1. Hōʻikeʻike

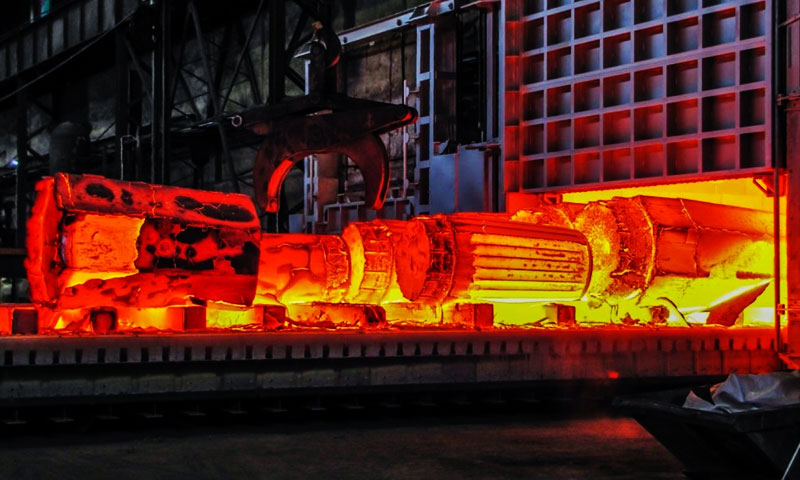

ʻO kahi hoʻonāukiuki he mau mea nui ʻO ka hana wela nā kaʻina hana e kūpono i nā waiwai o nā metala, e hoʻokō iā lākou e hoʻokō i nā koi o nā noi o nāʻenehanaʻoihana.

ʻOiai e pili ana i nā mea i hanaʻia a me ka hōʻoluʻolu, ko lākou mau pahuhopu core, kaʻina hana, a me nā hopena he kumu kūponoʻole:

Annalile hana mua, kaumaha kaumaha, a me ka formability, oiai huhū nā mea aloha i ka hōʻemiʻana i ka brittleness a me ka ikaika o ka ikaika / paʻakikī i nā metala paʻakikī mua.

He mea nui nā mea i hanaʻia i ka hana hou - koho a hoʻopaʻaʻia e hoʻokūkū i ka alloy, Goody, a me nā koi lawelawe lawelawe.

2. He aha ka mea e hoʻonāukiuki ai?

ʻO kahi hoʻonāukiuki i ke kaʻina hana i mālamaʻia i keʻano o keʻano o kahi mea i hoʻomehanaʻia kahi mea kila i kahi mahana kūikawā, ua mālamaʻia ma kēlāʻano ma keʻano he manawa, a laila e hoʻomoʻi mālie.

Ke kumu mua E hoʻomoʻi i ka metala, E hōʻoluʻolu i nā kaumaha kūloko, a hoʻomaikaʻi i ka ductility a me ka machinitability.

Hoʻololiʻo Annealing i ka Microstructure o ka metala, e hana ana i ka lole aʻoi aku ka maʻalahi a me ka maʻalahi e hana me nā hana hana ma hope.

Nā hiʻohiʻona nui o kaʻaeʻana:

- Nā mea paʻakikī a iʻole nā metala anu i hanaʻia no ka maʻalahi a me ka machining.

- E hōʻoluʻolu i nā kaumaha kaumaha ma muli o ka welding, Kauhi, a iʻole ka deformation.

- E hōʻoluʻolu i keʻano grain grain a me homogelizes alama.

- Hoʻoulu i ka hana uila no nā metala non-ferous e like me ke keleawe a me ka alumini.

- Hoʻonui i ka dimensional ma kahi o ka hōʻemiʻana i ka pilikia o ka cracking a iʻole kaua.

