1. Գործադիր ամփոփագիր

Case hardening creates a thin, շատ կոշտ մակերեսային շերտ («գործը») ավելի կոշտի վրա, Խոզանակի միջուկ. It combines surface wear and fatigue resistance with a ductile core that resists shock.

Typical uses are gears, լիսեռներ, ախեր, pins and bearings. Achieving excellent functional performance is an engineering task (մետալուրգիա, Գործընթացի վերահսկում, distortion management, զննում).

Making the part look great requires planning: control where and how finishes are produced, sequence polishing/grinding relative to heat treatment, and finish with an appropriate protective and decorative surface treatment (օր., controlled temper colors, Սեւ օքսիդ, PVD, լաք).

2. What is case hardening?

Դեպի կարծրացում (Նաեւ կանչվել է surface hardening) is the family of metallurgical processes that produce a hard, wear-resistant surface layer — the case — on a part while leaving a relatively soft, ductile interior — the հիմնական.

The objective is to combine high surface hardness and wear/fatigue resistance հետ core toughness and impact resistance, delivering components that resist surface damage without becoming brittle through-and-through.

Core concepts

- Կոշտ մակերես (case): a thin zone (typically tenths of a millimetre to a few millimetres) engineered to be hard (օր., 55–64 HRC for carburized martensite or 700–1,200 HV for nitrides).

- Ductile core: the bulk material remains relatively soft and tough to absorb shocks and avoid catastrophic brittle fracture.

- Gradual transition: a controlled hardness gradient from the surface into the core (not an abrupt interface) to improve load transfer and fatigue life.

- Localized treatment: case hardening can be applied to entire parts or selectively to functional zones (bearing journals, gear teeth, contact faces).

3. Common case-hardening processes

Below I describe the principal case-hardening technologies you will encounter in engineering practice.

Խամարմացնել (գազ, vacuum and pack variants)

Մեխանիզմ: carbon is diffused into the steel surface at elevated temperature to raise the near-surface carbon content; the part is then quenched to form a martensitic case and tempered to achieve the required combination of hardness and toughness.

Տարաներ & պայմաններ:

- Գազ խամարմացնել (industrial standard): performed in a controlled hydrocarbon atmosphere (endothermic gas or natural gas mixtures) at roughly 880-950 ° C.

Carbon potential and soak time determine case depth; practical effective case depths commonly range from 0.3 մմ դեպի 2.5 մմ for many components; surface hardness after quench/temper typically 58-62 HRC for high-carbon martensite. - Վակուում (ցածր ճնշում) խամարմացնել: uses hydrocarbon injection in a vacuum furnace, often at 900-1050 ° C with subsequent high-pressure gas quench.

Advantages include minimal oxidation/scale, excellent carbon control and lower residual distortion; this route is favored where surface appearance and tight tolerances are required. - Pack (ամուր) խամարմացնել: older shop method using carbonaceous powders at 900-950 ° C; lower capital cost but poorer control and cleanliness—less suited for appearance-critical parts.

Կողմնակից: can produce relatively deep, tough martensitic cases; well understood and economical for medium–large production.

Կողմ: quenching from high temperature causes significant thermal stress and potential distortion; surface oxidation and scaling must be managed (especially in conventional gas or pack carburizing).

Ածխածնավոր

Մեխանիզմ: a combined diffusion of carbon and nitrogen into the surface at temperatures generally lower than carburizing, followed by quench and temper.

Nitrogen increases surface hardness and may improve wear and scuff resistance relative to carburized only cases.

Պայմաններ: typical process temperatures are 780-880 ° C; effective case depths are shallower than carburizing, սովորաբար 0.1-1.0 մմ, and surface hardnesses after quench/temper land around 55–60 HRC for appropriate steels.

Կողմնակից: faster cycles and good as-machined wear properties; produces a tougher, nitrogen-enriched case beneficial for abrasive or adhesive wear.

Կողմ: shallower case depth limits use under high contact stresses; Գործընթացի վերահսկում (atmosphere purity, ammonia level) is critical to avoid undesirable compound layers or color irregularities.

