Surface quality of castings is a function of every step that touches the pattern, mold and metal — from die/pattern condition and pattern-material rheology through shell/facecoat preparation, dewaxing and shell firing, to melting, pilti, cooling and final handling.

Controlling surface roughness (Ra) and avoiding micro-scale irregularities demands rigorous attention to tooling, Medžiagos, process parameters and post-casting handling.

This article analyzes the principal factors, quantifies practical control ranges where possible, and gives actionable process and inspection recommendations.

1. Mold-Related Factors

The mold serves as the foundation of Investicijų liejimas, as its quality directly determines the shape and surface state of the wax pattern, which is ultimately transferred to the final casting.

The impact of molds on wax pattern surface quality can be elaborated from three aspects:

Mold Structure Design and Surface Quality

Unreasonable mold structure design often leads to scratches and galling during wax pattern demolding. Repaired wax pattern surfaces are inevitably inferior to the original, and these defects will be directly replicated on the casting surface.

Pavyzdžiui, Aštrūs kampai (without fillets R<0.3mm), insufficient draft angles (<1° for complex cavities), or uneven parting surfaces in the mold structure increase friction between the wax pattern and the mold cavity, causing surface damage during demolding.

Mold surface roughness is a decisive factor for wax pattern surface quality. If the mold surface roughness is only Ra3.2μm, the resulting wax pattern will have even lower surface quality (Ra4.0–5.0μm), which is directly transmitted to the casting.

Practical experience shows that the optimal surface roughness of the mold should be controlled within Ra0.8μm; excessive smoothness (Pvz., Ra0.2μm) does not significantly improve wax pattern quality but increases mold processing costs by 30%–50%.

Mold Temperature Control

Mold temperature has a significant impact on wax fluidity and replication accuracy. For medium-temperature wax systems, the optimal mold temperature is 45–55℃.

When the mold temperature is too low (<35℃), the fluidity of the wax material decreases sharply, resulting in poor surface replication of the wax pattern, accompanied by flow marks and cold shuts.

More critically, if the mold temperature drops below the dew point of water (typically 15–20℃ in workshops), numerous water droplets will form on the mold surface.

These droplets occupy the space of the wax material during injection, leading to an uneven wax pattern surface—a defect also caused by excessive release agent (spraying thickness >5μm).

Maintaining an appropriate mold temperature is essential. Properly increasing the mold temperature (to 50–55℃) and injection pressure (to 0.3–0.5MPa) can effectively improve the fluidity of the wax material, enhance the replication ability of the wax pattern on the mold surface, and thus indirectly improve casting surface quality.

Tačiau, excessively high mold temperature (>60℃) may cause the wax material to cool and solidify too slowly, leading to wax pattern deformation (dimensional deviation >0.5mm) and increasing production cycle time, requiring a balance between quality and efficiency.

Wax Injection Gate Size

The size of the wax injection gate directly affects the injection pressure and wax filling speed.

For small castings (svoris <500g), the optimal gate diameter is **φ8–φ10mm**; for large castings (svoris >500g), the gate diameter can be increased to φ10–φ12mm.

Appropriately increasing the gate size helps to increase the wax injection pressure, ensure full filling of the mold cavity, and reduce surface defects such as underfilling and flow marks on the wax pattern.

For complex castings with thin walls (<2mm), multi-gate design (2–4 gates) is recommended to further improve filling uniformity.

2. Impact of Wax Material

The type and performance of the wax material are core factors determining wax pattern surface quality, as different wax materials exhibit distinct crystallization and solidification behaviors.

Lentelė 1 summarizes the key performance parameters and surface quality effects of common wax materials for investment casting.