Nā wehewehe wehewehe & Nā hiʻohiʻona maʻamau

Hiki ke hanaʻiaʻo Annealing i nāʻano likeʻole ma muli o keʻano metala, Makemake nā mea hana i makemakeʻia, a me ka hoʻohanaʻana ma hope. Aia ma lalo nei heʻano hoʻohālikelike o nāʻano ala maʻamau:

| THANANE TRit | Ka mahana maʻamau (° C) | Keena Kūʻai | Kumu / Nā hopena |

| Piha piha | 750-920 | Furnace Slow | Hana i nā mea ferrite palupalu + Milita ma ke kila; ʻO ka hapa nui a me ka mancinability |

| Ke kaʻina hana / Alei Opana | 450-700 | Ea a lohi paha | Hoʻihoʻi hou i ka ductility i nā metala anu; hōʻoluʻolu maikaʻi |

| Shoproid | 650-720 (wawana lōʻihi) | Lohi loa | Nā mea lawe spherical crabie i nā mea hele ma nā kila no ka manikini maikaʻi loa |

| Sysfe-relief anneal | 350-650 | Eamaka | Hoʻemi i nā kaumaha kūlohelohe mai ka hoʻokumuʻana / uldingʻole me ka loliʻole o ka microstructural |

| Hana maʻamau (Pili) | 820-920 | Eamaka | E hōʻoluʻolu i ka palaoa no nā waiwai mechamor |

ʻAiʻiaʻo Sue Time Temanline: ~ 15-60 mau minuke per 25 ke palika anu, Ke hilinaʻi nei i ka alloy a me ka umu.

ʻO nā kūpono kūpono & Nā pameters

Schepe: ʻO nā alloys ferry maʻamau a me nā ferrous alloys ka nui a iʻole ka hanaʻana i nāʻoihana (nā pāpale, nā mea hana hāmeʻa, hūnā i nā irons, keleawe, aluminum, Keihei, Ua likeʻoe).

ʻO nā waiwai he hana maʻamau e hana ai i nā mea kūʻai aku.

| Waiwai / Papa hana | ʻO keʻano maʻamau (° C) | Soat manawa hoʻokūkū | Keena Kūʻai | Kumu / Nā Pono Hoʻolālā |

| Hoʻohaʻahaʻa-Nā Kahu Pūnaewele (E.g., 1010-1020) | 720-800 (piha) | 15-60 mau minuke per 25 mm | Furnace Slow (furnace a iʻole kaʻoluʻolu) | Huahue, kaumaha kaumaha, hoʻomaikaʻi i ka ductility a me ka machinitability |

| Nā kākela lole odium-carbon (E.g., 1045) | 740-820 (piha) | 15-60 mau minuke per 25 mm | Furnace Slow | Hoʻemi i ka paʻakikī, spiroidIze inā pono ka matchinability |

| Nā kākela kiʻekiʻe / ʻO ka laweʻana i nā kāhiki | 650-720 (palalei mai, wawana lōʻihi) | Mau hola i 10+ huh (wawana lōʻihi) | Lohi loa a paʻa paha + lohi i ka mālie | Hana i nā cribicides carbides no ka machining maikaʻi; Pono e koi lōʻihi |

| Nā kiki (Cr, Mo, Nā hoʻohui e pili ana) | 720-900 (Hoʻohui) | 20-90 mau minuke per 25 mm | Furnace Slow | Homogegen, E hōʻoluʻolu i nā kaumaha; Hoʻoponopono i keʻano no nā hoʻohui hoʻohui |

| Nā mea hana hāmeʻa (E.g., A2, D2) | 650-800 (ʻO ka hoʻonāukiukiʻana a iʻole sub-sub-scitical) | Hola no d2; A2 pōkole | Furnace Slow; I kekahi manawa hana maʻamau | Hoʻomākaukau no ka machining; Hōʻalo i ka hoʻomehanaʻana e pale i ka ulu nui |

