-1450 | ʻO ke kāʻei maikaʻi a me keʻano o keʻano; Kūpono no nā mea hanaʻokiʻoki, Nā Vilves, a me nā mea kūʻai biomedical. |

| ʻO nā huila Titanium | Ti-6al-4v (paʻa) | 4.4-4.5 | 800-1100 | >1650 (Haka) | Māmā māmā, ikaika, corrosions-resistant; Pono keʻano o keʻano o ka hana hou a iʻole nā mea e ninini ana. Hoʻohanaʻia ma Aerospace, NA KEKI ANA, a me nā'āpana hana kiʻekiʻe. |

| Nā metala koʻikoʻi | Gula, Dala, Papa | 19-21 (Au) | Nāʻokoʻa | 1000-1100 (Au) | ʻO nā mea kūʻai waiwai kiʻekiʻe, maikaʻi loa, a me nā pilina uila uila kūikawā; ʻO ke kaʻina hana e hoʻomaikaʻi ai i ka hoʻopauʻana a me ka helu kiko'ī. |

7. Nā mea maʻamau a me ka hoʻopauʻana

Nalowale shop (Kāhaka kūʻai kūʻai) ua manaʻoʻia no kāna ʻO ka helu a me ka hopena kiʻekiʻe kiʻekiʻe a me ka maikaʻi, ʻO ka hana kūpono no nā mea i loaʻa i kahi kūpono a me keʻano o ke kaʻina hana liʻiliʻi.

Huahuai Aiko

| ʻAno hiʻohiʻona | Mea maʻamau | Nā memo |

| Nā lālā linear | ± 0.05-0.5 mm per 100 mm | Hilinaʻi i ka'āpana'āpana, Goody, a miry; ʻO nā mea i loaʻa i nā mea hana i loaʻa i ka mea hana e pono ai a me ka mālama ponoʻana. |

| 'Ākau / DRAFT | ± 0.5-1 ° | Nā kihiʻihi o ka 1-3 ° i manaʻoʻia e kōkua i ka laweʻana a me ka hale. |

| Hoop humuu / puni | ± 0.05-0.2 mm | Pono paha nā lua nui e pili ana i ka post machining. |

| Pilenawinui | ± 0.1-0.3 mm | Nā pāʻili (<1.5 mm) Eʻike paha i ka loli liʻiliʻi ma muli o ke kaheʻana o ke kahe a me kaʻili i ka nui. |

Hoʻopau ʻili

| Ana | Kaonaʻeha | Nā memo |

| Ra (huahua) | 0.8-6.3 μM (32-250 min) | E like me ka pale; hilinaʻi i ka maikaʻi o ka hana maʻamau, pau ka hopena slur, a me ka nui stucco. |

| Pau ka hopena (Polika) | 0.4-0.8 μm (16-32 min) | Hoʻokō me ka hana hana o ka mea kūʻai akuʻo Wax Wax. |

| Post-ho'ōla (Koho koho) | <0.4 }m (16 min) | Pana pua, Kāleka, peketio, a iʻole ka hoʻokaʻawaleʻana e hōʻemi hou aʻe. |

8. Nā hemahema maʻamau, Nā kumu kumu, a me nā mea hana kūpono

| Hewa ole | Nā kumu kumu | Nā Koho Hana Kūʻai |

| Potiwale (aila) | Komo i ke kino, ʻO ka URDROGEN PUT, turbuglence | Mell doglasing, Kapalakula, ʻO ka nininiʻana i kahi hale kūʻai, striceline ging |

| ʻO ka pololi | Meaʻaiʻole, ʻO ka hoʻonohonohoʻana o ka malihini | Hoʻomaikaʻi i ka hoʻolālā hānai, kuhikuhi i ka hōʻoia, lihuli |

| Poino / nā'ōpū anuanu | Nā hoʻomoe haʻahaʻa haʻahaʻa, ʻO ka maikaʻi maikaʻi | Hoʻonui i ka superheat i loko o nā spec, preheat moed, Hoʻoponopono i ka gating |