Lentelė 1: Performance Comparison of Common Wax Materials for Investment Casting

| Wax Material Type | Crystallization Temperature Range | Optimal Injection Temperature | Wax Pattern Surface Roughness (Ra) | Application Scenario |

| Low-temperature wax (Paraffin-Stearic Acid) | 48–52℃ (narrow range) | 60–65℃ | 4.0–5.0μm | Low-precision castings (Ra requirement >6.3μm) |

| Medium-temperature wax (Multi-component mixture) | 55–65℃ (platus asortimentas) | 70–75℃ | 1.6–3.2μm | General-precision castings (Ra requirement 3.2–6.3μm) |

| Filled wax (Ceramic powder filled) | 60–70℃ | 75–80℃ | 0.8–1.6μm | High-precision castings (Ra requirement <3.2μm) |

Low-Temperature Wax (Paraffin-Stearic Acid Wax)

Low-temperature wax, composed of paraffin (60%–70%) and stearic acid (30%–40%), produces wax patterns with the poorest surface quality.

As a crystalline wax, it has a narrow crystallization temperature range and coarse stearic acid grains (grūdų dydis >50μm).

During solidification, there is insufficient liquid wax to fill the gaps between grains, resulting in a rough wax pattern surface.

Even by increasing injection pressure or adjusting process parameters, the surface quality of wax patterns made from low-temperature wax cannot be significantly improved, limiting its application in high-precision casting.

Medium-Temperature Wax

Medium-temperature wax, a multi-component mixture containing microcrystalline wax, Derva, and plasticizers, has no fixed melting point and a wider solidification temperature range compared to low-temperature wax.

During solidification, due to the different solidification temperatures of its components, the liquid phase can fully fill the gaps between solid phases, resulting in wax patterns with significantly higher surface quality.

Tačiau, the performance of medium-temperature wax varies among different manufacturers; wax with a resin content of 5%–8% exhibits the best balance between fluidity and surface smoothness.

Filled Wax

Filled wax, reinforced with ceramic powder (5%–10%) or glass fiber (3%–5%), produces wax patterns with the highest surface quality.

The addition of fillers optimizes the crystallization behavior of the wax matrix, reduces solidification shrinkage (nuo 2.0% to 0.8%–1.2%), and enhances the surface hardness and wear resistance of the wax pattern.

This not only improves the surface smoothness of the wax pattern but also reduces deformation during storage and transportation (deformation rate <0.2% within 24h), ensuring stable transfer of surface quality to the casting.

Wax pattern cleaning and surface etching

Wax pattern cleaning is often misunderstood as merely removing release agents from the surface, but its most important function is surface etching.

For medium-temperature wax patterns, the optimal cleaning process uses a neutral etching agent (concentration 5%–8%) with a pH value of 6.5–7.5, soaking time of 1–2 minutes, followed by rinsing with deionized water and drying at 40–50℃ for 10–15 minutes.

During the cleaning process, a mild etching effect is formed on the wax pattern surface, which increases the surface roughness of the wax pattern at the microscale (Ra from 1.6μm to 2.0–2.5μm) and improves the wettability and adhesion of the subsequent surface coating.

Proper etching creates a “micro-rough” surface that allows the coating to adhere more firmly, avoiding coating peeling or uneven thickness during drying and roasting.

This is particularly critical for improving the surface smoothness of castings, as a well-adhered coating can effectively replicate the wax pattern surface and prevent sand penetration defects.

4. Surface Coating Factors

The surface coating (primary coating) is in direct contact with the wax pattern, and its performance and application parameters have a decisive impact on casting surface quality.

Surface Coating Material Properties

While the influence of surface powder and sand on surface quality is widely recognized, the effect of silica sol—an important component of the coating—on surface quality is less understood.

High-quality silica sol (whether imported or domestically produced) with uniform colloidal particle size (10–20nm) and low viscosity (2–5 mPa·s at 25℃) exhibits superior performance.

Under the same flow cup viscosity (Ford Cup #4: 20–25s), such silica sol can achieve a higher powder-liquid ratio (2.5:1–3.0:1 for zircon powder slurry), resulting in a denser primary coating.

A denser coating reduces surface porosity (poringumas <5%) and improves the ability to replicate the wax pattern surface, leading to a smoother casting surface (Ra reduced by 0.4–0.8μm compared to using low-quality silica sol).

