1. Hōʻikeʻike

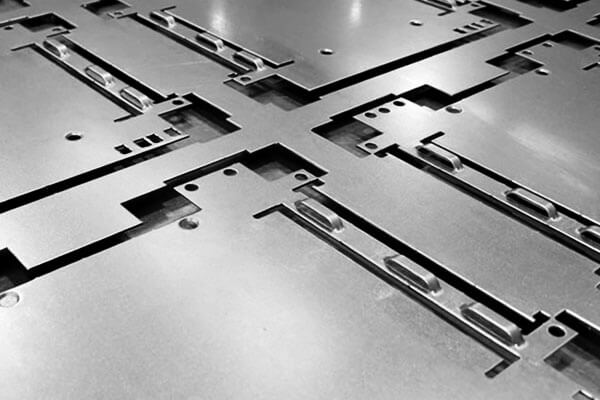

Laser cutting has emerged as a transformative technology in modern manufacturing, offering an unparalleled combination of precision, ka māmā holo, a me kekahi.

Unlike conventional cutting methods that rely on mechanical force or abrasive tools, laser cutting employs a concentrated beam of light to slice through materials with exceptional accuracy.

Initially developed for industrial applications, laser cutting has expanded into various fields, e komo pū me Automotive, AerERPPACE, mea uila, Papahana mālama ola kino, and even fashion.

I kēia mau lā, it plays a crucial role in both prototyping and full-scale production, allowing manufacturers to create intricate designs with minimal waste.

This article provides a comprehensive analysis of laser cutting technology,

covering its fundamental principles, core techniques, mea waiwai, Nā noi nui, Loaʻa, mea paʻakikī, a me nā haʻalulu e hiki ana i kaʻoihana.

2. Fundamentals of Laser Cutting

He aha ka ʻoki ʻoki ʻana?

Cuter cuting he leka uilaʻole, thermal-based manufacturing process that utilizes a high-powered laser beam to cut or engrave materials.

The beam is directed through optics and guided by computer numerical control (CNC) systems to achieve precise, intricate cuts.

Compared to traditional cutting methods such as mechanical sawing or waterjet cutting, laser cutting offers significant advantages in terms of speed, Hōʻike ', and accuracy.

It is widely used for processing metals, ilikai, Wood, Nā Kūlana, a me nā hoʻohui, making it a versatile solution for various industries.

Pehea e hana ai ka ʻoki ʻoki ʻana

The laser cutting process involves several key steps:

- Beam Generation – A laser source, such as a CO₂, fiber, or solid-state laser, generates an intense beam of light.

- Beam Focusing – Optical lenses and mirrors focus the laser beam to a precise point, increasing its energy density.

- Material Interaction – The concentrated laser beam heats, hehee, or vaporizes the material at the cutting point.

- Assist Gas Application – Inert or reactive gases (E.g., nitrogen, oxygen) help remove molten material and enhance cutting efficiency.

- Kākau Kani – CNC systems guide the laser head along a predefined path, ensuring accuracy and repeatability.

Key Components of a Laser Cutting System

A laser cutting machine consists of several critical components, each playing a specific role in ensuring precision and efficiency.

LASER SOU

The laser generator determines the power, wavelength, a me nā kūpono kūpono. Common types include:

- Nā Hana Hana – Ideal for cutting non-metals like plastics, Wood, and acrylic.

- Nā Lasares – Best for cutting metals such as aluminum, kila kohu ʻole, a me ke keleawe.

- ʻO Nd:YAG Lasers – Suitable for engraving and high-precision cutting.

Optical System

The optical system consists of mirrors and lenses that focus and direct the laser beam. ʻO ka maikaʻi kiʻekiʻe ZnSe (Zinc Selenide) lenses ensure minimal energy loss and improved cutting efficiency.

Cnc constroller

A Mana helu kamepiula (CNC) 'ōnaehana'ōnaehana automates the laser movement, ensuring high-speed, high-precision cutting with repeatability.

Advanced CNC systems use AI-driven algorithms to optimize cutting paths, reducing material waste and production time.

Assist Gas Supply

Different gases are used to enhance the cutting process:

- Oxycongen (OAHO): Increases speed for carbon steel but can cause oxidation.

- Nitrogen (₂): E hoʻomaʻemaʻe, oxidation-free cuts, commonly used for stainless steel and aluminum.

- Argon (ARHERE AR): Prevents chemical reactions, ideal for titanium and specialty metals.

Motion System

The motion system includes motors and rails that move the laser head across the material. High-speed servo motors enable rapid acceleration and deceleration for faster processing speeds.

3. Types of Laser Cutting Technologies

The primary types of laser cutting technologies include CO₂ laser cutting, fiber laser cutting, ʻO Nd: YAG laser cutting, and ultrafast laser cutting.

Each technology has unique characteristics, making it suitable for different applications.

This section provides an in-depth analysis of these laser types, their working principles, Loaʻa, PAHUI, a me nā hihia e hoʻohana pono ai.

