1. 介绍

Plug valve is a versatile quarter-turn valve widely used for isolation, 导流, and occasional throttling in industrial systems.

Its simple design—a cylindrical or conical plug rotating within a valve body—offers fast operation, low-pressure drop, and robust reliability.

Understanding its principles, 材料, 性能指标, and industrial applications is essential for selecting the right valve for high-pressure, 磨料, or space-constrained services.

2. 什么是旋塞阀?

一个 plug valve is a specialized quarter-turn rotary valve widely utilized in industrial piping systems for flow isolation, 导流, and occasional throttling.

The core operating principle relies on a cylindrical or conical plug housed within a valve body, which rotates to either align its internal port with the pipeline for unrestricted flow or to block the passage completely.

This simple yet robust mechanism allows rapid 90° operation, offering both efficiency and reliability in critical applications.

Core Features

- Quarter-turn Operation

Fast actuation (typically 90°) — ideal for emergency isolation, diverter duties and applications where rapid on/off action is required. - 简单的, Low-Obstruction Flow Path

Full-port configurations provide virtually pipe-bore flow with minimal pressure drop; reduced-port options trade flow capacity for lower torque and cost. - Multiple Port Configurations

Two-, three- and four-way plug arrangements allow diversion, mixing, sampling and complex routing without multiple valves. - Sealing Versatility

Available with metal-to-metal seats for high-temperature/abrasive services, 有弹性的 (PTFE/RPTFE, 弹性体) seats for bubble-tight shutoff and low torque, 或者 lubricated systems that extend seat life in dirty or erosive media.

3. Classification of Plug Valves by Design

Plug valves are categorized based on 机械设计, 密封方法, and flow configuration.

Understanding these classifications helps engineers select the right valve for pressure, 温度, 流动, and service requirements.

Based on Plug Type

| 类型 | 描述 | 优点 | 典型的应用 |

| Cylindrical Plug Valve | Straight cylindrical plug rotates inside a matching body cavity; simplest design. | Compact, 成本效益, low-pressure drop. | 水, 气体, low-pressure chemical lines. |

| 锥 (Tapered) Plug Valve | Conical plug wedged into the body for tighter sealing. | Excellent sealing; handles higher pressure and temperature. | 石化, 油 & 气体, 蒸汽线. |

Based on Port Configuration

| Port Type | 描述 | 优点 | 典型的应用 |

| Through Port (Full Port) | Port matches pipeline diameter; flow path straight through. | 最小压降; high-flow capacity. | Bulk fluid transport, 管道, slurry handling. |

| Reduced Port | Port smaller than pipe bore. | Lower operating torque; cost-efficient. | Moderate-flow systems, instrument lines. |

| 多端口 (Three- or Four-Way) | Allows flow diversion, mixing, or sampling through multiple ports. | Replaces multiple valves; flexible routing. | Sampling, diverter duties, 化学反应堆. |

Based on Plug Support

| Support Type | 描述 | 优点 | 限制 |

| Floating Plug | Plug rests between seats and rotates freely. | Self-aligning; simple construction. | Higher torque on large sizes; limited high-pressure use. |

| Trunnion-Mounted Plug | Plug anchored with top and/or bottom bearings. | Reduces operating torque; stable in high-pressure or large-size applications. | 更复杂的设计; 制造成本更高. |

Based on Sealing Design

Extended seat life; smooth operation in dirty or erosive fluids.

Periodic maintenance; not ideal for sanitary applications.

lymer seats provide tight sealing.

| Sealing Type | 描述 | 优点 | 限制 |

| Metal-to-Metal | Hard seat directly contacts plug. | 高温, 高压, abrasive service. | Requires higher torque; potential for galling without lubrication. |

