1. 導入

Laser cutting has emerged as a transformative technology in modern manufacturing, 精度の比類のない組み合わせを提供します, スピード, と効率.

Unlike conventional cutting methods that rely on mechanical force or abrasive tools, laser cutting employs a concentrated beam of light to slice through materials with exceptional accuracy.

Initially developed for industrial applications, laser cutting has expanded into various fields, 自動車を含む, 航空宇宙, エレクトロニクス, 健康管理, and even fashion.

今日, it plays a crucial role in both prototyping and full-scale production, allowing manufacturers to create intricate designs with minimal waste.

This article provides a comprehensive analysis of laser cutting technology,

covering its fundamental principles, core techniques, 材料, キーアプリケーション, 利点, 課題, 業界を形成する将来の傾向.

2. Fundamentals of Laser Cutting

レーザー切断とは?

レーザー切断 非接触です, thermal-based manufacturing process that utilizes a high-powered laser beam to cut or engrave materials.

The beam is directed through optics and guided by computer numerical control (CNC) systems to achieve precise, intricate cuts.

Compared to traditional cutting methods such as mechanical sawing or waterjet cutting, laser cutting offers significant advantages in terms of speed, 柔軟性, and accuracy.

It is widely used for processing metals, プラスチック, 木材, セラミックス, および複合材料, making it a versatile solution for various industries.

レーザー切断の仕組み

The laser cutting process involves several key steps:

- Beam Generation – A laser source, such as a CO₂, fiber, or solid-state laser, generates an intense beam of light.

- Beam Focusing – Optical lenses and mirrors focus the laser beam to a precise point, increasing its energy density.

- Material Interaction – The concentrated laser beam heats, 溶ける, or vaporizes the material at the cutting point.

- Assist Gas Application – Inert or reactive gases (例えば。, 窒素, 酸素) help remove molten material and enhance cutting efficiency.

- モーションコントロール – CNC systems guide the laser head along a predefined path, ensuring accuracy and repeatability.

Key Components of a Laser Cutting System

A laser cutting machine consists of several critical components, each playing a specific role in ensuring precision and efficiency.

レーザーソース

The laser generator determines the power, wavelength, およびアプリケーションの適合性. 一般的なタイプには含まれます:

- CO₂レーザー – Ideal for cutting non-metals like plastics, 木材, and acrylic.

- ファイバーレーザー – Best for cutting metals such as aluminum, ステンレス鋼, と銅.

- Nd:YAG Lasers – Suitable for engraving and high-precision cutting.

Optical System

The optical system consists of mirrors and lenses that focus and direct the laser beam. 高品質 ZnSe (Zinc Selenide) lenses ensure minimal energy loss and improved cutting efficiency.

CNCコントローラー

a コンピュータ数値制御 (CNC) システム automates the laser movement, ensuring high-speed, high-precision cutting with repeatability.

Advanced CNC systems use AI-driven algorithms to optimize cutting paths, reducing material waste and production time.

Assist Gas Supply

Different gases are used to enhance the cutting process:

- 酸素 (o₂): Increases speed for carbon steel but can cause oxidation.

- 窒素 (n₂): クリーンを生成します, oxidation-free cuts, commonly used for stainless steel and aluminum.

- Argon (ar): Prevents chemical reactions, ideal for titanium and specialty metals.

Motion System

The motion system includes motors and rails that move the laser head across the material. High-speed servo motors enable rapid acceleration and deceleration for faster processing speeds.

3. Types of Laser Cutting Technologies

The primary types of laser cutting technologies include CO₂ laser cutting, fiber laser cutting, Nd: YAG laser cutting, and ultrafast laser cutting.

Each technology has unique characteristics, making it suitable for different applications.

This section provides an in-depth analysis of these laser types, their working principles, 利点, 制限, そして理想的なユースケース.

CO₂ Laser Cutting

CO₂ laser cutting is one of the most established laser cutting methods.

It utilizes a gas mixture of carbon dioxide (co₂), 窒素 (n₂), and helium (彼) to generate a laser beam in the infrared spectrum (wavelength: 10.6 µm).

This wavelength is well-absorbed by non-metallic materials, making CO₂ lasers ideal for cutting plastics, 木材, ガラス, and textiles.

作業原則

- Gas Excitation: A high-voltage electrical discharge excites CO₂ molecules, producing laser light.

- Beam Focusing: The light is directed through mirrors and focused onto the material using a ZnSe (Zinc Selenide) lens.

- Material Interaction: The concentrated beam heats and vaporizes the material, while an assist gas (usually oxygen or nitrogen) removes debris.