Hūnā i nā irons (hinahina, ʻO Dāhihi) |

750-900 (kaumaha kaumaha / Annae) | 30-120 min | Furnace lohi a iʻole ka hau (Ma muli o ka pahuhopu) | Hoʻemi i ke kaumaha kūlohelohe, hoʻomaikaʻi i kaʻoihana (spiroidze no nā irons kiʻekiʻe-c irons) |

| keleawe (Maluhia, OCC) | 300-700 | 15-45 MIN ma muli o ka hana anuanu | Ka ea a he umu paha | Hoʻihoʻi hou i ka hana a me keʻano; kuai e'aeniana |

| Aluminum alloys (E.g., 3003, 6061) | 300-410 (resrystallization / kaumaha kaumaha) | 15-120 min | Eamaka (a i mālamaʻia) | Hoihoi a kaumaha paha; Hōʻalo i ka hoʻonāʻana o ka hopena ināʻaʻole i kuhikuhiʻia |

| keleawe / Bronze | 300-500 | 10-60 min | Ea a iʻole ka huluhulu wikiwiki | No laila no ka hoʻokumuʻana; Hōʻalo i ka hopena dezincification ma kekahi mau keleawe |

| Nā Alloys Annays Alloys (Ti-6al-4v) | 650-800 (kaumaha kaumaha) | 30-120 min | Furnace a iʻole ka hau e pili ana i ka pahuhopu | E hoʻohana i ke aniani i mālamaʻia e paleʻole ai; ʻO Anneal no ka hōʻoluʻolu koʻikoʻi |

Nā hopena ma nāʻano mechanical

ʻO ka hoʻonāukiukiʻana i kahi hopena pohihihi ma ka hana mechanical o nā metala, Ke hoʻololi nei i kā lākou hana a hana hou iā lākou i kūpono no ka hoʻokumuʻana, machining, a me ka hana hou.

Nā loli e pili ana i ka waiwai, type, a me nā hiʻohiʻona cycle.

| Waiwai | Ka hopena o kaʻaeʻana | Nā kūpono kūpono |

| Hālulu | E ho'ēmi nui | Lilo nā metals i mea e lanakila ai, huila, a iʻole keʻano; Hoʻemi i nā mea hana a me nā pilikia e hoʻopau ai |

| Kumaikalua / Ewangantion | Hoʻonuiʻia | Hoʻonui i ka hiki ke hoʻopaʻaʻia, hukiʻulu, a iʻole e hoʻokaʻawaleʻoleʻole |

| Paʻakikī | Hoʻonui pinepineʻia | Hoʻemi i ka kānalua i ka britled fricture ma lalo o ka ukana, ʻO nā mea nui no ke anuanu a iʻole nā mea kiʻekiʻe kiʻekiʻe |

| ʻO ke kaumaha noho | Ua hōʻemi nuiʻia | E hoʻomaikaʻi i ka paʻaʻana o ka dimensional; ho'ēmi i ke kauaʻana, Kauhai, a me keʻano hoʻohālikelike i ka hanaʻana i ka hana houʻana |

| Ka ikaika / Ikaika ikaika | E ho'ēmi maʻamau | Lilo ka mea i mea e minamina ai a emi mai ka mea i paleʻia i ka deformation plasticeation; ʻaeʻia no ka hoʻokumuʻana, ʻaʻole e hāʻawi i nā noi noi |

| Markinpalibility | Hoʻomaikaʻi | Hue moun, ʻoi aku ka nui o nā micsstructureʻoi aku ka wikiwiki, ka lole liʻiliʻi e komo ai, aʻoi aku ka maikaʻi o ka hoʻopauʻana |

Nā hiʻohiʻona Kūlana:

- Ua hana haʻahaʻa haʻahaʻa haʻahaʻa-carbon: Hiki i ka paʻakikī ke hāʻule mai >250 HB i ~ 120-150 hb ma hope o kahi hui piha piha, ʻOiai hiki i ka Ellngation ke hoʻonui mai 10-15% i 40-50%, e hana nui ana i ka hana.

- keleawe (OCC): Hoʻihoʻi hou i ka hoʻokaʻawaleʻana a me ka hana uila ma hope o ka hana anuanu; E hoʻonui paha ka elongation mai 20% i >60%.