Նիտրանտային (գազ, plasma/ion, and salt bath)

Մեխանիզմ: nitrogen diffuses into steel at relatively low temperatures to form hard nitrides (օր., FeN, Խուզ, AlN) within a diffusion zone; no quench is required because the process generally occurs below the austenitizing temperature.

The result is a hard, wear-resistant surface with very low distortion.

Տարաներ & պայմաններ:

- Գազ նիտրանտային: performed at 480–570 °C in an ammonia-based atmosphere; case depths typically 0.05–0.6 mm (diffusion zone), with surface hardness often in the 700–1,200 HV range depending on steel chemistry and time.

- Պլազմա (ion) նիտրանտային: uses a low-pressure glow discharge to activate nitrogen; offers superior uniformity, better control of the compound (սպիտակուց) շերտ, and a clean surface finish—advantages for aesthetic parts.

Typical temperatures are 450-550 ° C with adjustable bias to tune surface finish. - Salt-bath nitriding / nitrocarburizing (օր., Tenifer, Melonite): chemically active baths at ~560–590 °C produce good wear and corrosion characteristics but require careful environmental and waste handling.

Կողմնակից: Նվազագույն աղավաղում, excellent fatigue and wear performance, improved corrosion resistance in many cases, and attractive, consistent finishes (especially plasma nitriding).

Կողմ: diffusion layer is relatively thin compared with carburizing; steels must contain nitride-forming elements (Ալ, Խուզարկու, Վիճակ, Է) for best results; harmful compound layers (“white layer”) can form if parameters are not controlled.

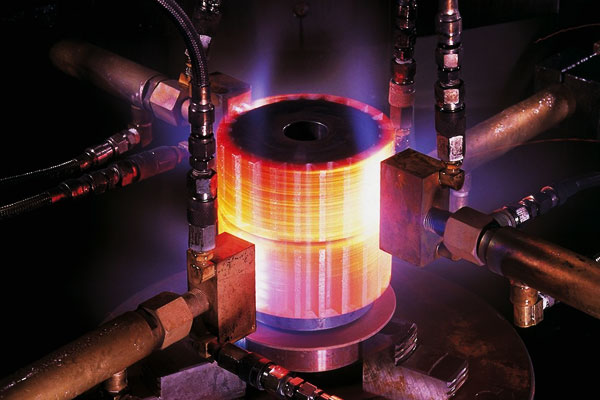

Ինդուկցիայի կարծրություն

Մեխանիզմ: high-frequency electromagnetic induction rapidly heats a surface layer to austenitizing temperature; a rapid quench (water or polymer) transforms the heated layer to martensite.

Because heating is local and very fast, hardening can be applied selectively and cycle times are short.

Տիպիկ պարամետրեր: surface temperatures often in the range 800-1100 ° C for short times (վայրկյան), with case depths controlled by frequency and time—from 0.2 mm up to several millimetres. Surface hardness commonly 50–65 HRC depending on steel and quench.

Կողմնակից: highly localized hardening (Առանցքակալներ, gear flanks, journals), very high throughput, reduced cycle energy, and reduced overall distortion relative to full-part quench if properly fixtured.

Կողմ: requires geometry amenable to induction coils; edge overheating or flash can produce discoloration; limitations on minimum wall thickness and effective hardenability of the chosen steel.

Flame hardening

Մեխանիզմ: surface heating by oxy-fuel flame to austenitizing temperature followed by quench.

A relatively simple field-repair capable technique that mimics induction hardening but uses flame as the heat source.

Typical conditions: surface heating to ~800-1000 °C immediately followed by quenching; case depths often 0.5–4 mm depending on heat input and quench.

Կողմնակից: flexible for large or field repairs, low capital equipment needs.

Կողմ: less uniform heat application than induction; higher risk of scale, oxidation and visual discoloration; greater skill required to achieve consistent aesthetic results.