重要な利点

- Highly effective for non-metals such as 木材, アクリル, レザー, ゴム, and fabrics.

- aを提供します smooth edge finish, 後処理の必要性を減らす.

- Capable of high cutting speeds, particularly for thin sheets.

制限

- Less effective for cutting metals unless specialized coatings or techniques are applied.

- Optical components, such as lenses and mirrors, require frequent cleaning and maintenance.

- CO₂ laser machines occupy a larger footprint compared to fiber laser systems.

一般的なアプリケーション

- 切断 acrylic and wood for signage and furniture.

- 処理 textiles and leather in the fashion and upholstery industries.

- 彫刻 glass and other delicate materials for decorative purposes.

ファイバーレーザー切断

Fiber laser cutting is a modern technology that uses an optical fiber doped with rare-earth elements such as ytterbium to generate a high-intensity laser beam.

Unlike CO₂ lasers, fiber lasers operate at a wavelength of 1.06 µm, which is highly absorbed by metals, making them the preferred choice for cutting steel, アルミニウム, と銅.

作業原則

- Laser Generation: The laser is produced by a solid-state fiber-optic system rather than a gas-filled tube.

- Beam Transmission: The laser beam is guided through fiber-optic cables, eliminating the need for mirrors.

- Material Cutting: The high-intensity beam melts or vaporizes metal, with assist gases (nitrogen or oxygen) aiding in the process.

重要な利点

- Highly efficient for metal cutting, outperforming CO₂ lasers by up to 50% in productivity.

- Lower maintenance costs due to the absence of mirrors and moving parts.

- コンパクトデザイン, requiring less floor space than CO₂ laser systems.

- Higher energy efficiency, converting 35-50% of electrical energy into laser output, compared to CO₂ lasers, which achieve 10-15% 効率.

制限

- Less effective for non-metallic materials such as 木材, アクリル, and glass due to absorption characteristics.

- Higher initial investment compared to CO₂ laser machines.

一般的なアプリケーション

- 産業 metal cutting で 自動車, 航空宇宙, and shipbuilding 産業.

- 高精度 machining of metal components for manufacturing.

- Production of electronic and medical devices requiring fine detail and accuracy.

Nd:YAG Laser Cutting (Neodymium-Doped Yttrium Aluminum Garnet)

Nd: YAG lasers are solid-state lasers that produce a high-energy beam at a wavelength of 1.064 µm, similar to fiber lasers.

These lasers are particularly useful for cutting metals and certain ceramics with high precision.

作業原則

- Energy Pumping: a flash lamp or diode excites the Nd:YAG crystal, generating a laser beam.

- Beam Amplification: The laser passes through an optical resonator to increase its intensity.

- Material Cutting: The high-energy beam interacts with the workpiece, melting or vaporizing it.

重要な利点

- に適しています high-precision micro-cutting, making it useful for medical and electronic applications.

- Works effectively with reflective metals, のような 金, 銀, およびアルミニウム, without beam reflection issues.

- Capable of high pulse energy, それを理想的にします welding and deep engraving.

制限

- Lower energy efficiency compared to fiber lasers, leading to higher power consumption.

- Less scalable for large-scale industrial applications.

一般的なアプリケーション

- Micro-welding and precision cutting で medical and aerospace industries.

- Engraving hard materials, 含む セラミックス, diamonds, and metals.

- Cutting thin foils and sheets で electronics manufacturing.

Ultrafast Laser Cutting (Femtosecond & Picosecond Lasers)

Ultrafast lasers operate in the femtosecond (10⁻¹⁵ sec) and picosecond (10⁻¹² sec) 範囲, 生産 extremely short pulses of light.

These lasers cut materials without generating heat, making them ideal for applications requiring ultra-high precision.

作業原則

- Pulse Generation: A series of ultrashort pulses deliver high peak power without excessive heat buildup.

- 材料除去: The process ablates material at a molecular level, preventing thermal damage.

- コールド処理: Unlike traditional laser cutting, this method eliminates 熱の影響を受けたゾーン (ハズ).

重要な利点

- Cold cutting process prevents thermal damage, making it suitable for delicate materials.

- Capable of sub-micron precision, 達成 nanometer-scale accuracy.

- Compatible with a wide range of materials, 含む ポリマー, ガラス, and bio-materials.

制限

- High cost due to specialized equipment and maintenance requirements.

- Slower processing speeds, making it less suitable for high-volume industrial cutting.

一般的なアプリケーション

- 医療機器, のような stent fabrication and eye surgery (LASIK).