- Apana Apana Aluminum (E.g., 6061): Hoʻomaikaʻi hou aku ka mea hana hou aku i ka hanaʻole a hoʻemi i ka hopena o ka cracking i ka wā e lilo ai a iʻole ka stamping.

3. He aha ka mea e huhū ai?

ʻO ka huhū kahi hana wela wela i pili i nā metala i loaʻa mua hākūʻia, ʻO nā mea kanu maʻamau maʻamau.

ʻO kāna kumu kumu mua E hōʻemi i ka brittleness, E hoʻonui i ka paʻakikī, a hoʻokō i kahi hui kūpono o ka paʻakikī a me ka neʻe.

ʻAʻole like, Hanaʻia ka huhū ma lalo o keʻano o ka loliʻana, No lailaʻaʻole ia e lūlū i ka mea hao piha akā maikaʻi maikaʻi-maikaʻi i kāna mau mea hana.

Nā hiʻohiʻona nui o ka huhū:

- Hōʻemi i ka brittleness o nā paʻakikī paʻakikī a iʻole nā metala.

- Hoʻonui i ka paʻakikī a me ka hopena hopena.

- Hoʻoponopono i ka paʻakikī e hoʻokō i nā koi noi.

- E hōʻoluʻolu i nā kūlana kaumaha i loko o ka quenching.

- Stabilizes micrstructure a me nā dimensions no nā'āpana koʻikoʻi.

Nā wehewehe wehewehe & Nā hiʻohiʻona maʻamau

Hanaʻia ka hoʻowalewaleʻana e ka hōʻehaʻana i ka metala paʻakikī i kahi mahana wela, ka hoʻopaʻaʻana no kahi manawa i weheweheʻia, a laila hoʻomaʻemaʻe, ʻO ka maʻamau ma ka lewa.

ʻO ka mahana a me ka manawa soak e hoʻoholo i ka kaulike hope ma waena o ka paʻakikī a me ka paʻakikī.

| Hoʻonuiʻana i ka laulā | Keka ao (° C) | Soak manawa | Ho'ōla | Ka hopena mechanical / Hoʻohana |

| Ka haʻahaʻa haʻahaʻa | 150-300 | 30-99 min | Eamaka | Ka hōʻemi paʻakikī, Ua hoʻemiʻiaʻo Britleness; Mālama i nā pale pale; kūpono no nā mea hana a me nā puna wai liʻiliʻi |

| ʻO keʻano hanohano-medium | 300-500 | 30-120 min | Eamaka | Paʻakikī paʻakikī a paʻakikī; hoʻohana maʻamau no nā mea hana structural e like me nā sffts, Kauluhi, a me nā'āpana automotive |

| Keʻano kiʻekiʻe kiʻekiʻe | 500-650 | 30-120+ min | Eamaka | Hoʻonui nui nui, ʻO ka nalowale paʻakikī; hoʻohanaʻia no nā'āpana kaumaha a iʻole nā'āpana i kauʻia i ka hopena |

ʻO nā kūpono kūpono & Nā pameters

Hoʻohana muaʻo ka huhū no ka paʻakikī ʻO ke kila a me ka hipa hao Akā e noiʻia paha kekahi i nā kinikini kiʻekiʻe kiʻekiʻe. Hoʻohana pinepineʻia nā memo non-ferous maʻamau e hoʻohana i nā kaʻina hana'ē aʻe ma mua o ka huhū.