CO₂ Laser Cutting

CO₂ laser cutting is one of the most established laser cutting methods.

It utilizes a gas mixture of carbon dioxide (Poliuawaena co₂), nitrogen (₂), and helium (Oia) to generate a laser beam in the infrared spectrum (wavelength: 10.6 }m).

This wavelength is well-absorbed by non-metallic materials, making CO₂ lasers ideal for cutting plastics, Wood, aniani, and textiles.

ʻO ka hanaʻana i ka mana

- Gas Excitation: A high-voltage electrical discharge excites CO₂ molecules, producing laser light.

- Beam Focusing: The light is directed through mirrors and focused onto the material using a ZnSe (Zinc Selenide) lens.

- Material Interaction: The concentrated beam heats and vaporizes the material, while an assist gas (usually oxygen or nitrogen) removes debris.

Loaʻa nā kiʻi nui

- Highly effective for non-metals such as Wood, acrylic, 'ōpū, ʻōpala, and fabrics.

- Hoʻolako i kahi smooth edge finish, ʻO ka hōʻemiʻana i ka pono no ka hoʻoiliʻana o ka hoʻoiliʻana.

- Capable of high cutting speeds, particularly for thin sheets.

PAHUI

- Less effective for cutting metals unless specialized coatings or techniques are applied.

- Optical components, such as lenses and mirrors, require frequent cleaning and maintenance.

- CO₂ laser machines occupy a larger footprint compared to fiber laser systems.

Nā noi maʻamau

- ʻOkiʻia acrylic and wood for signage and furniture.

- Ka hoʻoiliʻana textiles and leather in the fashion and upholstery industries.

- Ka heleʻana glass and other delicate materials for decorative purposes.

ʻOki ʻana i ka fiber laser

Fiber laser cutting is a modern technology that uses an optical fiber doped with rare-earth elements such as ytterbium to generate a high-intensity laser beam.

Unlike CO₂ lasers, fiber lasers operate at a wavelength of 1.06 }m, which is highly absorbed by metals, making them the preferred choice for cutting steel, aluminum, a me ke keleawe.

ʻO ka hanaʻana i ka mana

- Laser Generation: The laser is produced by a solid-state fiber-optic system rather than a gas-filled tube.

- Beam Transmission: The laser beam is guided through fiber-optic cables, eliminating the need for mirrors.

- Material Cutting: The high-intensity beam melts or vaporizes metal, with assist gases (nitrogen or oxygen) aiding in the process.

Loaʻa nā kiʻi nui

- Highly efficient for metal cutting, outperforming CO₂ lasers by up to 50% in productivity.

- Lower maintenance costs due to the absence of mirrors and moving parts.

- Hoʻolālā kūpono, requiring less floor space than CO₂ laser systems.

- Higher energy efficiency, converting 35-50% of electrical energy into laser output, compared to CO₂ lasers, which achieve 10-15% ʻOiaʻiʻo.

PAHUI

- Less effective for non-metallic materials such as Wood, acrylic, and glass due to absorption characteristics.

- Higher initial investment compared to CO₂ laser machines.

Nā noi maʻamau

- Kahahana metal cutting i aitompetitive, AerERPPACE, and shipbuilding nā hana hana.

- Ō machining of metal components for manufacturing.

- Production of electronic and medical devices requiring fine detail and accuracy.

ʻO Nd:YAG Laser Cutting (Neodymium-Doped Yttrium Aluminum Garnet)

ʻO Nd: YAG lasers are solid-state lasers that produce a high-energy beam at a wavelength of 1.064 }m, similar to fiber lasers.

These lasers are particularly useful for cutting metals and certain ceramics with high precision.

ʻO ka hanaʻana i ka mana

- Energy Pumping: A flash lamp or diode excites the Nd:YAG crystal, generating a laser beam.

- Beam Amplification: The laser passes through an optical resonator to increase its intensity.

- Material Cutting: The high-energy beam interacts with the workpiece, melting or vaporizing it.

Loaʻa nā kiʻi nui

- Kūpono no high-precision micro-cutting, making it useful for medical and electronic applications.

- Works effectively with reflective metals, e like me gula, dala, a me ka aluminum, without beam reflection issues.

- Capable of high pulse energy, He kūpono kūpono no ka welding and deep engraving.

PAHUI

- Lower energy efficiency compared to fiber lasers, leading to higher power consumption.

- Less scalable for large-scale industrial applications.

Nā noi maʻamau

- Micro-welding and precision cutting i medical and aerospace industries.

- Engraving hard materials, komo Nā Kūlana, diamonds, and metals.

- Cutting thin foils and sheets i electronics manufacturing.

Ultrafast Laser Cutting (Femtosecond & Picosecond Lasers)

Ultrafast lasers operate in the femtosecond (10⁻¹⁵ sec) and picosecond (10⁻¹² sec) Nā haʻona, ka hanaʻana extremely short pulses of light.

These lasers cut materials without generating heat, making them ideal for applications requiring ultra-high precision.