- マイクロエレクトロニクス, 含む precision cutting of silicon wafers and microchips.

- High-end optics, のような optical lenses and laser components.

4. Laser Cutting Processes & テクニック

Laser cutting is a versatile and precise material processing method that relies on a focused laser beam to cut, 刻む, or mark various materials.

This section provides an in-depth analysis of the main laser cutting processes,

including fusion cutting, flame cutting, sublimation cutting, and remote cutting, as well as essential techniques that enhance efficiency and precision.

4.1 Key Laser Cutting Processes

融合切断 (Melt and Blow Cutting)

Fusion cutting, とも呼ばれます melt and blow cutting, is a process where a laser melts the material, and a high-pressure inert gas (such as nitrogen or argon) blows away the molten metal.

Unlike flame cutting, fusion cutting does not involve oxidation, それを適切にします high-precision cutting of metals with minimal heat-affected zones (ハズ).

それがどのように機能するか

- The laser beam heats the material to its melting point.

- an inert gas jet (usually nitrogen or argon) removes the molten material from the kerf (cutting path).

- The process prevents oxidation, resulting in clean and smooth edges.

利点

- 生成 oxidation-free エッジ, 後処理の必要性を減らす.

- に最適です 高精度アプリケーション で ステンレス鋼, アルミニウム, とチタン.

- Enables high-speed cutting with minimal thermal distortion.

一般的なアプリケーション

- Aerospace and automotive industries for precise metal cutting.

- Medical equipment manufacturing requiring high-quality, contamination-free cuts.

- Precision engineering and electronics, where oxidation-free parts are essential.

炎の切断 (Reactive Cutting or Oxygen Cutting)

Flame cutting, とも呼ばれます oxygen-assisted laser cutting, is a process where a laser heats the material to its ignition temperature, and oxygen reacts with the metal to generate additional heat.

This exothermic reaction helps accelerate the cutting process, making flame cutting suitable for thick materials.

それがどのように機能するか

- The laser heats the material to its oxidation temperature.

- A jet of 酸素 is introduced, triggering a combustion reaction.

- The reaction produces additional heat, accelerating material removal.

利点

- Efficient for cutting thicker metals (その上 10 mm).

- 用途 lower laser power, making it more cost-effective for heavy industrial applications.

- Enhances cutting speed for carbon steels and low-alloy steels.

制限

- 生成 酸化エッジ, requiring post-processing for some applications.

- Less suitable for stainless steel and aluminum due to oxidation resistance.

- Greater heat-affected zones (ハズ), potentially altering material properties.

一般的なアプリケーション

- Shipbuilding and heavy machinery manufacturing for cutting thick steel plates.

- Structural fabrication for construction and infrastructure projects.

- Automotive and railway industries where large, strong components are required.

昇華の切断 (Vaporization Cutting)

概要

Sublimation cutting, 呼ばれます vaporization cutting, is a high-energy process in which a laser heats the material to its boiling point, causing it to transition directly from a solid to a gas.

Unlike fusion and flame cutting, sublimation cutting does not involve molten metal, それを理想的にします delicate materials and ultra-precise applications.

それがどのように機能するか

- The laser beam rapidly heats the material to its vaporization temperature.

- The material transitions directly from solid to gas, without melting.

- Assist gases such as argon or helium help remove vaporized material.

利点

- No molten metal residue, reducing contamination.

- 生成 ultra-precise and smooth cuts, に最適です thin films and delicate materials.

- Eliminates 熱応力, preserving material properties.

制限

- 必要 high laser power, increasing operational costs.

- Slower cutting speeds compared to fusion and flame cutting.

- に制限されています thin materials due to energy-intensive nature.

一般的なアプリケーション

- Electronics manufacturing, such as cutting silicon wafers and micro-components.

- Medical industry for precise cutting of 生物医学インプラント.

- High-end optics and glass cutting for ultra-precise applications.

Remote Laser Cutting

Remote laser cutting is a non-contact cutting process where a high-power laser scans the material without requiring assist gases.

This method enables 速い, 正確な, and distortion-free cutting, particularly in high-speed production environments.

それがどのように機能するか

- a high-energy laser beam is directed at the material without any physical contact.

- The material instantly vaporizes, creating a fine cutting line.

- CNC or robotic systems control the laser’s movement for high precision.

利点

- Eliminates the need for assist gases, reducing operational costs.

- Ultra-fast cutting speeds, 大量生産に最適です.

- Minimal mechanical wear, leading to lower maintenance.

一般的なアプリケーション

- Automotive industry, 特に high-speed cutting of thin sheets.