| Waiwai / Papa hana | Laulā maʻamau (° C) | Soat manawa hoʻokūkū | Keena Kūʻai | ʻO ka hopena maʻamau / Nā memo |

| Nā'ōlaʻi haʻahaʻa haʻahaʻa (kūlana paʻakikī) | 150-300 (mea hoʻohiwahiwa) | 30-99 min | Eamaka | ʻO ka hāʻule liʻiliʻi; E hōʻemi i ka brittleness; Mālama i ka paleʻana i ke kū'ē |

| ʻO nā meaʻaihue a me nā mea kūʻai aku o nā mea kūʻai aku (E.g., 4140) | 250-450 (huhū huhū) | 30-120 min | Eamaka | ʻO ke kaulike paʻakikī / paʻakikī no nā shafts, Kauluhi |

| ʻOna Manaʻo Kīwī / Nā kālalaʻo Alloy (E.g., W-, Cr-, MO-halihali) | 150-200 (ka mua) → 500-600 (re-temper ma muli o ka spec) | 30-120 min ma kēlā me kēia papa hana; pinepine pinepine i ka huhū | Kōkuhi'Āina; i kekahi manawa a iʻole ka hakahaka | ʻO nā mea hele wāwae pinepine e pāpālua i ka huhū e hoʻokūkū ai i nā dimension & waiwai; ʻO ka hoʻonuiʻana o ka huhū |

Nā wai puna wai (hāwana + huhū) |

200-400 (E like me ke koiʻia no ka helu pūnāwai) | 30-60 min | Eamaka | E hoʻonoho i nā waiwai o ka pūnāwai (ke koena, Kaʻa Kaʻamae) |

| Hūnā i nā irons (ua hala & wahine maila, E.g., Ht lawe) | 300-550 | 30-120 min | Eamaka | Improve toughness after austempering/quenching |

| Stainless martensitic grades (E.g., 410, 420) | 150-400 (depending on desired hardness and corrosion requirement) | 30-120 min | Air or forced air | Temper for toughness; note sensitization concerns for higher temps in some SS |

Nā hopena ma nāʻano likeʻole o ka huhū

Tempering has a direct and predictable impact on the mechanical properties of hardened metals, primarily steels.

By carefully controlling the tempering temperature and time, manufacturers can achieve the desired balance between paakiki, paʻakikī, a me ka defility.

| Waiwai | Effect of Tempering | Nā kūpono kūpono |

| Hālulu | Decreases from the as-quenched maximum | Softens overly brittle metals while retaining sufficient strength for functional use; higher temper temperatures lead to greater hardness reduction |

| Paʻakikī / Hopena ikaika | Increases significantly | Reduces brittleness, making metals more resistant to cracking, hopena, and sudden loads |

| Kumaikalua / Ewangantion | Improves moderately | Metals can deform slightly under stress without fracturing, mea nui no nā wai, Nā lako hana, a me nā'āpana hoʻonohonoho |

ʻO ke kaumaha noho |

Hoʻokaʻawaleʻia | Hoʻemi i ke kauaʻana a iʻole ke kalaʻana i ka wā o ka lawelawe, Hoʻopili i ka paʻa o ka dimensional |

| Ikaika / TENILEI | Hoʻohaʻahaʻa ikiʻia e hoʻohālikelikeʻia i ka moku'āina | E hōʻoia i kahi kaulike ma waena o ka paʻakikī a paʻakikī i kūpono no nā noi kūpono |

| E kāʻei i ke kū'ē | Mālamaʻia ma ka haʻahaʻa haʻahaʻa haʻahaʻa; ho'ēmi i ka hoʻonaninani kiʻekiʻe | ʻO ka haʻahaʻa haʻahaʻa haʻahaʻa e mālama i ka paʻakikī no nā mea i hoʻopaʻaʻia e like me nā mea hanaʻokiʻoki, ʻOiaiʻoi aku ka kiʻekiʻe o ke kiʻekiʻe e makemake ai i ka paʻakikī ma luna o ka pale |

Nā hiʻohiʻona Kūlana:

- ʻO nā kila kila kiʻekiʻe kiʻekiʻe: Hrc 63 (E like me ka haʻalele) → ka mea ma 200-250 ° C → HRC 58-60, ka paʻakikī nui i hoʻomaikaʻi nuiʻia no nā puna wai a iʻole nā mea hana lima.