ʻO ka hanaʻana i ka mana

- Pulse Generation: A series of ultrashort pulses deliver high peak power without excessive heat buildup.

- ʻO ka weheʻana: The process ablates material at a molecular level, preventing thermal damage.

- Ke kaʻina anuanu: Unlike traditional laser cutting, this method eliminates heat-affected zones (HAZ).

Loaʻa nā kiʻi nui

- Cold cutting process prevents thermal damage, making it suitable for delicate materials.

- Capable of sub-micron precision, hoʻokō nanometer-scale accuracy.

- Compatible with a wide range of materials, komo Polots, aniani, and bio-materials.

PAHUI

- High cost due to specialized equipment and maintenance requirements.

- Slower processing speeds, making it less suitable for high-volume industrial cutting.

Nā noi maʻamau

- Nā Pūnaewele Pūnaewele, e like me stent fabrication and eye surgery (LASIK).

- MicueleckCones, komo precision cutting of silicon wafers and microchips.

- High-end optics, e like me optical lenses and laser components.

4. Laser Cutting Processes & Hana Hoʻolālā

Laser cutting is a versatile and precise material processing method that relies on a focused laser beam to cut, kalai, or mark various materials.

This section provides an in-depth analysis of the main laser cutting processes,

including fusion cutting, flame cutting, sublimation cutting, and remote cutting, as well as essential techniques that enhance efficiency and precision.

4.1 Key Laser Cutting Processes

Cusion oki (Melt and Blow Cutting)

Fusion cutting, Uaʻikeʻia e like me melt and blow cutting, is a process where a laser melts the material, and a high-pressure inert gas (such as nitrogen or argon) blows away the molten metal.

Unlike flame cutting, fusion cutting does not involve oxidation, ke kūpono kūpono no high-precision cutting of metals with minimal heat-affected zones (HAZ).

Pehea Hana ana

- The laser beam heats the material to its melting point.

- He mamo nei inert gas jet (usually nitrogen or argon) removes the molten material from the kerf (cutting path).

- The process prevents oxidation, resulting in clean and smooth edges.

Loaʻa

- Hua oxidation-free mau kihi, ʻO ka hōʻemiʻana i ka pono no ka hoʻoiliʻana o ka hoʻoiliʻana.

- Kūpono no nā noi kūpono kūpono i kila kohu ʻole, aluminum, a me Titanium.

- Enables high-speed cutting with minimal thermal distortion.

Nā noi maʻamau

- Aerospace and automotive industries for precise metal cutting.

- Medical equipment manufacturing requiring high-quality, contamination-free cuts.

- Precision engineering and electronics, where oxidation-free parts are essential.

Clame cutting (Reactive Cutting or Oxygen Cutting)

Clame cutting, Uaʻikeʻia e like me oxygen-assisted laser cutting, is a process where a laser heats the material to its ignition temperature, and oxygen reacts with the metal to generate additional heat.

This exothermic reaction helps accelerate the cutting process, making flame cutting suitable for thick materials.

Pehea Hana ana

- The laser heats the material to its oxidation temperature.

- A jet of oxygen is introduced, triggering a combustion reaction.

- The reaction produces additional heat, accelerating material removal.

Loaʻa

- Efficient for cutting thicker metals (Nā luna 10 mm).

- Hoʻohana lower laser power, making it more cost-effective for heavy industrial applications.

- Enhances cutting speed for carbon steels and low-alloy steels.

PAHUI

- Hua nā kihi oxidized, requiring post-processing for some applications.

- Less suitable for stainless steel and aluminum due to oxidation resistance.

- Greater heat-affected zones (HAZ), potentially altering material properties.

Nā noi maʻamau

- Shipbuilding and heavy machinery manufacturing for cutting thick steel plates.

- Structural fabrication for construction and infrastructure projects.

- Automotive and railway industries where large, strong components are required.

Keʻokiʻia nei (Vaporization Cutting)

Hōʻuluʻike

Sublimation cutting, Ua kāheaʻia vaporization cutting, is a high-energy process in which a laser heats the material to its boiling point, causing it to transition directly from a solid to a gas.

Unlike fusion and flame cutting, sublimation cutting does not involve molten metal, He kūpono kūpono no ka delicate materials and ultra-precise applications.

Pehea Hana ana

- The laser beam rapidly heats the material to its vaporization temperature.

- The material transitions directly from solid to gas, without melting.

- Assist gases such as argon or helium help remove vaporized material.

Loaʻa

- No molten metal residue, reducing contamination.

- Hua ultra-precise and smooth cuts, Kūpono no thin films and delicate materials.

- Eliminates thermal style, preserving material properties.

PAHUI

- Pono high laser power, increasing operational costs.

- Slower cutting speeds compared to fusion and flame cutting.

- Palena thin materials due to energy-intensive nature.

Nā noi maʻamau

- Electronics manufacturing, such as cutting silicon wafers and micro-components.

- Medical industry for precise cutting of ʻO nā mea noi biomedical.

- High-end optics and glass cutting for ultra-precise applications.