| Nā Hoʻohui / non-metallics | Ulia i ka ulia, E hoʻokaʻawale i ka flux | ʻOi aku ka maikaʻi o ka hoʻomaʻemaʻe, filtration cerramic, hoʻopaʻa paʻaʻia |

| ʻOkiʻoki | Kūlouʻo Thermal, Kanaka, Pololei Dewax | Kāohiʻia dewax a me ka puhiʻana i nāʻaoʻao, Shell Thinity Offimization |

| Nā hana hana wax | Hōʻoia pihaʻole, Pū uilani, Kauhai | Hoʻomaikaʻiʻo Wax make dice, E kāohi i nā'āpana injection, ʻO ka hōʻoluʻolu kūpono |

| Waimaka wela | Hoʻoponopono paʻa, ʻO nā mea hoʻokūkū koʻikoʻi | E hoʻohui i nā kīʻaha, Adapt geometry, E kāohi i nā mea nui |

9. Loaʻa a loaʻa nā hemahema

Loaʻa i nā mea kūʻai aku i hala

- ʻO ka geometry paʻakikī

-

- Hana i nāʻano hoʻohālikelike, nā pāʻili, nā undercuts, nā lua kūloko, a paʻakikī nāʻike maikaʻi loa no nā hana kūʻai'ē aʻe.

- ʻO ka pololei kiʻekiʻe kiʻekiʻe

-

- Landar Tolerances maʻamau ± 0.05-0.5 mm per 100 mm, e hiki ai i nā'āpana likeʻole-net-net me ka machimal machining.

- Hoʻopau ʻili maikaʻi

-

- E like me-lawe-hele aku rassness ra ~ 0.8-6.3 μm; Hiki i ka mea hana kūʻai ke hoʻokō i RA ≤0.8 μM, e hōʻemi ana i ka hoʻoiliʻana.

- Alloy flixibility

-

- Kākoʻo iluminum, keleawe, kila kohu ʻole, nickel / cobalt speperallys, Titanium, a me nā metala nui.

- Mea kūponoʻole

-

- ʻO ka hanaʻana-Net-Shape e hōʻemi i nā mīkini paʻi kiʻi kiʻi, nui no nā uku kiʻekiʻe kiʻekiʻe.

- Liʻiliʻi-a-medium volume aloha

-

- Waiwai no nā prototypes, Nā'āpana maʻamau, a iʻole e holo ai ka hanaʻana i nāʻumi tausani i kēlā me kēia makahiki.

- ʻO ka hana koʻikoʻi koʻikoʻi

-

- Kūpono no ka aerospace, olakino, a me nā'āpana o ka ikehu i kahi kūpono, Kahiki Pāʻani Waiwai, a he mea nui loa ka intergrity kūpono.

Loaʻa i nā hemahema o ka paleʻana o Wax

- ʻOi aku ke kumukūʻai kiʻekiʻe no nā helu nui

-

- ʻO nā manawa lohi a me nā hana kiʻekiʻe /ʻoi aku ka nui o nā hana / waiwai ma mua o ka makeʻana, e hana ana i ka hoʻokūkū liʻiliʻi no ka hana nui.

- ʻO nā manawa alakaʻi

-

- Nā hana he nui (Wax kumu, Kaila, ke ahi, E ninini ana, Ke hoʻopauʻana) Hoʻonui i ka manawa hana.

- ʻO ke kaʻina hana

-

- Koi i ka hana akamai a me ka mālama ponoʻana i ka mold, Shell, a me nā'āpana hao; ʻO nā hana he nui e hoʻonui ai i nā pilikia hemahema.

- Nui a me nā palena hana

-

- Nā palena kūpono no nā'āpana nui a iʻole nā'āpana nui loa; Hiki paha i nā undercum ke nānā pono i nā manaʻo hoʻolālā kūikawā.