- Textile industry for non-contact fabric cutting.

- Packaging and labeling for intricate laser etching and marking.

4.2 Advanced Laser Cutting Techniques

High-Speed Galvo-Based Laser Cutting

A technique that uses galvanometer-controlled mirrors to rapidly deflect the laser beam, enabling ultra-fast engraving and cutting of thin materials.

一般的な用途:

- Laser marking and engraving on 金属, ガラス, and plastic.

- Micro-cutting in electronics and semiconductor industries.

Hybrid Laser Cutting (Laser & Water Jet Combination)

結合します laser precision と water jet cooling system to minimize heat-affected zones, enabling precise cutting of heat-sensitive materials.

一般的な用途:

- 切断 composite materials and heat-sensitive plastics.

- Aerospace industry for high-strength lightweight components.

Multi-Axis Laser Cutting (5-Axis & 6-Axis Systems)

Unlike conventional 2D laser cutters, multi-axis systems can cut in three dimensions, enabling the fabrication of complex geometries.

一般的な用途:

- Aerospace and automotive industries のために curved and angled cuts.

- 高度な robotic laser cutting in automation.

5. Materials Used in Laser Cutting

Laser cutting technology is highly versatile and can process a wide range of materials, 含む 金属, プラスチック, セラミックス, 複合材, and even organic materials like wood and textiles.

5.1 Metals for Laser Cutting

Metals are among the most commonly processed materials in laser cutting due to their widespread use in manufacturing, 工事, and engineering.

Different types of metals require different laser power levels, assist gases, and cutting techniques to achieve precise and high-quality results.

鋼鉄 (軟鋼, 炭素鋼, and Stainless Steel)

軟鋼 & 炭素鋼

- 特性: 炭素鋼 contains varying amounts of carbon, which influences its hardness and strength.

- Cutting Considerations: 必要 oxygen-assisted laser cutting to enhance cutting speed through an exothermic reaction.

- アプリケーション: 構造コンポーネント, 自動車部品, 産業機械, 重機の製造.

ステンレス鋼

- 特性: 耐性耐性, 高強度, and excellent durability.

- Cutting Considerations: Best processed using nitrogen-assisted fusion cutting to achieve oxidation-free, きれいなエッジ.

- アプリケーション: 医療機器, 航空宇宙コンポーネント, 食品加工装置, および装飾パネル.

アルミニウムおよびアルミニウム合金

- 特性: 軽量, 耐性耐性, and excellent strength-to-weight ratio.

- Cutting Considerations: 必要 high-power fiber or CO₂ lasers. Nitrogen or argon assist gas prevents oxidation and ensures a clean cut.

- アプリケーション: Aircraft parts, automotive body panels, 家電, and architectural structures.

チタンおよびチタン合金

- 特性: 高強度, 低重量, and excellent resistance to corrosion and high temperatures.

- Cutting Considerations: Argon or helium assist gases are used to prevent oxidation and contamination. High laser power is required due to titanium’s reflectivity.

- アプリケーション: Aerospace and aviation, 医療インプラント, and high-performance industrial components.

銅と真鍮

- 特性: 高い熱導電率および電気伝導率, excellent malleability, および腐食抵抗.

- Cutting Considerations: Highly reflective and conductive, 必要です ファイバーレーザー と higher power to cut effectively. Nitrogen is used to prevent oxidation.

- アプリケーション: 電気コンポーネント, 配管器具, 熱交換器, and decorative metalwork.

5.2 Non-Metallic Materials for Laser Cutting

Laser cutting is widely used for non-metal materials, especially in industries requiring 複雑なデザイン, 細かい詳細, and non-contact processing.

Plastics and Polymers

Plastics are extensively used in laser cutting due to their affordability, 軽量性, 処理の容易さ. しかし, some plastics emit toxic fumes when cut, requiring proper ventilation.

Commonly Used Plastics

- アクリル (PMMA): 生成 磨きました, flame-smooth edges when cut with a CO₂ laser. Used in signage, display cases, および装飾パネル.

- ポリカーボネート (パソコン): Challenging to cut with lasers due to its tendency to burn; used in industrial equipment and protective shields.

- ポリエチレン (PE) & ポリプロピレン (pp): Used for packaging and lightweight components. Low melting points require controlled laser settings.

- ABS (アクリロニトリル ブタジエン スチレン): Used in automotive components and consumer electronics. しかし, it releases harmful fumes when laser-cut.

Wood and Wood-Based Materials

Laser cutting is widely used in woodworking, furniture manufacturing, and crafts due to its ability to create intricate patterns and fine details.