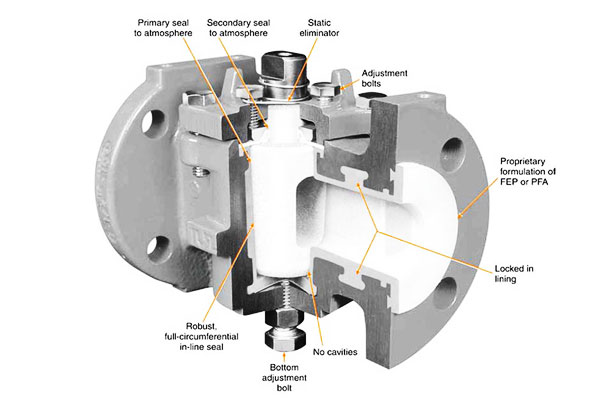

| Resilient Seats (ptfe, rptfe)

</td> |

Elastomer or po | Low torque; bubble-tight shutoff; 耐化学性. | Limited temperature range; potential degradation with aggressive media. |

| Lubr |

4. Main Components and Materials of Plug Valve

A plug valve’s performance, 耐用性, and suitability for specific applications depend on its components and materials.

Each part is engineered to withstand pressure, 温度, 腐蚀, and erosion while ensuring smooth operation and leak-tight sealing.

Main Components

| 成分 | 描述 | 功能 |

| 阀体 | The external housing that contains the plug and ports. | Supports pressure loads, provides the flow path, and connects to the pipeline. |

| 插头 | Cylindrical or conical rotating element with one or more ports. | Controls flow by aligning or blocking the port(s); primary flow-control element. |

| 座位 | Metal or resilient surfaces against which the plug seals. | Ensures bubble-tight shutoff and maintains long-term sealing integrity. |

| 干 / Handle | Shaft or lever used to rotate the plug. | Transfers torque from manual or automated actuator to plug. |

| Lubricant Chamber (选修的) | A reservoir between plug and body filled with lubricant (for lubricated plug valves). | Reduces friction, prolongs seat life, and prevents galling or corrosion. |

| 轴承 / Trunnions (for trunnion-mounted plugs) | Supports at top and/or bottom of plug. | Reduces operating torque and stabilizes the plug in large or high-pressure valves. |

| 腺 / 包装 | Sealing element around the stem or handle interface. | Prevents leakage along the stem/handle; allows smooth rotation. |

Materials Selection

| 成分 | 典型材料 | 关键属性 |

| 身体 & 引擎盖 | 碳钢 (A216 WCB), 不锈钢 (304, 316), 双工, 合金 20, 镍合金 | 力量, 耐腐蚀性, 温度公差 |

| 插头 | Same as body or hardfaced (星际, WC overlay) | 戴阻力, 维稳定性, 化学兼容性 |

| 座位 | 金属 (星际, 莫内尔), PTFE/RPTFE, UHMWPE | Sealing tightness, 耐化学性, 低摩擦 |

| 干 / Handle | 不锈钢, 合金钢 | 力量, 扭转刚度, 耐腐蚀性 |

| Lubricant | Mineral oil, synthetic grease, or FDA-approved lubricants | Reduces friction and protects against corrosion in lubricated valves |

5. Flow characteristics and hydraulic behavior

Flow capability (简历) — typical ranges

- Small instrument-sized plug valves (¼ – 1) may have Cv ~ 0.1–5.

- Common process sizes (2–6) typically range Cv ~ 5–200 depending on port design (full port vs. reduced port).

- Large diameter plug valves (8+) can achieve very high Cv values, comparable to ball valves and often exceeding globe valves for the same size.

Pressure drop and throttling

- Plug valves are primarily designed for 打开/关 或者 diverter service.

While they can be used for throttling, 他们是 less ideal than globe valves for precise modulation because of potential nonlinear flow characteristics and seat wear when throttled under high ΔP. - Pressure drop increases with flow and decreases with port size; high ΔP service requires special trims (multi-stage or pressure-reducing plugs) to avoid noise and erosion.

6. Performance metrics and classes

| 公制 | Typical concern / 范围 |

| Pressure class | ANSI 150–2500 common; higher with forged designs |

| Temperature range | 低温 (with suitable materials) up to ≈400–600°C in common alloys; specialty alloys extend range |

| 泄漏 | 金属座椅: low leakage but not bubble-tight in all cases; resilient seats: bubble-tight (practically zero leakage) |

| Cycle life | Lubricated metal seats: long life in clean service; resilient seats: thousands to tens of thousands of cycles |

| Fugitive emissions | Mitigate with bellows, live-loaded packing, and compliant stem seals |

| 标准 & 测试 | Shell/seat pressure testing, seat leakage testing, NDT on critical parts (射线照相, MPI) |

7. Manufacturing Process of Plug Valve

The manufacturing of plug valves involves precise 铸件, 加工, 集会, and testing to ensure durability, leak-tight sealing, and reliable operation under various industrial conditions.