- Ka mea hana kūʻai

-

- ʻO nā hiʻohiʻona wax he hoʻohana hoʻokahi; koi nā loli i nā hana hou a iʻole nā hiʻohiʻona paʻi, pili ana i ke kumukūʻai a alakaʻi i ka manawa.

10. Nā noi maʻamau

- Aerospace & nā wahi hau: MALEs, Nā Wili, nā'āpana hoʻohui, nā mea hou.

- Mana pā'āʻu & ikaika: Hōʻike Laulā, Nā Viona.

- Lapaau & Kāke: nā manaʻo, nā mea kani, nā'āpana waiwai.

- Petrochemimical & pono & aila: ʻO nā alaloa kiʻekiʻe a me nā kūpono kūpono.

- Kaʻa kaʻa huahua palale: Hoʻouluʻia nā'Āpana Brake, Nā'āpana Turbochger, ʻO nā mea hana hoʻolālā Niche.

- Kōhai & Nā Hana Hana Hana: nā hale kiaʻi kiʻekiʻe kiʻekiʻe ma nā metala koʻikoʻi.

- Nā Pumpsʻoihana & nā mea hoʻohālikelike: hanakai, ʻO nā hale kūʻaiʻokoʻa.

11. Hoʻohālikelike me nā hana kūʻai'ē aʻe

Nalowale shop (Kāhaka kūʻai kūʻai) Hāʻawi i nā mana kūʻokoʻa i hoʻohālikelikeʻia me nāʻano hana likeʻole e like me ke kauʻana o ka sand, Ke hoʻomau mau nei, a make.

Kaʻikeʻana i kēia mauʻokoʻa i kōkua i nā mīkini hana a me ke kūʻaiʻana i nā mea hoʻokele e koho i ke kaʻina hana kūpono e pili ana i ka nui o ka paʻakikī, waiwai, Volume, A me nā koina.

| Pili / Kūlana | Nalowale shop (Hoʻolei kālā) | Sand cread | Ke hoʻomau mau nei | Hoolei Make |

| Geometry paʻakikī | Kiʻekiʻe loa; nā pāʻili, nā lua kūloko, Nā kiko'ī kiko'ī | Loli; hiki i nā undercuts ke koi aku i nāʻano paʻakikī | Loli; palena palena palena, nā'āpanaʻokoʻa i hikiʻole | Loli; Uaʻaeʻia kekahi mau mea ma lalo |

| Dimensional pololei | High (± 0.05-0.5 mm per 100 mm) | Haʻahaʻa loa (± 0.5-1.5 mm) | ʻO ke kiʻekiʻe kiʻekiʻe (± 0.25-1 mm) | High (± 0.1-0.5 mm) |

| Hoʻopau ʻili (Ra) | Kūpono (0.8-6.3 μM) | Hālulu (6-25 μm) | Maikaʻi loa (2.5-7.5 μm) | Kūpono (1-5 μM) |

| Alloy flixibility | Laulā (AL, Cu, nā pāpale, Ni ti / coballlys superalys, No, nā metala koʻikoʻi) | Laulā (AL, Cu, nā pāpale, hūnā i nā irons) | Kaupalenaʻia i nā haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa (AL, Mg, Cu) | ʻO nā alloys haʻahaʻa haʻahaʻa haʻahaʻa (AL, Zn, Mg) |

| Ka Hoʻohuiʻana | Haʻahaʻa haʻahaʻa (prototyess i nāʻumi tausani kaukani) | Haʻahaʻa loa loa | Kūpono (mau tausani he haneri haneli) | Kiʻekiʻe loa (mau haneli mau tausani a me nā miliona) |

| Mea kūʻai | Loli (ʻO Wax Desies a iʻole 3D-PRED-PREDIT) | Hoʻohaʻahaʻa | High (ʻO nā Kaula keleawe) | Kiʻekiʻe loa (Nā Hana Hana) |