Commonly Processed Wood Types

- Plywood: 必要 controlled laser settings to prevent charring.

- MDF (Medium Density Fiberboard): Often used in furniture and signage, but produces significant smoke.

- Solid Wood: Cuts well but may require 後処理 to enhance the finish.

5.3 Composite and Advanced Materials

Composite materials offer unique properties by combining two or more distinct materials.

Laser cutting can be challenging due to varying 融点, 熱膨張, and material compositions.

Carbon Fiber-Reinforced Polymers (CFRP)

- 特性: 軽量, 高強度, used in aerospace and automotive industries.

- Cutting Considerations: 必要 high-power CO₂ or fiber lasers. Thermal damage and delamination are concerns.

- アプリケーション: 航空機コンポーネント, スポーツ用品, and racing car parts.

Glass and Ceramics

- 特性: Brittle but highly resistant to heat and chemicals.

- Cutting Considerations: Ultra-short pulse lasers (such as femtosecond lasers) are ideal to prevent cracking.

- アプリケーション: エレクトロニクス, 医療機器, およびアーキテクチャアプリケーション.

5.4 Choosing the Right Material for Laser Cutting

Factors to Consider

- 反射率: Metals like アルミニウム そして 銅 require specialized ファイバーレーザー due to high reflectivity.

- 熱伝導率: High thermal conductivity materials like copper and brass need higher power levels to ensure efficient cutting.

- Fume Emission: Some plastics and composite materials produce toxic gases, requiring proper ventilation.

- エッジ品質: Certain materials require assist gases (例えば。, 窒素, 酸素, またはアルゴン) to improve edge finish and prevent oxidation.

| 材料 | Best Laser Type | 一般的なアプリケーション | Assist Gas Used |

|---|---|---|---|

| 軟鋼 | co₂, Fiber | 自動車, 工事, 工業部品 | 酸素, 窒素 |

| ステンレス鋼 | Fiber, co₂ | 医学, 航空宇宙, キッチン用品 | 窒素, Argon |

| アルミニウム | Fiber, co₂ | 航空宇宙, エレクトロニクス, 看板 | 窒素 |

| チタン | Fiber | 航空宇宙, 医療インプラント | Argon, Helium |

| 銅 & 真鍮 | Fiber | 電気, 配管, 装飾 | 窒素 |

| アクリル (PMMA) | co₂ | 看板, displays, ジュエリー | なし |

| 木材 (Plywood, MDF) | co₂ | 家具, crafts, 建築要素 | なし |

| カーボンファイバー | Fiber, co₂ | 航空宇宙, 自動車, スポーツ用品 | なし |

| ガラス & 陶器 | Femtosecond Laser | エレクトロニクス, 光学, medical applications | なし |

6. Key Advantages of Laser Cutting

Laser cutting technology is especially popular for its precision, 効率, 汎用性, and ability to handle complex geometries.

Below are the key advantages of laser cutting that have contributed to its widespread adoption in both small-scale and large-scale manufacturing.

高精度と精度

One of the most significant advantages of laser cutting is its exceptional precision and accuracy.

Lasers can achieve extremely tight tolerances, often as fine as 0.1 mm or even smaller, depending on the material and laser type.

This makes it ideal for industries where 高品質, 複雑, and detailed cuts 必要です, inなど 航空宇宙コンポーネント, 医療機器, and microelectronics.

Key Points

- Minimal kerf width: The laser’s focused beam minimizes the width of the cut, leading to more accurate, consistent results.

- No tooling wear: Unlike traditional cutting methods that wear out tools over time, lasers maintain precision throughout the process.

- 複雑なジオメトリ: Lasers can easily cut shapes that would be difficult or impossible to achieve with mechanical tools.

材料間の汎用性

Laser cutting can process a wide range of materials, 金属を含む, プラスチック, セラミックス, ガラス, 複合材, and even organic materials like wood and textiles.

This versatility makes it highly adaptable across industries.

The laser’s ability to cut or engrave a variety of materials without needing extensive retooling means businesses can efficiently switch between different materials as needed.

Key Points

- Wide range of materials: Laser cutting can handle materials from thin sheets to thicker plates.

- カスタマイズ: Laser systems can be used to cut, 刻む, and etch with a high degree of customization on nearly any material.

- 材料廃棄物の減少: The precision of laser cutting minimizes scrap, 許可します optimal material usage.

Clean Cuts and Smooth Edges

Laser cutting produces スムーズ, きれいなエッジ that often require little to no post-processing.

This is because the laser’s intense heat melts the material and then cools it almost instantaneously, leaving behind a smooth, polished edge.