- HoʻolahaʻoʻAmelikaʻAmelikaʻAmelika (E.g., 4140): Hrc 58 → e hoʻomālamalamaʻia ma 400 ° C → HRC 45-50, ka hoʻokōʻana i kahi kaulike maikaʻi o ka ikaika, paʻakikī, a me ka hōʻeha kinoʻana no nā shafts a me nā gears.

- Mea Hana (E.g., D2): Pālua i ka huhū ma 525 ° C E hōʻemi i nā kaumaha kūloko, stabilizes paʻakikī (HRC 60-62), a hoʻomaikaʻi i ka paleʻana i ka hopena o ka hopena no ka make a me nā molds.

4. Nā noiʻenehana: I ka wā e hoʻohana ai i kēlā me kēia kaʻina hana

ʻO ka hoʻoweliweli a me ka lawelaweʻana Nā pahuhopuʻokoʻa I loko o nā mea hana metala, a ke kohoʻana i ke kaʻina kūpono e pili ana i nā waiwai Mechanical makemake, ʻO nā hana hana ma hope, a me nā koi noi.

Nā noi hoʻolaha

Ua hoʻohana muaʻiaʻo Annealing i lūlū i nā metals, E hōʻoluʻolu i nā kaumaha kūloko, a hoʻomaikaʻi i ka neʻe, Ke kūpono nei ia no nā metala e pili ana i ka hoʻokumuʻana, machining, a iʻole e lulu ana.

| ʻOihana Kahuna / Noi | ʻO ka hihia maʻamau | No ke aha e kohoʻia ai ka anneaaling |

| Kaʻa kaʻa | ʻO nā mea hao no nā pākuʻi kino, Nā Kūlana Kūlana | Eʻae i nā mea hao iʻaeʻia, kulou ana, a me ke kiʻiʻana me kaʻokiʻole |

| Aerospace | Alumini alyt pilils, copper wiring | Hoʻemi i ka hana paʻakikī; hoʻomaikaʻi hou i ka formability a me ka hana uila |

| Mea uila | Nā keleawe a me nā'āpana keleawe | Hoʻonui i nā ductitility no nāʻano paʻakikī a hoʻomaikaʻi i keʻano uila uila |

| Nā meaʻalaʻala / Machimen | Nā Bade Bars, ʻO nā Roos, Nā'āpana | Hana hou i ka hana ma hope o ka hanaʻana a me ka hōʻemiʻana i nā mea hana |

| Kūkulu hoʻi / Hewakai | Nā kila kila, rebar | E hōʻoluʻolu i nā kaumaha kūlohelohe ma hope o ka holoʻana a iʻole ke kalaʻana; E hoʻomaikaʻi i ka paʻaʻana o ka dimensional |

Nā noi noi

Hoʻohanaʻia ka huhū Ma hope o ka paʻakikī e hoʻonui i ka kaulike ma waena o ka paʻakikī a me ka paʻakikī, e hana pono i nā metals kūpono no lawena-lawe, komo-resistant, a iʻole nā noi noi-prone.

| ʻOihana Kahuna / Noi | ʻO ka hihia maʻamau | No ke aha e kohoʻia ai ka hoʻowalewale |

| Mea hana | ʻO nā lima hana, make, Nā Punches | Hōʻemi i ka brittle o nā kila paʻakikī i ka mālamaʻana i nā pale pale |

| Kaʻa kaʻa & Aerospace | Kauluhi, Nā papahele, punawai | E hōʻoia i ka paʻakikī a me ka hopena hopena no nā'āpana i kauʻia i nā ukana cyclic |

| NA KAHIKI | Nāʻokiʻoki, Nā Molds | ʻO ka paʻakikī paʻakikī a paʻakikī no ka loaʻaʻana o ka nui ma lalo o ke kaumaha kiʻekiʻe |

| Nā Kūlana Kūlana | Beams, ka hoʻopiliʻana i nā rods, Nā mea paʻa | Hoʻonui i ka paʻakikī me ka loaʻaʻole o ka ikaika nui, hoʻomaikaʻiʻana i ka palekana a me ka hilinaʻi |

| Punawai & Nā'āpana'āpana kiʻekiʻe | Loipulu, Nā'āpana i hoʻokuʻuʻia | Hāʻawi i ka elasticity aʻo ka mālamaʻana i ka ikaika a me kaʻehaʻeha |