Remote Laser Cutting

Remote laser cutting is a non-contact cutting process where a high-power laser scans the material without requiring assist gases.

This method enables LāʻIke, Pono UUA, and distortion-free cutting, particularly in high-speed production environments.

Pehea Hana ana

- A high-energy laser beam is directed at the material without any physical contact.

- The material instantly vaporizes, creating a fine cutting line.

- CNC or robotic systems control the laser’s movement for high precision.

Loaʻa

- Eliminates the need for assist gases, reducing operational costs.

- Ultra-fast cutting speeds, Kūpono no ka hana nui.

- Minimal mechanical wear, leading to lower maintenance.

Nā noi maʻamau

- Automotive industry, no ka high-speed cutting of thin sheets.

- Textile industry for non-contact fabric cutting.

- Packaging and labeling for intricate laser etching and marking.

4.2 Advanced Laser Cutting Techniques

High-Speed Galvo-Based Laser Cutting

A technique that uses galvanometer-controlled mirrors to rapidly deflect the laser beam, enabling ultra-fast engraving and cutting of thin materials.

Hoʻohana maʻamau:

- Laser marking and engraving on mea meta, aniani, and plastic.

- Micro-cutting in electronics and semiconductor industries.

Hybrid Laser Cutting (Laser & Water Jet Combination)

Hoʻohuiʻia laser precision me a water jet cooling system to minimize heat-affected zones, enabling precise cutting of heat-sensitive materials.

Hoʻohana maʻamau:

- ʻOkiʻia composite materials and heat-sensitive plastics.

- Aerospace industry for high-strength lightweight components.

Multi-Axis Laser Cutting (5-Axis & 6-Axis Systems)

Unlike conventional 2D laser cutters, multi-axis systems can cut in three dimensions, enabling the fabrication of complex geometries.

Hoʻohana maʻamau:

- Aerospace and automotive industries no ka curved and angled cuts.

- Hui robotic laser cutting in automation.

5. Materials Used in Laser Cutting

Laser cutting technology is highly versatile and can process a wide range of materials, komo melas, ilikai, Nā Kūlana, nā mea hoʻohui, and even organic materials like wood and textiles.

5.1 Metals for Laser Cutting

Metals are among the most commonly processed materials in laser cutting due to their widespread use in manufacturing, kūkulu hoʻi, a me kaʻenehana.

Different types of metals require different laser power levels, assist gases, and cutting techniques to achieve precise and high-quality results.

Kukui Kekuhi (ʻO kaʻaihueʻoluʻolu, ʻO ka hao hao, and Stainless Steel)

ʻO kaʻaihueʻoluʻolu & ʻO ka hao hao

- Nāʻano hiʻohiʻona: ʻAihue kīwī contains varying amounts of carbon, which influences its hardness and strength.

- Cutting Considerations: Pono oxygen-assisted laser cutting to enhance cutting speed through an exothermic reaction.

- Noi: Nā Kūlana Kūlana, nā'āpana automothetive, Nā mīkini mīkini, a me nā mea hana kaumaha kaumaha.

Kila kohu ʻole

- Nāʻano hiʻohiʻona: Corrosions-resistant, ikaika ikaika, and excellent durability.

- Cutting Considerations: Best processed using nitrogen-assisted fusion cutting to achieve oxidation-free, nā kihi maʻemaʻe.

- Noi: Nā mea hana lāʻau lapaʻau, Na'Āpanaʻo Aerospace, nā lako hana meaʻai, a me nā panena hoʻonaninani.

Alumini a me alumini alloys

- Nāʻano hiʻohiʻona: Māmā māmā, corrosions-resistant, and excellent strength-to-weight ratio.

- Cutting Considerations: Pono high-power fiber or CO₂ lasers. Nitrogen or argon assist gas prevents oxidation and ensures a clean cut.

- Noi: Aircraft parts, automotive body panels, mea uila, and architectural structures.

ʻO Titiani a me Titiani Alloys

- Nāʻano hiʻohiʻona: Ikaika ikaika, mea momona haʻahaʻa, and excellent resistance to corrosion and high temperatures.

- Cutting Considerations: Argon or helium assist gases are used to prevent oxidation and contamination. High laser power is required due to titanium’s reflectivity.

- Noi: Aerospace and aviation, NA KEKI ANA, and high-performance industrial components.

A me ke keleawe

- Nāʻano hiʻohiʻona: ʻO ka mareʻana o ke kālepa, excellent malleability, a me ke kū'ēʻana.

- Cutting Considerations: Highly reflective and conductive, koi Nā Lasares me higher power to cut effectively. Nitrogen is used to prevent oxidation.

- Noi: Nā'āpana uila, ʻO nā mea hoʻopihapiha, nā mea hana wela, and decorative metalwork.

5.2 Non-Metallic Materials for Laser Cutting

Laser cutting is widely used for non-metal materials, especially in industries requiring Hoʻokomoʻia nā hoʻolālā, Nā kiko'ī maikaʻi, and non-contact processing.