Surface Coating Thickness

For zircon powder slurries (zircon powder particle size 325–400 mesh), the optimal thickness of the primary coating is 0.08–0.1mm. Both excessive and insufficient thickness adversely affect casting surface quality:

- Insufficient thickness (<0.08mm): Easily leads to “cucumber thorn” defects—sharp, needle-like protrusions (height 0.1–0.3mm) on the casting surface caused by sand penetration or uneven coating.

- Excessive thickness (>0.1mm): Results in different forms of defects.

Due to shrinkage during drying and roasting (shrinkage rate 3%–5%), the thick coating may partially detach from the wax pattern surface, forming coarse, rounded convex particles (diameter 0.2–0.5mm) on the casting surface.

Controlling coating thickness requires precise adjustment of slurry viscosity (Ford Cup #4: 20–25s), dipping time (5–10s), and drying conditions (temperature 25–30℃, humidity 40%–60%, drying time 2–4h) to ensure uniform thickness and good adhesion.

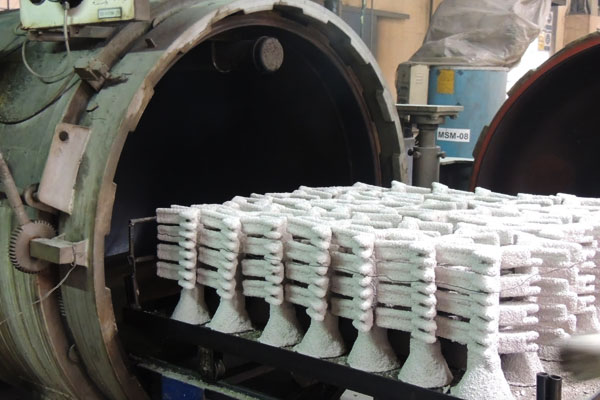

5. Dewaxing Process

The goal of dewaxing is to completely remove wax from the shell mold.

For medium-temperature wax, the optimal dewaxing process uses a steam dewaxing kettle with a pressure of 0.6–0.8MPa and a temperature of 120–130℃, dewaxing time of 15–25 minutes (adjusted according to shell size).

Residual wax in the shell (mass fraction >0.5%), if not fully burned during roasting, will produce carbon black and other impurities, which adhere to the casting surface and degrade surface quality—a point further discussed in the roasting section.

Tačiau, complete dewaxing does not mean prolonged dewaxing time. Under the premise of ensuring complete wax removal (residual wax <0.5%), the dewaxing time should be minimized.

The temperature in the dewaxing kettle exceeds that of general rapid dehydration equipment, and long-term exposure of wax to high temperatures (>130℃ for >30 minutės) accelerates wax aging.

Aged wax exhibits reduced fluidity (viscosity increase by 20%–30%) ir padidėjęs trapumas, which may affect subsequent wax recycling and increase the risk of defects in new wax patterns.

6. Shell Mold Storage

The storage method of shell molds depends on the cleanliness of the workshop, with the core goal of minimizing or preventing foreign objects from entering the shell cavity.

Lentelė 2 lists the optimal storage parameters for shell molds after dewaxing.

Lentelė 2: Optimal Storage Parameters for Dewaxed Shell Molds

| Storage Parameter | Recommended Value | Impact and Note |

| Storage Environment | Temperature 20–25℃, drėgmė <60%, dust concentration <0.1mg/m³ | High humidity causes shell moisture absorption; dust leads to surface contamination |

| Placement Method | Place on clean stainless steel racks, sprue cup facing upward, covered with PE film | Avoid placing on the ground or iron racks (sand particle contamination risk >80%) |

| Storage Time | ≤24h | Prolonged storage (>48h) leads to shell strength reduction and surface oxidation |

Many manufacturers mistakenly believe that placing the shell with the sprue cup facing downward ensures safety, but this is not always the case.

If shells are placed directly on the ground or iron frames contaminated with sand particles and other debris, foreign objects may enter the cavity during handling, causing inclusions in castings.