Casting or Forging the Body and Plug

The valve body and plug form the structural core of the plug valve. They can be produced via:

- 沙子铸造: Common for medium- to large-sized valves. Provides flexibility in complex geometries, including multi-port bodies, and allows embedded features such as trunnion supports.

Post-casting heat treatment reduces residual stress. - 熔模铸造 (失去蜡): Offers exceptional dimensional accuracy and smooth surfaces, ideal for precision or smaller valves with tight tolerances.

- 锻造: 产生密集, high-strength components for high-pressure or critical applications. Forged valves have fewer voids and superior fatigue resistance, suitable for API 6D pipeline standards.

精密加工

After casting or forging, 组件发生 CNC and manual machining to achieve exact tolerances and smooth surface finishes:

- Plug Boring and Grinding: Ensures the plug rotates freely while maintaining a tight seal against the seat.

- Seat Machining: Metal or resilient seats are machined to micron-level tolerances to ensure bubble-tight shutoff.

- Port Alignment: Critical for multi-port valves to guarantee correct flow paths and minimize pressure drop.

- 表面处理: 拍打, 抛光, or honing reduces friction, prevents galling, and improves long-term sealing reliability.

Hardfacing and Coatings

To enhance durability in 磨料, erosive, or corrosive media, plugs and seats may be:

- Hardfaced 和 星际, 碳化钨, or nickel-based alloys, increasing wear resistance and prolonging service life.

- Coated with corrosion-resistant layers such as PTFE, 镀镍, or epoxy.

- Lubricated in specialized valves to maintain low torque operation, prevent galling, and extend seal life, particularly in high-pressure slurry applications.

Assembly and Fitment

Assembly is a precision operation that ensures proper 结盟, smooth actuation, and sealing integrity:

- Plug Insertion: Carefully placed in the body; lubricated if required.

- Stem and Trunnion Installation: Bearings and trunnion supports are fitted to reduce operating torque and stabilize large plugs under high pressure.

- Packing and Gland Adjustment: Prevents leakage along the stem while ensuring smooth rotation.

- Seal and Seat Verification: Metal or resilient seats are checked for correct compression, 结盟, and surface contact.

测试和质量控制

Every plug valve undergoes rigorous testing to meet API, ISO, and ASTM standards:

- Hydrostatic and Pneumatic Pressure Tests: Validate body and seat integrity under rated working pressures and maximum allowable pressures.

- Seat Leakage Tests: Confirm bubble-tight closure according to ISO 5208 or API 598.

- 维验证: CNC coordinate measuring machines (CMM) ensure conformance to design specifications.

- Operational Torque Measurement: Ensures smooth rotation without excessive force, critical for automated or remote-actuated valves.

- 非破坏性测试 (NDT): Techniques such as dye penetrant, 磁性粒子, or ultrasonic testing detect micro-cracks, 孔隙率, or casting defects.

8. 优点和局限性

Key Advantages of Plug Valve

- Abrasive Fluid Resistance: Eccentric plugs with tungsten carbide seats last 300% longer than ball valves in mining slurries (per Mining Engineering Journal).

- 低压下降: Fully open plug valves reduce pump energy use by 10–15% vs. 地球阀 (EPA Energy Star data).

- Fast Operation: Quarter-turn design (0.5–2s for automated valves) – critical for emergency shutdowns (例如。, oil well blowouts).

- 多功能性: Handles liquids, 气体, and slurries across -196°C to 815°C – one valve type for multiple process streams.

- 泄漏紧密的性能: Soft-seated valves achieve Class VI leakage (≤0.00001%) – prevents loss of expensive/toxic fluids.