Plastics and Polymers

Plastics are extensively used in laser cutting due to their affordability, ALSPWEight Meaning, a mālie o ka hanaʻana. Akā naʻe,, some plastics emit toxic fumes when cut, requiring proper ventilation.

Commonly Used Plastics

- ʻAlika (PMMA): Hua Polu, flame-smooth edges when cut with a CO₂ laser. Used in signage, display cases, a me nā panena hoʻonaninani.

- Poycancibae Poloha (PC): Challenging to cut with lasers due to its tendency to burn; used in industrial equipment and protective shields.

- PoneThayynene (PE) & PolyProylene (PP): Used for packaging and lightweight components. Low melting points require controlled laser settings.

- ABS (Acrynithirile Bywene): Used in automotive components and consumer electronics. Akā naʻe,, it releases harmful fumes when laser-cut.

Wood and Wood-Based Materials

Laser cutting is widely used in woodworking, furniture manufacturing, and crafts due to its ability to create intricate patterns and fine details.

Commonly Processed Wood Types

- Plywood: Pono controlled laser settings to prevent charring.

- MDF (Medium Density Fiberboard): Often used in furniture and signage, but produces significant smoke.

- Solid Wood: Cuts well but may require post-ho'ōla to enhance the finish.

5.3 Composite and Advanced Materials

Composite materials offer unique properties by combining two or more distinct materials.

Laser cutting can be challenging due to varying Nā poʻomanaʻo, ka hoʻonuiʻana, and material compositions.

Carbon Fiber-Reinforced Polymers (Cfrp)

- Nāʻano hiʻohiʻona: Māmā māmā, ikaika ikaika, used in aerospace and automotive industries.

- Cutting Considerations: Pono high-power CO₂ or fiber lasers. Thermal damage and delamination are concerns.

- Noi: Nā wahi mokulele, nā lako hāmeʻa, and racing car parts.

Glass and Ceramics

- Nāʻano hiʻohiʻona: Brittle but highly resistant to heat and chemicals.

- Cutting Considerations: Ultra-short pulse lasers (such as femtosecond lasers) are ideal to prevent cracking.

- Noi: Mea uila, Nā Pūnaewele Pūnaewele, a me nā palapala noi.

5.4 Choosing the Right Material for Laser Cutting

Factors to Consider

- Himoli: Metals like aluminum and keleawe require specialized Nā Lasares due to high reflectivity.

- Ka HōʻaʻO Kokua: High thermal conductivity materials like copper and brass need higher power levels to ensure efficient cutting.

- Fume Emission: Some plastics and composite materials produce toxic gases, requiring proper ventilation.

- Kūmole maikaʻi: Certain materials require assist gases (E.g., nitrogen, oxygen, a iʻole argon) to improve edge finish and prevent oxidation.

| Waiwai | Best Laser Type | Nā noi maʻamau | Assist Gas Used |

|---|---|---|---|

| ʻO kaʻaihueʻoluʻolu | Poliuawaena co₂, Fiber | Kaʻa kaʻa, kūkulu hoʻi, koho'āpana | Oxycongen, Nitrogen |

| Kila kohu ʻole | Fiber, Poliuawaena co₂ | Lapaau, AerERPPACE, Kānekaha | Nitrogen, Argon |

| Aluminum | Fiber, Poliuawaena co₂ | Aerospace, mea uila, 'Āpana Noihia | Nitrogen |

| Titanium | Fiber | Aerospace, NA KEKI ANA | Argon, Helium |

| keleawe & keleawe | Fiber | Lako uila, plumbing, Hoʻokikola | Nitrogen |

| ʻAlika (PMMA) | Poliuawaena co₂ | 'Āpana Noihia, displays, Kōhai | Nookahi |

| Wood (Plywood, MDF) | Poliuawaena co₂ | Nā mea ukana, crafts, Pūnaewele Pūnaewele | Nookahi |

| ʻO ka pulupulu kalapona | Fiber, Poliuawaena co₂ | Aerospace, aitompetitive, nā lako hāmeʻa | Nookahi |

| Aniani & Nā Kūlana | Femtosecond Laser | Mea uila, opthocks, medical applications | Nookahi |

6. Key Advantages of Laser Cutting

Laser cutting technology is especially popular for its precision, ʻOiaʻiʻo, kūmole, and ability to handle complex geometries.

Below are the key advantages of laser cutting that have contributed to its widespread adoption in both small-scale and large-scale manufacturing.

Kiekie ka pololei a me ka pololei

One of the most significant advantages of laser cutting is its exceptional precision and accuracy.

Lasers can achieve extremely tight tolerances, often as fine as 0.1 mm or even smaller, depending on the material and laser type.

This makes it ideal for industries where ʻO ka maikaʻi kiʻekiʻe, kūlike, and detailed cuts koiʻia, e like me Na'Āpanaʻo Aerospace, Nā Pūnaewele Pūnaewele, and microelectronics.

Key Points

- Minimal kerf width: The laser’s focused beam minimizes the width of the cut, leading to more accurate, consistent results.