This feature is particularly beneficial when working with thin or delicate materials, where traditional cutting methods might cause distortion or a rough finish.

Key Points

- No burrs or rough edges: Laser cutting eliminates the need for secondary operations like deburring or edge finishing.

- Less distortion: Since the laser cuts with minimal contact and heat input, the material is less likely to warp or distort.

- Fine details: The laser can achieve intricate cuts, making it ideal for designs requiring precise detailing, such as jewelry, 看板, or electronic components.

速度と効率

Laser cutting is a highly efficient process, 提供 rapid cutting speeds, 特に thin materials.

The non-contact nature of the laser means there is no physical wear and tear on tools, enabling faster turnaround times without compromising quality.

The technology also offers the ability to automate the cutting process, increasing productivity and reducing labor costs in the long term.

Key Points

- High cutting speed: Lasers are able to cut much faster than traditional methods, especially for materials that are difficult to machine.

- No tool changes required: Laser cutting can quickly switch between different materials or designs without the need to change tools.

- Automation capabilities: Laser systems can be integrated into fully automated production lines, further improving efficiency and reducing downtime.

Ability to Cut Complex Shapes

Laser cutting excels in creating 複雑なジオメトリ and intricate designs that would be difficult or impossible to achieve with traditional cutting methods.

Whether cutting シャープアングル, 曲線, or internal holes, lasers can handle highly detailed designs with ease.

This flexibility in design is crucial for industries that require カスタム, one-of-a-kind parts または low-volume production runs.

Key Points

- Tight radii: The laser’s narrow beam enables it to cut very tight corners and intricate shapes.

- No tooling limitations: Traditional cutting tools can be limited by the shape or geometry of the tool itself.

With lasers, virtually any shape can be cut directly from a digital design without worrying about tool geometry. - Adaptability: Laser cutting allows for design changes with minimal impact on the production process.

Minimal Heat-Affected Zone (ハズ)

Compared to traditional cutting techniques, laser cutting creates a relatively small heat-affected zone (ハズ).

The HAZ refers to the portion of the material that experiences heat exposure, which could affect its properties, 硬度や強さなど.

Because the laser beam is highly focused and precise, it only heats a very small area, leaving the surrounding material largely unaffected.

Key Points

- Reduced material distortion: With less heat applied, there’s a lower risk of warping or shrinking in the material.

- Ideal for heat-sensitive materials: Materials that are prone to thermal damage, のような plastics and thin metals, benefit from laser cutting’s low heat input.

- 構造の完全性を改善しました: The minimal heat exposure helps preserve the material’s 物理的特性 for high-strength applications.

High Degree of Automation and Precision

Laser cutting machines can be integrated into automated production lines, 許可します 連続, high-precision cutting.

With the integration of コンピューター支援設計 (CAD) そして コンピューター支援の製造 (カム), laser cutting systems can operate autonomously with minimal human intervention.

This level of automation reduces errors, improves consistency, and enhances overall production efficiency.

Key Points

- Seamless integration: Laser cutting can be easily integrated into 自動システム, including robotic arms and conveyor belts, to achieve fully automated production lines.

- Consistent quality: Laser cutting ensures 一貫性のある, repeatable results, even in large production volumes.

- Quick changeovers: Automated systems allow for rapid reprogramming of the laser cutter for different jobs, improving flexibility in production.

7. 制限 & Challenges of Laser Cutting

While laser cutting offers significant advantages, it does come with certain limitations and challenges.

下に, we highlight the key factors businesses must consider when using laser cutting technology.

物質的な制限

Laser cutting works well with many materials, but thick or highly reflective materials like 銅 そして 真鍮 can present difficulties.

Materials such as アルミニウム also cause laser energy reflection, reducing cutting efficiency. Some materials like セラミックス are not suitable for laser cutting at all.

高い初期投資

The cost of purchasing laser cutting machines, especially industrial-grade systems, is high.

In addition to the initial investment, maintenance and energy costs can also add to the total cost of ownership, making it challenging for smaller businesses to afford.

Limited Thickness for Certain Materials

Laser cutting is most efficient with thin to medium-thickness materials.

Cutting thicker materials, especially metals, can reduce quality, requiring more passes and potentially leading to heat distortion or slower cutting speeds.

後処理要件

Though laser cutting produces precise cuts, materials often require deburring そして 研磨 post-processing to remove rough edges or slag, adding extra time and cost to the process.

Cutting Speed for Certain Applications

For thicker or reflective materials, laser cutting speeds can slow down. This may not be an issue for smaller runs but can be a bottleneck in mass production, impacting overall efficiency.