Ferritic nitrocarburizing and low-temperature thermochemical processes

Մեխանիզմ: low-temperature surface enrichment of nitrogen and carbon while the steel is in the ferritic state (below A1), producing a hard compound layer and diffusion zone without transforming the bulk microstructure.

Typical systems: salt bath ferritic nitrocarburizing or gas variants at ~560–590 °C produce shallow hard layers with improved wear and corrosion resistance and low distortion.

Կողմնակից: Գերազանց ծավալային կայունություն, improved corrosion resistance and a characteristic dark matte finish that is useful for appearance.

Կողմ: environmental concerns with certain salt baths (choose environmentally compliant processes) and limited case depth.

Thin hard coatings (PVD, CVD, DLC) — not diffusion cases but often used with case hardening

Մեխանիզմ: physical or chemical vapor deposition deposits a very thin, extremely hard layer (Անագ, Խուզ, Տրակպա, DLC) onto a substrate.

These are not diffusion cases; they rely on adhesion and thin-film mechanics rather than a graded metallurgical transition.

Typical attributes: coating thickness typically a few micrometres; hardness in the thousands of HV; visually striking (gold TiN, black DLC) and excellent wear/tribological performance.

Կողմնակից: excellent decorative finishes and additional wear resistance; compatible with nitrided substrates for improved adhesion and fatigue behavior.

Կողմ: coatings are thin—do not replace the need for a diffusion case where contact fatigue or deep wear resistance is required—adhesion depends on surface prep and substrate condition.

4. Material suitability and selection

| Material family | Typical steels / օրինակներ | Preferred processes | Aesthetic tendencies |

| Low ածր ածխածնային պողպատ | 1018, 20Mncr5, 8620 | Խամարմացնել, carbonitriding | Gas carburizing → uniform color; solid pack → variable |

| Ալյումինե պողպատ | 4140, 4340, 52100 | Induction, նիտրանտային (if nitride elements present) | Plasma nitriding → golden/brown or matte finishes |

| Չժանգոտվող պողպատներ | 316, 420 | Պլազմային նիտլանդական (careful), PVD | Nitrided stainless → subtle color, Լավ կոռոզիոն դիմադրություն |

| Չուգուն | Մոխրագույն, Դքսություններ | Նիտրանտային (select grades), flame hardening | Porous structure → less uniform color; needs finishing |

| Գործիք steels / HSS | AISI H11, D2 | Նիտրանտային, PVD, մեռած | PVD/DLC deliver premium colors (ոսկի, սեվ) |

5. Key Strategies to Optimize the Appearance of Case-Hardened Surfaces

Achieving a “great look” requires a systematic approach that integrates pre-treatment preparation, process parameter control, post-treatment finishing, և defect prevention.

Each step directly impacts surface aesthetics and functional performance.

Pre-Treatment: The Foundation of Aesthetic Uniformity

Մակերեւութային աղտոտիչներ (յուղել, քսուք, ժանգ, թեփուկ) and material defects (ծակոտկենություն, քերծվածքներ) are amplified during case hardening, leading to uneven color, մասշտաբը, or coating failure.

Pre-treatment steps must ensure a clean, uniform surface:

- Degreasing and Cleaning: Use ultrasonic cleaning (with alkaline detergents) or vapor degreasing (with trichloroethylene) to remove oil and grease.

Avoid chemical cleaners that leave residues (օր., chloride-based solutions), which cause pitting during heat treatment.

According to ASTM A380, the surface must have a water-break-free finish (no beading) after cleaning. - Grinding եւ փայլեցում: For aesthetic-critical parts, Prec շգրիտ grinding (surface roughness Ra ≤ 0.8 սուկ) եւ փայլեցում (ՀՀ ≤ 0.2 սուկ) remove scratches, գործիքի նշաններ, եւ մակերեւույթի խախտում.

This ensures uniform heat absorption and diffusion during case hardening, preventing localized discoloration. - Shot Blasting/Pickling: Կրակոց պայթյուն (with glass beads or aluminum oxide) removes rust and scale, improving surface adhesion for post-treatment.