5. Nā kuhi hewa maʻamau & Nā wehewehe

"ʻO keʻano o ka hoʻonāukiukiʻana i keʻano o ka hoʻonāukiuki"

Wahahee. ʻO ka hoʻonaninani he kaʻina hana post-paʻakikī e hahai wale ana i ka quenching, ʻOiaiʻo keʻano he kaʻina hana kūʻokoʻa no ka hoʻouluʻana i ka stiftening / spect relief.

Ua kue lākou i nā pahuhopu (ʻO ka ikaika e mālama ana i ka ikaika; ho'ēmi i ka hoʻonāukiuki iā ia).

"ʻO ke kiʻekiʻe kiʻekiʻe o keʻano wela = maikaʻi maikaʻi"

Wahahee. ʻO ka hoʻohālikelikeʻana o ka wela: mea hoʻohiwahiwa (200-300 ° C) hoʻonui i ka paʻakikī no nā mea hana; huhūʻano (500-650 ° C) maximizes paʻakikī no nā'āpana hoʻonohonoho.

Huhū nui (≥650 ° C) hoʻemi i ka ikaika i nā paeʻoleʻole.

"Hanaʻia nā hana kōkua no nā metala āpau"

Wahahee. Nā metala ferous (aluminum, keleawe) Mai hana i nā loli phase e like me ke kilokilo-ko lākou e hana ai i nā mea hou wale nō (huahue) ʻaʻohe hoʻololiʻana o ka moloka.

"E hoʻopau i ka lukuʻana i ke kaumaha kūʻokoʻa"

Wahahee. Hāʻawiʻo Tigpering i nā 70-80% o ka quanecking reentical insed-no nā noi koʻikoʻi (E.g., Nā Māhele kā Aerospace), Pono e koiʻia nā mea hou aku.

6. Nāʻokoʻa kīhua - Anneaaling vs huhū

Hāʻawi ka papa ma lalo nei i kahi maopopo, ʻaoʻao-ʻaoʻao-ʻaoʻao-ʻaoʻao o Alanui Voner, Ke hōʻike nei i kā lākou pahuhopu, nā kaʻina hana, a me nā hopena i nā waiwai metala.

| Aspect | Annalile | Huhū |

| Kumu | ʻO nā kalaʻala, hōʻoluʻolu i ke kaumaha kūloko, hoʻomaikaʻi i ka ductility a me ka machinitability | E hōʻemi i ka brittleness, E hoʻonui i ka paʻakikī, ʻO ke kaulike paʻakikī ma hope o ka paʻakikī |

| Pae wela | Ma luna o keʻano o keʻano hoʻololi (Austetinizing no nā mea hele mai) | Ma lalo o keʻano hoʻohālikelike |

| Typical Metals | Nā pāpale, keleawe, aluminum, Keihei, bronze | Nā mea paʻakikī, nā mea hana hāmeʻa, Martesetitic Stainlele, hae hao |

| Keena Kūʻai | Lohi ka huluhulu (I kekahi manawa ke kāohiʻia i ka ea no nā metala non-ferous) | Kōkuhi'Āina (Ka mea maʻamau), i kekahi manawa i hoʻopaʻaʻia a iʻole ka lewa |

| Hopena ma ka paʻakikī | E ho'ēmi nui | Ho'ēmi mau (mai ka paʻakikī paʻakikī) |

| Hopena ma ka paʻakikī | Hoʻomaikaʻiʻia, ka mea nui ma ke kaumaha kaumaha | Hoʻomaikaʻi nuiʻia, hōʻemi i ka brittleness |