| Ka manawa o waena o ka hoʻomaka a i ka wā pau | Lohi loa (Pahu kūkulu, ke ahi, Kauhi) | Pōkole i ka maʻalahi | Loli | Pōkole no ka hana kiʻekiʻe-Volume High |

| Post-ho'ōla | Pinepine pinepine; nā papa hana kūpono a kokoke i keʻano | Pinepine pinepine; koiʻia | Loli; E koi paha i ka machining no nā hiʻohiʻona koʻikoʻi | Pinepine pinepine; kokoke-like-ʻano |

| Nā noi maʻamau | Aerospace, NA KEKI ANA, Nā'āpana hana kūpono, Kōhai | Nā'āpana'āina nui, Nā poloka mīkini, Nā Hale Hōʻikeʻike | Nā'āpana automotive, huila, urowing | Mea uila, aitompetitive, Nā'āpana hana |

12. Nā innovations a me nā hiʻohiʻona e puka mai nei

ʻO Wax Wax Casting e ulu ana me kaʻenehana e hoʻouna i nā palena a me ka hoʻokōʻana i nā koi:

Mea hoʻohuiʻaha (AmU) Hoʻohui

- 3Nā hiʻohiʻona hana i paʻiʻia: Nā Kauka (E.g., 3D systems 'strepro catro) hoʻemi i ka manawa alakaʻi ma 70% A eʻae i nā hana lattice no nā'āpana māmā.

- TUMLELL TIMT AM vs. Makemake Wax: Nā dmls hoʻokūkū no nā helu haʻahaʻa haʻahaʻa (<100 Nā'āpana), Akā ua nalowaleʻo Wax he 30-50% cheaper no 100-10,000 mau'āpana.

Nā'āpana cemic kiʻekiʻe

- 'Olapapaʻahaha na mea: Hoʻikenu Zirconia-Alumina nanoMosies hoʻomaikaʻi i ka hakakāʻana o ka hūnāʻana o ka hoʻokaheʻana o ka hoʻokaheʻana o ka hoʻouka kauaʻana e 40%, ka hikiʻana o ka hanaʻana o 50 Nā Palapala Kg Titinium (i mua o 10 kg).

- Nā mea hoʻopili maikaʻi: Ka hoʻemiʻana o ka wai i ka wai e hoʻemi i nā emisons VOC 80% vsa. nā mea kūpono kūpono.

Kaʻina hana

- ʻO ka'ōpala robot: Hoʻololi ka hoʻomākaukauʻana o ka hana chemaric simpic i nā kumukūʻai hana ma ka 30-40% a hoʻomaikaʻi i ka pale lole maʻemaʻe (± 0.1 mm vs. ± 0.5 mm manual).

- Ai-phiwered ndt: ʻO nā kiʻi kiʻi kiʻi e hōʻike nei i nā kiʻi x-ray eʻike i nā hemahema me 98% pololei (vsa. 85% Hoʻohui).

13. Hopena

Makemake Wax (waiwai kūʻai) He ikaika, ʻO keʻano hana hana maʻalahi e kaupaona ana i ke kūʻokoʻa geometry, ʻO ka maikaʻi a me ka maikaʻi o keʻano kiʻekiʻe.

Ua kūpono ia i nā mea e pili ana i nā mea e paʻakikī ai, ʻO Metallirgy a hoʻopau i nā mea hoʻokele mua o ka waiwai.

Pono e hoʻohana pono i ka hoʻolālā pono no ka mālamaʻana, ʻO ke kaʻina hana kūpono, a me ka hoʻololiʻana i ka hanaʻana o ka hanaʻana (ʻO ka hana wela, machining, nānā) me nā koi kūpono.

No nā'āpana kūpono a me nā helu, Hāʻawi ka mea kūʻai aku i ke kūʻaiʻana i nā waiwai kūʻokoʻa i nāʻano likeʻole o nā kaʻina hana'ē aʻe.