Թթու (with dilute hydrochloric acid) is used for heavy scaling but must be followed by neutralization to avoid surface etching.

Post-Treatment Finishing: Enhancing Aesthetics and Functionality

Post-treatment transforms the as-hardened surface into a visually appealing finish while preserving or enhancing functional properties (հագնել, Կոռոզիոն դիմադրություն).

The choice of finishing method depends on the base process, նյութական, եւ էսթետիկ պահանջներ:

Mechanical Finishing

- Փայլեցում: For carburized or induction-hardened parts, sequential polishing (coarse to fine abrasives: 120 grit → 400 grit → 800 մանրել) achieves a mirror finish (ՀՀ ≤ 0.05 սուկ).

Use diamond abrasives for hard surfaces (HRC ≥ 60) to avoid scratching. Polishing after nitriding enhances the golden-brown color and improves corrosion resistance. - Բուֆետավորում: Use a cotton or felt wheel with polishing compounds (Ալյումինի օքսիդ, Քրոմի օքսիդ) to create a glossy finish.

Buffing is ideal for decorative parts (օր., Ավտոմոբիլային զարդարանք, jewelry fasteners) but may reduce surface hardness slightly (by 2–5 HRC). - Կրակոցներ: For non-glossy, matte finishes, shot peening with fine glass beads (0.1-0.3 մմ) creates a uniform texture while improving fatigue strength. The surface roughness can be controlled between Ra 0.4–1.6 μm.

Chemical and Electrochemical Finishing

- Սև օքսիդ ծածկույթ: Also known as bluing, this process forms a thin (0.5-1,5 մկմ) black iron oxide (₃₃₃) film on the surface. It is compatible with carburized and nitrided parts, providing a uniform black finish with mild corrosion resistance.

Գործընթացը (ASTM D1654) uses a hot alkaline solution (135–145℃) and requires post-oiling to enhance aesthetics and corrosion protection. - Էլեկտրական: Chrome Plating (կոշտ քրոմ, decorative chrome) or nickel plating can be applied after case hardening to create a glossy, Կոռոզիոն դիմացկուն ավարտ.

Ensure the surface is free of scale and porosity (via pre-polishing) to avoid plating defects (bubbling, peeling). Decorative chrome plating achieves a mirror finish with a Vickers hardness of 800–1000 HV. - Քիմիական փոխակերպման ծածկույթներ: Ֆոսֆատ (zinc phosphate, manganese phosphate) forms a gray or black crystalline film that improves paint adhesion.

It is used for parts requiring both aesthetics and corrosion resistance (օր., Մեքենաների բաղադրիչներ).

Anodizing is suitable for stainless steel nitrided parts, producing a range of colors (կապույտ, սեվ, ոսկի) via electrolytic oxidation.

Coating Technologies for Advanced Aesthetics

- Ֆիզիկական գոլորշիների տեղադրում (PVD): PVD ծածկույթներ (Անագ, Տրակպա, Խուզ) are applied via vacuum deposition, producing thin (2-5 մկմ), ծանր, and visually consistent films.

TiN offers a golden finish (popular in cutting tools and luxury hardware), while CrN provides a silver-gray finish. PVD is compatible with nitrided parts and enhances both aesthetics and wear resistance.Ալյումինե օքսիդ PVD ծածկույթ - Քիմիական գոլորշիների տեղադրում (CVD): CVD coatings (Ադամանդի նման ածխածնի, DLC) create a matte black or glossy finish with exceptional hardness (HV ≥ 2000) եւ կոռոզիոն դիմադրություն.

They are ideal for high-performance parts (օր., Ավիատիեզերական բաղադրիչներ) but require high-temperature processing (700–1000℃), which may affect the core properties of case-hardened parts.