Hopena ma ka ductility / Ewangantion |

Hoʻonui ikaika | Hoʻonui i nā haʻahaʻa |

| Hopena ma ke kaumaha kūlohelohe | Hoʻomaha | Hoʻokaʻawaleʻia (Ma hope o ke kauʻana i ka palena) |

| Nā hoʻololi hoʻololi Microstructural | Homogenizes grains, nā'āpana palupalu (Ferrite / Priceite i ke kila, nā māla i loaʻa i nā metala non-ferous) | ʻO ka martite martided i ke kila; stabilizetes microstructure me keʻano piha |

| Hoʻohana maʻamau | Hana, kulou ana, hukiʻulu, machining, kaumaha-relief | Mea hana, Kauluhi, punawai, Nā Kūlana Kūlana, nā'āpana paʻa |

| Ka lōʻihi o ka lōʻihi | Lā (mau hola ma muli o ka mānoanoa a me ka alloy) | Puhi (mau minuke i nā hola, Ke hilinaʻi nei i ka nui a me ka'āpana'āpana) |

7. Hopena

ʻO keʻano o ka hoʻonāukiukiʻana ma keʻano he corerastone e hana ana i nā hana matal.

Hoʻomakaʻo Annealing i nā metala no ka hoʻokumuʻana, macirning a me ka safer defownsreamream e ka hoʻouluʻana a me ke kaumaha.

Hoʻonui ka huhū i nā waiwai o nā'āpana paʻakikī, ʻO ka hoʻololiʻana i ka brittle i ka brittleness i ka paʻakikī o ka hanaʻana i ka wā e mālama ai i ka ikaika pono.

Pono ka hoʻohana ponoʻana alloy chemistry, PAUKU PAUKU, ʻO ka hoʻomehana / soak mau manawa a me ka hōʻoluʻolu - a me ka hōʻoiaʻana i nā hopena me ka paʻakikī, ʻO nā hoʻokolohua a me nā hōʻike hoʻohālike.

FaqS

Hiki ke hoʻohanaʻia i ka umu likeʻole no keʻano o ka hoʻonāukiuki a me ka huhū?

ʻAe - hiki ke hoʻonohonohoʻia ka nui o ka nui o nā hana wela o ka wela i nāʻano likeʻole, Akā ke kaʻina hana (mahana o ke aniani, Hōʻailona) pono e hoʻokō i nā koi no kēlā me kēia hana.

ʻO ke kaʻina hanaʻoi aku ka ikaika?

ʻO kahi manawaleʻa ka manawa maʻamau- a me ka ikehu-e hoʻohana ana ma muli o nā manawa kiʻekiʻe kiʻekiʻe a me ka hoʻomahaʻana (Noho ka huluhulu); ʻoi aku ka pōkole o nāʻano likeʻole.

Pehea e hōʻoiaʻia ai nā hopena?

Nā Kūlana Kūlana maʻamau: Nā hōʻike paʻakikī (Pōhakukwell, Nā Vickers, Mau Kanaka Waiwai), Nā Hōʻike Tesile, hopena (Lihua) Nāʻikekima, Hoʻolālā Metal (optical / sem) a me keʻano kaumaha kaumaha (Xrd / hole drilling).

Ka huhūʻana i hoʻohanaʻia ma nā metalaʻole?

ʻO ka hua'ōlelo "huhū" i kūpono loa no nā mea hele (Martikete e hoʻowalewale).

ʻO nā alloys nā alloys e hoʻohana i nāʻohana o ka hana wela (Age paʻakikī, Annalile, ʻO ka hopena hana) Me nā pahuhopu maʻamau.

ʻO nā hōʻailona maʻamau maʻamau no nā hopena maʻamau?

(Wahi a, alloy-hilinaʻi) - 150-250 ° C Mālama i ka paʻakikī kiʻekiʻe (ʻO ka mea hana e pale ai i ke kū'ē), 300-450 ° C he mea paʻakikī paʻakikī / paʻakikī paʻakikī no nā'āpana hoʻonohonoho, 500-650 ° C Maximizes paʻakikī ma ke kumukūʻai o ka paʻakikī.