Such inclusions require grinding and welding repair, which severely damages the casting surface quality (Ra increased by 2.0–3.0μm after repair).

7. Shell Mold Roasting

Residual wax in the shell mold must be fully burned during roasting to avoid carbonaceous residues. The optimal roasting process for zircon-based shells is as follows:

- Heating stage: Heat from room temperature to 500℃ at a rate of 5–10℃/min (slow heating to avoid shell cracking).

- Insulation stage 1: Hold at 500℃ for 30 minutes to burn residual wax.

- Heating stage 2: Heat from 500℃ to 900–1100℃ at a rate of 10–15℃/min.

- Insulation stage 2: Hold at 900–1100℃ for 2–3 valandos to improve shell strength and remove residual moisture.

To ensure complete combustion of residual wax, the oxygen content in the roasting furnace should reach 12% (monitored by oxygen sensors in high-end equipment).

When the oxygen content is only around 6%, thick black smoke will appear at approximately 800℃, which should be avoided.

For equipment without oxygen supply functionality, partially opening the furnace door (gap 5–10cm) to increase air intake can improve oxygen levels and promote complete wax combustion.

Proper roasting also enhances shell strength (gniuždymo stiprumas >20MPA) and reduces surface porosity, further optimizing casting surface quality.

8. Tirpimas, metal cleanliness and pouring

The melt and pouring practice affect surface oxidation, reactivity and the formation of films on the surface.

Key influences

- Charge and slag control: contaminated charge materials and poor fluxing yield higher inclusions at the surface or oxide films that entrap near-surface roughness.

- Pouring temperature and speed: over-high pouring temperatures can increase oxidation or excessive reaction with the shell; too low a temperature may cause incomplete filling and roughness from premature freezing.

- Post-pour cooling method: control of cooling rate and avoidance of surface reoxidation (Pvz., use of pouring boxes/coverings) help minimize surface altercation.

Practical controls

- Tight control of furnace charge, effective deoxidation and clean flux/slag practices.

- Define pouring temperature windows and gating schemes that promote laminar, non-turbulent filling to reduce gas entrapment and surface film formation.

- Minimize exposure to oxidizing atmosphere during early solidification (Pvz., use of covered molds when appropriate).

9. Post-Finishing Stage

Many castings exhibit acceptable surface quality immediately after pouring but become severely damaged after post-finishing—making this stage the primary culprit for surface quality degradation in many manufacturers.

Two key issues stand out: collision damage and shot blasting.

Collision Damage Prevention

Implement a classified storage and transportation system: use plastic trays with soft padding (EVA foam thickness 5–10mm) for small castings; use dedicated fixtures for large castings to avoid direct contact between castings. This can reduce collision damage rate by more than 80%.

Shot Blasting Process Optimization

Shot blasting is used to remove surface oxides and sand, and its process parameters directly affect casting surface quality. The optimal shot blasting parameters for stainless steel castings are as follows:

- Steel shot specifications: Cast steel shot, diameter 0.3–0.5mm, hardness HRC 40–50.

- Shot blasting pressure: 0.4–0.6MPa.

- Shot blasting time: 10–15 minutes per cycle (no more than 15 minutės).

- Equipment requirements: Use shot blasters with uniform projection systems (projection uniformity ≥90%) and stable current control (current fluctuation <5%).

Shot blasting time should be strictly controlled—no more than 15 minutes per cycle. If the surface is not sufficiently cleaned, multiple short cycles are preferred over prolonged single-cycle blasting to avoid excessive surface erosion (Ra increased by 1.0–2.0μm after over-blasting).

10. Išvada

Surface quality of castings is a multi-disciplinary outcome: metalurgija, ceramic processing, thermal engineering and mechanical handling all contribute.

By treating surface finish as a process-critical quality attribute — defining numeric targets, monitoring critical parameters (tool Ra, srutų klampumas, face coat thickness, dewax oxygen levels, melt/ pour windows) and embedding inspection checkpoints — foundries can produce consistently smooth, high-quality castings with predictable manufacturability and lower rework costs.