- No tooling wear: Unlike traditional cutting methods that wear out tools over time, lasers maintain precision throughout the process.

- Nā geomet paʻakikī: Lasers can easily cut shapes that would be difficult or impossible to achieve with mechanical tools.

ʻO kaʻoiaʻiʻo ma waena o nā lako

Laser cutting can process a wide range of materials, me nā metala, ilikai, Nā Kūlana, aniani, nā mea hoʻohui, and even organic materials like wood and textiles.

This versatility makes it highly adaptable across industries.

The laser’s ability to cut or engrave a variety of materials without needing extensive retooling means businesses can efficiently switch between different materials as needed.

Key Points

- Wide range of materials: Laser cutting can handle materials from thin sheets to thicker plates.

- Nā pilikino: Laser systems can be used to cut, kalai, and etch with a high degree of customization on nearly any material.

- Hoʻemiʻia ka pauʻole: The precision of laser cutting minimizes scrap, aeʻaeʻia optimal material usage.

Clean Cuts and Smooth Edges

Laser cutting produces makei, nā kihi maʻemaʻe that often require little to no post-processing.

This is because the laser’s intense heat melts the material and then cools it almost instantaneously, leaving behind a smooth, polished edge.

This feature is particularly beneficial when working with thin or delicate materials, where traditional cutting methods might cause distortion or a rough finish.

Key Points

- No burrs or rough edges: Laser cutting eliminates the need for secondary operations like deburring or edge finishing.

- Less distortion: Since the laser cuts with minimal contact and heat input, the material is less likely to warp or distort.

- Fine details: The laser can achieve intricate cuts, making it ideal for designs requiring precise detailing, such as jewelry, 'Āpana Noihia, or electronic components.

Wikiwiki a me ka makemake

Laser cutting is a highly efficient process, hāʻawi rapid cutting speeds, kūikawā no thin materials.

'Ōlelo non-contact nature of the laser means there is no physical wear and tear on tools, enabling faster turnaround times without compromising quality.

The technology also offers the ability to automate the cutting process, increasing productivity and reducing labor costs in the long term.

Key Points

- High cutting speed: Lasers are able to cut much faster than traditional methods, especially for materials that are difficult to machine.

- No tool changes required: Laser cutting can quickly switch between different materials or designs without the need to change tools.

- Automation capabilities: Laser systems can be integrated into fully automated production lines, further improving efficiency and reducing downtime.

Ability to Cut Complex Shapes

Laser cutting excels in creating nā geomet paʻakikī and intricate designs that would be difficult or impossible to achieve with traditional cutting methods.

Whether cutting Anghi Raile, nā kāʻei, or internal holes, lasers can handle highly detailed designs with ease.

This flexibility in design is crucial for industries that require 'Ākana, one-of-a-kind parts Oole low-volume production runs.

Key Points

- Tight radii: The laser’s narrow beam enables it to cut very tight corners and intricate shapes.

- No tooling limitations: Traditional cutting tools can be limited by the shape or geometry of the tool itself.

With lasers, virtually any shape can be cut directly from a digital design without worrying about tool geometry. - Adaptability: Laser cutting allows for design changes with minimal impact on the production process.

Minimal Heat-Affected Zone (HAZ)

Compared to traditional cutting techniques, laser cutting creates a relatively small heat-affected zone (HAZ).

The HAZ refers to the portion of the material that experiences heat exposure, which could affect its properties, e like me ka paʻakikī a me ka ikaika.

Because the laser beam is highly focused and precise, it only heats a very small area, leaving the surrounding material largely unaffected.

Key Points

- Reduced material distortion: With less heat applied, there’s a lower risk of warping or shrinking in the material.

- Ideal for heat-sensitive materials: Materials that are prone to thermal damage, e like me plastics and thin metals, benefit from laser cutting’s low heat input.

- Hoʻomaikaʻi maikaʻiʻia: The minimal heat exposure helps preserve the material’s Nā Pūnaewele Pūnaewele for high-strength applications.

High Degree of Automation and Precision

Laser cutting machines can be integrated into automated production lines, aeʻaeʻia Ke Mau, high-precision cutting.

With the integration of Hoʻolālā ka kamepiula (Cad) and ʻO ka hana kamepiula kamepiula (CAMH), laser cutting systems can operate autonomously with minimal human intervention.

This level of automation reduces errors, improves consistency, and enhances overall production efficiency.

Key Points

- Seamless integration: Laser cutting can be easily integrated into 'ōnaehana'ōnaehana, including robotic arms and conveyor belts, to achieve fully automated production lines.

- Consistent quality: Laser cutting ensures Ke kaulike nei, repeatable results, even in large production volumes.

- Quick changeovers: Automated systems allow for rapid reprogramming of the laser cutter for different jobs, improving flexibility in production.

7. PAHUI & Challenges of Laser Cutting

While laser cutting offers significant advantages, it does come with certain limitations and challenges.

Ma lalo, we highlight the key factors businesses must consider when using laser cutting technology.

Nā palena palena

Laser cutting works well with many materials, but thick or highly reflective materials like keleawe and Keihei can present difficulties.