Limitations of Plug Valve

- High Torque Requirements: Non-lubricated and metal-seated valves need 2–3x more torque than ball valves – larger valves require costly pneumatic/hydraulic actuators.

- 维护需求: Lubricated valves require quarterly grease injection – missed maintenance causes plug binding (downtime 4–8 hours per incident).

- High-Temperature Limits: 柔软的座椅 (ptfe) degrade above 260°C – limited to low-temperature service (例如。, 食品加工).

- 成本: Eccentric and high-performance plug valves cost 20–50% more than ball valves – justified only for harsh conditions.

- Slurries with Large Solids: Multi-port and cylindrical plugs clog with solids >5 mm – require strainers or eccentric designs.

9. Application of Plug Valve

Plug valves excel in harsh industrial environments where other valves fail.

Below are key sectors and use cases:

油 & 气体

- Upstream (Wellheads): API 6A lubricated plug valves (1000 酒吧, 350°C) regulate crude oil and sour gas – NACE MR0175 compliance resists H₂S corrosion.

- Midstream (管道): Eccentric plug valves (6d大火) act as block valves for natural gas (flow rates up to 10,000 m³/h) – low pressure drop reduces compressor energy use.

- Downstream (炼油厂): Metal-seated plug valves handle heavy oil and asphalt (400°C) – Tungsten carbide plugs resist coke particle abrasion.

Water and Wastewater Treatment

- Sludge Handling: Eccentric plug valves (柔软的座椅, VI类) handle sludge with 20–30% solids – no clogging, 60% less downtime than ball valves.

- Chemical Dosing: Non-lubricated plug valves (PTFE座椅) control chlorine/fluoride dosing – Class VI leakage prevents water contamination.

- 淡化: 316L plug valves handle saltwater (538°C) – corrosion resistance ensures 10+ year service life.

Chemical and Pharmaceutical

- Acid Processing: Hastelloy C276 plug valves handle 98% 硫酸 (650°C) – zero corrosion, 遇到ISO 15848-1 Class AH.

- 药品: PTFE-lined plug valves (ASME BPE) regulate API dosing – Class VI leakage and CIP capability prevent cross-contamination.

发电

- Thermal Plants: Metal-seated plug valves control superheated steam (540°C, 200 酒吧) – used in turbine bypass systems.

- Nuclear Plants: 316L plug valves with metal bellows packing handle borated coolant – zero leakage (VI类) prevents radiation release.

Mining and Minerals

- Slurry Transport: Eccentric plug valves (tungsten carbide seats) handle mining tailings (30% 固体) - 300% longer life than rubber-lined ball valves.

- Flotation Processes: Rubber-seated plug valves control froth flotation chemicals – low cost and easy maintenance for remote sites.

10. Comparison with Other Valves

Plug valves are one of several valve types used in industrial fluid control.

Understanding their relative strengths and limitations helps engineers select the most appropriate valve for a specific application.

The table below compares plug valves with other commonly used valves:

| 阀类型 | 设计 & 手术 | 关键优势 | 限制 | 典型的应用 |

| Plug Valve | Rotating cylindrical or conical plug with port; quarter-turn operation | 简单的, 袖珍的, bubble-tight shutoff; low-pressure drop; versatile for multi-port flow | Manual operation torque can be high for large sizes; lubrication often required; 有限的节流 | 浆料, 油 & 气体, chemical process lines, diverting flow, 采样 |

| 球阀 | Spherical ball with bore; 四分之一转 | 快速操作; bubble-tight sealing; good for high-pressure/temperature; low torque | Limited multi-port configurations; not ideal for erosive media | 水, 煤气管道, chemical lines, on/off applications |

| 闸阀 | Sliding gate between seats; linear motion | 完全打开时压力下降最小; 双向; 适用于大直径 | 缓慢的操作; 节流不良; bulky; potential vibration or chatter | 蒸汽, 水, 石油管道; isolation duties |

地球阀 |

Plug/seat or disc/seat linear motion; throttling design | Excellent flow regulation; 精确控制; robust sealing | 较高的压降; 更复杂; 操作较慢; 成本更高 | 过程控制, 化学植物, 发电, throttling duties |

| 蝴蝶阀 | Rotating disc; 四分之一转 | 轻的, 袖珍的; moderate throttling; 大直径的成本效益 | Limited sealing tightness under high pressure; not suitable for abrasive fluids | HVAC, 水处理, low-pressure chemical lines |

| 针阀 | Tapered needle and seat; linear motion | Fine flow control; precise metering | Not for high flow; 运行缓慢; small size | 仪器, 采样, laboratory applications |

关键见解:

- 密封性能: Plug valves provide bubble-tight shutoff similar to ball valves but can handle multi-port flow more efficiently.