6. Ընդհանուր թերություններ, root causes, and prevention

| Արատ | Typical root cause | Կանխարգելում |

| Մասշտաբ / Օքսիդացում | Oxygen in furnace / poor atmosphere control | Vacuum processes, inert purge, strict PO₂ control |

| Discoloration / blotchiness | Uneven heating, inconsistent atmosphere | Uniform heating, atmosphere monitoring, plasma nitriding for uniformity |

| White layer (brittle nitride) | Excessive ammonia / high nitriding energy | Control NH₃, bias, ժամանակ; remove thin white layer if needed |

| Թաթ | Chloride contamination / residual salts | Residue-free cleaning, neutralization after pickling |

| Warpage / աղավաղում | Uneven quench / asymmetric geometry | Balanced design, polymer/quench control, հարմարանքներ, vacuum HP quench |

| Adhesion failure of coatings | Surface porosity or oil residues | Պատշաճ մաքրում, surface preps, ծակոտկենության վերահսկում, adhesion tests |

7. Aesthetic design considerations for case-hardened components

A visually successful case-hardened part is the product of integrated design, process selection and finishing — not an afterthought.

Specify process consistency for color matching

If parts are intended to be seen together (gear sets, fastener kits, assemblies), require the same hardening and post-treatment route across the set.

Plasma nitriding followed by a given post-finish (Սեւ օքսիդ, clear lacquer or PVD) produces highly repeatable tones;

mixing fundamentally different processes (for example carburizing on one part and nitriding on another) makes consistent color and surface response difficult to achieve and should be avoided when visual uniformity is required.

Use deliberate texture contrast to create visual hierarchy

Combine matte and polished zones to emphasize form and function.

Օրինակ, a polished nitrided tooth flank contrasted with a shot-peened or bead-blasted hub creates an attractive, engineered look while serving functional needs (polished teeth reduce friction; matte hubs improve grip and hide handling marks).

Define texture targets quantitatively (Ra or surface finish class) so finishers can reproduce the effect.

Design geometry to control thermal effects and dimensional stability

Geometry influences heating, cooling and distortion during surface hardening. Add generous fillets, avoid sharp abrupt section changes, and balance cross-sectional mass to reduce the risk of edge overheating and warpage.

For induction hardening, observe practical minimum section rules (typical minimum wall/thickness ≈ 3 մմ) and allow for fixturing to ensure uniform heating.

Where tight post-hardening tolerances are required, plan for rough machining before treatment and finish grinding afterward.

Integrate corrosion-protection into the aesthetic plan

Բացօթյա համար, marine or exposed architectural use, combine the case hardening route with durable corrosion finishes that preserve color over time.

Օրինակներ: plasma-nitrided stainless steel followed by a clear DLC or PVD topcoat for long-term color stability; carburized housings that receive electroless nickel or powder coating on non-sliding areas.

Specify compatible coating systems and curing/pretreatment steps (յուղազերծել, պասիացնել, ֆոսֆատ) to avoid adhesion problems and maintain appearance.

Protect functional surfaces and plan masking/assembly

Decide early which surfaces must retain the diffusion case (bearing journals, Կնքման դեմքեր) and which may receive decorative coatings.

Use masking or removable inserts during finishing when coatings would impair function.

Where mating surfaces must remain uncoated, document this in drawings and process sheets to avoid accidental coverage.

Tolerancing and finish sequence control

Document the finish sequence: rough machine → harden → finish grind/polish → final coating. State dimensional tolerances after hardening if no post-grind is planned.

For aesthetic quality, define acceptance criteria (color reference, gloss or matte target, allowable blemishes) and require photographic or sample approvals on first articles.

8. Application-Specific Aesthetic Optimization Examples

The following examples illustrate how to tailor case hardening and finishing for different industries, balancing aesthetics and functionality:

Ավտոմոբիլային բաղադրիչներ (Gears, Լիսեռներ, Զարդարանք)

For transmission gears (20MnCr5 steel): Gas carburizing (case depth 1.0 մմ) → quenching + tempering → precision grinding (ՀՀ 0.4 սուկ) → black oxide coating. This achieves a uniform black finish with high wear resistance.