Materials such as aluminum also cause laser energy reflection, reducing cutting efficiency. Some materials like Nā Kūlana are not suitable for laser cutting at all.

ʻO ka loaʻa kālā kālā kiʻekiʻe

The cost of purchasing laser cutting machines, especially industrial-grade systems, is high.

In addition to the initial investment, maintenance and energy costs can also add to the total cost of ownership, making it challenging for smaller businesses to afford.

Limited Thickness for Certain Materials

Laser cutting is most efficient with thin to medium-thickness materials.

Cutting thicker materials, especially metals, can reduce quality, requiring more passes and potentially leading to heat distortion or slower cutting speeds.

Nā koi post-ho'ōla

Though laser cutting produces precise cuts, materials often require Deburing and Kāleka post-processing to remove rough edges or slag, adding extra time and cost to the process.

Cutting Speed for Certain Applications

For thicker or reflective materials, laser cutting speeds can slow down. This may not be an issue for smaller runs but can be a bottleneck in mass production, impacting overall efficiency.

Nā hopohopo kūlohelohe

Laser cutting can generate harmful fumes and gases, especially when cutting plastics or coated metals. Proper ventilation and filtering systems are required to mitigate environmental impact.

Skill Requirements and Training

Operating laser cutting machines requires specialized training for proper machine configuration, nā mea hana lima, a me ka palekana.

Lack of skilled operators can compromise the process, reducing efficiency and quality.

8. Applications of Laser Cutting Across Industries

Hana ai.uk & Industrial Fabrication

Laser cutting is widely used for sheet metal ka hoʻoiliʻana, custom parts fabrication, and industrial machinery production.

It enables manufacturers to achieve complex geometries with high precision, reducing the need for secondary processing.

Kaʻa kaʻa & Aerospace

I ka aitompetitive ʻOihana Kahuna, laser cutting is used for precision welding, body panel fabrication, and engine component manufacturing.

I Aerospace, it allows for lightweight structural components with tight tolerances, hoʻomaikaʻiʻana i ka pono feel.

Lapaau & Papahana mālama ola kino

Hiki i kaʻokiʻoki keʻokiʻana i ka hanaʻana o ka hanaʻana Nā Pūnaewele Pūnaewele, such as stents, nā mea kani, and prosthetic components.

Femtosecond lasers are particularly useful for cutting biocompatible materials without causing heat damage.

Mea uila & Nā Hana Hana Semiconductor

I nā uila, laser cutting is used for printed circuit boards (Pcs), microchips, and high-precision uila nā pā.

The ability to cut with sub-micron accuracy makes it invaluable in semiconductor manufacturing.

9. Laser Cutting vs. Water Jet Cutting vs. Plasma Cutting vs. Nāʻokiʻoki: Nāʻokoʻa kī

| Pili | ʻoki ʻoki laser | Water Jet Cutting | ʻO kaʻokiʻana o Plasma | Nāʻokiʻoki |

|---|---|---|---|---|

| 'Clelo pololei | ±0.1mm or better | ±0.25mm to ±0.5mm | ±1mm to ±2mm | ±0.2mm to ±1mm |

| Wela wela (HAZ) | Minina | Nookahi | Nui | Nui |

| Nā mea waiwai | Nā metala, ilikai, Wood | Nā mea waiwai (stone, aniani) | Thick metals (Kukui Kekuhi, aluminum) | Thick metals, particularly steel and aluminum |

| ʻOki wikiwiki | E wikiwiki no nā kumuwaiwai | Slower than laser cutting | Fast for thick metals | Slower for intricate designs, faster for basic cuts |

| Kālā | Uku uku kumukūʻai, but efficient for high precision | High initial setup cost but low running costs | Lower initial cost, but rougher cuts | Lower initial investment, more labor-intensive |

| Hāmeʻa lole | No tool wear | No tool wear | Some wear on electrodes | Significant wear on tools (KauMai, KA HANUI) |

| Post-ho'ōla | Minina | No HAZ, but may need polishing | Rough edges that need cleanup | Often needs deburring or smoothing |

10. Innovations and Future Trends in Laser Cutting

Laser cutting technology has undergone significant advancements in recent years, driven by innovations that enhance speed, 'Clelo pololei, and material compatibility.

As the demand for efficiency and versatility continues to grow across industries, laser cutting is poised for further transformation.

Iiiai, we explore some of the most promising innovations and future trends in laser cutting.

Integration of Artificial Intelligence (Ai) and Machine Learning

ʻO ka naʻauao kaulana (Ai) and Pūnaewele Hoʻolālā Pūnaewele are increasingly being incorporated into laser cutting systems to improve performance and reduce errors.

AI algorithms can analyze cutting patterns, optimize path planning, and adjust parameters in real-time to adapt to changes in material properties or thickness.

This level of automation reduces the need for manual intervention and enhances the precision of the cutting process.

Loaʻa nā pono nui:

- Real-time adaptation: AI can continuously monitor cutting conditions, such as material surface variations, to adjust parameters in real-time for optimal results.