- Throttling Capability: Linear valves like globe and needle valves excel in precise flow control; plug valves are better suited for on/off and diversion duties rather than fine throttling.

- 压降: Plug and ball valves have 低ΔP in fully open positions; globe and gate valves can introduce significant pressure drop.

- Maintenance and Durability: Lubricated plug valves require regular inspection in abrasive or corrosive media; metal-seated plug valves provide long-term reliability in harsh conditions.

- 多功能性: Plug valves with multi-port configurations can replace several valves in diverter, mixer, or sampling systems, reducing piping complexity.

11. 结论

Plug valves are rugged, compact quarter-turn devices ideal for on/off, diverting and many isolation duties.

Their performance depends on careful selection of plug support (浮动与Trunnion), seat type (metal vs resilient), materials and actuation.

They are not the best choice for precision throttling, but when fast action, simple construction and robust handling of dirty or abrasive fluids are required, plug valves are often the most practical solution.

Modern materials, coatings and digital actuators continue to expand their applicability.

Custom Valve Assemblies from LangHe

狼河 优惠 custom valve assembly solutions, specializing in tailored components to meet specific industrial requirements.

Leveraging advanced casting, 精确加工, and material expertise, LangHe provides plug valves, 控制阀, and other valve assemblies with:

- Custom Materials: 碳钢, 不锈钢, 双工, 镍合金, and high-performance materials for corrosive or high-temperature applications.

- Tailored Designs: Single-port, multi-port, lubricated, or metal-seated plug valves engineered to client specifications.

- 精密加工: CNC-finished bodies and plugs with tight tolerances for smooth operation and leak-tight sealing.

- 组装和测试: Fully assembled valves, hydrostatically and functionally tested to meet ISO, API, or client standards.

狼河’s customized services enable industries such as 油 & 气体, 化学处理, 水处理, 和发电 to integrate valves that meet unique operational, spatial, and performance constraints, ensuring reliability, 效率, 和长期使用寿命.

Contact LangHe today to design and manufacture valve components tailored to your exact specifications.

常见问题解答

What is the difference between a plug valve and a ball valve?

Plug valves use a cylindrical/tapered plug (eccentric designs reduce wear), while ball valves use a spherical ball.

Plug valves excel in abrasive/corrosive fluids (300% longer life in slurries), while ball valves are cheaper for non-abrasive, high-flow applications.

Which plug valve type is best for abrasive slurries?

Eccentric plug valves with tungsten carbide seats (85–90 HRC) are best.

The eccentric design lifts the plug off the seat (no sliding contact), and tungsten carbide resists wear from solids—extends life to 1–2 years vs. 3–6 months for ball valves.

How often should lubricated plug valves be lubricated?

Quarterly under normal service (油 & 气体, 水); monthly for abrasive fluids (矿业). Automatic lubrication systems (pneumatic injectors) can extend intervals to 6–12 months.

Can plug valves handle high temperatures?

是的. Metal-seated plug valves (星际 6, Hastelloy C276) handle up to 815°C (nuclear/power plants). Soft-seated valves (ptfe) are limited to 260°C.

What is the leakage class of plug valves?

Soft-seated plug valves (PTFE/Viton) achieve ANSI FCI 70-2 VI类 (≤0.00001% leakage) – critical for toxic/expensive fluids.

Metal-seated valves achieve Class IV (≤0.01% leakage) – suitable for high-temperature service.

How do I reduce torque requirements for plug valves?

Use lubricated plugs (graphite-PTFE grease reduces friction by 50%); select eccentric designs (lifts plug off seat); ensure proper piping alignment (avoids binding).