環境問題

Laser cutting can generate harmful fumes and gases, especially when cutting plastics or coated metals. Proper ventilation and filtering systems are required to mitigate environmental impact.

Skill Requirements and Training

Operating laser cutting machines requires specialized training for proper machine configuration, マテリアルハンドリング, そして安全.

Lack of skilled operators can compromise the process, reducing efficiency and quality.

8. Applications of Laser Cutting Across Industries

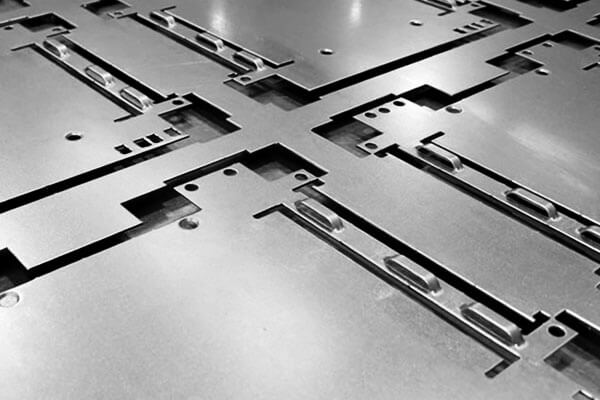

製造 & Industrial Fabrication

Laser cutting is widely used for sheet metal 処理, custom parts fabrication, and industrial machinery production.

It enables manufacturers to achieve complex geometries with high precision, reducing the need for secondary processing.

自動車 & 航空宇宙

で 自動車 業界, laser cutting is used for precision welding, body panel fabrication, and engine component manufacturing.

航空宇宙, it allows for lightweight structural components with tight tolerances, 燃費の向上.

医学 & 健康管理

レーザー切断により、複雑な生産が可能になります 医療機器, such as stents, 手術器具, and prosthetic components.

Femtosecond lasers are particularly useful for cutting biocompatible materials without causing heat damage.

エレクトロニクス & 半導体産業

電子機器, laser cutting is used for printed circuit boards (PCB), microchips, and high-precision 電子 エンクロージャー.

The ability to cut with sub-micron accuracy makes it invaluable in semiconductor manufacturing.

9. Laser Cutting vs. Water Jet Cutting vs. Plasma Cutting vs. 機械的切断: 重要な違い

| 特徴 | レーザー切断 | Water Jet Cutting | プラズマ切断 | 機械的切断 |

|---|---|---|---|---|

| 精度 | ±0.1mm or better | ±0.25mm to ±0.5mm | ±1mm to ±2mm | ±0.2mm to ±1mm |

| 罹患ゾーン (ハズ) | 最小限 | なし | 大きい | 大きい |

| 材料 | 薄い金属, プラスチック, 木材 | 厚い素材 (stone, ガラス) | Thick metals (鋼鉄, アルミニウム) | Thick metals, particularly steel and aluminum |

| 切断速度 | 薄い材料の場合は高速 | Slower than laser cutting | Fast for thick metals | Slower for intricate designs, faster for basic cuts |

| 料金 | 高い機器コスト, but efficient for high precision | High initial setup cost but low running costs | Lower initial cost, but rougher cuts | Lower initial investment, more labor-intensive |

| ツールウェア | No tool wear | No tool wear | Some wear on electrodes | Significant wear on tools (のこぎり, ドリル) |

| 後処理 | 最小限 | No HAZ, but may need polishing | Rough edges that need cleanup | Often needs deburring or smoothing |

10. Innovations and Future Trends in Laser Cutting

Laser cutting technology has undergone significant advancements in recent years, driven by innovations that enhance speed, 精度, and material compatibility.

As the demand for efficiency and versatility continues to grow across industries, laser cutting is poised for further transformation.

ここ, we explore some of the most promising innovations and future trends in laser cutting.

Integration of Artificial Intelligence (ai) and Machine Learning

人工知能 (ai) そして 機械学習 are increasingly being incorporated into laser cutting systems to improve performance and reduce errors.

AI algorithms can analyze cutting patterns, optimize path planning, and adjust parameters in real-time to adapt to changes in material properties or thickness.

This level of automation reduces the need for manual intervention and enhances the precision of the cutting process.

主な利点:

- Real-time adaptation: AI can continuously monitor cutting conditions, such as material surface variations, to adjust parameters in real-time for optimal results.

- Increased efficiency: Machine learning algorithms can predict potential failures or issues based on historical data, enabling preventive measures to be taken before they cause downtime.