- Increased efficiency: Machine learning algorithms can predict potential failures or issues based on historical data, enabling preventive measures to be taken before they cause downtime.

- Improved material utilization: AI can optimize cutting paths, reducing material waste and maximizing the output from a given sheet or piece.

Fiber Lasers and Advancements in Laser Source Technology

Fiber lasers have already surpassed traditional CO2 lasers in many applications due to their higher efficiency, faster cutting speeds, and ability to work with a broader range of materials.

Laser technology continues to evolve, with innovations in beam quality, Mana, and wavelength, enabling faster cutting of thicker materials with improved edge quality.

Nā Hō'īʻo:

- High-power fiber lasers: Advances in high-power fiber lasers are allowing for cutting thicker materials, especially metals like kila kohu ʻole, aluminum, and Titanium.

This reduces the need for additional equipment like plasma or mechanical cutting for heavy-duty applications. - Laser beam quality: Higher beam quality from advanced fiber lasers results in finer cuts and better surface finishes, which can be critical for industries like aerospace and medical devices.

- Cost reductions: As fiber laser technology becomes more affordable,

it is expected to be more accessible to a broader range of manufacturers, including small and medium-sized enterprises (Sm).

Hybrid Laser Cutting and 3D Printing

Ka hui pūʻana o cuter cuting and 3D paʻi technologies is an exciting area of innovation. Hybrid systems are emerging that integrate laser cutting with mea hoʻohuiʻaha nā kaʻina hana.

This allows manufacturers to combine the precision and material efficiency of laser cutting with the flexibility of 3D printing to produce complex parts and components.

Loaʻa nā pono nui:

- Enhanced design possibilities: Hybrid systems offer greater design flexibility, enabling the production of complex geometries that cannot be achieved with traditional cutting methods alone.

- Faster prototyping: Manufacturers can produce prototypes faster by combining additive and subtractive processes, reducing time-to-market for new products.

- Mea kūponoʻole: Hybrid systems allow for more efficient use of materials by adding layers of material through 3D printing and finishing them with laser cutting, resulting in less waste.

Automation and Robotics in Laser Cutting

Ka hoʻohuiʻana o nā roboticles with laser cutting systems is accelerating.

Automated laser cutting cells are becoming more common, enabling continuous, high-speed operations with minimal human intervention.

Robotics in laser cutting helps improve precision, streamline material handling, and reduce operational costs.

Loaʻa nā pono nui:

- Increased throughput: Robotics systems enable faster material loading and unloading, reducing downtime and increasing production capacity.

- Precision and flexibility: Robots can adapt to various tasks, including part picking, noho au e kau ana, and cutting, with high precision and flexibility for complex or customized components.

- 24/7 ka hana: Automated systems can operate around the clock, leading to higher production efficiency and reducing labor costs.

Sustainable Laser Cutting

As sustainability becomes a top priority for industries, laser cutting technology is adapting to meet eco-friendly manufacturing standards.

Several innovations are making laser cutting more energy-efficient and reducing its environmental impact.

Nā hana hoʻokō:

- Laser cutting with recyclable materials: There is an increasing focus on using recycled metals and other eco-friendly materials in laser cutting processes.

Manufacturers are also improving the recycling of laser-cut scrap materials, contributing to waste reduction. - Energy-efficient lasers: New laser technologies, kūikawā Nā Lasares, are more energy-efficient than traditional CO2 lasers, reducing power consumption during cutting operations.

- Hoʻemiʻia ka pauʻole: The high precision of laser cutting results in less material waste compared to traditional cutting methods, contributing to more sustainable manufacturing practices.

Hoʻohui me nāʻoihana 4.0 a me ka hana akamai

Laser cutting technology is also evolving as part of the broader trend toward ʻOihana Kahuna 4.0 and ʻO ka hana akamai.

The integration of laser cutting systems with Iot (Pūnaewele o nā mea), cloud computing, and big data allows for smarter, more connected production environments.

Loaʻa nā pono nui:

- Predictive maintenance: IoT-enabled sensors monitor the performance of laser cutting machines in real time,

detecting issues such as wear and tear or misalignment before they lead to equipment failure. - Data-driven optimization: Cloud-based platforms can collect and analyze data from laser cutting machines, enabling manufacturers to optimize processes, hoʻemi i ka downtime, a hoʻomaikaʻi i ka maikaʻi.

- Remote monitoring and control: Manufacturers can monitor and adjust laser cutting systems remotely, offering greater flexibility and reducing the need for on-site interventions.

11. Hopena

Laser cutting continues to push the boundaries of modern manufacturing, offering unmatched precision, ka māmā holo, a me ka versitility.

E like me ka holomua o kaʻenehana, industries adopting AI-driven optimization, sustainable practices, and hybrid manufacturing will gain a competitive edge.

Investing in laser cutting technology today will drive innovation and efficiency in the years to come.

LangHe is the perfect choice for your manufacturing needs if you need high-quality Laser cutting services.