Langhe Long Hax Canding a me nā lawelawe lawelawe

LangHe Hāʻawi i nā mea kūʻai aku e hoʻopau i nā mea kūʻai aku i ka hopena o nā mea kūʻai aku no nā mea kūʻai aku a me nā mea kūʻai aku o kaʻoihana. Nā Manaʻo Kūʻaiʻo ka lawelawe:

- Kākau & hoao: ʻO Wax Die Defes a me ka Resort; 3D paʻi no nā prototypes rapid.

- Ka hana semimic: E kāohi iā mulluayer mullipyer.

- ʻO ka paleʻana: Gravity, ʻO nā mea hoʻomaha a me nā mea kōkua i kōkuaʻia; ʻike i ka hanaʻana i nā mea kanu lāʻau, Nickel mau, Alloys Kekahi, ʻO Titanium lāuaʻo Copper Alloys.

- Lawelawe lawelawe: ʻO ka hana wela, pololei cnc machining, surface finishing (pana pua, Kāleka, Wehe), a me ke kaulike dinamic.

- O ka kūlana & Manaʻo: Ke nānāʻole neiʻo Dimensonal (Cmm), hoʻoili pūnaewele, ʻO ka ho'āʻoʻana, ʻO ka loiloi waiwai a me ka nui o ka traceability piha i kēlā me kēia.

- ʻO ka laweʻana: mai ka prototyping i nā hana liʻiliʻi liʻiliʻi / medium me ka hana i ke kaʻina hana a me ke kākoʻo kākoʻo.

LangHe nā kūlana iā ia iho he hoa hana no nā māhele e pono ai e koi i ka intergrity kūpono, ʻO ka mana o ka geometry paʻa a me ka laweʻana i ka laweʻana.

Hoʻokaʻa'ōlelo No nā kūkākūkā hiki, Nā polokalamu hoʻohālike a iʻole nā noi noi i'ōleloʻia i kāu helu helu.

FaqS

He aha nā mea hana hana e lilo ai i ka lole wax e nalowale ana?

ʻO Wax Wax Casting ka hoʻokele kālā mai nā prototypes fet- a me nāʻano-kiʻekiʻe (ʻO ka maʻamau ma nā'āpana haʻahaʻa haʻahaʻa o hoʻokahi makahiki); hilinaʻi nui nā waiwai waiwai ma ka'āpana a me ka waiwai.

ʻO nā alloys ka mea maikaʻi loa no ka paleʻana i ka wana wax?

ʻO ke kaʻina hana i ka palette ākea: aluminum, keleawe, nā mea kanu lāʻau, nickel a me corbat, Titanium (Me ka mālama kūikawā), a me nā metala nui.

Pehea e nalowale ai ka hoʻopiʻiʻana i ka heleʻana?

Nā mea maʻamau ± 0.05-0.5 mm per 100 mm, Me ka hoʻopauʻana i kaʻaoʻao Ra ~ 0.8-6.3 μm; Loaʻa nā hiʻohiʻona a me nā hiʻohiʻona maikaʻi a me ka mālamaʻana i ke kaʻina hana.

He aha nā kumu nui o ka poosity a pehea hoʻi lākou e pale ai?

ʻO Polosity e kū mai ana mai ka hoʻokomoʻana, Nā kīwīwīwīwīwīwīwīwīwīwīwīwīwīwī.

Countermea: mell doglasing, filtration cerramic, ʻO nā mea hana kūʻai / hoʻoikaikaʻana i nāʻenehana.

Pehea ka lōʻihi e hele ai e hele mai ka hoʻolālāʻana e hana?

Hiki i nā pahuhopu prototype me nā hiʻohiʻona paʻi paʻi nā lā i nā pule. Piha piha me ka wax make, ʻO ka hoʻolālāʻana a me ka mākaukau maʻamau e lawe maʻamau mau pule i kekahi mau mahina.