For luxury ավտոմոբիլային զարդարել (4140 պողպատ): Պլազմային նիտլանդական (golden-brown finish) → buffing → clear PVD coating. The clear coating preserves the golden color and enhances corrosion resistance.

Precision Tools (Կտրող գործիքներ, Wrenches)

For cutting tools (HSS steel): Նիտրանտային (case depth 0.2 մմ) → TiN PVD coating. The golden TiN finish is visually distinctive and provides exceptional wear resistance.

For wrenches (1045 պողպատ): Induction hardening → shot peening (փայլատ) → manganese phosphating. The gray phosphate finish improves grip and prevents rust.

Architectural Hardware (Door Handles, Railings)

For stainless steel door handles (316 պողպատ): Plasma nitriding → anodizing (black or bronze) → clear coat. The anodized finish offers color customization and weather resistance.

For cast iron railings: Flame hardening → sandblasting (matte texture) → powder coating. Powder coating provides a durable, uniform finish in a range of colors.

9. Կայունություն, safety and cost considerations

- Էներգիա & արտանետումներ: heat treating is energy-intensive. Vacuum carburizing reduces emissions from combustion but uses electricity and gas pulses. Optimize cycle times and load density to reduce footprint.

- Միջավայր & անվտանգություն: avoid legacy cyanide or hexavalent chromium salts. Prefer vacuum, գազ, plasma or environmentally controlled salt baths with approved waste handling.

- ՔԱՂԱՔՆԵՐ: Գործընթացի ընտրություն (vacuum vs gas vs induction), ցիկլի ժամանակը, secondary grinding and finishing, scrapping rates due to distortion.

Choose process matched to required performance: vacuum carburize for precision, nitriding for low distortion, induction for low volume localized hardening. - Կյանքի ցիկլ & վերանորոգում: nitrided and PVD finishes extend life with low rework; induction hardening enables field re-hardening in some cases.

10. Եզրափակում

Case hardening is a versatile surface modification technology that, when optimized, can deliver both superior functional performance and exceptional aesthetics.

The key to a “great look” lies in systematic process control (նախնական բուժում, parameter optimization, post-finishing) և application-specific tailoring (Նյութի ընտրություն, defect prevention, design integration).

Chemical processes like plasma nitriding offer inherent aesthetic advantages (uniform color, minimal deformation), while thermal processes like induction hardening require more post-treatment to achieve visual appeal.

Advanced finishing technologies (PVD, DLC coatings) bridge the gap between functionality and aesthetics, enabling case-hardened parts to meet the demands of high-end applications.

ՀՏՀ

What is the difference between case depth and case hardness?

Case depth is the thickness of the hardened/diffused layer; case hardness is the hardness at or near the surface.

Both must be specified because a thin very-hard case may fail rapidly, while a deep but soft case may not resist wear.

Should I polish before or after case hardening?

Critical functional surfaces (bearing journals, Կնքման դեմքեր) should be finish-ground հետո կարծրացող. Pre-hardening polishing is acceptable only for decorative surfaces that won’t be ground later.

How deep should the case be for gears?

Typical gear faces are carburized to 0.6-1.5 մմ effective case depth (depth to a defined hardness) depending on load. Heavy-duty gears may require deeper cases or through-hardening alternatives.

Is nitriding “better” than carburizing?

It depends. Nitriding gives very low distortion, excellent surface hardness, and better corrosion resistance in some environments, but the case is thinner and nitrided surfaces lack the martensitic core toughness obtainable by carburizing + հանգցնել. Choose by application.

How to avoid cracking after case hardening?

Control material chemistry, use proper preheat and quench practice, use appropriate temper cycles and reduce retained austenite (subzero if necessary).

Avoid hard, brittle untempered microstructures on thin sections.

Can PVD be applied over a carburized surface?

Yes — but surface preparation (մաքրում, possibly thin diffusion barrier) and control of deposition parameters are required for adhesion.

PVD layers are thin and primarily decorative/wear-enhancing, not a substitute for a diffusion case.