- Improved material utilization: AI can optimize cutting paths, reducing material waste and maximizing the output from a given sheet or piece.

Fiber Lasers and Advancements in Laser Source Technology

Fiber lasers have already surpassed traditional CO2 lasers in many applications due to their higher efficiency, faster cutting speeds, and ability to work with a broader range of materials.

Laser technology continues to evolve, with innovations in beam quality, 力, and wavelength, enabling faster cutting of thicker materials with improved edge quality.

将来の傾向:

- High-power fiber lasers: Advances in high-power fiber lasers are allowing for cutting thicker materials, especially metals like ステンレス鋼, アルミニウム, そして チタン.

This reduces the need for additional equipment like plasma or mechanical cutting for heavy-duty applications. - Laser beam quality: Higher beam quality from advanced fiber lasers results in finer cuts and better surface finishes, which can be critical for industries like aerospace and medical devices.

- Cost reductions: As fiber laser technology becomes more affordable,

it is expected to be more accessible to a broader range of manufacturers, including small and medium-sized enterprises (中小企業).

Hybrid Laser Cutting and 3D Printing

の組み合わせ レーザー切断 そして 3D印刷 technologies is an exciting area of innovation. Hybrid systems are emerging that integrate laser cutting with 添加剤の製造 プロセス.

This allows manufacturers to combine the precision and material efficiency of laser cutting with the flexibility of 3D printing to produce complex parts and components.

主な利点:

- Enhanced design possibilities: Hybrid systems offer greater design flexibility, enabling the production of complex geometries that cannot be achieved with traditional cutting methods alone.

- Faster prototyping: Manufacturers can produce prototypes faster by combining additive and subtractive processes, reducing time-to-market for new products.

- 材料効率: Hybrid systems allow for more efficient use of materials by adding layers of material through 3D printing and finishing them with laser cutting, resulting in less waste.

Automation and Robotics in Laser Cutting

の統合 ロボット工学 with laser cutting systems is accelerating.

Automated laser cutting cells are becoming more common, enabling continuous, high-speed operations with minimal human intervention.

Robotics in laser cutting helps improve precision, streamline material handling, and reduce operational costs.

主な利点:

- Increased throughput: Robotics systems enable faster material loading and unloading, reducing downtime and increasing production capacity.

- Precision and flexibility: Robots can adapt to various tasks, including part picking, ポジショニング, and cutting, with high precision and flexibility for complex or customized components.

- 24/7 手術: Automated systems can operate around the clock, leading to higher production efficiency and reducing labor costs.

Sustainable Laser Cutting

As sustainability becomes a top priority for industries, laser cutting technology is adapting to meet eco-friendly manufacturing standards.

Several innovations are making laser cutting more energy-efficient and reducing its environmental impact.

持続可能な慣行:

- Laser cutting with recyclable materials: There is an increasing focus on using recycled metals and other eco-friendly materials in laser cutting processes.

Manufacturers are also improving the recycling of laser-cut scrap materials, contributing to waste reduction. - Energy-efficient lasers: New laser technologies, 特に ファイバーレーザー, are more energy-efficient than traditional CO2 lasers, reducing power consumption during cutting operations.

- 廃棄物の減少: The high precision of laser cutting results in less material waste compared to traditional cutting methods, contributing to more sustainable manufacturing practices.

業界との統合 4.0 およびスマートマニュファクチャリング

Laser cutting technology is also evolving as part of the broader trend toward 業界 4.0 そして スマートマニュファクチャリング.

The integration of laser cutting systems with IoT (モノのインターネット), cloud computing, そして big data allows for smarter, more connected production environments.

主な利点:

- Predictive maintenance: IoT-enabled sensors monitor the performance of laser cutting machines in real time,

detecting issues such as wear and tear or misalignment before they lead to equipment failure. - Data-driven optimization: Cloud-based platforms can collect and analyze data from laser cutting machines, enabling manufacturers to optimize processes, ダウンタイムを短縮します, 品質を向上させます.

- Remote monitoring and control: Manufacturers can monitor and adjust laser cutting systems remotely, offering greater flexibility and reducing the need for on-site interventions.

11. 結論

Laser cutting continues to push the boundaries of modern manufacturing, 比類のない精度を提供します, スピード, および汎用性.

技術が進むにつれて, industries adopting AI-driven optimization, sustainable practices, and hybrid manufacturing will gain a competitive edge.

Investing in laser cutting technology today will drive innovation and efficiency in the years to come.

ランゲ is the perfect choice for your manufacturing needs if you need high-quality Laser cutting services.